Ianadmin

UPM pulp and paper mills’ environmental performance reported in EMAS 2014 statements

UPM has published the EU Eco-Management and Audit Scheme (EMAS) statements for the year 2014. The company has certified all its European pulp and paper mills, the UPM Fray Bentos pulp mill in Uruguay and the UPM Changshu paper mill in China in accordance with the EMAS.

UPM has published the EU Eco-Management and Audit Scheme (EMAS) statements for the year 2014. The company has certified all its European pulp and paper mills, the UPM Fray Bentos pulp mill in Uruguay and the UPM Changshu paper mill in China in accordance with the EMAS.

Transparency and openness with stakeholders are an essential part of UPM’s corporate responsibility worldwide. The EMAS registration and third-party verified reporting promote continuous improvement.

“As a forerunner in the integration of the bio and forest industries, UPM is committed to innovation-driven future. We see circular-economy thinking – making more with less - as the future business model, Anssi Klinga, Senior Vice President UPM Pulp, Bernd Eikens, Executive Vice President, UPM Paper ENA, and Kim Poulsen, Executive Vice President, UPM Paper Asia state in the report.

“Sustainability-driven not only describes our solutions, but also our way of performing,” they continue.

EMAS requires participants to have an Environmental Management System and to publish a third-party verified Environmental Statement, which increases the credibility and reliability of environmental data. The corporate statement includes group-level information and core indicators on e.g. energy and material efficiency. The mill supplements deepen the corporate statement with local information, such as environmental targets and accomplishments.

In addition to the EMAS - in which the company has participated for about 20 years - UPM provides comprehensive environmental information assured by third parties from corporate level right through to the mills and individual products. Ecolabelled products, product declarations and certified operations are used to inform the company’s stakeholders about responsibility and transparency.

The corporate statement and paper and pulp mill specific supplements are available on UPM web site.

For more information:

Päivi Salpakivi-Salomaa, Vice President, Environment and Responsibility, UPM, tel. +358 400 754 748.

UPM

Through the integration of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 20,000 people and its annual sales are approximately €10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

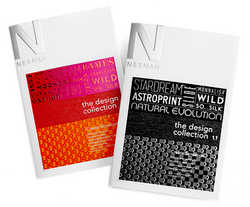

Neenah Expands The Design Collection with Companion Swatchbook

Neenah Paper has announced that its world-class selection of colored, pearlized and textured papers, The Design Collection, has been expanded to include four new premium paper grades from Italian papermaker Gruppo Cordenons. Neenah also announced the expansion of the popular STARDREAM® and WILD® Papers lines. Additions are featured in anew companion swatchbook to the original Design Collection swatchbook, available now.

Neenah Paper has announced that its world-class selection of colored, pearlized and textured papers, The Design Collection, has been expanded to include four new premium paper grades from Italian papermaker Gruppo Cordenons. Neenah also announced the expansion of the popular STARDREAM® and WILD® Papers lines. Additions are featured in anew companion swatchbook to the original Design Collection swatchbook, available now.

With the expansion, The Design Collection now offers more unique options for designers to set their work apart. These papers are specified for premium packaging, look books, high-end brochures, gift card holders, greeting cards, identity materials, and other print collateral for brands that desire to distinguish themselves by both hand and eye.

NEW PAPER LINES

NATURAL EVOLUTION Papers, with a special surface coating on both sides, provide a soft natural texture with an elegant touch and outstanding print performance. Colors: White, Frost and Ivory.

MONNALISA® Papers, the smooth sister to NATURAL EVOLUTION Papers, offers a smooth bright white surface for hang tags, business cards, books, brochures. Colors: Premium White.

SLIDE™ Papers are considered the “packaging version” of the popular PLIKE® Papers, optimized for more resilience. Colors: Black and White.

ASTROPRINT Papers include three unique, embossed textures with a 64 text weight ideal for box wrap. Colors: White

EXPANDED PAPER LINES

Neenah has also expanded these popular lines:

STARDREAM Papers, added C1S text weights for box wrap in the most popular colors.

