Ianadmin

Toscotec fired up two AHEAD-1.5M tissue machines at Vinda Sichuan and Vinda Shandong Paper

The two Toscotec-supplied AHEAD-1.5M ES tissue lines came on stream according to schedule at Vinda’s tissue mills in Deyang, Sichuan and Laiwu, Shandong. The tissue machines are already running at the maximum operating speed of 1,500 mpm with full satisfaction of the user for tissue quality and machine performance.

After four years of strategic partnership, the Italian manufacturer and the Chinese producer are closely working together at six of Vinda’s production sites. “Toscotec’s solutions represent the best available technology in tissue machinery nowadays. We are particularly satisfied with their superior energy efficiency. Our Toscotec machines run with the lowest possible consumption figures and offer a crucial advantage in terms of cost-effective production.” says Mr. Dong Yi Ping, Vinda Group’s Executive Director and Chief Technology Officer.

With a design speed of 1,700 mpm and a net web width of 3,400 mm, the two machines are equipped with Toscotec’s second generation Steel Yankee Dryer TT SYD, Toscotec’s jumbo suction press roll for improved dryness and softness and feature different energy saving solutions for Yankee hood design, with gas and steam. As a result, Vinda’s production capacity has overall increased by 60,000 t/y. Another unit identical to this one at the Shandong paper mill is scheduled for start-up in the second half of 2016. Vinda’s mill in Laiwu already hosts PM1 & 2, both supplied by Toscotec, running steadily at 1500 m/min and producing a combined capacity of 50,000 t/y.

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

UPM and LEIPA discuss the potential sale and conversion of UPM Schwedt mill into liner production

UPM and LEIPA Georg Leinfelder GmbH discuss the potential sale of the UPM Schwedt mill site and relevant assets to LEIPA for the aim of a conversion into liner production.

UPM and LEIPA Georg Leinfelder GmbH discuss the potential sale of the UPM Schwedt mill site and relevant assets to LEIPA for the aim of a conversion into liner production.

LEIPA will commence a study on the potential conversion at the Schwedt site immediately.

The planned production capacity would be approximately 450,000 tons of liner annually. LEIPA intends to continue all employment relations with the current employees of the UPM Schwedt mill.

Number of issues remain open and the discussions and the study are expected to last several months.

For further information please contact:

Winfried Schaur, SVP, Newspaper Publishing, UPM Paper ENA, This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +49 173 9199014

Nenad Nemarnik, LEIPA Group GmbH, Director Marketing and Sales Coordination, This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +49 160 2548278

About UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

UPM Schwedt

UPM Schwedt manufactures standard newsprint with the annual capacity of 280,000 tonnes. Located in the north-eastern part of Germany the mill employs about 250 people.

About LEIPA

LEIPA Georg Leinfelder GmbH is part of the LEIPA GROUP. Currently the LEIPA group of companies produces approximately 900,000 tons of graphic paper and packaging paper per year at its Schwedt and Schrobenhausen locations, based on sustainable and environmentally friendly production processes.

In 2014, the family-run medium-sized enterprise with 1,450 members of staff generated consolidated sales of approximately EUR 650 million. www.leipa.de

Metso selected as main supplier of valve solutions for Metsä Fibre's next-generation bioproduct mill to be built in Finland

Metso has signed a comprehensive framework agreement with Metsä Fibre to supply valve solutions for the world's first next-generation bioproduct mill in Äänekoski, Finland. Metso's valve solutions will be used in all of the mill's process phases. The delivery includes more than one thousand valves and peripheral devices and is one of Metso's largest valve orders in Finland. Metso also takes care of the spare part services for the mill.

"We are very pleased that Metsä Fibre trusts our valve expertise. The design of the bioproduct mill puts special emphasis on minimized emissions, low specific water consumption, and high energy and material efficiency, among other things. The availability and efficiency of the production processes can be maximized by utilizing optimally selected, reliable valve solutions," says Mika Sjöholm, Vice President, Pulp and Paper business line, Metso.

