Ianadmin

Xerium Introduces Blue Diamond Advanced Polyurethane Roll Cover Technology

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Blue Diamond, a new generation of advanced polyurethane roll cover technology for superior performance on the harshest of press nip conditions. Blue Diamond roll covers are specifically engineered to deliver exceptional stability in the most demanding nip conditions providing long-running dewatering performance and superior resistance to groove closure, which is critical for consistent venting performance. The new roll covers are available in grooved and drilled patterns and include the company’s exclusive Fusion bonding system for additional life. Learn more about Blue Diamond technology at http://www.xerium.com/news/xerium-news.aspx.

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, recently launched Blue Diamond, a new generation of advanced polyurethane roll cover technology for superior performance on the harshest of press nip conditions. Blue Diamond roll covers are specifically engineered to deliver exceptional stability in the most demanding nip conditions providing long-running dewatering performance and superior resistance to groove closure, which is critical for consistent venting performance. The new roll covers are available in grooved and drilled patterns and include the company’s exclusive Fusion bonding system for additional life. Learn more about Blue Diamond technology at http://www.xerium.com/news/xerium-news.aspx.

“As always, our mission is to develop innovative technology to help our customers achieve new performance levels with reduced operating costs.”

“The rolls technology team has developed this new generation of polyurethane for those demanding nip conditions where conventional covers suffer from premature groove closure. Blue Diamond’s exclusive formulation delivers stable performance and long life which is especially important on covers with grooved and drilled patterns for enhanced dewatering performance,” said Mr. Bill Butterfield, EVP and CTO of Xerium. “As always, our mission is to develop innovative technology to help our customers achieve new performance levels with reduced operating costs.”

About Xerium

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. Xerium has 26 manufacturing facilities in 12 countries, two new plants under construction in 2 countries and employs approximately 3,100 employees.

Xerium Technologies, Inc.

Steve Cole, 336-260-4672

Director – Global Marketing

This email address is being protected from spambots. You need JavaScript enabled to view it.

Catalyst announces major investment in Rumford mill

Catalyst Paper (TSX:CYT) has announced an investment of nearly $16 million in the Rumford pulp and paper mill in Maine, U.S. This is a planned second quarter investment that includes the company's single largest maintenance expenditure in 2015.

Catalyst Paper (TSX:CYT) has announced an investment of nearly $16 million in the Rumford pulp and paper mill in Maine, U.S. This is a planned second quarter investment that includes the company's single largest maintenance expenditure in 2015.

Approximately $11.4 million will be invested in various maintenance projects including upgrading the Rumford mill's Recovery Boiler C, which involves completely replacing the 35-year-old generating bank. An additional $4.5 million in capital investments will be made in Q2 (with $1.8 million invested in Q1).

The Rumford mill is exposed to significant seasonal energy cost fluctuations, and with record cold in 2015 resulting in higher than average first quarter energy costs of $3.0 million, this significant maintenance effort will maximize the overall operation and reliability of Recovery Boiler C, leading to improved energy efficiency and reduced energy costs to help mitigate future seasonal energy cost exposure.

"Today's announcement reflects the strategic investments we're making in our recently acquired US assets to accelerate operational excellence improvements that will ultimately deliver enhanced performance and results," said Joe Nemeth, President & Chief Executive Officer. "We expect to realize the benefits of this and other key investments in the second half of 2015 as we complete planned maintenance and capital work, and manage the significant costs we anticipated related to the integration of our US operations. With these and other costs behind us, our assets are well positioned to meet improving market conditions in the second half of the year."

Catalyst anticipates the replacement of the generating bank and additional, related maintenance work at the Rumford mill will be complete by May 30.

About Catalyst Paper

Catalyst Paper manufactures diverse printing papers such as coated freesheet, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Joe Nemeth, President & Chief Executive Officer, (604) 247-4012

This information is being distributed to you by / Cette information vous est transmise par : Catalyst Paper Corporation

2nd Floor, 3600 Lysander Lane, Richmond, BC, V7B 1C3, Canada

www.catalystpaper.com

Do you want to know everything about your Yankee Section Runnability?

FOCUS ON YANKEE SECTION RUNNABILITY EFFICIENCY

– Training at expertise level, 22-25 June, online, via LIVE e-Learning, in English –

We all know that the connection between machine efficiency and best operational practices is of significant importance. IBC Paper Training’s program is specially conceived to help mill personnel to reduce the TOC and improve machine operating skills. The key for an optimized production is represented by a mix of knowledge and skills.