WILD Papers now includes four new colors in popular 111 lb. Cover: Sand, Clay, Brown and Black.

THE DESIGN COLLECTION 1.1

With these additions, The Design Collection now offers 15 paper brands, blending six iconic paper lines from North America and 9 on-trend Italian brands.

“The Design Collection 1.1 includes more on trend colors and high touch surfaces for print and packaging with SLIDE, ASTROPRINT and STARDREAM Papers as well as new colors for letterpress in WILD Papers,” said Ellen Bliske, Sr. Brand Manager at Neenah. Neenah also continues to grow its commercial print offering with best-of-both-worlds print performance in NATURAL EVOLUTION and MONNALISA Papers.

“The demand for The Design Collection has surpassed our every expectation,” said Bliske. “We can’t wait to see what designers will do with all the new items.”

INFO & SAMPLES

New Companion Swatchbook: contact your Neenah paper merchant

Free paper samples: http://www.neenahpaper.com/finepaper/designcollection

The Design Collection: http://www.neenahpaper.com/designcollection

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles.

Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

About Gruppo Cordenons

Gruppo Cordenons is a leading Italian manufacturer of graphic and digital fine papers and technical papers. Its large portfolio, that includes metallic and iridescent papers, textured papers, inspired from natural fabrics, felt-marked and papers with a special touch, is available throughout the world.

Contact

Neenah

Jamie Saunders

678-518-3222

This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM introduces its renewed UPM Color range – Salmon, Pink, Yellow and Orange

UPM is presenting its renewed UPM Color range with Salmon, Pink, Yellow and Orange. The renewed UPM Color is an ideal combination of low basis weight, high bulk with an additional yield benefit. The renewed UPM Color enables higher quality printed products with improved haptic properties. This grade is part of standard newsprint papers and is suitable for both Coldset and Heatset Offset printing.

UPM is presenting its renewed UPM Color range with Salmon, Pink, Yellow and Orange. The renewed UPM Color is an ideal combination of low basis weight, high bulk with an additional yield benefit. The renewed UPM Color enables higher quality printed products with improved haptic properties. This grade is part of standard newsprint papers and is suitable for both Coldset and Heatset Offset printing.

UPM Color range increases the awareness of a printed product

The printed product, be it a whole newspaper, a section or an independent flyer, is distinguishable by its color. UPM Color increases the attractiveness of newspapers, supplements, directories and special publications.

These papers are now produced at UPM Jämsä River Mills (at Kaipola), Finland. This new product represents highest sustainability standards, including the most comprehensive environmental certification, the EU Ecolabel, as well as forest certifications FSC® and PEFC™. In addition, UPM Color contains recycled fibre.

UPM CSWO papers for every end use

UPM CSWO papers offer customers the largest product range and widest coverage in Europe by providing the right paper for every potential end use. Most UPM papers for CSWO are EU Ecolabelled.

“The production of UPM Color has been transferred from UPM Chapelle, France, to UPM Jämsä River Mills at Kaipola, Finland, this month. Our wide range of products has been developed to meet customers’ future needs,” states Terry Parry, Technical Sales Director, Newspaper Publishing, UPM Paper ENA.

Technical specifications of UPM Color can be found in the online paper catalogue: upmpaper.com/papers » or its mobile version: m.upmpaper.com »

To request samples and information about availability of different colors, please contact your UPM local sales representative.

For further information please contact:

Terry Parry, Technical Sales Director, Newspaper Publishing, UPM Paper ENA, tel. +44 161 252 7201

UPM leads the reformation of the bio and forest industries. We are building a sustainable future in six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper Europe and North America and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve a global base of customers. We employ approximately 20,000 people and our annual sales are approximately EUR 10 billion. UPM's shares are listed on NASDAQ OMX Helsinki. UPM – The Biofore Company – www.upm.com

UPM Paper ENA (Europe & North America) is the world’s leading producer of graphic papers, serving customers in Magazine Publishing & Advertising, Merchants, Home & Office, and Newspaper Publishing. A leader in sustainable and high performance papers, UPM Paper ENA’s production is located in Finland, Germany, the United Kingdom, France, Austria, and the United States. To learn more about UPM Paper ENA visit: www.upmpaper.com or follow us in Twitter www.twitter.com/UPM_Papers

Synthron launches a new innovative release aid for the paper industry

The Paper Making Industry has faced a lot of restructuring over recent years. But despite all of the changes SYNTHRON has continued to develop new and exciting products for this Industrial Sector.