Metso will supply the plant with Neles® ball valves, segment and butterfly valves for on-off and control applications and Neldisc® butterfly valves for manual on-off duty. The control valves are equipped with Neles® ND9000 series intelligent valve controllers, which have the capability for advanced performance follow-up and also enable predictive maintenance planning activities.

Metso's aim is to also ensure the correct timing of future maintenance needs of the mill's valve installations by utilizing digital valve controller properties and product information management.

Furthermore, to ensure best possible valve utilization rate Metso offers spare part inventory and maintenance services for the new mill. The service agreement is appended to the existing service agreement between Metsä Fibre and Metso.

"Our valve production plant and our experts in Vantaa will play an important role in the manufacturing process of the new mill's products. We will use our global valve operations network in an optimal manner to offer competitive solutions to Metsä Fibre. The comprehensive valve maintenance services and our service center close to the customer ensure trouble-free production at the new mill," says Mika Sjöholm.

The value of the framework agreement is not disclosed. Part of the order is included in Metso's fourth-quarter 2015 orders received with following quarter bookings during 2016. Metso's deliveries will start at the beginning of 2016, and the bioproduct mill will start its operations in the third quarter of 2017.

Metso has the leading valve and service solutions for the pulp and paper industry

Metso is the global market leader in control and on-off valves for the pulp and paper industry, and about 75 percent of the world's pulp flows through Metso's valves.

Metso has strong expertise in valve solutions for the pulp and paper industry, and its comprehensive value-added services improve customers' process efficiency. Metso's flow control offering and services for the pulp and paper industry focus on three areas: solving the customer's technical or process-related challenges, improving operational performance, and overall responsibility for an agreed area of operations. Metso has more than 40 valve and field device service centers around the world.

Many pulp and paper industry valve innovations come from Metso, like the capping valve for batch cooking, high-consistency valve for bleaching, NelesACE(TM) valve for basis weight control, ceramic ball valve for erosive applications. Additionally, Metso is the leading supplier of intelligent valve controllers globally.

The company's valve technology centers and valve production plants are located in Finland, the United States, Germany, China, South Korea, India and Brazil.

Next-generation bioproduct mill

Metsä Fibre's, which belongs to Metsä Group, new bioproduct mill is the largest investment in Finnish forest industry history, with total value of EUR 1.2 billion. Upon completion, the new mill will be the world's first next-generation bioproduct mill. Pulp production at the Äänekoski mill in central Finland will increase to 1.3 million tons from the current approx. 0.5 million tons per year. In addition to high-quality pulp, it will produce a broad range of other bioproducts, such as tall oil, turpentine, lignin products, bioelectricity and wood fuel. The bioproduct portfolio is expanding in the future. www.bioproductmill.com, www.metsagroup.com

Metso is the world's leading industrial company in the mining and aggregates industries and in the flow control business. Our knowledge, people and solutions help drive sustainable improvements in performance and profitability in our customers' businesses.

Metso has an uncompromising attitude towards safety. Our products range from mining and construction equipment and systems to industrial valves and controls. Our solutions are delivered and supported by decades of process knowledge and a broad scope of services backed by a global footprint of over 90 service centers, thousands of service employees, and an extensive logistics network.

Metso is listed on the NASDAQ OMX Helsinki, Finland. In 2014, Metso's net sales totaled EUR 3.7 billion. Metso employs approximately 13,000 industry experts in more than 50 countries. Expect results.

www.metso.com, www.twitter.com/metsogroup

For further information, please contact:

Mika Sjöholm, Vice President, Pulp and Paper Business Line, Metso, tel. +358 20 483 5308, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Anne Rantanen, Director, Global Communications, Metso Corporation, tel. +358 20 484 2253, email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Resolute Grows Into Tissue with Acquisition of Atlas Paper

Resolute Forest Products Inc. has announced the acquisition of Atlas Paper Holdings, Inc., a leading manufacturer of at-home and away-from-home tissue products, including recycled and virgin paper grades.

