Ianadmin

BASF to set up new global business unit combining all pigments activities

BASF will form a global business unit (GBU) combining all of its pigments activities effective January 2016. In the second half of 2016, BASF intends to carve out its pigments business and establish separate legal entities.

BASF will form a global business unit (GBU) combining all of its pigments activities effective January 2016. In the second half of 2016, BASF intends to carve out its pigments business and establish separate legal entities.

With sales of about €1 billion in 2014 and 2,500 employees globally, BASF holds a leading position in the pigments market, offering the broadest portfolio of products and technology. The new GBU will likely be headquartered in the Ludwigshafen area. All employees who are dedicated to the pigments business will be transferred to the new GBU.

“We have achieved and maintained a leading position in the pigments market through acquisitions and a series of successful restructuring measures. The new global business unit will fully concentrate on the pigments business and thus be even more focused on supporting the needs of our pigments customers,” said Dr. Markus Kramer, President of BASF’s Dispersions & Pigments division.

Dr. Alexander Haunschild, Senior Vice President of the regional business unit Pigments and Resins Europe and appointed head of the GBU, stated: “By creating an organization fully dedicated to pigments, we will adapt better to the challenges in the pigments industry. Our customers will benefit from tailored services and higher responsiveness.”

BASF’s pigments business serves a variety of industries including paints & coatings, printing & packaging and plastics. The portfolio comprises of color pigments such as phthalocyanines, high performance pigments, azo pigments, effect pigments, inorganic pigments, dyes and pigment preparations.

About BASF’s Dispersions & Pigments division

The Dispersions & Pigments division of BASF develops, produces and markets a range of high-quality pigments, resins, additives and polymer dispersions worldwide. These raw materials are used in formulations for coatings and paints, printing and packaging products, construction chemicals, adhesives, fiber bondings, plastics, paper as well as for electronic applications such as displays. With its comprehensive product portfolio and its extensive knowledge of the industry, the Dispersions & Pigments division offers its customers innovative and sustainable solutions and helps them advance their formulations. For further information about the Dispersions & Pigments division, please visit www.dispersions-pigments.basf.com.

About BASF

At BASF, we create chemistry – and have been doing so for 150 years. Our portfolio ranges from chemicals, plastics, performance products and crop protection products to oil and gas. As the world’s leading chemical company, we combine economic success with environmental protection and social responsibility. Through science and innovation, we enable our customers in nearly every industry to meet the current and future needs of society. Our products and solutions contribute to conserving resources, ensuring nutrition and improving quality of life. We have summed up this contribution in our corporate purpose: We create chemistry for a sustainable future. BASF had sales of over €74 billion in 2014 and around 113,000 employees as of the end of the year. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (AN). Further information on BASF is available on the Internet at www.basf.com.

Safety in Numbers: James Cropper staff secures RoSPA Health and Safety Accolade

Productivity and innovation cannot come at any price and James Cropper Paper’s efforts to ensure the health and safety of staff and visitors has been recognised by the Royal Society for the Prevention of Accidents (RoSPA) at their annual awards ceremony.

L-R: Debbie Ingram, Health Safety and Environment Advisor and Anthony Bowness, Group Safety Health and Environment Manager.

Meeting the paper demands of international luxury brands and manufacturers can be done safely and a recent award for James Cropper Paper from the Royal Society for the Prevention of Accidents (RoSPA) goes to prove it once again. Awarded in a Gala Ceremony at the London, ExCeL Exhibition Centre on Thursday 16 June 2015, the RoSPA Occupational Health and Safety Awards panel awarded James Cropper their Gold Award for Occupational Health and Safety.

The award is judged against demanding criteria and comes in recognition of consistent high standards in monitoring health and safety on site and maintaining a process of continual improvement. The company’s benchmarking of safety performance against the high standards of RoSPA offers an unquestionable level of scrutiny into the day-to-day operations of all parts of the business.