The Paper Making Industry has faced a lot of restructuring over recent years. But despite all of the changes SYNTHRON has continued to develop new and exciting products for this Industrial Sector.

SYNTHRON is a subsidiary of the PROTEX INTERNATIONAL Group and has been active for more than 40 years in the paper making industry. The Group invests 5% of sales turnover in R&D to develop innovative products for paper-makers and paper pulp producers.

SYNTHRON has a strong range of products for tissue making, packaging and specialty papers, SYNTHRON anticipates the needs of customers by developing expertise for products and applications which can be applied to a wide variety of substrates, in the this strongly growing segment.

SYNTHRON manufactures Paper Making chemical auxiliary products at the industrial site of Saint-Avold in Moselle and Auzouer-en-Touraine in Indre-et-Loire in France and also in United States and in China.

SYNTHRON recently launched SYNTHRO®-PEL SCR 38, which has been developed, produced and marketed in Europe. The interesting feature of SYNTHRO®-PEL SCR 38 is that the product based on different chemistry to replace the silicone which is usually contained in most Release Aids, which also usually require the use of a separate catalyst which can then add to production costs...

SYNTHRO®PEL SR 38 is based on non-silicone materials and the application process does not require the need for a separate catalyst this can offer some interesting potential cost-savings.

Many paper based products have a requirement for a “Release Aid”, such as product labels, glassine paper, transfer papers which are use print a motif on textiles and clothing.

According to Robert MOOR, President of SYNTHRON: “our Company is involved in various industrial sectors, and we have worked in the Paper Making manufacturing sector for many years. Here our main focus has been on specialties and niches, such as Release Aids. We have a Research Centre in France and product application centres round the world SYNTHRON continues to enjoy an excellent reputation for new product development and innovation”

SYNTHRON continues to build strong partnerships with both private and public, French and overseas R + D organizations, within a framework of a research programme for paper making auxiliary chemicals. And in particular, Robert MOOR stays on the lookout for opportunities for external growth to strengthen the Groups overall position.

About PROTEX INTERNATIONAL: PROTEX INTERNATIONAL is one of the last independent family owned French chemical groups. The company, was founded in 1932, and initially sold auxiliary products for textile processing and then diversified into niche markets, such as ink and paints, adhesives, water treatment, perfume compositions and more recently speciality products for electronics.

The Group has a turnover of 170 million Euro turnover in 2014 and forecasts 200 million Euro sales in 2015, 80% of sales are outside France. There are 700 employees in more than twenty industrial and commercial subsidiaries in Europe, United-States, and South-East Asia (China, South Korea, Thailand, Indonesia, and Taiwan) and more recently in Brazil.

Today with a healthy internal organic growth, the Group also pursues a policy of external growth via acquisition of targeted companies, in France or abroad.

Crofton mill resolves operating issues and resumes production

Catalyst Paper Corporation (TSX:CYT) has announced that due to operating issues that have been fully resolved, the Crofton mill has incurred production losses of approximately 8,600 tonnes of pulp and 8,600 tonnes of paper in the month of June. These production losses will not impact current customer orders but will reduce second quarter EBITDA approximately $5 to 6 million.

Catalyst Paper Corporation (TSX:CYT) has announced that due to operating issues that have been fully resolved, the Crofton mill has incurred production losses of approximately 8,600 tonnes of pulp and 8,600 tonnes of paper in the month of June. These production losses will not impact current customer orders but will reduce second quarter EBITDA approximately $5 to 6 million.

No health or environmental issues occurred during this period, and the mill has returned to production capacity.