Resolute Forest Products Inc. has announced the acquisition of Atlas Paper Holdings, Inc., a leading manufacturer of at-home and away-from-home tissue products, including recycled and virgin paper grades.

"This is a step-change acquisition that provides us with an immediate position in the multi-billion-dollar North American consumer tissue market," said Richard Garneau, president and chief executive officer of Resolute Forest Products. "We're following through on our strategy toward the Resolute of the future with an acquisition that capitalizes on our unique ability to capture synergies by integrating forward our U.S. market pulp assets. This acquisition also gives us immediate tissue industry experience as we work toward bringing our Calhoun tissue project online by early 2017."

Based in Florida, Atlas Paper manufactures branded and private label tissue products for the at-home and away-from-home markets. It offers both virgin and recycled products, covering economy, value and premium grades. Atlas Paper operates three tissue machines, with an annual production capacity of approximately 65,000 short tons; 14 converting lines in Hialeah (Miami) and Sanford (Orlando); and a paper recycling facility in Tampa. Atlas Paper employs about 360 people. It will be "business as usual" at Atlas Paper in terms of relationships and commitments to suppliers and customers.

Resolute is uniquely positioned to generate synergies and related benefits with this acquisition, by:

- optimizing Atlas Paper's pulp supply using Resolute's strong U.S. market pulp network;

- capitalizing on excess tissue converting capacity;

- immediately integrating Atlas Paper's tissue expertise for the start-up of the Calhoun tissue project in Tennessee; and

- offering a greater range of products – economy, value and premium grades – to existing and future customers.

Richard Garneau added: "This transaction fits nicely with our June announcement to build state-of-the-art tissue and converting facilities in Calhoun that will produce approximately 66,000 short tons (60,000 metric tons) per year of at-home, premium bath tissue and towel focused on the private label market. By integrating our U.S. pulp assets to produce high-quality products, we will compete in that market as one of only a few integrated producers, using the latest technology. With today's announcement, we enter the tissue market right away, and we do so by way of an acquisition that is synergistic and also integrative. We will benefit from the know-how and the expertise of Atlas Paper's experienced tissue manufacturing, sales and management teams, and we will have access to its customer base."

"We are excited about becoming part of a larger, diversified company that views the tissue market as a cornerstone of its future," stated Jim Brown, president and chief executive officer of Atlas Paper Holdings, Inc. "This is a win-win: For Atlas Paper, we will benefit from pulp supply efficiencies and we will offer a wider range of products to our customers once the Calhoun tissue project is up and running. For Resolute, my team can bring the market knowledge and expertise that will help us all meet our common business objectives."

The purchase price in the transaction, which closed today, was $156 million, including working capital. The company estimates approximately $23 million of annualized earnings before interest expense, income taxes, and depreciation and amortization, or "EBITDA," including synergies, starting in the first quarter of 2016. Resolute expects to maintain Atlas Paper's current structure, and that most employees, including management, will remain with the organization. The financial results attributable to these assets will be reported in a stand-alone "tissue" segment. The company paid for Atlas Paper with available cash, but expects to explore financing opportunities in the coming months, considering its previously-reported significant capital expenditure expectations in connection with the Calhoun tissue project.

BMO Capital Markets acted as the financial advisor and Akerman LLP acted as the legal advisor to Resolute on the transaction.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including newsprint, specialty papers, market pulp and wood products. The company owns or operates some 40 pulp and paper mills and wood products facilities in the United States, Canada and South Korea, and power generation assets in Canada. Marketing its products in close to 80 countries, Resolute has third-party certified 100% of its managed woodlands to at least one of three internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

SOURCE Resolute Forest Products Inc.

UPM celebrates its 20th anniversary on EU's EMAS registration

The European Eco-Management and Audit Scheme EMAS celebrated its 20th anniversary on 13th November by organising a high level conference at the European Central Bank in Frankfurt. The conference highlighted the best practice approaches to environmental management and the experiences of leading EMAS organisations.

The European Eco-Management and Audit Scheme EMAS celebrated its 20th anniversary on 13th November by organising a high level conference at the European Central Bank in Frankfurt. The conference highlighted the best practice approaches to environmental management and the experiences of leading EMAS organisations.