Dave Watson, Chief Operations Officer, said: “There are few other awards which sum up a company’s commitment to keeping people safe than those presented by RoSPA, so we are honoured by the decision to present us with this. At the same time, we expect to achieve the highest standards and judge ourselves by these award criteria during the course of each day. This is due recognition of the meticulous plans and procedures implemented and respected by our colleagues.”

The Gold Award is the highest single level of award that RoSPA present to companies and entrants must provide rigourous evidence of a good health and safety management system. As a result of this accolade, James Cropper Paper will have the opportunity to use the award logo on company stationery and website.

Domtar introduces one of the founding fathers of comics at Comic-Con International

To underscore how great work typically starts on paper, Domtar Corporation (NYSE: UFS) (TSX: UFS) released a video that shows how comic fans got to meet one of the industry's founding fathers at the recent Comic-Con International.

To underscore how great work typically starts on paper, Domtar Corporation (NYSE: UFS) (TSX: UFS) released a video that shows how comic fans got to meet one of the industry's founding fathers at the recent Comic-Con International.

The film shows a massive 8-foot sheet of paper interacting with fans at Comic-Con, which started as a showcase for comic books and has become one of the world's largest pop culture events. More than 130,000 fans gathered in San Diego, and paper became an instant hit.

Fans - many of whom dressed as aliens, superheroes and characters from movies, television shows and comic books - drew sketches and wrote notes on the giant paper, dancing with it and taking selfies.

"This is a fun way to remind people that this popular event hinges on great work that began with paper as an integral part of the creative process," said Paige Goff, Domtar's vice president of Sustainability and Business Communications. "That's why we used the hashtag #StartedOnPaper. Many of the best comic books, posters and movie scripts have always stemmed from the creativity, imagination, fantasy, adventure and entertainment that originate on paper."

The paper character was created by the company that designed Iron Man, and it used Google Glass technology to allow the person inside to see. Some comic book fans considered it to be one of the most notable things at the show.

The video marks the latest effort in Domtar's award-winning PAPERbecause campaign, which was developed by Eric Mower + Associates to showcase the effectiveness and sustainability of paper. Since its launch in 2010, PAPERbecause has been profiled in The New York Times, featured on the front page of USA Today, and, last month, it won a Silver Lion at the Cannes Lions International Festival of Creativity, which is considered the world's most prestigious annual advertising and communications award honoring marketing excellence.

Today's release is the latest video in a series that has been viewed more than half a million times on YouTube. It's also the second time PAPERbecause has focused on comic books.

In 2012, Domtar ran this vintage-style print ad in a special issue of Newsweek, showing a boy dressed as a superhero and reading a comic book, while his mother proudly watches. The message: while entertainment options may have changed, people still enjoy reading on paper. An online poll of readers honored the ad as the best in the magazine.

"With PAPERbecause, we've used humor and creativity, we've highlighted environmental stewardship, and we've even developed an app that helps teachers and students," Goff said. "All of it is to emphasize an important point. When you make paper the right way, it's environmentally sound. And even in a digital age, it continues to play a vital role in our lives."

Viewers can watch the video at https://www.youtube.com/domtar.

About Domtar

Domtar Corporation (NYSE: UFS) (TSX: UFS) designs, manufactures, markets and distributes a wide variety of fiber-based products, including communication papers, specialty and packaging papers, and absorbent hygiene products. The foundation of our business is a network of world-class wood fiber-converting assets that produce papergrade, fluff and specialty pulp. The majority of our pulp production is consumed internally to manufacture paper and consumer products. Domtar is the largest integrated marketer and manufacturer of uncoated freesheet paper in North America with recognized brands such as Cougar®, Lynx® Opaque Ultra, Husky® Opaque Offset, First Choice®, EarthChoice® and Xerox® Paper and Specialty Media. Domtar is also a marketer and producer of a broad line of absorbent hygiene products marketed primarily under the Attends®, IncoPack® and Indasec® brand names. In 2014, Domtar had sales of $5.6 billion from some 50 countries. The Company employs approximately 9,800 people. To learn more, visit www.domtar.com.

