Ianadmin

Kaleidoscope of Colours Inspires Arjowiggins Graphic latest Cocoon campaign

Arjowiggins Graphic, the leading manufacturer of recycled papers, has announced the launch of a new Cocoon global campaign. The campaign, which uses the tagline, “white, recycled and so much more” showcases a spectrum of colour and range of print finishes on Cocoon Offset.

The campaign features the iconic Cocoon butterfly, inspired by how a caterpillar in a cocoon transforms into a beautiful butterfly. In the new campaign, the Cocoon butterfly appears in a geometrical, technical and coloured design, like that of a kaleidoscope. It reflects the colour and print potential of Cocoon, an established high performing, extra-white and 100% recycled paper.

The campaign features the iconic Cocoon butterfly, inspired by how a caterpillar in a cocoon transforms into a beautiful butterfly. In the new campaign, the Cocoon butterfly appears in a geometrical, technical and coloured design, like that of a kaleidoscope. It reflects the colour and print potential of Cocoon, an established high performing, extra-white and 100% recycled paper.

The campaign, which will be rolled out by Antalis in the UK and target designers, printers and end users, will run from October 20th until December 4th across 26 countries. It includes an elegant mailer, which features embossing on the front cover and an insert with detachable paper butterfly stickers. The mailers will be printed on Cocoon Offset 300 gsm 4 colour Komori energy efficient H-UV offset and will be presented in Cocoon Offset 100gsm envelopes.

The campaign is supported by HTML emails and a dedicated website - www.white-and-recycled.co.uk, where customers are encouraged to answer a simple question correctly to be entered into a free prize draw with the chance to win one of two long weekends for two in the colourful Italian village of Cinque Terre. 20 boxes of Italian wine (mix of red, white and rose) will also be available for the lucky runner up winners.

Angela DeVorchik, Operational Marketing Manager at Arjowiggins Graphic UK, comments: “Our campaign is a great way to showcase the outstanding print performance of Cocoon paper which is high performing, versatile and 100% recycled. We hope the Cocoon campaign will demonstrate to printers and businesses that they can produce high quality printed marketing materials without compromising environmental credentials.”

Mike Bennett, Marketing Manager, Antalis UK says, “We are pleased to be exclusive stockists of Cocoon. It’s range of 100% and 50% Recycled* FSC® certified uncoated and coated papers have the qualities and appearance of virgin fibre paper but with superior environmental credentials. The printed mailer is a fantastic demonstration of the versatility and print finish of this excellent product.”

About Arjowiggins Graphic

Arjowiggins Graphic is a leader in the development of innovative environmental paper solutions, offering consistently high quality coated and uncoated recycled papers. The branch is part of Arjowiggins, the world's leading manufacturer of creative high-tech materials and papers. With over 4,000 employees and 20 paper mills around the world, Arjowiggins generates sales of around €1 billion. Arjowiggins is the manufacturing arm of Sequana

About Cocoon

Cocoon consists of a comprehensive range of coated and uncoated recycled papers manufactured from 100% and 50% FSC certified recycled de-inked pulp produced using pioneering methods at Greenfield S.A.S. mill. The products offer the same performance standards as virgin fibre papers, with excellent runnability, printability and whiteness and are available in weights ranging from 80 gsm - 400gsm. Cocoon satisfies the strictest environmental standards and has been certified as follows: European Ecolabel, FSC Recycled-certified, OHSAS 18001, ISO14001 and ISO 50001.

About Antalis

Antalis is one of the leading distributors of communication support materials in the UK and Ireland. Our market leading range of over 13,000 products includes papers, envelopes and consumables, as well as packaging, promotional and visual communication products. Antalis has 16 logistic centres across the UK and Ireland.

Antalis is the leading paper, packaging and visual communications merchant in Europe. As number 2 worldwide with a turnover of 2.585€ billion in 2014, the Group employs 5,585 people serving over 120,000 clients, companies and printers, in 44 countries via their 118 distribution centres. Antalis carries out 14,000 deliveries each day in the world and distributes 1.8 million tonnes of paper per year on a global level. Antalis is the distribution branch of Sequana.

Antalis and Arjowiggins are fully owned subsidiaries of Sequana

Sonoco-Alcore to Offer European Coreboard Mill for Sale 95,000-Ton Facility Located in Schweighouse, France

Sonoco-Alcore S.a.r.l. has announced its intention to offer for sale its Schweighouse-sur-Moder uncoated recycled coreboard mill in Alsace, France. The company has notified the local works council of this opportunity.

