Ianadmin

Wepa starts up the new Toscotec tissue line in Lille, France

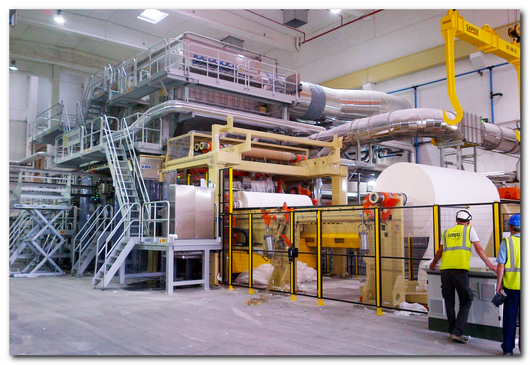

The WEPA Group announces the successful start-up of the new Toscotec’s tissue line installed in Lille, France. The machine came easily on stream after the commissioning period and is now producing high quality tissue products according to the guaranteed technological parameters.

Established in 1948, WEPA started out as a trading company, grew to become a processing company, and since 1958 it has been successfully running its core business as a paper manufacturer, until to be now one of the largest manufacturers in the German Industry for hygiene paper product, and one of the four largest supplier in Europe.

The new Toscotec's line, based on the best available technology, includes an AHEAD-2.0 crescent former tissue machine with TT Headbox-MLT double-layer, a Steel Yankee Dryer (TT SYD-15FT), Milltech hood, steam&condensate and dust removal system. The supply also comprises stock preparation plant for virgin pulp, vacuum plant, boiler plant, air compressors and electrification & control system and an automatic roll handling system. Erection, supervision and training are also included in the scope of the furniture.

With a net web width of 2820 mm and a maximum drying capacity of 120 tpd, the new tissue line has a capacity of 35,000 tpa.

The new machine started up at Wepa Lille site, is already running at the maximum operating speed of 2,000 mpm with great satisfaction of WEPA and Toscotec team.

“This new project strengthens the collaboration with Toscotec, our trusted partner in tissue machinery supply – says Mr. Martin Krengel, President of WEPA. All the start-up phases were performed very well and the machine has achieved excellent performance with high quality tissue at 2,000 mpm just a month after the take-over.

Our readiness to invest in state-of-the-art machinery, choosing the right partner, makes our sustained orientation to the future a success”.

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

For further information www.toscotec.com

SCA intends to close down a paper machine at Ortviken paper mill and recognize an impairment loss for the mill

SCA intends to close down a newsprint machine at Ortviken paper mill in Sundsvall, Sweden, and recognize an impairment loss for the mill. Efficiency improvement measures will be implemented at the Obbola and Munksund kraftliner mills. The closure, impairment loss and efficiency improvement measures entail total costs of approximately SEK 1.4 billion and will result in annual cost savings of about SEK 180m, of which approximately SEK 120m in lower depreciation, with full impact in 2017.

The paper machine that is planned for closure at the end of 2015 has a capacity of 135,000 tons and is the smallest and oldest of the four paper machines at Ortviken paper mill.

“The global demand for publication paper has declined in recent years, particularly for newsprint, and we have weak profitability at Ortviken paper mill. By closing down our smallest and oldest paper machine, we will be able to focus on profitable orders for the more efficient paper machines. Ortviken remains one of the world’s largest publication paper mills and we have the prerequisites to become one of the most competitive. We have developed several new publication paper products, which in a short time have captured considerable market shares in a declining market. We are now focusing on producing and developing profitable publication paper products”, says Ulf Larsson, President, SCA Forest Products.

In conjunction with the closure of the paper machine, SCA intends to reduce staffing in production, transport and sales by approximately 95 positions. The efficiency improvement measures at the Obbola and Munksund kraftliner mills are intended to lead to staff reductions at the two mills by approximately 30 positions. Codetermination negotiations over the changes have been initiated.

The impairment loss amounts to approximately SEK 1.3 billion and will be recognized as an item affecting comparability in the third quarter of 2015. The restructuring costs amount to approximately SEK 90m and will be reported as an item affecting comparability in the fourth quarter of 2015.

NB: This information is such that SCA must disclose in accordance with the Securities Markets Act or the Financial Instruments Trading Act. The information was submitted for publication on October 29, 2015, at 07:45 a.m. CET.