SOURCE Domtar Corporation

Kemira Oyj's Interim Report January-June 2015: Revenue growth with improved profitability

Kemira's President and CEO Jari Rosendal:

"We had a strong second quarter with 15% revenue growth and improved operative EBITDA margin of 12.6%. Favorable currency exchange rates continued to contribute to the revenue growth. The acquired AkzoNobel's paper chemicals business has been consolidated since May 2015. We have succeeded well with business continuity and integration has started according to plan. Earlier communicated synergies are expected to start showing towards the end of the year.

"We had a strong second quarter with 15% revenue growth and improved operative EBITDA margin of 12.6%. Favorable currency exchange rates continued to contribute to the revenue growth. The acquired AkzoNobel's paper chemicals business has been consolidated since May 2015. We have succeeded well with business continuity and integration has started according to plan. Earlier communicated synergies are expected to start showing towards the end of the year.

Organic growth in the Paper segment continued above-the-market at 4%. Growth was driven mainly by higher sales volumes across continental Europe and increasing pulp chemical deliveries to the new Montes del Plata pulp mill in Uruguay. I am glad to note that in the second quarter, Paper segment's profitability improved notably, despite the significant efforts put on the integration of a major acquisition.

In the Oil & Mining segment sales volumes have been impacted by the significant reduction of shale drilling and fracking activity in the US. However, despite the decline of sales volumes, absolute operative EBITDA contribution remained at the level of the comparable quarter. In EMEA, we started first polyacrylamide shipments for the chemically enhanced oil recovery.

The Municipal & Industrial segment's turnaround and revenue recovery continued and the segment delivered profitable growth in line with its strategic objective. Organic growth reached 3% driven by higher sales volumes in all regions and the operative EBITDA margin was more than 14%.

I am satisfied with Kemira's progress in the first half of the year. Our businesses delivered solid results, despite the current slowdown of activity in shale operations in US."

This is a summary of the January - June 2015 Interim report. The complete January - June 2015 Interim report with tables is attached to this release and available at www.kemira.com/investors.

Second quarter:

- Revenue increased 15% to EUR 594.8 million (518.2) supported by the acquisition of AkzoNobel's paper chemicals business, completed on May 4, and favorable currency exchange rates. Revenues in local currencies, excluding acquisitions and divestments remained largerly unchanged.

- Operative EBITDA increased 24% to EUR 74.7 million (60.2) with an improved margin of 12.6% (11.6%).

January-June:

- Revenue increased 10% to EUR 1,147.8 million (1,048.1).

- Operative EBITDA increased 20% to EUR 141.1 million (117.7) with a margin of 12.3% (11.2%).

- Operative earnings per share increased 10% to EUR 0.32 (0.29).

- Kemira's outlook for 2015 is updated to include the acquisition of AkzoNobel's paper chemicals business. Kemira expects its revenue and operative EBITDA in 2015 to increase compared to 2014.

KEMIRA'S FINANCIAL TARGETS 2017 AND UPDATED OUTLOOK for 2015

Kemira will continue to focus on improving its profitability and operative cash flow. The company will also continue to invest in order to secure future growth to serve selected water intensive industries.

The company's financial targets for 2017 are:

- Revenue EUR 2.7 billion

- Operative EBITDA-% of revenue 15%

- Gearing level <60%.

Kemira expects its capital expenditure-to-sales ratio, excluding acquisitions to increase in the next few years from the 2014 level of 6.3%. In addition, Kemira expects its medium-term operative tax rate to be in the range of 22%-25%. This rate excludes non-recurring items.

The basis for growth is the expanding market for chemicals and Kemira's expertise that helps customers in water intensive industries to increase their water, energy and raw material efficiency. The need to increase operational efficiency in our customer industries creates opportunities for Kemira to develop new products and services for both current and new customers. Research and Development is a critical enabler of organic growth for Kemira, providing differentiation capabilities in its relevant markets. Kemira will invest in innovation, technical expertise, and competencies in its selected focus areas.

Outlook for 2015 (updated to include the acquisition completed in May, 2015)

Updated outlook for 2015: In 2015, Kemira will focus on profitable growth both organically and inorganically. Kemira's revenue and operative EBITDA in 2015 are expected to increase compared to 2014. The outlook includes the impact of AkzoNobel's paper chemicals business.