UPM is among the companies who have been registering under the EMAS since it was established.

"UPM pulp and paper mills started with EMAS registration soon after the scheme was established, and has been persistent with registration ever since. In 2012 and 2013 UPM extended its EMAS registration to its mills outside Europe, i.e. to UPM Fray Bentos pulp mill in Uruguay and UPM Changshu paper mill in China. On global scale, there are only two companies who have registered their mills outside Europe in the EMAS," says Sami Lundgren, Director, Ecolabels and Reporting in Frankfurt.

"EMAS has helped thousands of organisations since its inception in 1995. Users have become more resource-efficient, consumed energy more wisely, saved on costs and reduced their environmental impacts at the same time. Its environmental reporting requirement has meant registered organisations are among the most transparent in the world, as regards to environmental data," says Karmenu Vella, European Commissioner for Environment, Maritime Affairs and Fisheries.

"UPM is very committed to improve its environmental performance and to disclose openly information on its impacts on environment, society and economy," says Ulla-Riitta Unkuri, Vice President, Stakeholder Relations, UPM Paper ENA.

"Transparency and openness towards stakeholders are an essential part of UPM's corporate responsibility worldwide. The global EMAS registration and the third-party verified reporting promote continuous improvement in all of our operations," Unkuri says.

In addition to corporate EMAS statement and the paper and pulp mill specific supplements, UPM provides comprehensive environmental data assured by third parties on corporate, mill and on a single product's level. Ecolabelled products, product declarations and certified operations are the proof for UPM's responsibility and transparency.

For further information, please contact:

Sami Lundgren, Director, Ecolabels and Reporting, tel. +358 40 5800 910

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Valmet started up new coaters at Mayr-Melnhof Kolicevo board machine in Slovenia

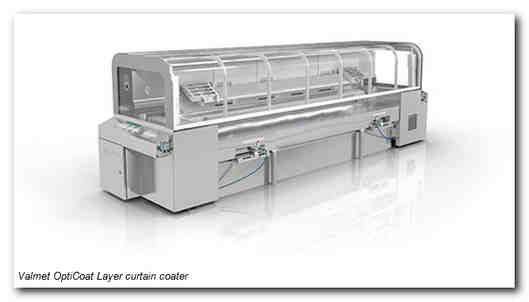

Valmet has successfully started up new coating technology, featuring multilayer curtain coating, at Mayr-Melnhof Kolicevo board machine 3 (BM 3) in Slovenia. Valmet's delivery included a new OptiCoat Layer curtain coater with supply system and a new OptiCoat blade coater.

Compared to other curtain coating solutions OptiCoat Layer is compact in size and straightforward to install. This enables lower investment cost and shorter shut-down time. The start-up was very smooth, thanks to the pre-assembly and pre-testing. This and the good cooperation between Valmet and experienced Kolicevo mill resulted inhigh-quality production right after the start-up.

"The assembly was finished on time and the start-up was done by just pushing the button. We are happy that the high targets set for this project have been met. The cooperation with Valmet was very good, on an open base during the whole project and startup phase, preventing all possible disturbances, before they even could occur," says Technical Mill Manager Rado Kunavar from Mayr-Melnhof Kolicevo.

Benefits with curtain coating

Mayr-Melnhof has been using curtain coaters from different suppliers for several years. Due to the compact design of Valmet's coater, the coating trials performed in Järvenpää and the good cooperation during the sales phase, they decided to choose Valmet this time. The selected coating concept including the 2-layer curtain coating makes it possible to reduce coat weight resulting in cost savings.

OptiCoat Layer uses slide dye curtain coating, which enables versatile use of coating color substances and layer thicknesses. The method also provides flawless coating coverage. The supply system includes the necessary degassing equipment. Effective degassing is essential in curtain coating since even the smallest air bubbles affect the stability of the curtain.

"2-layer coating has been tested with dry edges, and equipment works as expected. It has proven to be very good that we chose the degassing system from Valmet. We are very pleased with it," says Production Manager Aljaz Hafner at Mayr-Melnhof Kolicevo.