For additional information please contact:

Linda Nyberg, VP Media Relations, 46 8 788 51 58

Johan Karlsson, VP Investor Relations, 46 8 788 51 30

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Futura confirms Andromeda Concept order from Resolute

Futura has announced that its Andromeda Concept high performance tissue converting technology is to be delivered to Resolute Forest Products ready for the expected start of tissue production in the first quarter of 2017.

The Andromeda concept at FuturaLab following It’s Tissue 2015

The Andromeda concept represents a complete new converting solution which redraws the boundaries for tissue roll products converting. It was demonstrated for the first time in its complete form in FuturaLab during iT’s Tissue in Lucca this June, witnessed by hundreds of tissue professionals over the five days of the event.

Futura North America CEO Christian Viviers said: “Resolute is showing true vision by diversifying into tissue and it is our privilege to join them on that journey. The Andromeda concept has provided great inspiration since we presented it to the market in June, and Resolute is one of a number of leading North American companies which have built it into their growth plans.”

SCA divests its business in South East Asia, Taiwan and South Korea for integration with Vinda

SCA, a leading global hygiene and forest products company, strengthens the cooperation with Vinda International Holdings Limited (“Vinda”) by integrating its business in South East Asia, Taiwan and South Korea into Vinda. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies.

SCA, a leading global hygiene and forest products company, strengthens the cooperation with Vinda International Holdings Limited (“Vinda”) by integrating its business in South East Asia, Taiwan and South Korea into Vinda. SCA is the majority shareholder in Vinda, one of China’s largest hygiene companies.

As part of the transaction, SCA and Vinda have signed an agreement regarding the exclusive license to market and sell the SCA brands; TENA (incontinence products), Tork (Away-from-Home tissue), Tempo (consumer tissue), Libero (baby diapers), and Libresse (feminine care) in South East Asia, Taiwan and South Korea. With this agreement, Vinda will hold the rights to these product brands in these Asian markets. Vinda will acquire the brands Drypers, Dr.P, Sealer, Prokids, EQ Dry and Control Plus in these markets. SCA will continue to provide innovation and technical support for the business.

“Asia is an important growth market for SCA with a large population and low penetration of hygiene products. This transaction strengthens the collaboration between SCA and Vinda and enables us to further leverage on our strengths to build a leading Asian hygiene business” says Magnus Groth, President and CEO of SCA.

SCA has been a shareholder in Vinda since 2007, became its majority shareholder in late 2013, and has consolidated Vinda financials since the first quarter of 2014. In 2014, SCA divested its hygiene business in China (Mainland China, Hong Kong and Macau) for integration with Vinda.

SCA’s hygiene business in South East Asia, Taiwan and South Korea had net sales of approximately SEK 2.2 billion in 2014. The business has approximately 1,600 employees and three personal care production sites in Malaysia and Taiwan. The purchase consideration amounts to HKD 2.8 billion (approx. SEK 3.1 billion) on a debt-free basis.

The agreement is subject to approval by the independent shareholders of Vinda. Closing of the transaction is expected during the first quarter of 2016. Vinda is listed on the Hong Kong Stock Exchange.

As a consequence of this transaction SCA’s Shanghai office will stop to have operations. This is expected to lead to approximately SEK 90m in restructuring costs that will be recognized as an item affecting comparability in the fourth quarter of 2015.

NB: This information is such that SCA must disclose in accordance with the Securities Markets Act or the Financial Instruments Trading Act. The information was submitted for publication on October 29, 2015, at 01:00 a.m. CET.

For additional information please contact:

Linda Nyberg, VP Media Relations and Online Communications, 46 8 788 51 58

Johan Karlsson, Vice President Investor Relations, 46 8 788 51 30

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Mondi’s Color Copy for Xeikon® available from Premier Paper Group

Mondi, an international packaging and paper group, announces that it has a new stockist for one of its papers in the UK with immediate effect. Mondi’s Color Copy for Xeikon® has now been listed with Premier Paper Group on an exclusive basis.

Mondi, an international packaging and paper group, announces that it has a new stockist for one of its papers in the UK with immediate effect. Mondi’s Color Copy for Xeikon® has now been listed with Premier Paper Group on an exclusive basis.