Previous outlook for 2015: In 2015, Kemira will focus on profitable growth both organically and inorganically. Kemira's revenue in 2015 is expected to increase compared to 2014 and operative EBITDA in 2015 to remain approximately at the same level or to increase compared to 2014. The outlook excludes the impact of AkzoNobel's paper chemical business (acquisition expected to close in the second quarter of 2015). At closing, AkzoNobel's paper chemical business is expected to add revenue of more than EUR 200 million on an annualized basis.

Xerium Announces New Business in China

Two Plants, New Headquarters, New Supply Chain, $60 million Investment

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, has announced that it has materially completed the $60 million successful restructuring of its business in China. The business is now in a position to locally serve customers in China, Asia, and also export certain products globally. The make-over of its China and Asian business has taken over 3 years to complete with a number of key aspects required for full implementation. Xerium has implemented an all-Asian business model and will now run its entire Asian business from Shanghai.

Kunshan, China Press Felt Plant (Photo: Business Wire)

Highlights of the repositioning of Xerium’s Asia business are as follows:

- Production has begun at Kunshan, China Press Felt Plant – Xerium completed a 2 year, multi-million dollar construction project to build and equip a brand-new press felt plant in Kunshan, China. This greenfield plant is located in the heart of the Yangtze River paper-making region, which is at the center of the largest paper-making region in the world - China. It took over 2 years to design, build, equip, and commission. Until this new plant began production, Xerium served this region mainly as an exporter of products made in Europe. Xerium has significantly increased its competitive position with this plant and will now be able to more closely partner with customers in China and the rest of the world.

For the first time ever, customers in China will receive locally provided and optimized state-of-the-art press felt solutions from Xerium. Xerium will conduct business in local currency and local languages. The Kunshan plant will be able to service the largest pulp, paper, paperboard, and tissue machines in the world, as the main machine in the plant is greater than 15 meters wide. This central machine and its foundation weighed almost 1 million pounds at installation, and is one of the largest of its type in the world. For some press felt designs, the company will be able to make 3 pieces simultaneously - a first for the company. The plant has state-of-the-art information systems and supply chain interfaces along with real time operational communication systems throughout the site. It is conducting business from a new Infor™ information technology platform. The company is moving a large portion of its press felt production to this plant in China. The plant has initiated production.

- Renovated Changzhou, China Rolls Plant – Xerium completed a 2 year, multi-million dollar investment program to completely renovate its rolls and mechanical service plant in Changzhou, China. This plant is located in the Yangtze River paper-making region. Until this renovation was completed, Xerium had served this region for many decades by exporting high-end working rolls from Europe. Xerium has now transferred all of its technology to this plant – SMART® Roll production cell, spreader roll production cell, polyurethane production cell, suction box production cell, upgraded extrusion and drilling equipment. The plant can now produce all of Xerium’s designs. The plant recently received ISO-9000 quality certification.

- Implemented new Asia Headquarters in Shanghai- Moved and reincorporated Xerium Asia headquarters into the Shanghai Free Trade Zone. This special Chinese government approval allows Xerium to import/export at the lowest possible cost, expedite customs processing, provide shorter lead times for materials transfer, enables maximum leverage of working capital for Xerium across Asia, and receive improved tax treatment as a local Chinese business entity. The entity is now in place.

- Implemented new Chinese Capital Structure – Implemented a local capital structure and banking relationship by moving a portion of the Xerium corporate debt structure to China. The company has implemented a multi-million RMB on-going loan in China with ICBC, the largest bank in the world. Xerium will now conduct local business in local currency (RMB), finance and fund its China business locally in RMB. This will also enable Xerium to both secure a natural business hedge and receive local entity tax treatment. The new loan and new ICBC financial relationship are complete and in place.