Sonoco-Alcore S.a.r.l. has announced its intention to offer for sale its Schweighouse-sur-Moder uncoated recycled coreboard mill in Alsace, France. The company has notified the local works council of this opportunity.

The Schweighouse facility is one of 20 paper mills that Sonoco operates globally. Established in 1878, the mill has two machines with a total capacity of 95,000 tonnes.

Sonoco Alcore S.a.r.l. is wholly owned by Sonoco (NYSE:SON) and operates 29 tubes and cores plants and five paperboard mills in Europe.

Contact: Brian Risinger

+843/383-7509

This email address is being protected from spambots. You need JavaScript enabled to view it.

This announcement is distributed by NASDAQ OMX Corporate Solutions on behalf of NASDAQ OMX Corporate Solutions clients.

The issuer of this announcement warrants that they are solely responsible for the content, accuracy and originality of the information contained therein.

Source: Sonoco Products Company

Xerium Completes Renovation Program at 4 Machine Clothing Plants, Further Optimizing Global Footprint, Cost Structure and Lead Times

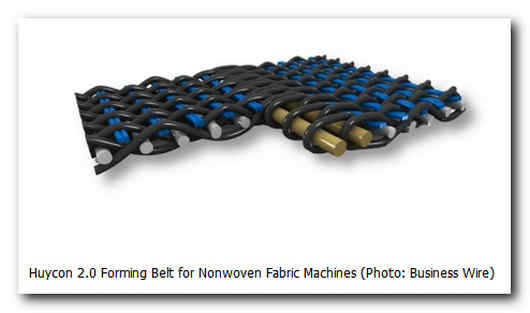

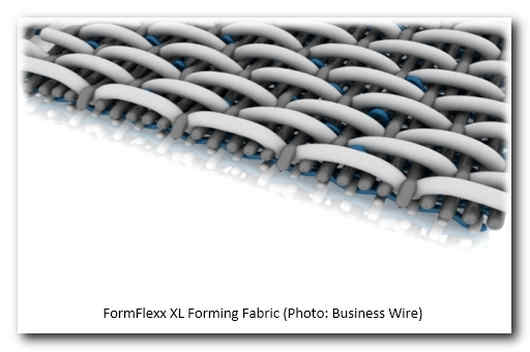

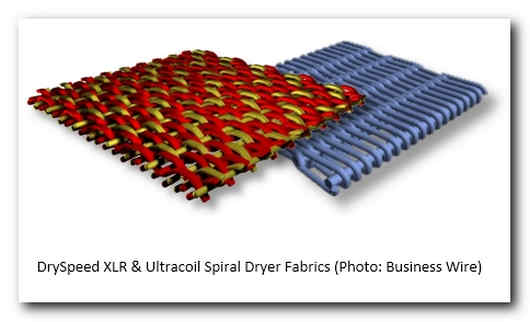

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that it has completed the renovation program at four machine clothing plants that took over two years to design, construct, equip and commission. The Company is aggressively pursuing growth in its popular products, growing grades and regions that are outpacing global industry growth. This global renovation program, involving facilities in North America, South America, Europe and Asia reconfigures its 10-plant machine clothing footprint to serve its customers more effectively with better lead times and global availability of its innovative and rapidly-growing portfolio of patented technology. Key highlights of these projects:

North America – the expansion of the Kentville, Canada forming fabric plant to manufacture woven dryer fabrics in North America for the first time in over a decade. The expansion transitions Xerium from a position of being competitively disadvantaged in dryer fabrics to improved responsiveness to customer quality and delivery expectations. The existing sales force can now leverage relationships in complementary products to accelerate penetration in this currently underserved market. The commissioning of this newly expanded facility and the installed assets was completed in Q3 2015.

South America – the renovation and expansion of the Piracicaba, Brazil plant to manufacture spiral dryer fabrics. Xerium previously manufactured spiral dryer fabrics at its smaller and higher cost Argentina plant. Upon closure of this facility, Xerium made the strategic decision to purchase all new production equipment and modernize its product technology. This initiative, the largest of the four, will enable Xerium to offer both higher quality products and shorter lead times, while operating under a significantly more advantageous cost structure and was fully operational in Q3 2015.

