Ianadmin

Hammermill® Paper Once Again Joins St. Jude Thanks And Giving® Campaign

Hammermill paper, a brand of International Paper, announced today that it will once again partner with St. Jude Children's Research Hospital® for the St. Jude Thanks and Giving® campaign, an unprecedented union of celebrities, media and more than 70 of the nation's leading brands and companies that ask consumers to donate while they shop during the holiday season to help St. Jude advance research and treatment of childhood cancer.

![]() This is the fifth year the Hammermill brand has participated in the campaign, which began as a holiday-focused fundraising effort and has grown into an annual tradition that has raised more than $587 million in 11 years thanks to tremendous public support. These funds are critical given that no family ever receives a bill from St. Jude for treatment, travel, housing or food – because all a family should worry about is helping their child live.

This is the fifth year the Hammermill brand has participated in the campaign, which began as a holiday-focused fundraising effort and has grown into an annual tradition that has raised more than $587 million in 11 years thanks to tremendous public support. These funds are critical given that no family ever receives a bill from St. Jude for treatment, travel, housing or food – because all a family should worry about is helping their child live.

Beginning Thanksgiving week and running through the end of the year, customers will see original patient artwork gracing the front of select Hammermill reams. In addition, customers can read the St. Jude patient's story on the back of the ream.

"I am so grateful for International Paper's dedication to helping the children and families of St. Jude," said Marlo Thomas, national outreach director, St. Jude Children's Research Hospital. "During the holiday shopping season, their Hammermill brand's participation in the St. Jude Thanks and Giving campaign makes it easy for its customers to help our doctors and scientists continue the research and treatment that leads to cures and gives these children the chance to enjoy many more holidays for years to come."

St. Jude Children's Research Hospital is leading the way the world understands, treats and defeats childhood cancer and other life-threatening diseases. Treatments invented at St. Jude have helped push the overall childhood cancer survival rate from 20 percent to more than 80 percent since it opened more than 50 years ago, and they won't stop until no child dies from cancer. The hospital freely shares the breakthroughs it makes, so every child saved at St. Jude means doctors and scientists worldwide can use that knowledge to save thousands more children.

Created by Marlo, Terre and Tony Thomas – children of St. Jude founder Danny Thomas – the St. Jude Thanks and Giving campaign asks people to "Give thanks for the healthy kids in your life, and give to those who are not" in order to help St. Jude continue its mission of finding cures and saving children.

For more information on the Hammermill brand, visit www.Hammermill.com.To learn more about the St. Jude Thanks and Giving campaign or to make a donation, visit www.stjude.org or call 1-800-4STJUDE.

About St. Jude Children's Research Hospital:

St. Jude Children's Research Hospital is leading the way the world understands, treats and defeats childhood cancer and other life-threatening diseases. St. Jude has the world's best survival rates for the most aggressive childhood cancers, and treatments invented at St. Jude have helped push the overall childhood cancer survival rate from 20 percent to 80 percent since we opened more than 50 years ago. St. Jude is working to drive the overall survival rate for childhood cancer to 90 percent in the next decade. St. Jude freely shares the breakthroughs we make, and every child saved at St. Jude means doctors and scientists worldwide can use that knowledge to save thousands more children. Families never receive a bill from St. Jude for treatment, travel, housing or food – because all a family should worry about is helping their child live. Join the St. Jude mission by visiting stjude.org or following St. Jude on facebook.com/stjude and twitter.com/stjude.

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

Holmen: Fire at Hallsta Paper Mill

A fire broke out on Friday evening at Hallsta Paper Mill in Hallstavik, outside Norrtälje, Sweden. No-one was injured, but production has been stopped.

The fire took place in the pulp factory in the north of the factory site. It was put out by the emergency services, and clean-up efforts began immediately at Friday night. The two paper machines at the mill were not affected or damaged by the fire.

The fire took place in the pulp factory in the north of the factory site. It was put out by the emergency services, and clean-up efforts began immediately at Friday night. The two paper machines at the mill were not affected or damaged by the fire.

Paper production has been halted until activities in the fire-damaged pulp factory can be resumed. The current assessment is that it will be possible to start up the pulp factory again, in any case partially, within two to three weeks.

“We’re initiating immediate dialogue with those customers next in line for deliveries from the mill, and we’ll be doing our utmost to ensure that our customers are affected to as minor an extent as possible,” says Nils Ringborg, CEO at Holmen Paper.

