Ianadmin

Successful startup: Voith retrofits Braviken PM 53 to produce new paper grades

Voith has upgraded and successfully commissioned the paper machine PM 53 at Holmen Paper in Braviken, Sweden. The PM 53 can now produce various paper grades ranging from newsprint to sophisticated SC papers, including the recently developed Holmen UNIQ SC paper. This paper grade in the basis weight range 43 – 50 g/m2 is suitable for magazines, catalogs and advertising supplements.

Voith has upgraded and successfully commissioned the paper machine PM 53 at Holmen Paper in Braviken, Sweden. The PM 53 can now produce various paper grades ranging from newsprint to sophisticated SC papers, including the recently developed Holmen UNIQ SC paper. This paper grade in the basis weight range 43 – 50 g/m2 is suitable for magazines, catalogs and advertising supplements.

As part of the three-week upgrade, Voith replaced the former EcoSoft calenders with a Janus MK 2 calender. The special design of this calender, featuring a 45° incline of the roll stack, meant that the existing Nipco rolls could be reused while achieving a 40 percent higher line load. The MasterReel reel winder was relocated for reasons of space and fitted with a LunaReel rubber roll cover, a minor adjustment that was necessary to be able to produce the higher-quality paper grades.

The special machine concept of the Janus MK 2 calenders allowed the upgrade to be carried out quickly and efficiently. There was no need for major structural work in the building, as the new calender could be placed on the existing paper machine foundations thanks to the 45° incline of the roll stack, putting it on the same level as the paper machine. The inclined stack configuration also provides furtherbenefits like reduced susceptibility to vibrations, shorter roll change times and very good access.

Holmen Paper was happy with the cooperation with Voith and the paper quality as Production Manager Jenny Melander confirms: “The paper was already of a very good quality directly after startup.” The rebuild allows Holmen Paper to enhance its flexibility, because the PM 53 can switch the calender between single, double or multi-nip operating modes at any time without interrupting production, enabling it to produce paper qualities ranging from matt to glossy and from low to high density.

Holmen Paper is part of the Swedish Holmen Group and a major manufacturer of graphic papers. At mills in Braviken and Hallsta in Sweden and Madrid, Spain, it produces high-quality papers for newspapers, magazines, catalogs, advertising supplements and books.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing re-source-saving products to reduce the use of energy, water, and fibers. Fur-thermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw mate-rials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

Paper Tech Foundation bestows Honor Award on WMU researcher

The Western Michigan University Paper Technology Foundation has recognized a pioneering researcher in the area of flexible printed electronics with its highest award.

The Western Michigan University Paper Technology Foundation has recognized a pioneering researcher in the area of flexible printed electronics with its highest award.

The foundation awarded Dr. Margaret Joyce, a WMU professor of chemical and paper engineering, with a PTF Honor Award for her outstanding contribution to the paper engineering program. The award was presented at the foundation's recent annual banquet in October.

Joyce's contribution to the pulp, paper and allied industries and interest in the foundation has enhanced the reputation of the Department of Chemical and Paper Engineering and Western Michigan University. Joyce has demonstrated exemplary performance in training young men and women to enter the pulp, paper and allied industries.

Joyce has been a member of the WMU faculty since 1996, having received chemical engineering and wood and paper science bachelor's degrees, a textile and polymer chemistry master's degree and a wood and paper science doctoral degree, all from North Carolina State University, and has gone on to become an extremely productive scientist. Prior to joining the faculty, she was employed at SYN-CHEM Inc. as technical service manager and director of research from 1985-96. During her tenure in the private sector and as a faculty member, she is acknowledged to have made a significant contribution to the paper industry as a research scientist and demonstrated creative talents, particularly in the coating and printing areas.

Joyce has both presented and published her research extensively for the benefit of academia and paper and printing industries, demonstrating both her creativity and tremendous productivity in both the printing and paper industries, contributing to analytical technique, formulation, methodology, equipment design and configuration and new product design. Her work in the areas of nanotechnology, high-speed curtain coaters and radio frequency identification, or RFID, are considered at the leading edge of development. She is a member of a long list of professional societies within the industry, including the Technical Association of the Pulp and Paper Industry, or TAPPI, Phi Lambda Upsilon, the American Chemical Society, Society of Rheology and International Association of Packaging, as well as a reviewer for the International Journal of Solids and Structures. In 2013, she won the TAPPI Coating and Graphic Arts Division's Education and Mentoring Award and MeadWestvaco Prize.