Europe – the expansion of the Gloggnitz, Austria plant to produce belts and fabrics for nonwoven fabrics machines. Xerium has installed special-purpose machines, which will more than double its global capacity for its nonwoven products portfolio. Concurrent with this expansion, Xerium enhanced its product technology to deliver higher levels of performance on the most modern nonwoven production lines and will provide global support for a variety of product types from this site. This expansion further leverages one of Xerium’s most cost competitive and high quality facilities. The expansion is on schedule to reach its full production rate capability by year-end 2015.

Asia – the expansion of the Asahi, Japan plant to produce Xerium’s most advanced forming fabrics for containerboard machines. Xerium has historically manufactured machine clothing for large containerboard machines in its European plants and shipped them to Asia. This investment enables Xerium to serve the Japanese and the entire Asian markets locally with shorter lead times, significantly lower shipping costs to the customer while delivering Xerium’s most modern product portfolio. The commissioning is underway and remains on schedule to reach its full production rate capability by year-end 2015.

Mr. Harold Bevis, President and CEO of Xerium, commented regarding these business transformation projects; “Xerium is committed to quantifiably increasing profits of its customers. These investments enable Xerium to strengthen our partnerships by being closer to its customers with transformative innovation, on-site product experts, and in-region short lead times. The pace of technical breakthrough requests from our customers continues to quicken. We must have shorter product life cycles and faster supply chains to compete and win. Our products and services make a difference for owners of sophisticated large machines, and these machines are dispersed globally. We are very optimistic that these machine clothing programs will be another successful step in our transformation to deliver better financial and operational results and continue to improve our growing stature of supplier of choice in the most attractive regional markets. We do not expect to achieve sales growth by waiting for, and then riding, a global GDP growth cycle. With uncertain global economic conditions, we are strategically deploying our people, innovation, and know-how into expected growth regions.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,000 employees.

Neenah Introduces Five Creative Packaging Ideas for Building a Brand’s Character

The new Neenah Character promotion shows how packaging with unique, premium paper can extend a company’s branding.

At first glance it looks like a cool shopping bag from an avant-garde fashion brand, but it’s actually the new Neenah Character promotion. The sleek and mysterious carry case with “pick me up” appeal houses five different creative packaging samples that showcase a multitude of Neenah’s premium packaging papers and printing techniques.

The promotion, designed by Design Army, is the third in a series of three-dimensional Neenah promotions that focus on brand packaging. “We want people to think of paper as more than just paper — it’s a versatile material, just like fabric or metal, and it can have a 3D form,” said Pum Lefebure, Design Army’s Co-Founder & Chief Creative Officer.

The outer carry case, constructed of a combination of NEENAH® Folding Board, and SO…SILK® Papers, uses a deep, full emboss and foil stamping to create an elegant, yet sturdy structure.

Design Army developed brand characters for each of the five samples found inside the case — each representing different demographics and branches of the retail industry, with a compelling and useful look at “who are they?” and “what hooks them?” According to Lefebure, “The content is trend-driven, but these are long-term trends that will affect retailers for years to come.”

MEET THE CHARACTERS

The Digi-Generation: Plastic is out, paper is in — especially when paper can look this cool. Meet the gift card for the world’s next digital music mammoth, BOOM. A folded, embossed, debossed and foil stamped sleeve houses three, printed, paper gift cards that look like cassette tapes with redemption codes for digital songs; a subtle wink to mixtape culture. The cards are produced on NEENAH IMAGEMAX™ Card and NEENAH DURAMAX™ Card. Be sure to check out the API Holo Foil Revolution + Blind Emboss on Cassette 2.

The New Shopaholic: On the cutting edge of style and social networking, with disposable income to boot, this millennial market is primed for packaging that replicates the sensation of luxury outside the retail environment. SO…SILK® Papers with tone-on-tone foil stamping on luscious hangtags that evoke the feeling of high-end lingerie conjures ‘40s screen sirens. Ooh la la, indeed.

The Artisan Crafters: Reared on cooking shows and food blogs, today’s at-home cooks are hungry for ingredients with integrity, and sourced close to home. And not all labels are created equal, marrying craftsmanship and creativity are the two things that matter most to Artisan Crafters — die-cut labels and artful type can blend “artisanal” and “authentic” in a masterful recipe for irresistible results. NEENAH® Folding Board, Deep Black creates three bottles that showcase labels for craft tequila, wine and olive oil on ESTATE LABEL® and BELLA LABEL® Papers.