- Localized all Asian Leadership - Moved its Asia business leadership from the United States and Europe to China. The key top personnel moves were: moved President and CFO positions from the US to Shanghai, moved Sales leadership from Europe and Australia to Shanghai, moved technical leadership from Europe to Shanghai. All of these personnel moves are complete.

- Implemented Chinese IT structure - Moved its IT and data support from Europe to Shanghai. The company has completed its data center in Shanghai and is partnered with SAP as its provider for rolls plant information technology, and is partnered with Infor™ for machine clothing plant information technology. Both technology providers have huge businesses in China and are also located in Shanghai.

- Implemented Contemporary Asian Supply Chain - Moved its Asia supply chain and warehousing activities from in-house/locally provided into a global partnership with Panalpina. Panalpina is one of the world’s leading providers of end-to-end supply chain solutions. Xerium is connecting its internal systems with Panalpina to give its customers a seamless electronic supply chain. The supply chain moves are in place.

Changzhou, China Rolls & Mechanical Service Plant (Photo: Business Wire)

Mr. Harold Bevis, President and CEO of Xerium, made several comments regarding this business realignment. “Competing and winning in China and throughout Asia is central to Xerium’s corporate repositioning. Xerium’s legacy markets in North American and European newsprint, printing and writing are all under pressure. These market segments are going through permanent correction. Several years ago, the Board of Xerium decided to tackle this situation head-on and reposition its assets and commercial profile directly into growth markets globally.

“These China investments have taken a few years and a lot of money to implement. We are very happy that these new investments are coming on line now. The commercial objective is to provide machine optimization solutions with world-class technology and shorter lead times, at a local cost structure. Customers will immediately benefit from improved costs, better lead times, better technology, and better service. This new business start-up is a key part of Xerium’s investment strategy to realign its global business model and global factory locations to line up with growth markets in the world.

This business restructuring is an important part of the business strategy being deployed at Xerium – to reposition the company into growth markets. We are excited about our new future in Asia. This restructured business is now underway producing and selling machine clothing, performing on-machine service, and performing in-factory rolls and mechanical service.” added Mr. Bevis.

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 27 manufacturing facilities in 13 countries around the world, Xerium has approximately 3,100 employees.

Voith: MultiForm IR and MultiForm IC forming fabrics launched worldwide

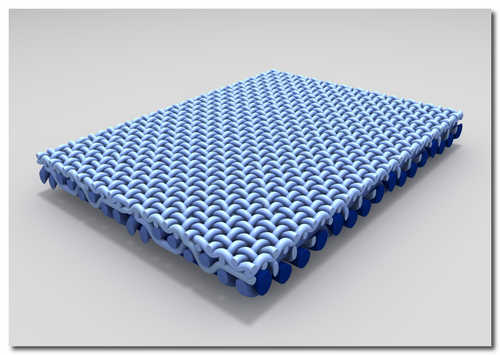

Voith has launched two new forming fabrics, designed for manufacturing demanding board and packaging papers and also graphic grades. As the names of the MultiForm IR and MultiForm IC suggest, these forming fabrics are part of Voith’s I-Series. All products in this series are based on a unique SSB concept. The special feature of the fabrics in the I-Series is their warp ratio of 3:2.

The new forming fabrics were specifically developed for positions that put high demands on dimensional stability and dewatering performance. The unique warp principle of both MultiForm forming fabrics combines a fine paper side with an extremely stable machine side. This allows an increase in paper quality and a longer service life for the fabric. Further benefits are the good runnability of the fabrics at high speeds and their positive impact on resource consumption.

Voith’s I-Series has already been used to produce around 14 million metric tons of paper worldwide. The I-Series forming fabrics are being used in a wide range of applications from fine paper through to demanding packaging papers and are suitable for all kinds of former types.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Sappi sells Cape Kraft recycled packaging mill to Golden Era Group

Following on Sappi’s recent announcement of the sale of its Enstra Mill and recycled packaging business, Sappi wishes to announce the sale of its Cape Kraft recycled packaging paper Mill to the Golden Era Group. In March 2015 Sappi initiated a closed tender process after receiving many expressions of interest to buy the mill. It is expected that the transaction will close in September 2015. The disposal is not categorisable in terms of section 9.5 of the JSE Listings Requirements. Sappi will receive just short of R600 million from the two transactions.