An investigation into the cause of the fire and the extent of the damage is in progress. The incident is expected to have a negative impact on results for the fourth quarter amounting to SEK 30 million.

This is information that Holmen AB is obliged to disclose under the Swedish Securities Market Act and the Swedish Financial Instruments Trading Act. The information was submitted for publication on 22 November 2015 at 17:15 CET.

Holmen is a forest industry group that manufactures paperboard, printing paper and sawn timber and runs forestry and energy production operations. In 2014 Holmen’s net sales were SEK 16 billion and the group has approx. 3,400 employees. Holmen’s shares are listed on Nasdaq Stockholm, Large Cap. For more information, visit www.holmen.com

Pöyry awarded two engineering services assignments for BillerudKorsnäs, Sweden

BillerudKorsnäs has awarded Pöyry with two engineering services assignments in Sweden. One for a new board machine project in their production site in Gruvön; and the other for the machine glazed (MG) paper machine relocation project from Tervasaari in Finland to Skärblacka in Sweden.

BillerudKorsnäs has awarded Pöyry with two engineering services assignments in Sweden. One for a new board machine project in their production site in Gruvön; and the other for the machine glazed (MG) paper machine relocation project from Tervasaari in Finland to Skärblacka in Sweden.

BillerudKorsnäs is a leading supplier of renewable fibre-based packaging materials and solutions, and one of the world leaders in liquid packaging board and other virgin fibre cartonboard. Driven by global megatrends, the demand for these types of board is increasing. BillerudKorsnäs is investigating the possibility of installing a new board machine at the production unit in Gruvön. The machine would become one of the most cost efficient in the world with a capacity of approximately 500 000 t/a of liquid packaging board, cartonboard, food service board and white kraftliner. Pöyry has been awarded pre-project engineering services to develop the investment plan into a viable technical concept.

Simultaneously, BillerudKorsnäs is launching a separate investigation into potential further structural change and growth in specific kraft paper segments. The investigation includes exploring the possibility of moving and integrating the MG paper machine in Tervasaari, Finland, to pulp production at Skärblacka, Sweden. The investigation will also look at investment in further value adding surface treatment capacity at the existing MG paper production in Skärblacka. If implemented, the investments would strengthen Skärblacka's position as one of the world's most efficient production units for white MG papers while also opening up opportunities in attractive market segments within medical papers, food packaging and release liners. Pöyry's assignment covers pre-project engineering services for the machine relocation.

"These projects are evidence of our successful operation model where global competence and local presence are combined. We are executing this project with experts from Sweden and Finland to ensure the best result for the client. We are proud to be the selected partner of BillerudKorsnäs with these strategically important development opportunity investigations. These assignments further strengthen Pöyry's position as the world's leading pulp and paper engineering consultancy.", says Johan Ehrnrooth, Pöyry's Vice President, Pulp & Paper Europe.

The values of the orders are not disclosed. The orders will be recognised within the Industry Business Group order stock in Q4/2015.

PÖYRY PLC

Additional information by:

Johan Ehrnrooth

Vice President, Pulp & Paper Europe

Tel: +358 10 33 22294

Stefan Nyström

Managing Director, Pöyry Sweden

Tel: +358 40 733 6145

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

Improved paper as a result of a dryer section rebuild at BillerudKorsnäs, Pietarsaari

EV Group (EVG) has delivered a dryer section modification on the PM1 at BillerudKorsnäs Finland Oy, Pietarsaari. After the modification the draw differences between the press and dryer section have been reduced with improved end product properties as a result. Simultaneously also the amount of web breaks have been reduced, improving the overall runnability and production line efficiency.

EV Group (EVG) has delivered a dryer section modification on the PM1 at BillerudKorsnäs Finland Oy, Pietarsaari. After the modification the draw differences between the press and dryer section have been reduced with improved end product properties as a result. Simultaneously also the amount of web breaks have been reduced, improving the overall runnability and production line efficiency.

EVG made modifications to shorten the long open draw between the press and dryer section. Grooved cylinders in the first dryer group were modified to vacuum rolls by drilling the cylinder surface. EV EasyOne eco high release web stabilizers were installed above these drilled vacuum rolls. The installation also included a low pressure compressor and compressed air piping. The remaining first dryer section pockets were equipped with EVsf2 web stabilizers to ensure a good runnability of the web. DST doctors and needed modifications and additions to existing air systems were also included into the scope of supply, as the field activities including installation and start-up services.

