Super User

Valmet to supply a hard nip sizer to Asia Paper Manufacturing in the Republic of Korea

Valmet will supply a new sizing section with a hard nip sizer to Asia Paper Manufacturing at Sihwa Mill in the Republic of Korea. The main target for the rebuild of paper machine PM 1 is to increase strength properties of produced container and gypsum board grades. The start-up of the rebuilt paper machine is scheduled for the second half of 2021.

The order is included in Valmet's orders received of the first quarter 2020. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 5-10 million.

“Valmet was able to offer technical advantages to produce high quality gypsum and testliner board grades with low raw material cost. We were able to get proof for those targets as we run pilot trials at Valmet’s Paper Technology Center in Finland. We also visited a reference mill, which has an OptiSizer Hard sizer. It is important to have a supplier who we can trust and who has a good reputation,” says Kyoung-Taek Lee, Vice Mill Manager of Asia Paper.

“Valmet was able to offer technical advantages to produce high quality gypsum and testliner board grades with low raw material cost. We were able to get proof for those targets as we run pilot trials at Valmet’s Paper Technology Center in Finland. We also visited a reference mill, which has an OptiSizer Hard sizer. It is important to have a supplier who we can trust and who has a good reputation,” says Kyoung-Taek Lee, Vice Mill Manager of Asia Paper.

“We came up with a solution where the customer is able to reduce basic weight without sacrificing strength properties. Asia Paper was very interested in a non-contact starch application method for recycled board because it reduces the wear of consumables, and thus improves time efficiency of the machine. There is no competing technology at the moment,” says Kwon Tae-Yeon, Sales Manager, Valmet.

Technical details of the delivery

Valmet's delivery will include an OptiSizer Hard sizer with hard nip and spray application, a TurnFloat web turning device, surface size preparation and supply systems, Valmet DNA machine control and Valmet IQ quality control systems.

Compared to conventional sizer, OptiSizer Hard has a pair of hard covered nip rolls. Starch is sprayed on the nip rolls. In addition to increased surface strength, OptiSizer Hard improves also the internal strength values of produced board. Starch is dosed in the roll nip with higher nip pressure, which increases the density of fibers. This leads into better strength properties.

“Asia Paper is expecting a lot of product quality improvement based on Valmet’s new technology and wishes to continue good cooperation with Valmet for further development,” says Dong-Kyu Kim, Production Manager of Asia Paper.

The 5,900-mm-wide (wire) PM 1 produces testliner and gypsum board grades with a basis weight range of 80–300 g/m2. The design speed of the new parts will be 850 m/min. The daily design capacity will be approximately 1,100 tonnes depending on the produced grade.

Information about the customer Asia Paper

Since its foundation in 1958, Asia Paper Mfg. Co., Ltd. has specialized in the production of kraft paper, gypsum linerboards and testliner. Asia Paper is highly regarded in Korea, not only as the country's first industrial enterprise, but also for the high quality of its products and modern production processes.