Following on Sappi’s recent announcement of the sale of its Enstra Mill and recycled packaging business, Sappi wishes to announce the sale of its Cape Kraft recycled packaging paper Mill to the Golden Era Group. In March 2015 Sappi initiated a closed tender process after receiving many expressions of interest to buy the mill. It is expected that the transaction will close in September 2015. The disposal is not categorisable in terms of section 9.5 of the JSE Listings Requirements. Sappi will receive just short of R600 million from the two transactions.

Commenting on the transaction, Sappi Southern Africa CEO Alex Thiel said: “The sale of the Cape Kraft and Enstra mills and the recycled packaging paper business is in line with Sappi Southern Africa’s strategy to unlock value from non-core assets and free up resources for investment in dissolving wood pulp, virgin containerboard and other new business opportunities. The sales also support the Sappi Limited strategy to strengthen the group’s balance sheet and focus on high-growth opportunities.”

Golden Era Group CEO Kishor Chhita remarked: “We are very pleased to be able to acquire this top quality asset from Sappi. It will strengthen our position in the market as a service-oriented company that offers packaging solutions and will further help us to achieve our goal of creating lasting team-based partnerships with our customers.”

Golden Era Group, started in 1955, is today the third largest printing and packaging company in South Africa. The Group has a national footprint company specializing in the manufacturing of kraft paper, corrugated cases, folding cartons, notestiks, paperbags, self-adhesive and IML labels, shrink sleeves, three piece metal cans, vacuum-formed and thermos-formed packaging.

Sappi Limited (JSE: SAP), is a global company focused on dissolving wood pulp, paper pulp and paper-based solutions to our direct and indirect customer base in some 161 countries around the world. Headquartered in Johannesburg, South Africa, with over 13,000 employees and manufacturing operations on three continents in seven countries and group sales of US$6 billion. Learn more about Sappi at www.sappi.com.

Minerals Technologies Appoints W. Rand Mendez, Senior Vice President & Managing Director, Paper PCC

Minerals Technologies Inc. has announced that its Board of Directors has appointed W. Rand Mendez as Senior Vice President and Managing Director of its Paper PCC business unit. Mr. Mendez joins Minerals Technologies Inc. from E. I. du Pont de Nemours and Co., where he held a variety of operational and product leadership positions across a number of businesses. He will become an officer of Minerals Technologies and a member of the company's management team.

Minerals Technologies Inc. has announced that its Board of Directors has appointed W. Rand Mendez as Senior Vice President and Managing Director of its Paper PCC business unit. Mr. Mendez joins Minerals Technologies Inc. from E. I. du Pont de Nemours and Co., where he held a variety of operational and product leadership positions across a number of businesses. He will become an officer of Minerals Technologies and a member of the company's management team.

"We are happy to have Rand Mendez join Minerals Technologies," said Joseph C. Muscari, Chairman and Chief Executive Officer. "He brings more than 32 years of business and leadership experience, and will be a strong addition to our management team. Rand's main focus will be on continuing the growth of Paper PCC through geographic expansion and new product innovation."

Mr. Mendez will succeed D.J. Monagle, III, who was previously named Chief Operating Officer, Specialty Minerals Inc. and the Minteq Group, in February of 2014, but had also maintained responsibility for the company's Paper PCC business as Senior Vice President and Managing Director.

Mr. Mendez joined DuPont in 1982 and assumed positions of increasing responsibility. In 1996, he was appointed Global Business Manager, DuPont Specialty Chemicals. He was subsequently named Sales and Marketing Director, DuPont Surfaces; Business Director, DuPont Safety Resources; and in 2008, Corporate Marketing Director, DuPont Corporate Marketing & Sales.

Rand Mendez holds a Bachelor's of Science Degree in Mechanical Engineering and a Master's of Business Administration, both from Duke University.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, environmental, energy, polymer and consumer products industries. The company reported sales of $1.725 billion in 2014.