As a result of the modification the end product properties were improved as expected. Less web breaks has also led to an improved runnability in the press and dryer section.

BillerudKorsnäs Pietarsaari PM1 produces kraft and sack paper in the basis weight of 50 - 150g/m2. Machine speed is 900 m/min, width 6.6 m and with a yearly production capacity of 200.000 tons.

For more information, please contact:

Timo Haverinen,

This email address is being protected from spambots. You need JavaScript enabled to view it.

, +358 500 829 672

Check out our new website at www.evgroup.fi

Fibria selects Veolia to supply all three water units for pulp mill expansion in Brazil

Veolia, through its subsidiary Veolia Water Technologies Brazil, was awarded a contract to build three units for demineralized water production, raw water treatment and effluent treatment at Fibria’s new pulp production line located in Três Lagoas in Mato Grosso do Sul, a central western state of Brazil.

Fibria is a Brazilian forest-based company and world leader in eucalyptus pulp production. The 26-month EPC contract signed with Veolia is for Project Horizonte 2, which involves the construction, at the Três Lagoas Unit, of a second production line with annual pulp capacity of 1.75 million tons. After the expansion, whose start up is expected in the fourth quarter of 2017, the Mato Grosso do Sul unit will reach full annual production capacity of 3.05 million tons of pulp. As a result, Fibria’s total annual pulp production capacity, considering all of its units, will increase from the current 5.3 million tons to over 7 million tons. Fibria's total investment in the expansion of Três Lagoas is equivalent to about $ 2.5 billion.

Fibria is a Brazilian forest-based company and world leader in eucalyptus pulp production. The 26-month EPC contract signed with Veolia is for Project Horizonte 2, which involves the construction, at the Três Lagoas Unit, of a second production line with annual pulp capacity of 1.75 million tons. After the expansion, whose start up is expected in the fourth quarter of 2017, the Mato Grosso do Sul unit will reach full annual production capacity of 3.05 million tons of pulp. As a result, Fibria’s total annual pulp production capacity, considering all of its units, will increase from the current 5.3 million tons to over 7 million tons. Fibria's total investment in the expansion of Três Lagoas is equivalent to about $ 2.5 billion.

Veolia will design and build the three water treatment units using cutting-edge, patented Veolia processes. The first unit will use reverse osmosis and condensate polishing to produce 16,600 m3/d of demineralized water to supply the boilers. The second unit will feature the Actiflo® high rate clarification process combined with TGV filters to treat 185,000 m3/d of raw water before it is used in the pulp production process. Finally, the effluents from the pulp plant will go to a third unit where the AnoxKaldnes™ BAS™ process will be used to treat 166,000 m3/d of wastewater. This last unit will be designed by Veolia business unit Aquaflow who is specialized in effluent treatment for the pulp & paper industry.

The effluent treatment plant was designed to comply with the most stringent environmental standards enforced in Mato Grosso do Sul, ensuring that the discharged water meets the highest levels of quality. All three water treatment units are to be equipped with processes known for providing efficient, stable and robust treatment in a small footprint, reducing construction costs.

Ruddi De Souza, General Manager of Veolia Water Technologies’ design & build activities in Latin America, said: “All around the world, Veolia partners with industries in their search for improved environmental and economic performance. We are very proud to be involved in this project with Fibria, and to work with them towards expending their production in a cost-effective way while conforming with the state of Mato Grosso do Sul’s very strict environmental regulations”.

The opening of the three treatment units is schedule for the fourth quarter of 2017.

Veolia group is the global leader in optimized resource management. With over 179,000 employees* worldwide, the Group designs and provides water, waste and energy management solutions that contribute to the sustainable development of communities and industries. Through its three complementary business activities, Veolia helps to develop access to resources, preserve available resources, and to replenish them.

In 2014, the Veolia group supplied 96 million people with drinking water and 60 million people with wastewater service, produced 52 million megawatt hours of energy and converted 31 million metric tons of waste into new materials and energy. Veolia Environnement (listed on Paris Euronext: VIE) recorded consolidated revenue of

€24.4 billion* in 2014. www.veolia.com

(*) 2014 pro-forma figures, including Dalkia International (100%) and excluding Dalkia France.