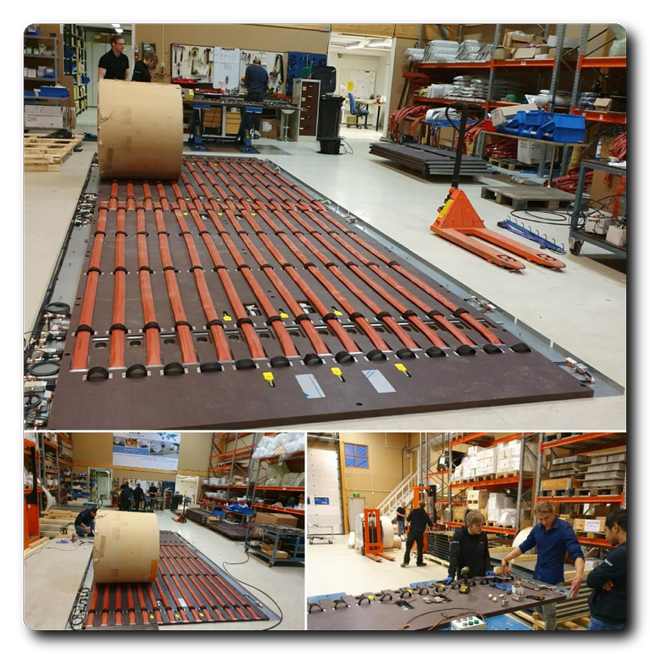

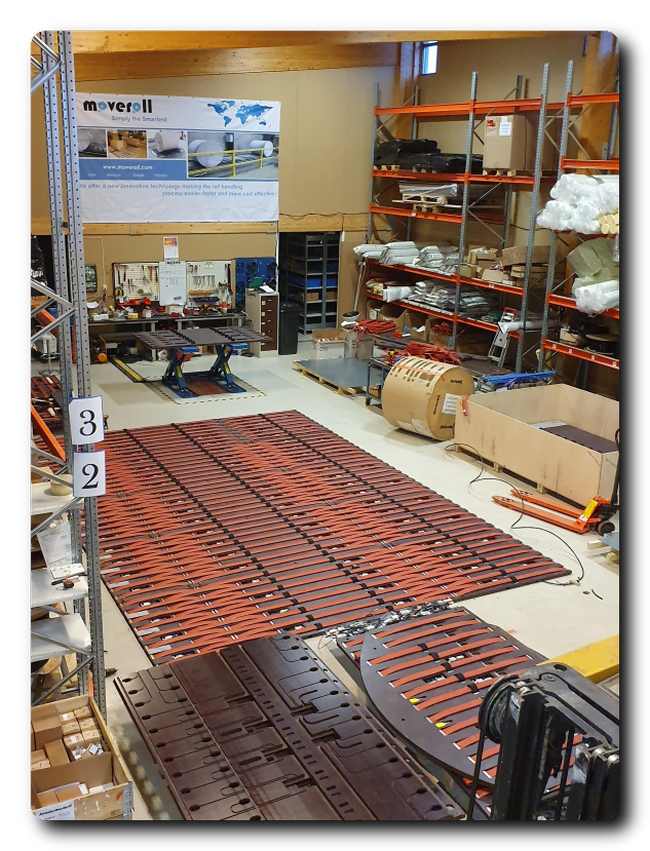

ISO 9001/2015 quality standards for MoveRoll production

We are proud to announce that in February 2019 the manufacturing and assembly of MoveRoll products has been certified according to the ISO 9001/2015 standards.

Quality management is very important for MoveRoll and the MoveRoll production. That is why the seven quality management principles customer focus; leadership; engagement of people, process approach; improvement; evidence-based decision making; and relationship management have already clearly been reflected in MoveRoll’s day-to-day operations before the ISO certification has been achieved.

“Managing the quality of our products and services is very important. The ISO 9001/2015 certification was an additional process to further improve our quality management standards as well as to better fulfill our customers’ requirements. There is no contradiction between striving to offer new innovative roll handling and following established quality standards. On the contrary, adhering to high quality standards and keeping the importance of quality for all processes in mind, we can ensure that our customers receive safe and reliable products”, says CEO Mikko Rantanen.

MoveRoll deliveries continue to grow

The year we left been a busy and successful year for MoveRoll. We have delivered a variety of different MoveRoll conveyor modules to several system integrators in North America, Europe and Asian markets. We are delighted that both paper mills and system integrators have increased their demand for MoveRoll horizontal conveyors, Zero Energy Receivers and Braking Pads throughout the last year.

MoveRoll has also had a busy start on 2020 for MoveRoll. Over 35 conveyor modules have been already manufactured and shipped in period January – March. Our deliveries continue to grow Globally showing that the innovative technology developed by MoveRoll has made easier, safer and more efficient roll handling in paper mills. MoveRoll continues to cooperate with most reliable roll handling Partners. Our Partners are experts of roll handling who can offer tailored roll handling solutions for all different applications.