With her help, WMU will play a critical role in a new $171 million manufacturing innovation initiative announced Aug. 28 by U.S. Secretary of Defense Ashton Carter at NASA's Ames Research Center in San Jose, California. The Flexible Hybrid Electronics--FHE--Manufacturing Innovation Institute is the nation's newest member of the Obama administration's Nationwide Network for Manufacturing Innovation. WMU is one of four nodes around the nation named in the proposal and as such, will create the Flexible Electronics Applications and Technology--FEAT--Center on campus. This is the culmination of two year's effort demonstrating the capabilities and results of CAPE--the University's Center for the Advancement of Printed Electronics, which has been honored for its groundbreaking work in advancing the field of flexible electronic and printed electronic technologies. Joyce is co-director of the new FEAT center.

Mondi launches PERGRAPHICA® design papers

New portfolio aims for perfection in graphic design and fine printing

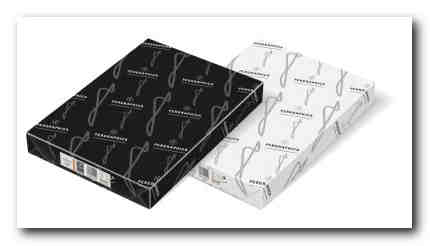

Mondi has launched PERGRAPHICA®, a new portfolio of premium uncoated fine papers designed for the exacting needs of the creative and commercial print industries. In central and eastern Europe, it is sold exclusively through Mondi’s long-term distribution partner Europapier. The PERGRAPHICA portfolio provides excellent printability on a choice of textures, shades and weights. Produced by the Mondi Neusiedler mill in Austria, PERGRAPHICA is FSC® and EU Ecolabel certified.

PERGRAPHICA® complements Mondi’s offering at the high end of its professional print portfolio. It is called ‘Paper for Perfectionists’ because it fulfils the most demanding requirements for sophisticated and elegant printed documents. Graphic designers, advertising agencies and fine book publishers are just a few of the creative industries that will appreciate PERGRAPHICA’s variety of options: two textures (Rough and Smooth), three shades (High White, Classic and Natural) and six grammages between 90 and 300 g/m2.

Johannes Klumpp, Marketing and Sales Director, Mondi Uncoated Fine Paper, says, “We are delighted to work with Europapier as we launch PERGRAPHICA® in central and eastern Europe. We aimed for perfection in developing these design papers and believe the resulting portfolio offers unlimited creative possibilities.”

Innovative. Every Day.

Mondi left no stone unturned in developing PERGRAHPICA® as a premium design paper. To ensure optimal colour reproduction, Mondi worked with X-rite, the industrial leader in colour management systems, to develop specific PERGRAPHICA® ICC profiles and CxF files. The new portfolio already even meets the soon-to-be-introduced ISO print standard ISO 12647-2:2013M1.

As a hybrid paper, PERGRAPHICA® works well with all printing technologies. It delivers consistent, high-quality results whether used for offset or digital printing. It is also well-suited to a variety of post-print processing such as cellophaning, embossing, creasing, die-cutting and more. PERGRAPHICA® is available in standard folio formats 64x90 cm SG/LG, 72x102 cm SG/LG and other folio formats upon request.

Sustainable. Every Day.

PERGRAPHICA® is a Mondi Green Range product – one of many that support customers in going green. It is FSC® certified for responsible forestry, bears the EU’s Ecolabel and is produced exclusively in an ISO 14001-certified mill. It is also the only design paper brand included in the WWF’s ‘Check Your Paper’ resource for third-party audited, environmentally friendly pulp and paper products (checkyourpaper.panda.org).

Johannes Klumpp adds, “The story of PERGRAHICA® begins at the crossroads of design and creativity. With its look and feel PERGRAPHICA® reflects emotions that bring your story to life.”

More information about PERGRAPHICA® design papers is available at www.mondigroup.com/PERGRAPHICA

We are Mondi. IN TOUCH EVERY DAY.

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are in central Europe, Russia, North America and South Africa. We offer over 100 packaging and paper products, customised into more than 100,000 different solutions for customers and end consumers. In 2014 Mondi had revenues of €6.4 billion and a return on capital employed of 17.2%.