This event is “de facto” an improvement program meant to give you deeper knowledge of ways to optimize pressing, drying, coating & creping section and give you tips and tools to improve efficiency.

IBC is pleased to offer a training at expertise level, held by high qualified experts and specialists in the field coming from all over Europe. The course is open to all (worldwide) customers, enabling you to share experiences and knowledge with other participants and with the expert lecturers.

Don’t miss out this occasion and book your place now! Please send an e-mail at This email address is being protected from spambots. You need JavaScript enabled to view it. or at This email address is being protected from spambots. You need JavaScript enabled to view it. if you are interested in attending or if you have any questions!

For additional details about the training click here!

*** THE COST OF PARTICIPATION TO THE TRAINING IS PER CONNECTION. Therefore there can be several people from the same production site to follow the training behind just one connection. ***

Please be aware that there is a limited number of possible connections!!!

Safe communication in digitally networked plant of the future

ACHEMA 2015: With HIPRO-S V2, HIMA introduces first-of-its-kind safety protocol for efficiently migrating existing plants to new systems.

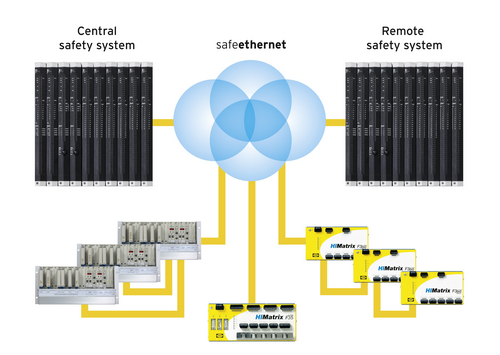

To help the process industry migrate to tomorrow’s digitally networked plants, HIMA Paul Hildebrandt GmbH will introduce at ACHEMA 2015 in Frankfurt, Germany, a new protocol that enables Ethernet-based, safety-related communication (SIL 3). Now safe communication is enabled between the company’s three controller families: HIMatrix, HIMax and HIQuad.

The new safety protocol HIPRO-S V2 enables Ethernet-based, safety-related communication (SIL 3) between the three HIMA product families: HIMatrix, HIMax and HIQuad.

“HIMA supports the incremental digitalization of our customers’ plants with very clear migration paths,” said Peter Sieber, Vice President Global Sales at HIMA. “Customers can select and combine the best HIMA controller for their application and know that the safe, reliable and fast networking of HIPRO-S V2 and safeethernet will allow them to efficiently operate their digitally networked plant, even in the future. The HIPRO-S V2 protocol will help to accelerate commissioning and ensure the fast restart of the plant and reduce the risk of delays. A long service life, and thus optimum investment protection, are guaranteed.”

Separate certification is not necessary

HIPRO-S V2 does not need a separate certificate, as it is a component of HIQuad, HIMax and HIMatrix controllers and is covered by their certificates. HIPRO-S V2 can be implemented universally.

Like safeethernet, HIPRO-S V2 uses UDP packets. These packets can be transmitted via standard Ethernet infrastructures, such as switches, firewalls, WLANs or devices, that are suitable for Ex zones. Use of these proven, industrial infrastructure components (COTS) enables economical and reliable solutions.

The new safety protocol HIPRO-S V2 enables Ethernet-based, safety-related communication (SIL 3) between the three HIMA product families HIMatrix, HIMax, and HIQuad.

HIMA safety protocols are distinct in that they can be operated in the same network with non-safe protocols; for example, Modbus TCP or the connection via OPC. Controllers can also be programmed via this network. This helps to reduces costs in generating and maintaining the network infrastructure.

About HIMA

HIMA is the world’s leading specialist for safety-related automation solutions. HIMA solutions provide maximum safety and maximum availability and can be integrated into any automation environment. During the past 45 years, more than 35,000 HIMA systems have been installed in over 80 countries to protect the equipment of the world’s largest companies in the oil, gas, chemical, pharmaceutical and power generation industries. In the fields of rail, logistics and machine safety, HIMA solutions are leading the way to increased safety and profitability. The HIMA LIFECYCLE SERVICES concept gives customers an overview of all the requirements of “functional safety” allowing them to always make the right decision at the appropriate time.

For more information about HIMA, please visit: www.hima.com

The Printing Charity marks the 150th anniversary of its first Royal Charter

A walk through history with The Printing Charity

The Printing Charity marked the 150th anniversary of the granting of its first Royal Charter with a reception held at St Bride Foundation on 12 May 2015. The event’s theme was looking to the future, building on the past.