Manon Painchaud

off. : + 1 418 573 2735

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.veoliawatertechnologies.com

Environment and Energy Award for Workington Mill

Iggesund Paperboard’s commitment to continuous improvement and sustainability was recognized last night when we received the Environmental and Energy Awareness Award at the CN Group Business Awards.

The judges picked out Iggesund as winners having understood the scale of the contribution to the reduction in fossil fuel CO2 emissions resulting from the investment in the Biofuel CHP plant.

The judges picked out Iggesund as winners having understood the scale of the contribution to the reduction in fossil fuel CO2 emissions resulting from the investment in the Biofuel CHP plant.

Moreover, it was also acknowledged that Iggesund had shown a broad commitment to improving the impact on the environment through a dedicated and structured approach to maximizing its process efficiencies within the wider Pulpmill, Boardmachine and Finishing operations over the years as well as minimizing its process wastes.

This is being exemplified by the ongoing work preparing for certification under the Energy Management Standard ISO 50001 to complement the existing Environmental Management Standard 14001.

The presentation evening was held at the Racecourse at Carlisle with around 250 representatives of the counties business community in attendance.

Marie Whitehead, director of CN Events, chaired the judging panel. She said: "Once again the task of judging has been both rewarding and challenging as the quality of entries rises each year. It is highly encouraging to see so many businesses investing in their products, their staff and their premises to make sure the business offer in Cumbria remains strong and vibrant."

“We can be very proud of the award and what it recognizes in Iggesund Paperboard. It is a reminder that we have achieved an enormous amount already in recent years. We still have some exciting developments ahead in this area and through people continuing to engage with identifying and proposing ideas and opportunities for our future energy and environmental improvements we will be able to maintain this progress into the future”, comments Jonny Lowe, head of HR at Iggesund Paperboard’s Workington Mill.

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Verso Issues Media Correction Regarding Duluth and Stevens Point Mills

A number of media outlets have erroneously reported that Verso Corporation (OTCQB: VRSZ) yesterday announced that the company is considering closing its Duluth, Minnesota, and Stevens Point, Wisconsin, mills in conjunction with its evaluation of restructuring alternatives, which is not the case. Verso is considering the potential sale of the Duluth and Stevens Point mills.

A number of media outlets have erroneously reported that Verso Corporation (OTCQB: VRSZ) yesterday announced that the company is considering closing its Duluth, Minnesota, and Stevens Point, Wisconsin, mills in conjunction with its evaluation of restructuring alternatives, which is not the case. Verso is considering the potential sale of the Duluth and Stevens Point mills.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at www.versoco.com.

SOURCE Verso Corporation

Linde to make EUR 15 m gas production investment in Finnish pulp and paper industry

Linde Gases, a division of The Linde Group, has announced it will construct ECOVARTMstandard on-site nitrogen and oxygen production plants for CP Kelco and Metsä Fibre,respectively, in Äänekoski, Finland. The long-term on-site gas supply agreements include plant installation, operation and maintenance. Both plants will be constructed by Linde’s Engineering Division.

Linde Gases, a division of The Linde Group, has announced it will construct ECOVARTMstandard on-site nitrogen and oxygen production plants for CP Kelco and Metsä Fibre,respectively, in Äänekoski, Finland. The long-term on-site gas supply agreements include plant installation, operation and maintenance. Both plants will be constructed by Linde’s Engineering Division.

The nitrogen production installation at CP Kelco will incorporate Linde’s ECOVARTM ADSOSSTM-N gas generation plant, which separates nitrogen from air employing the adsorption-based PSA (pressure swing adsorption) process. The customer uses nitrogen for inerting processes in the production of CMC (carboxymethyl cellulose) in order to control the level of oxygen content.

The uninterrupted supply of nitrogen is of primary importance to the production process, product quality and operational safety. To guarantee CP Kelco a continuous supply of nitrogen under all conditions, a back-up system based on vapourisation of liquid nitrogen will also be installed. Implementation of the ECOVARTMplant is underway, with operations beginning early 2016.

Linde has also agreed with Metsä Fibre, part of Metsä Group, long-term deliveries of oxygen based on a similar ECOVARTM supply concept, this time incorporating an ADSOSSTM-O oxygen plant. The plant will extract oxygen by means of adsorption. ADSOSSTM-O gas generation plants are typically designed with two cyclically operated adsorber vessels to extract oxygen continuously, known as vacuum pressure swing adsorption (VPSA) technology.