Information about the customer Mayr-Melnhof Group and the Kolicevo mill

The Mayr-Melnhof Group's operations are entirely concentrated on the core business areas which are managed in two operative segments MM Karton and MM Packaging. MM Karton is the worldwide leading manufacturer of coated recovered cartonboard with a growing position in virgin fiber based board. The Division is composed of seven mills in Europe with a total annual production capacity of more than 1.6 million tons.

The recycling and virgin fiber based cartonboard grades are produced at the Kolicevo mill. Specializing in weights between 200 and 500 g / m², the products are used in particular for food packaging, cosmetics, pharmaceutical packaging and other high-quality applications.

Further information, please contact:

Michael Kremsner, Product Sales Manager, Paper Mills Business Unit, Valmet, tel. +43 1 7996255 83

Petri Paloviita, Product Manager, Coaters and Sizers, Paper Mills Business Unit, Valmet, tel. +358 40 5918622

Valmet Corporation is the leading global developer and supplier of technologies, automation and services for the pulp, paper and energy industries. Valmet's vision is to become the global champion in serving its customers.

Valmet's services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. The strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet's advanced automation solutions range from single measurements to mill wide turnkey automation projects.

Valmet's net sales in 2014 were approximately EUR 2.5 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the NASDAQ OMX Helsinki Ltd.

Portucel officially opens two production units at the Cacia and Vila Velha de Ródão complexes

![]() The Portucel Soporcel group, Portugal's third largest exporter and the leading European manufacturer of uncoated woodfree (UWF) printing and writing paper, has officially opened two of it latest capital projects at its industrial complexes in Cacia and Vila Velha de Ródão, representing total investment of € 95.3 million, and also announced plans to invest a further €120 million through to 2017, in Cacia, on a new tissue paper production line.

The Portucel Soporcel group, Portugal's third largest exporter and the leading European manufacturer of uncoated woodfree (UWF) printing and writing paper, has officially opened two of it latest capital projects at its industrial complexes in Cacia and Vila Velha de Ródão, representing total investment of € 95.3 million, and also announced plans to invest a further €120 million through to 2017, in Cacia, on a new tissue paper production line.

This array of projects - joined by others, such as the vertically integrated forestry project in Mozambique, with a value of € 2.1 billion euros, and the construction of a pellets factory in the US, representing around € 100 million - is part of plans drawn up by the Portucel Soporcel group to expand and diversify its business over the next few years, in pursuit of the goal of sustained growth for this increasingly important multinational with its roots in Portugal.

20% more pulp in Cacia

This morning, the Cacia industrial complex officially opened the extension to its pulp mill, the result of an investment project worth € 56.3 million which is set to boost the Group's annual exports to more than 120 countries by a further € 30 million.

This capital project has increased the production capacity at the mill by 20%, from 294 to 353 thousand tons of paper pulp per annum, accompanied by an increase in production of renewable energy of around 9%, to a total of 336.7 MW/year.

The new extension to the mill has created a further fifteen direct jobs, and potentially generated around 290 indirect jobs, in particular in the forestry industry and in port logistics and road haulage sectors. As many as 1520 external workers were recruited during the construction period.

Significantly, the changes at the Cacia mill have incorporated the latest industrial and environmental technology, and innovative measures have been adopted to improve

environmental performance, including the collection, processing and incineration of malodorous gases (17 km of piping are used to collect and treat these gases), as well as the fitting of a new burner in the existing lime kiln, the installation of an electrofilter for the new lime kiln and partial substitution of the use of fuel oil by natural gas in the lime kilns. In terms of specific achievements, the project has cut atmospheric emissions of malodorous gases from the production process and allowed water from the production process to be reused, thanks to a new cooling tower, resulting in a significant reduction in consumption.

The work on building the new facilities and installing the new equipment all took place with the Cacia mill in full operation, except for the months from January to June this year, when work had to be carried out on the existing equipment, and to integrate the new equipment into the existing system.