The Savvy Socials: Devoted to cultivating their online personas alongside their real-life personalities, these image-conscious consumers are quick to sniff out products and brands that feel inauthentic. Capture this dynamic demographic with packaging that speaks in their voice and reflects them at their best. An iridescent digital printing paper like STARDREAM® Papers in Crystal, with silver and pink foil, catches the eye of even the most device-addicted shopper, and the combination of elegant finish and shine invites a tantalizing touch.

The Eco Evangelizers: Sustainability has never been so stylish or sleek, and an eco-friendly iteration of practically every product is simply a click away. To connect with consumers that truly care about their footprint — and are compelled to share their experiences on social media — brands should look to sustainable packaging with a second life. How about a light bulb box that doubles as a lampshade. This minimalist pairing of recycled NEENAH® Folding Board and ENVIRONMENT® Papers with white ink feels as stylish as it is sustainable.

“Neenah is always striving to inspire designers by introducing new papers, new techniques, and new ideas. We hope the Neenah Character promotion helps designers think about paper differently, consider paper as a possible driver in design, because often times a customer’s first introduction to the brand is through paper, when they pick up the package, hold it and interact with it,” said Jamie Saunders, Marketing Communications Manager, Fine Paper and Packaging, Neenah Paper.

To get the new Neenah Character promotion, contact your local merchant or Neenah sales rep.

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles.

Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

Contact

Neenah, Jamie Saunders, 678-518-3222, This email address is being protected from spambots. You need JavaScript enabled to view it.

SUEDE-FEEL PAPER REPRESENTS HEIGHT OF LUXURY IN PACKAGING

British Master Papermaker, James Cropper, has successfully mimicked the luxurious look and feel of suede in paper form, creating a new generation of tactile luxury papers.

Craftsmanship, progress and an unequalled expertise with leather are the founding pillars of the luxury brand, LOEWE. Recognising that craft, experience and innovation are also at the heart of papermaking excellence, the Spanish-based brand approached James Cropper to fashion a suede-effect paper for its product packaging. LOEWE was looking to create statement packaging, that paired functionality with an incredible tactile softness, to emulate the look and feel of its world renowned range of leather goods. The result of the collaboration between the two companies, each with 170 years of business success, was Carvetian Suede.

Susan Wilson, Luxury Packaging Director, said: “We are always striving to create new and innovative papers to meet the demand for high quality, luxury products. Carvetian Suede offers people in the design and packaging industries something that exudes opulence. The product has great foundations, a base paper designed specifically to meld with the soft-touch surface to create a suede paper of the highest quality. In addition we use a high percentage of recycled fibres so it’s very eco-friendly, making it all the more appealing to our clients by helping them achieve their sustainability objectives.”

Following on from the success of the 2013 packaging launch for LOEWE, Carvetian Suede is now available to international buyers and presents an opportunity not only to create luxurious packaging but creative print and advertising materials with a wonderful tactile feel.

The product has been employed in a variety of uses since its inception. In 2013 a sculpture of a dog in a stylish Carvetian Suede coat was presented at the Gerald and James exhibition in New York.

From 21 – 23 October 2015, visitors to the prestigious Luxe Pack event at the Grimaldi Forum in Monaco will also have the opportunity to discover Carvetian Suede for themselves. The product has been selected for display in the Luxe Pack Arena, a space dedicated for leading product developments, and can also be found on the James Cropper stand, DB9.

Carvetian Suede is produced using a minimum of 40 per cent recycled, post consumer fibres making it an environmentally-friendly choice.

Available in a range of four natural colours, Carvetian Suede takes its name from the Carvetii, Iron Age settlers in the North of England, reflecting the roots of James Cropper’s heritage.

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

As well as paper products, James Cropper PLC also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors. For further information visit: www.jamescropper.com and www.tfpglobal.com

Tieto Integrated Paper Solution to support the execution of Suominen’s growth strategy

Suominen, a global supplier of nonwovens for wiping, medical and hygiene products, has made an agreement on strategic IT partnership with Tieto. The four-year agreement with one year option and significant value covers the building and maintenance of Suominen’s business applications and platform services. The partnership supports the execution of Suominen’s growth strategy.