The Mondi Group is fully integrated across the packaging and paper value chain – from managing forests and producing pulp, paper and compound plastics to developing effective and innovative industrial and consumer packaging solutions. Our innovative technologies and products can be found in a variety of applications including hygiene components, stand-up pouches, super-strong cement bags, clever retail boxes and office paper. Our key customers are in industries such as automotive; building and construction; chemicals; food and beverage; home and personal care; medical and pharmaceutical; packaging and paper converting; pet care; and office and professional printing.

Mondi has a dual-listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc under the ticker code MNDI.

For us, sustainable development makes good business sense. We don’t just talk about sustainability; we make it part of the way we work every day. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is a business unit of Mondi’s Europe & International Division. In 4 paper mills in Austria, Slovakia, and Russia Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

Strong cellulose filaments win the Van den Akker Prize

A research team from the Wallenberg Wood Science Center has won the Van den Akker Prize for Paper Physics for the article ‘Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments’, published in Nature Communications.

The prestigious Van den Akker Prize is presented each year for the best publication within paper physics. This year’s prize was awarded to an interdisciplinary research team from the Wallenberg Wood Science Center, which includes Innventia, KTH Royal Institute of Technology and Chalmers University of Technology. The team received the prize for the article ‘Hydrodynamic alignment and assembly of nanofibrils resulting in strong cellulose filaments’, published in Nature Communications in June 2014.

Their award-winning work involves putting together fibrils from cellulose to create very strong filaments. In this new method, the fibrils are oriented in a controlled manner along the direction of the filament during the production process.

Innventia has applied for a patent for this new technique for spinning, which is an example of the development of materials from nanocellulose currently being carried out within nanocellulose processes. One contributing factor behind Innventia’s efforts towards new application for nanocellulose is the pilot facility for the production of nanocellulose (also known as CNF), which was opened in 2011. The pilot facility means that sufficient quantities of raw materials can be produced to work with different applications.

“This award is confirmation that what we have achieved is appreciated and is of value to the forest industry, even if it doesn’t relate directly to paper,” says Karl Håkansson, the first author of the article. “So I hope that this cooperation can continue, and perhaps even be broadened to develop the process described in the article further.”

“We’re extremely proud to have received this award,” adds Torgny Persson, Director of the Material Processes business area. “This is an excellent example of successful cooperation between institutes and academia, in terms of both R&D and resources for upscaling and verifying research findings.”

FITNIR Analyzers Launches Kappa Analyzer

Accurate and Consistent Pulp Properties Measurements within 20 seconds

FITNIR Analyzers Inc. launched the latest addition to its suite of process analyzers at the 2015 TAPPI PEERS conference held in Atlanta, Georgia at the end of October. FITNIR Kappa uniquely measures kraft pulp properties without requiring extensive sample preparation or the use of chemicals. The announcement of the analyzer garnered much attention from the kraft pulp producers in attendance at the conference, as kappa number plays a critical role in the efficiency of digester and bleaching operations.

FITNIR Analyzers Inc. launched the latest addition to its suite of process analyzers at the 2015 TAPPI PEERS conference held in Atlanta, Georgia at the end of October. FITNIR Kappa uniquely measures kraft pulp properties without requiring extensive sample preparation or the use of chemicals. The announcement of the analyzer garnered much attention from the kraft pulp producers in attendance at the conference, as kappa number plays a critical role in the efficiency of digester and bleaching operations.

The advancement of NIR spectroscopy has led to the development of an innovative solution for the quantification of true kappa number that steps up where traditional measurement techniques fall short. When combined with FITNIR Benchtop for pulp liquor analysis, a chemical-free laboratory is attainable.

Wet pulp samples are simply washed with water and pressed into a pad, which is then analyzed by the spectrometer within 20 seconds. “FITNIR Kappa provides accurate and reliable measurements without the need for any chemicals,” said Tom Sands, President, FITNIR Analyzers. “This translates into savings ranging from $150,000 to $250,000 per year. In addition to minimizing environmental impact and the risks of hazardous chemicals, this is a significant advantage for our customers.”

Procurement applications and final product testing is also now possible. “FITNIR Kappa is the first of its kind to directly measure kappa number on dry pulp sheets without the use of chemicals, yet can provide rapid, reliable and accurate results,” explains Thanh Trung, VP of Technology. “The data from FITNIR Kappa lends itself to process optimization, ensuring the target product quality is reached and maintained.”