This project has made it possible to optimise performance at the Cacia mill, helping to improve reliability in the mill facilities and to eliminate bottlenecks in certain production areas.

AMS doubles output

In the afternoon, AMS officially opened its new tissue paper production line at its plant in Vila Velha de Ródão, which was taken over by the Portucel Soporcel group at the start of this year. This expansion project involved investment of € 39 million and has created 70 new direct jobs, doubling the production capacity of the plant, which is now set to increase exports by around 40% and EBITDA by 72%.

Purchasing around 40% its supplies from local companies, the new mill has increased its factory floor space from 40,000 m2 to 70,000 m2 and is fitted with the latest environmental technologies which will allow it to cut CO2 emissions by 22,000 tons/year.

With this new production line in Vila Velha de Ródão, the Portucel Soporcel group can now assert itself as one of Europe's most competitive manufacturers in the tissue market, a position it intends to improve further through its plans (as mentioned above) for investing a further € 120 million in a new production unit in Cacia, due to start up in 2017, which will have rated annual capacity of 70 thousand tons, incorporating equivalent finishing capacity.

About the Portucel Soporcel group

The Portucel Soporcel group is Portugal’s third leading exporter, and the exporter generating the highest level of national value added. The Group accounts for approximately 1% of Portugal's GDP, around 3% of the country's total exports of goods, close to 8% of all containerized cargo and 7% of all containerized and conventional cargo exported through Portuguese ports.

In 2014, the Portucel Soporcel group set a new record for paper output, increasing the sales volume by

3% to over 1,564 thousand tons, allowing the Group to achieve growth in turnover to € 1,542.3 million.

Having consolidated its position as the leading European manufacturer, and the sixth largest in the world, of uncoated woodfree (UWF) printing and writing paper, the Group is also Europe's top producer of BEKP (Bleached Eucalyptus Kraft Pulp), and the fifth largest in the world.

The Group has successfully pursued a strategy of innovation and development of its own brands, which today account for 62% of sales of manufactured products. Special mention should be made of the Navigator brand, the world’s best-selling product in the premium office paper segment.

The Group sells its products to 127 countries over five continents, with a special focus on Europe and the US, giving it the largest export base of any Portuguese company.

As a vertically integrated forestry group with its own forestry research institute, it leads the world in the genetic improvement of the Eucalyptus globulus. It manages vast tracts of forest in Portugal certified under the FSC® and PEFC™ systems (FSC license C010852 and PEFC license 13-23-001), and boasts annual production capacity for 1.6 million tons of paper, 1.4 million tons of pulp (of which 1.1 million is integrated into paper) and power generation of 2.5 TWh, adding up to annual turnover approximately of approximately 1.5 billion euros.

The Group operates one of Europe’s largest nurseries for forestry plants, with annual production capacity of approximately 12 million certified plants of various species, destined for use in renewing Portugal’s woodlands.

As part of its strategy for international expansion, the Group recently acquired a tissue paper manufacturer - AMS - and is implementing a major vertically integrated forestry project in Mozambique, as well as a new pellets factory in the US.

Yuen Foong Yu has signed another contract with PMP - strategic partnership is successfully continued

In October 2015, Yuen Foong Yu has signed a contract with PMP for rebuild of TM#7 in Ching Shui Mill (Taiwan). The delivery includes steel Intelli-YDTM, Intelli-CapTM and Steam & Condensate equipment. PMP has been chosen again as a strategic partner supporting YFY’s development.

In October 2015, Yuen Foong Yu has signed a contract with PMP for rebuild of TM#7 in Ching Shui Mill (Taiwan). The delivery includes steel Intelli-YDTM, Intelli-CapTM and Steam & Condensate equipment. PMP has been chosen again as a strategic partner supporting YFY’s development.

PMP is a global provider of paper, board and tissue technology and has been serving pulp & paper industry for over 160 years. PMP has built business partnership with Yuen Foong Yu in Asia that lasts several years already.