Guests were taken on a walk through history with scenes presented by professional actors in ten of the Foundation’s rooms. The history snapshots included the charity’s founding in 1827 at the Kings Head Tavern, Poultry; a Festival dinner with a reading of an extract from Charles Dickens’ “A Christmas Carol”; the signing of the charity’s Charter by Queen Victoria; the London Blitz; and the 1980s’ Wapping dispute.

An Adana Printing Press was set up at the reception so guests could print their own pledge of support for The Printing Charity whether it be encouraging people they know needing financial support to contact the charity, fundraising ideas or cash donations.

Jon Wright, The Printing Charity’s Chairman, explained: “Our Royal Charter sets out why we exist, what we can do, and the people we can help. Since our first Royal Charter, we’ve been granted a Supplemental Charter in 1972 and a second Royal Charter in 2014 enabling us to help more people, including young people who intend working in the industry.”

Stephen Gilbert, The Printing Charity’s Chief Executive, said: “We’re not going to disappear because we know there are people out there who need our help as much as they did in 1865 when our first Royal Charter was granted.”

About The Printing Charity:

Whatever a person’s job is or was for three years in an organisation that produces a printed output – printing, publishing, packaging, operating presses, driving, cleaning, advertising, warehousing, photography, journalism, graphic arts, making ink, recycling paper – The Printing Charity helps people of all ages, including dependent family members. See www.theprintingcharity.org.uk

SCA comments on reports in Swedish media regarding the joint venture Productos Familia S.A.

The Colombian competition authority is conducting an anti-trust inquiry that includes the company Productos Familia S.A. The company is listed on the Colombian Stock Exchange. SCA owns 50% of Productos Familia S.A.

The Colombian competition authority is conducting an anti-trust inquiry that includes the company Productos Familia S.A. The company is listed on the Colombian Stock Exchange. SCA owns 50% of Productos Familia S.A.

“Free and undistorted competition is an important cornerstone in every society and for every business operation. We take a very serious view of all cases in which our business is called into question. In this particular area, SCA has a comprehensive, ongoing program for training employees and ensuring adherence to competition rules,” says Kersti Strandqvist, Senior Vice President, Corporate Sustainability, SCA.

SCA conducts operations in more than 100 countries and, in many cases, holds leading market positions. It is natural that SCA, similar to other major international companies, is the subject of investigations by such institutions as competition authorities in various contexts and for various reasons.

At present, competition authorities are reviewing the joint venture Familia’s operations in Colombia, Ecuador and Peru, as well as SCA’s wholly owned businesses in Chile, Spain, Poland and Hungary. In all instances, SCA and/or joint ventures is/are cooperating with the authorities and providing the requested information. SCA has assessed that the ongoing inquiries will not have a material financial impact.

For further information, please contact:

Karl Stoltz, Media Relations Manager, 46 8 788 51 55

SCA is a leading global hygiene and forest products company. The Group develops and produces sustainable personal care, tissue and forest products. Sales are conducted in about 100 countries under many strong brands, including the leading global brands TENA and Tork, and regional brands, such as Libero, Libresse, Lotus, Nosotras, Saba, Tempo and Vinda. As Europe’s largest private forest owner, SCA places considerable emphasis on sustainable forest management. The Group has about 44,000 employees. Sales in 2014 amounted to approximately SEK 104bn (EUR 11.4bn). SCA was founded in 1929, has its headquarters in Stockholm, Sweden, and is listed on NASDAQ OMX Stockholm. For more information, visit www.sca.com.

Good start to 2015 for the Södra Group

Södra’s operating profit for the first four months of the year amounted to SEK 941 million (503). Sales increased 7 percent to SEK 6,243 million and the operating margin improved to 15 percent (9).

“The year started well for Södra, with healthy sales and strong results. The market has been stable, prices relatively good and the currency situation favourable. Production has also been efficient and we are seeing the results of continued rationalisation,” commented CEO Lars Idermark.

“The year started well for Södra, with healthy sales and strong results. The market has been stable, prices relatively good and the currency situation favourable. Production has also been efficient and we are seeing the results of continued rationalisation,” commented CEO Lars Idermark.

The wood supply in southern Sweden was in line with the preceding year, but considerably higher than the average for the past five years. The supply of wood to Södra’s mills functioned effectively. Deliveries of sawn timber showed a positive trend. In moulding and panelling, competition from manufacturers in the Baltic countries remained intense. Demand for pulp remained stable, but the currency trend with a strengthened USD against the EUR led to a slightly lower world market price for softwood sulphate pulp (NBSK).