These uses are only the tip of the iceberg for this versatile technology. Applications are already available for Air Dry (AD) content, while many other possible parameters for improving product quality are in development. FITNIR Kappa represents a paradigm shift in how pulp properties measurement is done. Its simplicity reduces operator-to-operator variability, while providing faster, more accurate results for improved efficiency and profitability.

ABOUT FITNIR ANALYZERS INC.

FITNIR’s automated online and benchtop analyzers reliably measure complete pulp liquor compositions. Fast, frequent and accurate measurements drive control strategies that decrease process variability and environmental impact for improved efficiencies and profitability. Proven applications for the digester, recausticizer, recovery boiler, ClO2 generator, brownstock washer, and now kappa measurements for wet and dry pulp, FITNIR is the next generation of process analyzers.

Visit www.fitnir.com and www.fitnir.com/kappa to learn more about FITNIR Analyzers Inc. and FITNIR Kappa.

What pain relief can be administered to declining paper markets?

A Pöyry Point of View examining whether it is possible to actively change paper pricing through a strategic acquisition and consolidation strategy

Whilst world demand for paper and paperboard is forecast to grow, the graphic paper market is facing huge challenges in Europe. Pöyry proposes a different attitude to consolidation strategy to save the declining industry.

Whilst world demand for paper and paperboard is forecast to grow, the graphic paper market is facing huge challenges in Europe. Pöyry proposes a different attitude to consolidation strategy to save the declining industry.

The graphic paper industry and newspapers in particular, have never really recovered from the recession of 2001-2002. Overcapacities remain in the graphic paper market and prices of newsprint have reached a historic low of around 450 EUR/t and below in the first and second quarter of 2015. At this price level even cost leaders are not able to cover their capital costs anymore.

Whilst world demand for paper and paperboard is forecast to grow, the graphic paper market is facing huge challenges in Europe. The current response from industry figures has been rapid reductions in capacity. In Europe more than 20% of capacity has been reduced, with shutdowns in the first quarter of 2015 already equating to 650,000 tonnes of annual capacity. Pöyry forecasts further demand reductions of approximately 3 million tonnes by 2025 – a deep cut to the industry

The recent spate of shutdowns of the least competitive plants has flattened and lowered the cost supply curve and thereby lowered the price for paper. Marginal producers have reacted by lowering their prices in a bid to regain market share.

Christoph Euringer, Senior Consultant, Pöyry Management Consulting, said, “Bottom lines in the newsprint and other graphic paper markets are taking a hit and demand decline in many grades is expected to continue. Businesses need to button down the hatches and make smart strategic decisions to weather the storm. The solution lies in an intelligent consolidation – companies must ensure they review their and competitors’ portfolios smartly to buck the decline trend.”

Pöyry experts argue that the closing of the least competitive plants will further deteriorate the situation whereas strategic closings will help to stabilize and even increase prices. While the same amount of capacity exits the market, in both cases the effect is different. Rather than flattening the supply curve the slope of the curve increases and inaction will just allow market forces to further depress prices and challenge the viability of every company’s operations.

Download the Point of View: What pain relief can be given to declining paper markets?

For further information contact:

Metin Parlak

H+K Strategies

This email address is being protected from spambots. You need JavaScript enabled to view it.

+44 207 413 3771

About Pöyry

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

HRH The Duke of York, KG highlights the importance of apprenticeships at The Printing Charity’s Annual Luncheon

HRH The Duke of York, KG, in his role as The Printing Charity’s President for 2015, attended the charity’s 188th Annual Luncheon at Stationers’ Hall, London on 5 November.

HRH The Duke of York, KG, in his role as The Printing Charity’s President for 2015, attended the charity’s 188th Annual Luncheon at Stationers’ Hall, London on 5 November.

The Duke of York said it had been an honour to be The Printing Charity’s President for 2015 and congratulated the charity on what it has done and continues to do to help people in difficulty, as well as young people coming into the printing industry to develop the skills they need.

Speaking at the event, The Duke of York said: “Printing is part of life, but it requires skills. Thank you to everyone here today for the work you do to raise the printing industry’s profile and encourage young people to become skilled.”

The Printing Charity’s Chairman, Jon Wright, announced that in 2015, the year the charity is marking the 150th anniversary of the granting of its first Royal Charter by Queen Victoria, it will help over 1,000 people. He outlined how the charity will achieve this through its financial grants programme, its two sheltered homes, initiatives such as the Print Futures Awards, and partnerships with other charities and organisations.