About Catalyst Paper Corporation

Catalyst manufactures diverse specialty mechanical printing papers, newsprint and pulp. Its customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.1 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Eduarda Hodgins, Director, Organization Development & Communications, 604-247-4369, This email address is being protected from spambots. You need JavaScript enabled to view it.

International Conference "Russian Pulp and Paper Industry - new Realities, new Opportunities"

RUSSIAN PULP & PAPER INDUSTRY — NEW REALITIES, NEW OPPORTUNITIES

8th-9thDecember 2015, Vienna (Austria)

Grand Hotel Wien

It will bring together representatives of business, banking community, authorities, and professionals of Forestry and Pulp & Paper Industry. The specialists will discuss prospects for the future development of the Russian Timber Industry.

The conference program. Key topics:

- “Key projects of the forest sector: from idea to implementation”

- “Cooperation of the Government with business and professional community aimed at the development of the Russian Timber Industry Complex”

- “The strategy directed toward the growth of the RussianTimberComplex’sshareof Russia's GDP”

- “ Funding for companies and projects in current conditions

Participants:

- Arkhangelsk Pulp & Paper Mill OJSC

- SFT Group

- Segezha Group

- Selenginsk Pulp & Paper MillOJSC

- Kama Pulp & Paper MillOJSC

- Kondopoga OJSC

- Manufacturers and Exporters of Russia

- Ministry of Industry and Trade of the Russian Federation

- Russian Federal Forestry Agency

- Union of Timber Manufacturers and Exporters of Russia

- ASPPI

- SVEZA Group

- Siberwood

- Pestovsky Pulp & Paper Mill

- Banking sector: representatives of VEB, VTB, etc.

- Financial institutions: Finnvera, OEKB, IPIDC, etc.

- Representatives of the banking sector in China

New Mitsubishi HiTec Paper website

Mitsubishi HiTec Paper, the German manufacturer of coated speciality paper, has a re-designed its internet presence from scratch. www.mitsubishi-paper.com now has a fresh and modern responsive design.

The new website is visually clear and has a tidy design. Impressive new photos clearly show the company's passion for its high-tech speciality papers. The clear menu facilitates navigation, and the new career area offers the possibility of online applications. All service information is now accessed easily from a Download Centre.

Mitsubishi HiTec Paper is active on all continents and markets its speciality papers worldwide. Interested parties from all over the world can now also find their local contact person simply through an interactive world map, as well as their contact in our international customer service department.

"We are delighted with the new website which provides an opportunity to learn about us and our products," says Ralf Buhl, Marketing Manager at Mitsubishi HiTec Paper. "Look around our website, find out about our services and explore the possibilities of the efficient use of coated speciality papers for all printing technologies and a variety of applications."

PC, laptop, tablet or smartphone - wherever you look, the new website of Mitsubishi HiTec Paper conveys the competence and high performance, which is what the company and its products stand for worldwide.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's most important manufacturers of speciality paper. The roughly 700 employees at Mitsubishi HiTec Paper Europe produce high-quality thermal papers (thermoscript), digital imaging papers (jetscript), carbonless papers (giroform) and label papers (supercote) at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for integrated paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper Europe supplies a full range of speciality papers featuring a modular system for every application – and is a highly capable partner whenever customized coated paper solutions are required.

BASF completes divestiture of textile chemicals business to Archroma

BASF has closed the previously announced transaction to divest its global textile chemicals business to Archroma, a supplier of specialty chemicals to the textile, paper and emulsions industries. BASF will continue to manufacture and supply textile chemical products to Archroma.

BASF has closed the previously announced transaction to divest its global textile chemicals business to Archroma, a supplier of specialty chemicals to the textile, paper and emulsions industries. BASF will continue to manufacture and supply textile chemical products to Archroma.

Included in the transaction is the legal entity BASF Pakistan (Private) Ltd., Karachi. The closing of this divestiture is expected by August 2015. All remaining businesses of BASF in Pakistan, which are conducted by BASF Chemicals & Polymers Pakistan (Private) Limited, are not in the scope of the transaction.