Suominen, a global supplier of nonwovens for wiping, medical and hygiene products, has made an agreement on strategic IT partnership with Tieto. The four-year agreement with one year option and significant value covers the building and maintenance of Suominen’s business applications and platform services. The partnership supports the execution of Suominen’s growth strategy.

Tieto is providing Suominen with a full stack solution, including new ERP and MES systems, based on the standard SAP and TIPS integrated solution with new capabilities and hosting from the Tieto cloud. The investment provides new business capabilities for Suominen’s information driven supply chain and production excellence, including e.g. functions for demand management, sales management, centralized planning, production management, reporting and analytics.

“We have the target to be an innovative and agile game changer in our industry, and we seek to achieve significant growth through product leadership. We want to utilize efficiently our global presence in a harmonized way and strive for excellence in all actions. We had a tight schedule to build a basis for growth and renewal, and Tieto supported us in an excellent way in the planning phase,” says Timo Rautakorpi, CIO at Suominen.

“Tieto has created an integrated paper industry solution based on SAP and its own TIPS product family for the global market. This agreement proves our solution’s attractiveness. This is also a showcase for our transformation knowledge in process industry. We are very proud of the trust shown by Suominen,” says Henrik Reims, head of Forest Industry at Tieto.

For more information, please contact:

Timo Rautakorpi, CIO, Suominen, tel. +1 860 205 1022, email: timo.rautakorpi[at]suominencorp.com

Henrik Reims, VP, Forest Industry, Tieto, tel. +358 40 515 5719, email: henrik.reims[at]tieto.com

Tieto is the largest IT services company in the Nordics providing full lifecycle IT services. We also provide global product development services for companies in the communications and embedded technologies arena. Through industry insight, technology vision and innovative thinking, Tieto proactively strives to inspire and engage its customers in finding new ways of accelerating their business.

Building on a strong Nordic heritage, Tieto combines global capabilities with local presence. Headquartered in Helsinki, Finland, Tieto has over 13 000 experts in more than 20 countries. Turnover is approximately €1.5 billion. Tieto’s shares are listed on NASDAQ in Helsinki and Stockholm. www.tieto.com

Suominen manufactures nonwovens as roll goods for wipes as well as for medical and hygiene products. The end products made of Suominen’s nonwovens – wet wipes, feminine care products and swabs, for instance – bring added value to the daily life of both consumers and professionals worldwide. Suominen is the global market leader in nonwovens for wipes. The company employs approximately 600 people in Europe and in the Americas. The Suominen share (SUY1V) is listed in NASDAQ OMX Helsinki Stock Exchange. http://www.suominen.fi/en/

Major Asian Papermaker to Adopt Minerals Technologies' FulFill® E-325 High-Filler Technology

Minerals Technologies Inc., has announced that it has entered into a commercial agreement with another leading Asian papermaker to provide FulFill® E-325 higher filler technology.

Minerals Technologies Inc., has announced that it has entered into a commercial agreement with another leading Asian papermaker to provide FulFill® E-325 higher filler technology.

"We are very pleased that this prestigious Asian papermaker, who wishes to remain unnamed for competitive reasons, is adopting our FulFill® E-325 technology," said Joseph C. Muscari, chairman and chief executive officer. "Our technology will allow this paper company to produce quality paper at lower cost by replacing higher-cost fiber with PCC."

Minerals Technologies now has 23 agreements with paper mills that have adopted the FulFill® technology that the company introduced in late 2010. The company has nine agreements with paper companies in Asia; eight in North America; five in Europe; and one in South America.

"These agreements confirm the commercial progress of the FulFill® brand," said W. Rand Mendez, senior vice president & managing director, Paper PCC. "MTI is also actively engaged with more than 10 other paper mills around the world that are interested in this technology."

PCC is a specialty pigment for filling and coating high-quality paper. By substituting PCC for more expensive wood fiber, papermakers are able to produce brighter, higher quality paper at lower cost. Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills and the concept was a major factor in revolutionizing North American papermaking from an acid to an alkaline-based technology. Minerals Technologies constructed its first PCC satellite plant in 1986. Today, the company has 64 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries. The company reported sales of $1.725 billion in 2014.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

Contact:

Rick B. Honey

(212) 878-1831

Billerudkorsnäs reports strong performance and structural opportunities

CEO Per Lindberg comments on the development during Q3 2015:

“The third quarter performance and overall market situation strengthen our belief in our long-term strategic direction. The growth strategies per Business Area were confirmed, and our belief, that the contemplated investments in our own production structure will allow us to capture market opportunities, is strengthened.”