Jon Wright said: “Our work is also focused on apprenticeships. This includes helping to fund a teacher’s resource pack promoting apprenticeships to 15-18 year olds. In 2016, as part of the print industry led apprenticeship trailblazer, the charity will be assisting apprentices with costs associated with their study.”

At the event, The Duke of York presented Lord Black of Brentwood, Executive Director of the Telegraph Media Group and the charity’s Vice President, with a President Emeritus Award for his work on the charity’s behalf.

Valmet to supply press section technology for Marusumi Paper Co., Ltd. in Japan

Valmet will supply a paper machine rebuild to Marusumi Paper's Ohe mill in Japan. The rebuild includes a new press section utilizing Valmet's modern shoe press technology.

Valmet will supply a paper machine rebuild to Marusumi Paper's Ohe mill in Japan. The rebuild includes a new press section utilizing Valmet's modern shoe press technology.

The main target of the rebuild is to decrease energy consumption at the plant. The rebuilt machine will be started up during fourth quarter of 2016.

The order was included in Valmet's third quarter 2015 orders received. The value of the order is not disclosed.

"The trend in newsprint production has recently been towards lighter paper weights, driven by resource and energy savings. To further meet this lighter weight tendency, Marusumi Paper has decided to proceed with a press rebuild project in order to improve productivity and end product quality. We chose Valmet as a supplier for this rebuild for several reasons. The original supplier of the machine is Mitsubishi Heavy Industries, and Valmet has acquired the company's paper machinery technology. We have also had good experience with Valmet in an earlier project when installing a sizer for Ohe mill's PM 3 in 2005. We are expecting great performance from Valmet also with this project", says Toru Shinohara, Director and Mill Manager, Marusumi Paper Co., Ltd.

"Valmet can offer key technologies for challenging rebuilds, and pressing technology is one of our core know-how areas. Modern pressing technology can help our customers to achieve higher end product quality and significantly decrease energy consumption," says Petri Paukkunen, Vice President, Paper Mills Sales and Marketing, Valmet.

Key features of the delivery

Valmet's delivery includes a new center roll based press section with modern shoe press technology as well as related runnability solutions, new press section frames, installation, motors and electrification. The existing press section at PM 2 will be rebuilt into Valmet's OptiPress Center press section. With this tri-nip solution, the new 1st press, the 2nd press and the 3rd press shoe nip maximizes the dry content, decreases steam consumption and increases the wet strength of the paper.

The 9000-mm-wide (wire) PM 2 produces newsprint grades at the design speed of 1200 m/min.

About Marusumi Paper Co., Ltd.

Marusumi Paper Co., Ltd. is the Japanese paper making company which produces and sells paper products. The company was founded in 1919 with almost 100 years of history, and it is based in Ehime Prefecture, Japan.

Further information, please contact:

Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

Kazuhiko Endo, Director, Sales, Valmet Japan, tel. +81 (0)3 6744 3024

Australia Pulp Expansion Now Possible: Pulp & Paper Strategic Review Provides the Data

Australia could be on the cusp of a pulp production expansion over the coming years, as domestic demand for pulp increases.

Australia's pulp consumption rose 3.3% in 2014-15, reaching a new record of 1,730,000 tonnes.

Local production was supplemented by an important 291,000 tonnes of imported pulp. Imports accounted for just less than 17% of total pulp consumption.

All but 3,000 tonnes of the imported pulp was chemical pulps of various types. In total, chemical pulp accounted for around three quarters of pulp utilisation for the year, as it does in most years.

Australia's current pulp supply deficit is set to expand in 2016 and again in 2017, pushing out to approximately 400,000 tonnes per year, on conservative estimates. The main driver for the growth is the expansion of tissue production announced recently by ABC Tissue.

IndustryEdge's estimate is that the tissue sector already uses more than two-thirds of Australia's imports of pulp. That will rise to around three quarters (300,000 tonnes) by the end of 2017.

On that basis alone, and without taking into account general growth in demand, pulp imports will increase over the next two years, but that does not have to be the case. In fact, for local tissue producers, access to domestically produced pulp could prove to be a significant advantage.

Currently, tissue producers are paying more for their pulp, largely due to the depreciation of the Australian Dollar, although that is being tempered somewhat by lower global pulp prices. Secure domestic supplies of pulp would be welcomed by at least some producers, and would, as a minimum, reduce currency risks.