Indian Institute of Forest Management (IIFM) and International Paper sign Memorandum of Understanding

Indian Institute of Forest Management (IIFM), and International Paper, India signed a Memorandum of Understanding today to further their mutual interest in the field of forest sustainability. This wide-ranging partnership will entail action research, capacity building and academic exchange involving experts and researchers from both International Paper and Indian Institute of Forest Management.

Left to Right - Mr Girdhar Kinhal - Director IIFM Mr Rampraveen Swaminathan - Chairman MD International Papers AAPM Ltd and Mr Ashok Lavasa

The MoU was signed by Dr. Giridhar Kinhal (IFS), Director - IIFM and Mr. Rampraveen Swaminathan, President – International Paper India in the presence of Mr. Ashok Lavasa – IAS, Secretary, Ministry of Environment, Forest and Climate Change. In addition, senior dignitaries from the Ministry of Environment, Forest and Climate Change, other relevant functions of Government of India, and the state government, senior members from the environment and forestry related organizations like WWF, TERI, Forest plus and IUCN etc in India, were present at the signing ceremony of the MoU at Indira Paryavaran Bhavan, New Delhi.

The highlight of this MoU is the setting up of the “IIFM – IP Paul Brown Center of Excellence” (CoE) at IIFM, Bhopal. This CoE will be established to facilitate and anchor several activities under this partnership – both organizations will collectively carry forward applied research in the field of forestry, fiber sustainability and in forestry management with sharing of best practices, case studies and knowledge sharing. The collaboration between both the organizations also covers training and capacity building for students, researchers and professionals of IIFM.

The functioning of this CoE will be undertaken jointly by IIFM and International Paper which will share its global best practices & learning and will invest towards implementation of the objectives of the MoU.

This collaboration will also provide a common and synergic platform for both IP and IIFM to develop training modules and knowledge for the future sectoral workforce.

“International Paper has decades of knowledge on creating world class products through sustainable practices – methods that help not only conserve the natural resources but actually contribute significantly to maintain and grow the ecosystem. This partnership, as with several others that we have forged globally in the past, will allow us to share our learning’s with the industry and academia to make sustainability a part of life. We are immensely pleased to be partnering with a leading academic institution like IIFM to create this platform as it gives an opportunity to share our experience and expertise with the Paper and Pulp Industry and contribute to the country’s sustainability efforts in the future,” added Mr. Rampraveen Swaminathan, President, International Paper - India and Chairman & Managing Director – IP-APPM.

Broadly the MoU will focus on the following, facilitated and anchored by the Center of Excellence:

- Collaborative Research Initiatives: Includes work on common areas such as forestry, fiber sustainability, supply chain management, safety in forestry & paper industry, dependence of vulnerable communities on natural ecosystems for livelihood and subsistence, economic valuation of services provided by natural ecosystems, gender issues amongst other issues

- Partnership and capacity building of sectoral workforce: Both organizations will share intellectual inputs in developing training modules and products on the subjects of mutual interests for local and national level including current and future sectoral workforce

- Hosting visiting delegations: Together the organizations will facilitate exchange and hosting of distinguished academicians, civil servants and thinkers who will deliver public lectures and conduct seminars and related activities to the issues related to forestry and other related topics. These will be held to promote greater interaction and forge stronger links between academia and other related specialists and professionals

- Exchange of relevant publications: Sharing of research publications undertaken by respective organizations.

After signing the MoU with International Paper, Dr. Giridhar Kinhal (IFS), Director - IIFM said, “We are honored to be chosen as International Paper’s academic partners in their quest for achieving environmental sustainability. We are certain that these initiatives undertaken under the Centre of Excellence (CoE) will enhance the intellectual interaction between both IP and IIFM. We look forward to learn from International Paper’s global experience and knowledge in India in the Forestry Initiatives that will help augment our processes, and promote excellence in our studies.”