Yuen Foong Yu’s core business is paper manufacturing. Company produces printing, writing, industrial and home use paper. YFY owns three major brands of tissue paper at present: Mayflower, Tender and Delight. Its production lines cover paper products such as toilet paper, tissue paper, facial tissues, paper towels and napkins. YFY is not only one of leading Asian papermakers, it also ranks among the 50 largest paper manufacturers in the world.

This time, the scope of supply covers 12’ steel YD designed and manufactured by PMP (2420 mm sheet width on Yankee), a high efficiency Yankee cap supplied with an air fan – Intelli-CapTM – and a Steam & Condensate equipment. Designed Yankee is a steel welded construction with bolted on journals. In order to increase Yankee efficiency, PMP offers optimized and tailor-made solutions. Intelli-YDTM designed for YFY will be capable to operate up to 9.5 bar(g) of steam pressure and a maximum design speed of 1200 mpm. Additionally PMP will exchange existing steam Yankee Hood with Yankee Cap to reduce steam consumption. Appropriate changes in Steam & Condensate system will be implemented to fit new system conditions.

YFY decided to choose PMP Intelli-YDTM due to great running references representing very high performance and ultra-low media consumption. This project is an example where PMP’s technological knowledge combined with high-tech equipment can become a key factor to achieve common success. The delivery is scheduled on June 2016, followed by erection at site and start-up on August 2016.

BPM Manufactures MG Grades for Specialty Paper Applications

BPM Paper, a leader in the manufacturing of MG papers and specialty papers, manufactures an extensive range of machine glazed papers for the flexible packaging industry. With continuous improvements of machine modifications, BPM’s MG grades deliver consistent converting and print capabilities for specialty paper applications.

With continuous improvements of machine modifications, BPM MG grades deliver consistency to printing and converting.

“BPM is a respected and innovative specialty paper mill in the MG paper industry,” stated Mitchell Mekaelian, Vice President of Sales and Marketing for BPM Inc. “We are looking to grow our MG market in light of the recent major shut down of a European MG machine. As an experienced supplier, we know this market. BPM is recognized for its quality MG papers and with continuous improvement and commitment, we are able to drive market innovation and offerings.”

“BPM is a respected and innovative specialty paper mill in the MG paper industry,” stated Mitchell Mekaelian, Vice President of Sales and Marketing for BPM Inc. “We are looking to grow our MG market in light of the recent major shut down of a European MG machine. As an experienced supplier, we know this market. BPM is recognized for its quality MG papers and with continuous improvement and commitment, we are able to drive market innovation and offerings.”

Located in northern Wisconsin, the mill’s Yankee paper machine has received several upgrades and updates over recent years. From new software package to improvements in the head box and steam box, the upgrades have assisted in reduced variability of basis weights and moisture profiles. The paper machine has a 123” trim width with the majority of the company’s paper production is in the range of 20 to 30 lb. papers, with capabilities that range from 14 to 45 lb.

BPM manufacturers a robust line of MG papers that can be engineered to meet the needs of a wide array of applications. Product offerings include PH Neutral Papers, food release, wet strength, coating and laminating bases, baking papers, confectionery, meat and cheese interleave, and wrapping papers. The company is known for its specialty paper manufacturing flexibility, excellent service and willingness to develop custom-made solutions.

The company’s MG products have an excellent surface finish resulting in better print capability and run-ability. With in-house printing, converting and waxing capabilities, customer’s needs can be tailor-made for specific end-use solutions. The mill also has a unique offering of colored MG papers. Common colors are natural, brown, orange and yellow with custom colors available upon request.

BPM Inc.

Rebecca Schoenebeck, 715-582-5253

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.bpmpaper.com

Intertek supports Sappi's development of novel materials for automotive or consumer product applications

Supporting innovation through assessment of a new cellulose reinforced polypropylene

Intertek, a leading provider of quality solutions worldwide has successfully completed an assessment of Sappi’s new cellulose reinforced polypropylene material, in order to determine its suitability for processing and automotive or consumer product applications.