IndustryEdge's analysis, based on the detailed data in the 2015 edition of the Pulp & Paper Strategic Review, shows that Australia's total pulp needs could be supplied locally, with only modest additional investments.

To be clear, that doesnt necessarily involve the building of a new pulp mill, although that would of course be welcome.

Instead, expansions of existing pulping capacity at mills in New South Wales and Victoria could deliver the required additional pulp. In addition, there is the opportunity for more de-inked recycled fibre to be produced and supplied to the tissue sector.

There are two significant challenges to this opportunity.

The first challenge is that even with additional capacity, pulp bleaching remains a limitation in Australia and requires investment.

The second and more complex challenge is establishing the conditions in which investment in expanded capacity and pulp bleaching would be viable. Translating demand into specific and bankable sales may require some form of longer term supply agreement between a pulp producer on the one hand and a paper manufacturer on the other.

That would result in the tentative development of market pulp capacity in Australia, but with a difference.

Australia's abundant wood resources and excellent fibre recovery and recycling credentials, makes the opportunities all the more tantalising. What is certain, is that importers are ready to meet the new supply opportunities.

Working in part with the data from the 2015 Pulp & Paper Strategic Review, our feature in this month's edition of Pulp & Paper Edge will consider pulp markets in Australia, New Zealand and the Asian region more generally.

To examine a sample of the Strategic Review, as well as the full Table of Contents and Lists of Charts and Tables, click here

ANDRITZ : favorable business development in the third quarter of 2015

In the third quarter of 2015, international technology Group ANDRITZ showed a favorable business development.

In the third quarter of 2015, international technology Group ANDRITZ showed a favorable business development.

Sales amounted to 1,583.5 MEUR in the third quarter of 2015 and were thus 8.2% higher than the figure in the third quarter of 2014 (1,463.5 MEUR), with all four business areas increasing their sales. In the first three quarters of 2015, Group sales rose by 11.3% to 4,589.1 MEUR compared to last yearʼs reference period (Q1-Q3 2014: 4,122.9 MEUR).

The order intake in the third quarter of 2015, at 1,187.6 MEUR, was 25.4% below the high figure for the previous yearʼs reference period (Q3 2014: 1,591.5 MEUR), which included some large orders in the PULP & PAPER and METALS business areas. In connection with the decline in order intake it has to be mentioned that the large order awarded to ANDRITZ by Fibria in July 2015 to supply equipment for a new pulp mill in Brazil was booked in the fourth quarter of 2015; typical order values of comparable projects are about 600 MEUR. In the first three quarters of 2015, the order intake amounted to 3,767.6 MEUR and was thus 17.6% below the high previous year’s reference figure (Q1-Q3 2014: 4,571.6 MEUR).

Earnings of the ANDRITZ GROUP developed favorably. In the third quarter of 2015, EBITA rose to 110.1 MEUR, which is an increase of 9.0% compared to the previous yearʼs reference figure (Q3 2014: 101.0 MEUR). The EBITA margin amounted to 7.0% (Q3 2014: 6.9%). As announced at the end of August 2015, around 55 MEUR of financial provisions were booked in the reporting period for optimization of the value chain at Schuler. These provisions were partly offset by project-related one-off improvements in the amount of approximately 30 MEUR in the PULP & PAPER business area. After adjustment of these extraordinary effects, the Groupʼs EBITA amounted to 135.1 MEUR and the EBITA margin to 8.5% in the third quarter of 2015. Earnings also increased substantially in the first three quarters of 2015. At 295.0 MEUR, the EBITA was 25.9% higher than the figure for the previous yearʼs reference period (Q1-Q3 2014: 234.4 MEUR), while the EBITA margin amounted to 6.4% (Q1-Q3 2014: 5.7%). Excluding the extraordinary effects booked in the third quarter of 2015, the EBITA increased to 320.0 MEUR and the EBITA margin to 7.0%.

Net income (without non-controlling interests) in the first three quarters of 2015 reached 181.3 MEUR (Q1-Q3 2014: 123.6 MEUR).

On the basis of this business development, the project activity in the ANDRITZ business areas, and the order backlog as of end of September 2015, ANDRITZ currently expects an increase in sales and net income for 2015 compared to the previous year. However, if the economic weakness looming in the emerging economies (particularly China) worsens in the coming months and the global economy further weakens, this could have a negative impact on ANDRITZ’s business development.