About International Paper

International Paper (NYSE: IP) is a global leader in packaging and paper with manufacturing operations in North America, Europe, Latin America, Russia, Asia and North Africa. Its businesses include industrial and consumer packaging along with uncoated papers and pulp. Headquartered in Memphis, Tenn., the company employs approximately 58,000 people and is strategically located in more than 24 countries serving customers worldwide. International Paper net sales for 2014 were $24 billion. For more information about International Paper, its products and stewardship efforts, visit internationalpaper.com.

About IIFM

Indian Institute of Forest Management (IIFM) Bhopal is a sectoral management institute which constantly strives to create knowledge useful for the managers in the areas of Development, Environment, Natural Resource Management and allied sectors. It also disseminates such knowledge to its students and clients in ways that promote its application by individuals and organizations.

Domtar announces redemption of certain outstanding notes and new debt financing

Domtar Corporation has announced the partial redemption of certain notes and a new debt financing.

Domtar Corporation has elected to redeem on August 20, 2015, the redemption date, $55 million in aggregate principal amount of its 9.5% Notes due 2016, representing 59.16% of the outstanding notes, and $215 million in aggregate principal amount of its 10.75% Notes due 2017, representing 77.39% of the outstanding notes. The redemption price for the notes to be redeemed will be equal to 100% of the principal amount of such notes, plus accrued and unpaid interest, plus a make-whole premium. The accrued interest will be paid for the period from February 1, 2015 (for the 9.5% Notes) and from June 1, 2015 (for the 10.75% Notes) up to, but excluding, the redemption date. The make-whole premiums will be calculated three days prior to redemption in accordance with the terms of the indenture governing the notes.

Domtar Corporation has elected to redeem on August 20, 2015, the redemption date, $55 million in aggregate principal amount of its 9.5% Notes due 2016, representing 59.16% of the outstanding notes, and $215 million in aggregate principal amount of its 10.75% Notes due 2017, representing 77.39% of the outstanding notes. The redemption price for the notes to be redeemed will be equal to 100% of the principal amount of such notes, plus accrued and unpaid interest, plus a make-whole premium. The accrued interest will be paid for the period from February 1, 2015 (for the 9.5% Notes) and from June 1, 2015 (for the 10.75% Notes) up to, but excluding, the redemption date. The make-whole premiums will be calculated three days prior to redemption in accordance with the terms of the indenture governing the notes.

The terms of both redemptions are described in the notice of redemption sent to registered holders today.

Notes to be redeemed are to be surrendered to The Bank of New York Mellon, as trustee and paying agent, in exchange for the payment of the redemption price. Holders who hold their notes through The Depository Trust Company, or DTC, will receive payment through DTC.

In addition, Domtar's 7.125% notes will mature on August 15, 2015 in the aggregate principal amount of $167 million.

The above-noted redemptions and repayment of notes will be funded through a combination of cash on hand, borrowings under our credit facilities and proceeds from a new $300 million 10-year term loan agreement with a syndicate of bank lenders.

Domtar expects an improved debt maturity schedule as well as reduced financing expense on its outstanding debt after these transactions.

About Domtar

Domtar Corporation (NYSE: UFS) (TSX: UFS) designs, manufactures, markets and distributes a wide variety of fiber-based products, including communication papers, specialty and packaging papers, and absorbent hygiene products. The foundation of our business is a network of world-class wood fiber-converting assets that produce papergrade, fluff and specialty pulp. The majority of our pulp production is consumed internally to manufacture paper and consumer products. Domtar is the largest integrated marketer and manufacturer of uncoated freesheet paper in North America with recognized brands such as Cougar®, Lynx® Opaque Ultra, Husky® Opaque Offset, First Choice®, EarthChoice® and Xerox® Paper and Specialty Media. Domtar is also a marketer and producer of a broad line of absorbent hygiene products marketed primarily under the Attends®, IncoPack® and Indasec® brand names. In 2014, Domtar had sales of $5.6 billion from some 50 countries. The Company employs approximately 9,800 people. To learn more, visit www.domtar.com.

SOURCE Domtar Corporation

INVESTOR RELATIONS: Nicholas Estrela, Director, Investor Relations, Tel.: 514-848-5555 x 85979