Intertek, a leading provider of quality solutions worldwide has successfully completed an assessment of Sappi’s new cellulose reinforced polypropylene material, in order to determine its suitability for processing and automotive or consumer product applications.

As a global forest product leader focused on dissolving wood pulp, paper pulp and paper-based solutions, Sappi is strategically committed to maximize the value of wood derived products by exploring new possibilities and innovations with the materials now used to make paper. Recently, Sappi has developed a new material by using cellulose from trees to create a cellulose reinforced polypropylene. This material has potential applications in a variety of markets including automotive, consumer electronics and furniture.

Intertek polymer engineers assessed the new material by using their laboratory polymer processing facility to show that it is easily processed and can be made into “life-sized” items such as automotive components. These were then tested to explore their properties. The test results demonstrated good mouldability as well as high rigidity with low density, low odour, good colouring possibilities and good scratch resistance. The assessment benefitted Sappi by providing critical insight on the material’s performance which has helped to reduce risk of product failure and also enabled initial customer trials to be conducted, leading to rapid market introduction following a very short development period.

Intertek has entered into a collaboration with the Symbio team, part of a corporate start-up initiative within Sappi, to support their product development of next generation cellulose reinforced materials which are already in development. Intertek will continue to play a supporting role by providing testing and polymer processing expertise (injection moulding and extrusion) to assist Sappi develop new materials with improved impact resistance.

Intertek polymer engineers, chemists and regulatory experts work with clients to continually enhance polymer development through advanced analytics, problem solving, pilot plant injection moulding, film extrusion and compounding pilot line facilities. With this expertise, Intertek supports the development of new and innovative polymer products for numerous applications including packaging, consumer products, automotive and aerospace.

The Intertek team will highlight this news at the AutomotiveNL Supplier Day 2015, November 13th 2015, Automotive Campus 30, Helmond, The Netherlands

Learn more about Intertek materials verification programs:

www.intertek.com/polymers/composites/characterization

Learn more about Sappi’s cellulose reinforced polypropylene:

www.forestplastics.com

Contacts:

Intertek

Frank Huijnen

Senior Consultant Polymers

Intertek Life Sciences

Koolwaterstofstraat 1 | 6161 RA Geleen | The Netherlands

Mobile +31 (0)6 10 894 659

Sappi

Jacob Hartstra

New Business Development Manager

Sappi Europe

Biesenweg 16 | 6211 AA Maastricht | The Netherlands

Tel +31 433822 432 | Mobile +31 (0) 6 31 920 074

About Intertek

Intertek is a leading quality solutions provider to industries worldwide. From auditing and inspection, to testing, training, advisory, quality assurance and certification, Intertek adds value for its customers by helping improve the quality and safety of their products, assets and processes. With a network of more than 1,000 laboratories and offices and over 38,000 people in more than 100 countries, Intertek supports companies’ success in the global marketplace, by helping customers to meet end users’ expectations for safety, sustainability, performance, integrity and desirability in virtually any market worldwide. Visit www.intertek.com

About Sappi

About Sappi Sappi Europe SA is the leading European producer of coated fine paper used in premium magazines, catalogues, books and high-end print advertising. Headquartered in Brussels, Belgium, Sappi Europe is recognised for innovation and quality. Its graphic paper brands include Magno™, Quatro™, Vantage™, Royal™, Galerie™ and GalerieArt™ ranges. Algro®, Leine®, Parade®, Fusion® and atelier™ are the brands for innovative solutions of speciality papers and boards. Sappi papers are produced in mills accredited with ISO 9001, ISO 14001 and OHSAS 18001 certification and EMAS registration for all our mills in the EU. Sappi European mills hold chain-of-custody certification under the Forest Stewardship Council (FSC®) and/or the Programme for the Endorsement of Forest Certification (PEFC™) schemes. Sappi Europe SA is a division of Sappi Limited (JSE), a global company headquartered in Johannesburg, South Africa, with over 13,000 employees and manufacturing operations on three continents in seven countries, sales offices in 50 countries, and customers in over 100 countries around the world.

Learn more about Sappi at www.sappi.com