THE RESULT

I am pleased with the adjusted operating profit for the quarter of SEK 683 million. Of course the continued weak SEK continues to be a positive profit driver, but at the same time we see 5% year on year volume growth in Consumer Board in line with our targets, record margins in Containerboard, and a balanced development for Packaging Paper with some weaker and some stronger areas. Simultaneously, our ROCE is above target at 14% adjusted and our balance sheet strengthens further to a net debt/equity ratio of 0.46.

MARKET OUTLOOK

The overall market is stable, thus continuing sideways with only minor variations in segment demand and pricing. Looking ahead, we expect this pattern to continue with normal demand patterns and small variations in local pricing.

Within Packaging Paper the MG markets are continued strong, whereas MF and white sack paper markets are weaker but stable. Unfortunately, the market has not been strong enough to absorb the announced price increases for kraft and sack paper earlier in the year. Our production capacity in some segments has not been fully utilized due to increased competition, selective pressure on local prices, and in the non-integrated mills also due to unsatisfactory profitability. As a consequence, we have in October taken the decision to close our production in Tervasaari completely, after having run it underutilized during the year with insufficient profitability. This has been a tough decision to make. The local team in Tervasaari has made significant efforts to improve profitability and utilization, but the cost position of the machine in combination with an increasingly commoditized product portfolio proved too big of a burden to carry.

Within Packaging Paper the MG markets are continued strong, whereas MF and white sack paper markets are weaker but stable. Unfortunately, the market has not been strong enough to absorb the announced price increases for kraft and sack paper earlier in the year. Our production capacity in some segments has not been fully utilized due to increased competition, selective pressure on local prices, and in the non-integrated mills also due to unsatisfactory profitability. As a consequence, we have in October taken the decision to close our production in Tervasaari completely, after having run it underutilized during the year with insufficient profitability. This has been a tough decision to make. The local team in Tervasaari has made significant efforts to improve profitability and utilization, but the cost position of the machine in combination with an increasingly commoditized product portfolio proved too big of a burden to carry.

Consumer Board market continues to be strong and we are experiencing delivery pressures from our main markets. I am happy we have decided to invest in increased capacity in Consumer Board for continued volume growth.

Business area Containerboard noted an all-time high operating margin. Fluting demand continue to be strong. The new flute from the upgraded PM6 in Gruvön lives up to the high quality expectations and is a solid product for continued value growth. The liner segment shows a stable demand and attempts for price increases has been made on the market even with more capacity coming on line upstream.

STRATEGY

Growing demand driven by global megatrends favours our markets and to support the volume growth strategy within business area Consumer Board we have started a pre-project investigating the opportunity to invest in a new board machine to be placed in Gruvön. In addition to increased cost efficient capacity it would also include a streamlining of the production structure within business area Packaging Paper as the current production of kraft papers at the Gruvön production unit would be discontinued and replaced by production at other BillerudKorsnäs units. This supports business area Packaging paper’s selective growth strategy and in a second pre-project we focus our efforts on further structural changes to enable growth in the attractive growing kraft paper segments within medical papers, food packaging and release liners and the discontinuation in the less attractive commodity segments. The investigation explores the possibility of moving the paper machine in Tervasaari to Skärblacka and make it an integrated unit, as well as investment in further value adding surface treatment capacity at existing MG paper production in Skärblacka.

Should both pre-projects materialise it would imply an overall efficient production structure for the group, capacity increases in very attractive areas and improved margins due to better product mix including removal of any exposure to the pulp market.

| The information is such that BillerudKorsnäs AB (publ) is obligated to publish under the Swedish Securities Market Act. Submitted for publication at 07.02 CET, 21 October 2015. |

For further information, please contact:

Per Lindberg, President and CEO +46 (0)8 553 335 00

Susanne Lithander, CFO, +46 (0)8 553 335 00

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fiber based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 21 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Verso Releases New PAPER@WORK(TM) Brief

Verso Corporation (OTCQB: VRSZ), a leading supplier of printing papers, specialty papers and pulp, today released Flexible Packaging: Anatomy of a Special(ty) Relationship, the fifth installment in its popular PAPER@WORK™ series. This brief explores Verso's 40-year-plus relationship with American Packaging Corporation (APC) and examines keys to success in the flexible packaging market.