The earnings improvement for the first four-month period is the result of healthy demand for Södra’s products and services and a favourable currency situation. Profit for the Södra Cell business area increased to SEK 968 million (517), while profit for Södra Wood amounted to SEK 22 million (21) and profit for Södra Skog to SEK 41 million (51).

| 2015 | 2014 | 2014 | |

| Jan-Apr | Jan-Apr | 1 Jan-31 Dec | |

| Net sales, SEK million | 6,243 | 5,838 | 17,339 |

| Operating profit before depreciation, amortisation and impairment (EBITDA), SEK million | 1,262 | 832 | 2,552 |

| Operating profit, SEK million | 941 | 503 | 1,516 |

| Operating margin, % | 15 | 9 | 9 |

| Cash flow after investments, SEK million | 740 | 515 | 267 |

| Return on capital employed, % | 22 | 11 | 13 |

For questions, please contact:

Lars Idermark, President and Chief Executive Officer

Telephone: +46 470 894 35

Carina Olson, Chief Financial Officer

Telephone: +46 470 892 62

Annica Gerentz, Senior Vice President Corporate Communications

Telephone: +46 470 894 81

Södra’s members to receive dividends totalling SEK 553 million

Södra’s Annual General Meeting agreed to distribute SEK 553 million to members and to elect Lena Ek as the Board’s new Chairman. Hans Berggren was elected new Board member.

Södra’s Annual General Meeting agreed to distribute SEK 553 million to members and to elect Lena Ek as the Board’s new Chairman. Hans Berggren was elected new Board member.

Approximately 300 people, including 200 delegates, attended Södra’s Annual General Meeting in Växjö Concert House on 19 May. The Meeting resolved to distribute profits of SEK 553 million, comprising dividends of 6 percent on contributed capital (SEK 170 million) and 8 percent on wood deliveries (SEK 324 million), and a bonus issue of 5 percent on paid-up contributed capital as of 31 December 2014 (SEK 60 million). A decision to issue a dividend of 7.7 percent on subordinated debentures, series D, totalling SEK 10 million, was also adopted.

“Södra performed extremely well in 2014, which will also benefit members in the form of a solid dividend totalling SEK 553 million. It is important that our owners feel we have a long-term approach to dividends, and that they receive a return on both their risk capital and their wood deliveries. The profit distribution contributes to the profitability of active forest management and active participation in Södra,” says Christer Segerstéen, who will now step down from his role as Chairman of Södra.

Lena Ek was elected new Chairman and Hans Berggren as new Board member. In addition to Christer Segerstéen, Anders Grennborg and Caroline Sundewall also stepped down from the Board.

Lena Ek was born in 1958, holds a Bachelor of Law with a specialisation in international law and lives in Valdemarsvik, where she also owns forest. She has worked politically at municipal, county, national and EU levels, and serves on the Board of the Swedish Centre Party as well as the Party’s Executive Committee. She was Minister for the Environment from 2011-2014 under the Swedish Alliance government and since the election in 2014, has been a Member of the Riksdag and Deputy Chair of the Committee on Environment and Agriculture. She served on Södra’s Board from 2000-2010.

Hans Berggren was born in 1956, is an agronomist and lives north of Karlshamn where he also owns forest. Since 2010, he has served as President of the co-operative association Sveriges Stärkelseproducenter and its subsidiaries Lyckeby Culinar AB, Lyckeby Starch AB and Kockens AB.

The Meeting addressed a total of 17 motions concerning such issues as profit-distribution policies, the development of broader financial advisory services for members and the effects of climate change on forestry.

For more information, please contact:

Lars Idermark, President and CEO, tel: +46 470-894 35

Magnus Berg, Director of Members, Södra, tel: +46 (0)70-52 894 83

Annica Gerentz, Director of Communications, Södra, tel: +46 (0)70-398 42 09

Iggesund expands its presence in North America

Iggesund Paperboard is expanding distribution in the US making its flagship product Invercote available coast to coast. Increasing interest in Invercote’s unique properties from brand owners on the West Coast, and some key new business acquisitions made expanding west a natural next step.

Rickard Österlindh, President Sales the Americas © Iggesund

Iggesund Paperboard has established an inventory position and sheeting capabilities in Pomona, CA with the objective of making Invercote readily available for quick turn market demand. The primary goal is to be able to serve the commercial print and packaging cluster in California and beyond.

“We’ve been in the US for more than thirty years but our distribution footprint has been concentrated on the east coast,” explains Rickard Österlindh, President Iggesund Americas. “Now is the time to increase our presence on the West Coast, where we know there is a density of brand owners who will appreciate the quality level we offer with Invercote.”