About BASF

At BASF, we create chemistry – and have been doing so for 150 years. Our portfolio ranges from chemicals, plastics, performance products and crop protection products to oil and gas. As the world’s leading chemical company, we combine economic success with environmental protection and social responsibility. Through science and innovation, we enable our customers in nearly every industry to meet the current and future needs of society. Our products and solutions contribute to conserving resources, ensuring nutrition and improving quality of life. We have summed up this contribution in our corporate purpose: We create chemistry for a sustainable future. BASF had sales of over €74 billion in 2014 and around 113,000 employees as of the end of the year. BASF shares are traded on the stock exchanges in Frankfurt (BAS), London (BFA) and Zurich (AN). Further information on BASF is available on the Internet at www.basf.com.

Toscotec to rebuild PM1 at ISMA 2000 S.L in La Torre de Claramunt-Spain

Toscotec with its associate Milltech have been awarded a contract to deliver a major dry-end rebuild of the ISMA 2000 S.L. PM 1 in La Torre de Claramunt, Barcelona- Spain. The start-up of the rebuilt machine is scheduled for the beginning of 2016.

ISMA 2000 SL, is a familiar Company, with operating centers in Catalonia and the Balearic Islands The main business in Barcelona, is the production and processing of tissue products, while in Mallorca the activity is focused on the collection and recovery of waste paper. The main recognized company products are from 100% recycled paper and include: AFH towel, Kitchen rolls, sheets stretcher rolls, napkins, toilet paper.

Toscotec's delivery includes a major rebuild of the PM1 dry end section, which will be replaced with a TT DOES (Drying Optimization for Energy Saving) package. This will features a new TT SYD-3600MM provided with Toscotec patented solution for head insulation, a new Yankee steam & condensate system and a Duo-system Yankee hood, SMART type, from Milltech.

Engineering, training start up and commissioning services are also included in the package.

The aim of the rebuild is to increase the production and the performances of the crescent former machine up to 90 tpd. This is the decision that has driven ISMA 2000 to apply for the TT DOES package from Toscotec.

“Our broad conclusion after a deep technical evaluation - says Fernando Luz, Company General Manager, - is that we are forced either to increase output for the same or less specific energy consumption input. Toscotec large experience and reliable approach with its proven TT DOES package, already applied in several mills working conditions worldwide, has matched our requirement in this direction. This rebuild completes the one already initiated in the phase of pulp treatment allowing us to use complex raw material with high quality fibers and increasing efficiency and reducing energy consumption”

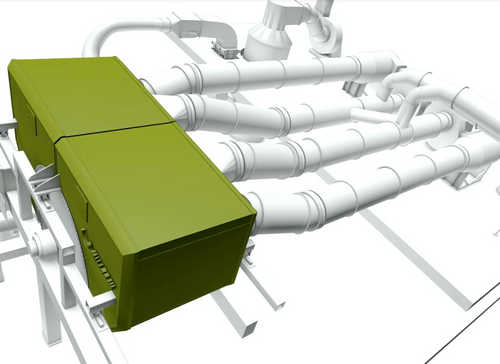

TheWall disperser filling from Voith: efficient fiber treatment due to a unique design

TheWall is a new disperser filling from Voith that was developed to ensure an improved fiber treatment during a long service life. The design of TheWall is innovative and unique. It is made of an especially strong material and used by tissue, newsprint and magazine paper manufacturers as well as board and packaging paper producers. It can be integrated into all current Voith dispersers and in selected dispersers of other manufacturers.

TheWall features three impressive innovations. Firstly, on the inner circle, the rotor vanes of TheWall ensure that the stock can be feeded uniformly to the distributing teeth. The new design also has a continuous functional barrier between the individual working edges of the filling. This prevents the stock from passing by untreated (short circuit flow) and gives the fine rows of teeth more stability. Another new feature is that the operating gap is adjustable in a wide range without impairing the efficiency of the disperser. Thus the energy input can be kept constant over the entire service life of the filling. At the same time, TheWall uses less energy than conventional disperser fillings while offering the same technological results.

Around 25 test installations are now successfully operating in various paper mills, with several customers ordering TheWall even before completion of the test phase. They will use them as their standard equipment.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.