Verso Corporation (OTCQB: VRSZ), a leading supplier of printing papers, specialty papers and pulp, today released Flexible Packaging: Anatomy of a Special(ty) Relationship, the fifth installment in its popular PAPER@WORK™ series. This brief explores Verso's 40-year-plus relationship with American Packaging Corporation (APC) and examines keys to success in the flexible packaging market.

In consumer packaging, brand is everything and paper is a brand builder. Companies in this highly competitive realm know print consistency is critical to building and maintaining their brands. That signature red -- or blue or yellow or metallic gold -- has to be the same each and every time, across each and every product and package. This is why printing surface is so important and why a strong, collaborative supplier relationship is crucial to success.

"This new brief delves into the successful Verso-APC relationship," says Jason Handel, Verso Group Vice President of Specialty, Pulp and Product Development, "but also touches on what makes any customer-supplier relationship work, that is, a mutual understanding of goals and what it takes to achieve them together as a team."

"APC is a trusted provider in the packaging industry and it is very important for us to have a collaborative relationship with all of our suppliers," says Jeff Huber, APC Director of Corporate Purchasing. "Working with Verso on this PAPER@WORK™ brief highlights our shared values of quality, innovation and commitment."

PAPER@WORK™ is an ongoing series of briefings from Verso Corporation which details a spectrum of important topics impacting the world of specialty papers.

Please visit www.versoco.com/specialtypapers or email This email address is being protected from spambots. You need JavaScript enabled to view it. to request a copy of this free PAPER@WORK™ brief.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

About American Packaging Corporation

American Packaging Corporation is an ISO 9001:2008 certified company specializing in the manufacture of flexible packaging laminations for a variety of specialty markets. The company has three process focused facilities: Rotogravure Printing and Laminating, Flexographic Printing and Laminating, and Engineered Laminations and Coatings. The company is privately-held and has been serving the packaging industry for over 100 years. ampkcorp.com.

New Pratt Mill Starts Production

Pratt Industries has announced its new $260 million recycled paper mill had started production in Valparaiso, In.

Pratt, which has now built three of the last 4 paper mills constructed in the U.S., said the new 100 percent recycled facility would supply the company’s rapidly-expanding Midwest operations. In just two years, company chairman Anthony Pratt said Pratt had invested more than $400 million in the U.S.

“This is a great day for Pratt Industries,” he said. “This mill represents the single biggest investment we’ve ever made in the U.S.”

Pratt said the new mill would also increase the company’s annual revenues from approximately $2.1 billion to approaching $2.5 billion.

“This puts us in a very strong position to exceed our medium range target of $3.5 billion in sales ahead of schedule,” he said.

Pratt said America’s low energy costs and inherent entrepreneurial spirit had given rise to a new wave of manufacturing growth, especially in the Midwest where he says industry is booming and jobs are coming back from China and elsewhere.

“We’re riding that wave,” he said.

The mill, located 50 miles southeast of Chicago is on the same site as Pratt’s corrugated box plant, the world’s largest. It will supply that facility as well the company’s other box-making sites throughout the region with recycled paper.

The mill, located 50 miles southeast of Chicago is on the same site as Pratt’s corrugated box plant, the world’s largest. It will supply that facility as well the company’s other box-making sites throughout the region with recycled paper.

Pratt said it would be the industry’s most efficient paper mill, employing 120 people to make 370,000 tons a year – twice the productivity of many competitor mills.

“It is the world’s most environmentally-friendly paper mill and a showcase for the latest in 21st Century paper-making technology,” he said.

At capacity, the mill will save some 20,000 trees and divert up to 3500 cubic yards of paper from landfills every day and annually prevent more than 700,000 gross tons of co2 emissions through landfill avoidance.

It was also designed to use even less water, electricity and natural gas than its three sister mills in Georgia, New York and Louisiana.

“That’s important not only for our environment but also for our customers who realize the importance of sustainable packaging,” said Pratt.”Our environmental message is clearly resonating throughout the country which is why our sales and profits continue to hit record levels.”

He said the company would open a new $50 million corrugated box plant in Beloit, Wisconsin in just a few weeks.

Pratt Industries now has some 130 facilities in the U.S. and is currently the 5th largest corrugated packaging company in the U.S.