John Vic, Sales Director Digital Media at Premier Paper states that it was the quality that counted for him most of all. “In order to make full use of the technical possibilities of Xeikon® printing presses, it needs a paper with consistent and reliable quality. Color Copy for Xeikon® has an adjusted moisture level, so the paper stays flat in the print run. Printers can make full use of the speed of their Xeikon presses,” says Vic.

Color Copy is the leading uncoated colour laser paper and is offered with FSC® certification and CO2 neutral. Color Copy guarantees needle-sharp printouts and brilliant colours, especially with digital printing. Color Copy is offered in Xeikon® reels to complete the Color Copy range.

“For Mondi it is important to have a partner who knows about the paper requirements of printers with Xeikon® printing machines. We’re really happy that we can announce our new stockist for Mondi’s Color Copy for Xeikon® in the region” said Johannes Klumpp, Marketing & Sales Director, Mondi Uncoated Fine Paper. “It is our top priority at the moment to ensure continuous availability of the Mondi brands known and valued in the UK market. We’re looking forward to continuing our long and mutually beneficial cooperation with Premier Paper Group,” Klumpp concludes.

For more information please visit our online dealer locator under www.mondigroup.com/dealerlocator

About Premier Paper:

The Premier Paper Group is the UK’s leading independent paper merchant, with some 30,000 tonnes of paper held throughout its extensive branch network across its sixteen stock holding branches.

The Premier Paper Group endeavours to be an integral and valuable part of its customers’ business providing first class services, sharing its extensive knowledge and information, offering advice and a choice of quality products.

For further information about Premier Paper and its products, contact: Tel: 0121 313 1115 or, email: This email address is being protected from spambots. You need JavaScript enabled to view it. or view the website at: www.paper.co.uk

Successful ramp-up of the expansion in the UPM Kymi pulp mill

The ramp-up of the UPM Kymi pulp mill expansion has proceeded well on schedule. The EUR 160 million UPM investment project was started in the spring of 2014 and has now proceeded to final finishing work.

The new debarking plant started operation in June, the modernisation of the softwood fibre line was finished in August and the biggest project, the new pulp drying machine, started operation in August-September - approximately one month ahead of schedule. During the ramp-up, pulp production has exceeded expectations and the quality of pulp has improved. The entire Kymi pulp and paper mill integrate is benefiting from the improvements in energy efficiency and flexibility of operations.

UPM invests in the Kymi pulp mill to strengthen its position in the growing end-use sectors of the global pulp market. As the result of this investment, annual production capacity at the Kymi mill will increase by 170,000 tonnes to 700,000 tonnes of bleached northern softwood and birch pulp.

The investment will have a positive effect on the employment rates and businesses in the region. The increasing use of wood in the mill integrate will bring wood harvest and transportation work for forest industry professionals and stumpage earnings for forest owners.

For further information, please contact:

Mr Markku Laaksonen, General Manager, UPM Kymi, tel. 0400 754 649, This email address is being protected from spambots. You need JavaScript enabled to view it.

Mr Tero Ojala, Project Manager, UPM Kymi-700 project, tel. 040 7033817, This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM Pulp

UPM is one of the world's leading producers of northern softwood, birch and eucalyptus pulp supplying global customers mainly in the growing end use segments such as tissue, speciality papers and board through its own sales and technical service network close to the customers. UPM Pulp operates four modern pulp mills, three in Finland and one in Uruguay as well as eucalyptus plantations in Uruguay. UPM Pulp employs approximately 1,500 people. The Kymi investment increases the annual pulp production capacity of UPM's pulp mills to 3.5 million tonnes. Pulp Business is part of the UPM Biorefining Business Area. To learn more, visit: www.upmpulp.com

UPM Kymi

UPM Kymi is an environmentally efficient mill integrate producing pulp, paper and energy. UPM Kymi employs about 650 people and is located in south-east Finland in Kuusankoski, Kouvola. Kymi produces bleached birch and softwood pulp as well as coated and uncoated fine paper.

UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately EUR 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

Voith: New Paper product successful in the market

Voith announces the sale of the 100th HydroSeal sealing strip system for . Another step up the ladder of success for the sealing strip system after the State of Baden-Württemberg had awarded Voith with its Environmental Technology Prize for the HydroSeal in July.