Iggesund will focus its sales & marketing efforts on premium packaging and graphical print applications, building on the foundation of offset and digital print business recently established through a network of merchant distributors.

“Invercote’s unique attributes truly distinguish it from other products in the marketplace, and as such Iggesund will seek to identify applications where those properties add value. That’s why we’re also reinforcing our US sales organisation by recruiting people who can help increase sales both in areas where we had no previous presence and those where we already have a position,” Österlindh emphasises.

“Invercote is a niche product in the US. Unlike domestically produced paper and paperboard grades, Invercote’s is manufactured using a multi-layer construction, which means that it will not crack on the fold; neither with nor against the grain. This is an incredibly powerful selling point, which is further strengthened by a second-to-none environmental sustainability platform,” comments Neal Haussel, Sales Director & Marketing Manager US. Haussel adds, “We are pleased to formally announce the addition of Paige Brinkley to the Iggesund sales team to help us develop brand recognition on the West Coast, and deliver Invercote’s unique proposition to that heretofore untapped market. Paige brings a long history of working both in fine paper and board markets and has an extensive background working on the West Coast.”

Invercote is used by many strong brands." © Iggesund

Enhanced distribution from coast to coast in the US is just one step in Iggesund’s overarching effort to become a unified global entity by strengthening its service platform outside Europe. In step with that effort, the company has launched a broader service concept, which emphasises the resources and support functions offered to existing and potential customers. Care by Iggesund includes the fast, easy ordering of samples and inspirational materials, product safety information and certificates, and access to the analytical services of Iggesund’ s accredited Laboratory for Sensory and Chemical Analyses. Iggesund’ s extensive environmental documentation is also part of the Care by Iggesund campaign, serving as a guarantee that customers will not have any unpleasant surprises regarding the origins of forest raw material.

Iggesund’ s service offering encompasses everything associated with Invercote – from technical support in local markets to the paperboard expertise the company offers in the form of a wide range of reference materials.

“We don’t just want customers to buy our paperboard,” Rickard Österlindh concludes. “We want them to get the most out of the products we produce by making a resource base of knowledge available to them. All our documentation, together with an experienced team of local market technicians exists to ensure that.”

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Further information:

Staffan Sjöberg

Public Relations Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Iggesund Paperboard

SE-825 80 Sweden

Tel: +4665028256

Mobile: +46703064800

www.iggesund.com

Gudrun clearing largest carbon sink

Ten years after Cyclone Gudrun, the now reforested felled areas have become a large carbon sink and will remain so for more than 50 years. This has been shown by the development of Södra's property in Toftaholm, one of the worst affected by the storm in 2005, with 130,000 m³sub of wind-felled forest.

A clearing, where the forest has been harvested or wind-felled, for example, releases CO2. Growing forest, on the other hand - particularly young forest - absorbs CO2. When Gudrun swept over Sweden ten years ago, there were major concerns that the resulting deforestation would become a "carbon bomb" for many years to come. However, due to rapid processing of the storm-damaged timber and ambitious reforestation goals, re-growth has been faster than expected and eight years later, the forest has now begun to absorb more CO2 than it releases. A growing forest helps to reduce climate impact. Due to the vastness of the area that was deforested, which also represents the most fertile soils in Sweden, this is particularly important.

"At the time, there was a fairly distressing discussion on how much carbon would be released. The finger was pointed at poor forest management and it would probably take a long time before new forest began to absorb CO2," says Göran Örlander, Head of Forest Management at Södra.

Johan Bergh, professor at Linnaeus University, has studied the development of Södra's soils and claims that the forest began to absorb more carbon than it releases after replanting eight years ago.

"Measurements of the carbon balance show that while overall emissions of CO2 were about 80 tonnes per hectare, we saw a clear annual variation of absorption/emission after five years, and the forest now absorbs more than it releases. Reforestation has been successful and in the beginning, emissions declined as ground vegetation increased. With a rotation period of about 65 years, this forest will absorb and store large amounts of CO2 for more than 50 years," says Johan Bergh.

The new forest will now be managed with best management practices to reduce storm damage, such as cleaning and thinning performed correctly and in a timely manner. Cleaning and thinning are now carried out at an early stage, and in a way that makes trees grow faster in width to increase their stability, since taller trees are more prone to windthrow. This management approach will also enable earlier harvesting, generating a higher return on forests for forest owners.

"Gudrun gave us invaluable experience and knowledge for the continued development of responsible forestry," says Göran Örlander.

For questions, please contact:

Göran Örlander, Head of Forest Management

tel: +46 470 893 62

Annica Gerentz, Director of Communications

tel: +46 470 894 81