The installation will be built in the Metsä Group´s new bioproduct mill area, currently under construction. Oxygen is an essential chemical in the modern pulp mill and its uninterrupted delivery is vital. Metsä Fibre uses significant amounts of oxygen in its processes, for example, in the bleaching of pulp and oxidation of white liquor.

The Äänekoski ADSOSSTM-O oxygen plant will be one of the world’s largest oxygen plants based on VPSA and will begin operations at the same time as Metsä Group’s bioproduct mill in the third quarter of 2017.

“We are delighted to be able to contribute, through our expertise, to this new EUR 15 million investment project for the pulp and paper industry in Finland. Gases are an essential part of many production processes in this industry and these particular investments are an important focus for growth. The new bioproduct mill will create further opportunities for both our gases and gas technologies. As such, we have a commitment to our customers to continue to develop technologies and delivery concepts which improve the efficiency, productivity and sustainability of their processes,“ said Bo Dyrvold, Head of Linde’s Regional Business Unit Northern Europe.

The ECOVARTM delivery method is the most efficient way to deliver large amounts of gases for industrial processes, both in terms of energy consumption and a reduction in environmental impact. On-site production significantly reduces the need for road deliveries of gas and adsorption technology also saves energy compared to cryogenic distillation, commonly used in production of gases in large quantities. The plants are fully automated and operations are monitored from the company’s remote operation centre in Avesta, Sweden.

About The Linde Group

In the 2014 financial year, The Linde Group generated revenue of EUR 17.047 bn, making it the largest gases and engineering company in the world with approximately 65,500 employees working in more than 100 countries worldwide. The strategy of The Linde Group is geared towards long-term profitable growth and focuses on the expansion of its international business with forward-looking products and services. Linde acts responsibly towards its shareholders, business partners, employees, society and the environment – in every one of its business areas, regions and locations across the globe. The company is committed to technologies and products that unite the goals of customer value and sustainable development.

For more information, see The Linde Group online at www.linde.com.

Contact

Susan Brownlow

Public Relations Manager, Linde Gases Division

Telephone: +44 (0)7739 456292

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Lenzing Presents New Group Strategy “sCore TEN“: Profitable Growth Thanks to Eco-Friendly Specialty Fibers

The Lenzing Group is presenting its business strategy for the coming years entitled “sCore TEN”. Accordingly, Lenzing’s main priorities are strengthening the company’s core business, intensifying cooperation with customers along the value chain, increasing the share of specialty fibers to 50% of total revenue by 2020, expanding its quality and technological leadership for man-made cellulose fibers and opening up new attractive business areas.

- Lenzing takes advantage of megatrends

- Sustainability as a key innovation and growth driver

- Share of revenue generated by specialty fibers targeted to rise to 50% by 2020

- EBITDA growth of approx. 10% p.a. until 2020

- Increase in ROCE to more than 10% by 2020

“Our objective is to safeguard and expand Lenzing’s leadership role on the dynamic growth market for man-made cellulose fibers“, says Lenzing’s Chief Executive Officer Stefan Doboczky. “To achieve this, we will focus more intensively on the most attractive segments in the specialty fiber business. Lenzing will put value before volume in the future. We aim at achieving volume growth.”

Lenzing expects demand for man-made cellulose fibers to increase by 5 to 6% p.a. until 2020, which is nearly twice as fast as the global fiber market. The primary factors driving demand are the continuing growth of the world’s population and rising prosperity in the emerging markets. Forecasts call for a rise in per capita textile consumption in the emerging markets by all in all 50% in the period 2010 to 2020. In the industrialized countries the nonwovens industry, an important sales market for Lenzing, will profit from the increased demand for hygiene products. The nonwovens segment is expected to expand twice as fast as the textile market.

The new Lenzing strategy entitled “sCore TEN” was designed to take account of the major megatrends. On the one hand, the name stands for a resolute performance orientation (scoring) and for a strengthening of Lenzing‘s core business operations (core) and on the other hand, the new strategy reflects the objective of generating sustainable growth with specialty fibers such as Lenzing Modal® or TENCEL® (TEN). Five strategic measures comprise the cornerstones of sCore TEN:

- Strengthen the core: the target is to increase Lenzing’s pulp position through backward integration by increasing the Group’s own pulp production volumes and/or expanding strategic co-operations. Lenzing will strive to expand upon its quality and technology leadership. A program aimed at strengthening commercial processes is designed to deliver a positive EBITDA contribution totaling EUR 50 mn by the year 2017. The reorganization of the technical service units will be concluded in 2016.