HydroSeal is a sealing strip system with an integrated lubrication water feed for paper machine suction rolls. Since it was launched on the market, the HydroSeal has been used successfully in all suction roll types and for the production of all paper grades. “An important success factor is without doubt the fact that the patented design meets the ever-growing demand for resource-conserving production with low water and energy use. In both these respects, the HydroSeal has meanwhile demonstrated its effectiveness worldwide," says Jochen Honold, Global Product Manager Mechanical Roll Service at Voith Paper.

The benefit to the environment is immense: the rebuild of just a single suction roll achieves savings of up to 20,000 m³ fresh water and waste water per year. This volume is equivalent to the contents of around eight Olympic swimming pools. The energy savings possible with HydroSeal are also considerable: up to 1 million kWh per year.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Voith opens new Center of Excellence for Winders in Mönchengladbach, Germany

![]() Voith Paper is opening a new Center of Excellence for Winders in Mönchengladbach, where a team of more than 50 specialists will undertake winder upgrades and rebuilds. In particular, the team will provide an extensive range of services for all generations of the winders taken over from Jagenberg AG in 2002 and continuously developed by Voith since then. The facility will also offer solutions and services for winders made by other manufacturers.

Voith Paper is opening a new Center of Excellence for Winders in Mönchengladbach, where a team of more than 50 specialists will undertake winder upgrades and rebuilds. In particular, the team will provide an extensive range of services for all generations of the winders taken over from Jagenberg AG in 2002 and continuously developed by Voith since then. The facility will also offer solutions and services for winders made by other manufacturers.

At the new Voith Paper Center of Excellence in Mönchengladbach, mechanical and automation engineers will cover all functions from the initial idea to the production drawing for the hardware solution and the software engineering. Pre-acceptance inspection tests on automation solutions can also be carried out in Mönchengladbach. The supply of replacement parts will be ensured by specialists who will continue to have access to the complete Voith and Jagenberg data archives. A global network of commissioning and service specialists with more than a dozen winder servicing experts throughout Europe will be deployed on site at paper mills to undertake rebuilds, repairs and optimizations and deal with technical emergencies.

“By building a Center of Excellence at the Mönchengladbach site we want to make clear that winder modernization is one of Voith’s core areas of expertise with which we aim to achieve the greatest possible benefits for our customers. The large number of Voith machines already installed, the fact that we have access to their complete technical documentation, our longstanding experience and the extensive expertise of our winder team were all factors that had a huge influence on our decision," says Bernd Stibi, President Products & Service EMEA at Voith Paper, to explain the background to the decision to locate the new center in Mönchengladbach.

Voith has decades of experience and extensive project references in the maintenance, modernization and rebuilding of winders and has played a major role in new developments in this area. The investment in the new Center of Excellence will safeguard this know-how in the long term and create the basis for expanding the range of modern, productivity-enhancing service packages for winders. The specialist team in Mönchengladbach will be completely integrated into Voith Paper's global network, which supplies the paper industry worldwide in more than 50 countries with its workforce of almost 9,000 people.

Further information is available on Voith’s website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

About the company

Voith sets standards in the markets energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith employs more than 39,000 people, generates € 5.3 billion in sales, operates in about 50 countries around the world and is today one of the largest family-owned companies in Europe.

IBC Paper Training has opened last month the registrations

IBC Paper Training has opened last month the registrations for its brand new and innovative web seminar, specially conceived and designed to help all the paper and tissuemakers worldwide in reducing their raw material cost in papermaking.

LESS THAN 3 WEEKS LEFT TO REGISTER…

How to reduce your raw material cost in papermaking- Web Seminar, in English – 16-19 November 2015(available either LIVE: 1-5 PM Paris Time or by STREAMING (recording of the training):From 6 PM, Paris Time)

As we all know, raw material is certainly the biggest cost share in papermaking. Due to different factors and reasons, it has become a challenge nowadays to find solutions to optimize our raw material efficiency and to reduce its consumption. This seminar will teach you concrete and practical solutions regarding our existing raw material, as well as regarding new materials, such as nano-cellulose, cellulosic composites….