- Customer intimacy: Lenzing plans to establish regional competence centers for product innovations and will move greater decision-making powers to the regions. These steps will bring Lenzing closer to its customers.

- Specialization: Lenzing aims at generating 50% of total revenue from the business with eco- friendly specialty fibers such as TENCEL®, Lenzing Modal® and viscose fiber specialties by the year 2020. Lenzing will further increase production capacities for TENCEL® depending on market requirements.

- Forward solutions: Lenzing will selectively enhance its R&D activities along the value chain by new game-changing technologies.

- New business areas: Based on its core competencies, Lenzing will open up new business areas.

In the light of the increasing demand for textile fibers one of the major future challenges for the fiber industry is sustainability. Lenzing boasts a major competitive advantage in this respect. Its cellulose fibers originate in sustainably managed forests, are produced in an environmentally-friendly manner and are biodegradable. In particular, TENCEL® fibers are unrivalled on the marketplace when it comes to sustainability. Taking all parameters into account, TENCEL® is up to 17 times more environmentally compatible than other fibers. Lenzing fibers are outstanding as blending partners for cotton and polyester, and improve their sustainability.

“Compared to the previous year, we want to continually increase EBITDA by 10% annually and aim to increase the return on capital employed (ROCE) to more than 10% by 2020. At the same time, our objective is to keep net financial debt at a level which is less than 2.5 times EBITDA”, Doboczky explains in reference to the financial performance targets of sCore TEN. Lenzing plans to finance all necessary investments required to implement this strategy from its own capital resources and simultaneously strive for a dividend payout of up to 50% of the Group net profit.

The Lenzing Group

The Lenzing Group is a world market leader with headquarters in Austria, production sites in all major markets as well as a worldwide network of sales and marketing offices. Lenzing supplies the global textile and nonwovens industry with high-quality man-made cellulose fibers. The portfolio ranges from dissolving pulp, standard and specialty cellulose fibers to engineering services.

Lenzing quality and innovative strength set global standards for man-made cellulose fibers. With more than 75 years of experience in fiber production, the Lenzing Group is the only company worldwide combining the manufacturing of all three man-made cellulose fiber generations on a large industrial scale under one roof – from the classic viscose to modal and lyocell (TENCEL®®) fibers. The success of the Lenzing Group results from a unique combination of consistent customer orientation together with its leadership in innovation,

technology and quality.

Lenzing is committed to the principle of sustainable management and very high environmental standards. Lenzing's core business fibers is complemented by our activities in the business field engineering.

Key Figures Lenzing Group 2014:

Sales: EUR 1.86 bn

Export share: 92.3%

Fiber sales volumes: 960,000 tons

Staff: 6,356

TENCEL®, Lenzing Modal® and Lenzing Viscose® are registered trademarks of the Lenzing Aktiengesellschaft.

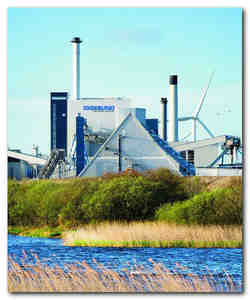

Commercial journey continues for DuraPulp

Södra is now taking further steps to commercialise the composite material DuraPulp. A project to construct a dry-process machine has commenced, financed through a grant of EUR 2.1 million from the EU's LIFE funding programme.

The material in DuraPulp has properties that require special handling during the moulding process. The current method is wet-moulding, but to meet customer requests, Södra is now investing in a machine that can dry-mould the material.

"To be specific, this is a more efficient production process because it uses less water and less energy. The wet-mould method we are using today takes about two minutes, while dry-moulding takes two seconds. This technology will enable us to demonstrate products for high-volume markets, such as electronics and consumer packaging," says Urban Blomster, a business developer at Södra.

The first stage of the project was to procure external resources for the construction of the machine, with former partner, SWT Development in Varberg, Sweden, being selected for the assignment.

The machine is scheduled to be operational by the end of 2016.

For further questions, please contact:

Urban Blomster, business developer at Södra

Tel: +46 (0)706-837 785