Main guidelines:

► Reduce your fiber consumption

► Understand the fiber and get solutions to maximize and optimize fiber efficiency

► Get to know the new fiber material and processes, as micro-nanotechnology, composites and others to improve paper quality…

Who should attend?

► Responsible personnel involved in the Production in the papermaking Field

► Experienced staff in the Paper Industry involved in the production or process optimization

► Suppliers who would like to gain a better understanding of their customers’ needs

for more info:- http://www.ibcpapertraining.com/wp-content/uploads/2015/09/IBC_Paper_Training_FRMO_Nov-20151.pdf

email addresses - This email address is being protected from spambots. You need JavaScript enabled to view it. and This email address is being protected from spambots. You need JavaScript enabled to view it.

Metsӓ Board recognised as world leader for corporate action on water security

For its actions to improve water security and better manage this shared resource, Metsä Board, one of Europe’s leading suppliers of paperboard, has been awarded with a position on CDP’s Water A List.

This list features companies that are seen as being on the path to sustainably managing water. It has been produced at the request of 617 investors with USD 63 trillion in assets by CDP, the global NGO which holds the most comprehensive dataset of publicly available corporate water information collected on behalf of investors.

Information provided by 405 listed companies has been independently assessed against CDP’s scoring methodology – developed in collaboration with leading peers and experts in corporate water stewardship – and ranked accordingly. Metsä Board is one of eight awarded an A grade for its water management efforts, earning a position on this exclusive global list of corporate leaders. The others are Asahi Group (Japan), Colgate Palmolive (US), Ford Motor Company (US), Harmony Gold Mining (South Africa), Kumba Iron Ore (South Africa), Rohm Co (Japan) and Toyota Motor Corporation (Japan).

In 2013, Metsä Board launched an extensive development project to improve water usage and material efficiency by reducing water intake and fibre loss. It will also improve the efficiency of sludge and wastewater management. The raw material for its paperboards, fresh forest fibre, already comes from northern forests that do not draw on recycled, brackish or processed water. Around 95% of water used for production is returned to its source, and carefully cleaned before release back into the watercourse, ensuring the environment surrounding Metsä Board’s mills is not affected by their water usage.

“We are proud that our efforts in water security and management have been recognised by our inclusion in the CDP Water A List, especially as the only forest industry company in this category,” says Mika Joukio, CEO of Metsä Board.

“Water is essential in making pulp and paperboard, but we continuously seek new ways to reduce its use. Our main water usage is fresh water, almost all of which is surface water from rivers and lakes, and we are very conscious of our need to minimise impact on this natural environment.”

Cate Lamb, head of water at CDP, says: “The business case for action to improve water security has never been stronger or more urgent. For this reason we congratulate those businesses that have achieved a position on CDP’s Water A List. These companies are responding to market demand for environmental accountability and at the same time are making progress towards the realisation of sustainable economies.”

The CDP Water A List, along with the disclosures of all companies publicly taking part in CDP’s water programme this year, is available on CDP’s website.

About CDP

CDP, formerly Carbon Disclosure Project, is an international, not-for-profit organization providing the only global system for companies and cities to measure, disclose, manage and share vital environmental information. CDP works with market forces, including 822 institutional investors with assets of US$95 trillion, to motivate companies to disclose their impacts on the environment and natural resources and take action to reduce them. More than 5,500 companies disclosed environmental information through CDP in 2015. CDP now holds the largest collection globally of primary climate change, water and forest risk commodities information and puts these insights at the heart of strategic business, investment and policy decisions.

For further information, please contact Metsä Board:

Katja Tuomola, Sustainability Manager, mobile: +358 (0)50 4605835, e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.metsaboard.com

Metsä Board is a leading European producer of fresh forest fibre folding boxboards and white linerboards, as well as a market pulp supplier. The company’s sales network serves brand owners, converters and merchants.

By providing high-performance paperboards, Metsä Board supports its customers in consumer goods, retail-ready and food service packaging. Metsä Board develops products and services for demanding end uses such as food, beautycare, healthcare and cigarette packaging as well as graphics.

Metsä Board is headquartered in Finland. In 2014, the company’s sales totaled EUR 2.0 billion, and it has approximately 2,600 employees. Metsä Board, part of Metsä Group, is listed on the NASDAQ OMX Helsinki.