ANDRITZ successfully starts up the world’s first fossil-free biomethanol plant at Södra, Sweden

International technology group ANDRITZ has recently started up the world’s first biomethanol plant using ANDRITZ’s self-developed A-Recovery+ concept at the Södra Cell Mönsterås pulp mill in southeastern Sweden.

The plant has an annual production capacity of 6.3 million liters of biomethanol from forest biomass. The fossil-free biomethanol can be used for applications in the pulp mill itself, or as a substitute for fossil-based methanol in the transport sector (biodiesel) and as a chemical base substance. The ANDRITZ delivery to Södra included proprietary process design and full EPC delivery, excluding automation, instrumentation, electrification and civil works.

Biomethanol plant (3D image) © ANDRITZ

Biomethanol plant (3D image) © ANDRITZ

The A-Recovery+ concept from ANDRITZ delivers commercial grade biomethanol by using a patented extraction process. It offers next-generation solutions for the chemical recovery cycle of pulp mills, with the target of utilizing the pulp mill side streams to the maximum extent possible. In addition to biomethanol production, A-Recovery+ also produces sulfuric acid from odorous gases and recovers lignin for the production of high-quality lignin to be used in advanced bioproducts.

With this first ever fossil-free biomethanol plant worldwide, ANDRITZ is strongly supporting Södra’s ambitions to make its operations entirely fossil-free and be climate-positive by the end of this decade. To achieve this aim, Södra is aiming at eliminating fossil fuel use throughout its operations and producing innovative products that replace fossil-based raw materials.

Tissue World Miami 2020 Confirms New Dates — Nov. 11-13, 2020 — for the Conference and Exhibition

North America’s largest tissue-related gathering will again be staged at the Miami Beach Convention Center

Originally scheduled in March, Tissue World Miami 2020 was postponed due to the COVID-19 virus outbreak and has been rescheduled for Nov. 11-13, 2020, at the Miami Beach Convention Center. All existing exhibitor and delegate bookings will move automatically to the new dates.

Working in tandem with the MBCC, the show organizers secured a tenancy for both the Tissue World Miami conference and exhibition that are set to run concurrently. The Informa Markets team currently is discussing the revised dates with speakers and exhibitors with the expectation of securing their participation in November.

Working in tandem with the MBCC, the show organizers secured a tenancy for both the Tissue World Miami conference and exhibition that are set to run concurrently. The Informa Markets team currently is discussing the revised dates with speakers and exhibitors with the expectation of securing their participation in November.

“We have been closely following developments since COVID–19 began spreading, and made the decision to postpone Tissue World Miami based on feedback from our customers,” said Agnes Gehot, deputy event director, Informa Markets. “By working closely with our venue partner Miami Beach Convention Center we were able to secure rescheduled dates for the conference and exhibition, which will now serve as an opportunity for our clients and exhibitors to gather in November.”

Holding the show later in the year “gives the market time to recover as demand catches up,” Gehot added.

“The rescheduled date provides clarity and ensures we have time and space to deliver the same fantastic event we promised, providing a safe and secure environment conducive to business, networking and professional education for the tissue production industry,” she said.

With the conference theme of “Ready for Reinvention, Ripe for Disruption: Will the 20s Roar for Tissue?” the conference and exhibition are expected to draw 200 exhibiting companies and more than 2,500 attendees from nearly 70 countries to South Florida.

Registration for North America’s largest gathering of the global tissue trade is still open and can be accessed at https://www.tissueworld.com/miami/en-us. Attendees typically include suppliers to the tissue industry, tissue converters, integrated tissue product makers, jumbo roll suppliers and retailers and distributors.

The Tissue World Miami conference brings fresh, critical and creative perspectives on America’s tissue business. Conference presenters will offer inspiration and interaction on these major themes:

Resilience

- Supply-side volatility and risk with a focus on fiber supply.

- Human risk factors such as attracting and retaining skills.

- Reliance on supplier knowledge as opposed to in-house skill.

- Cyber security and the vulnerabilities that increase with greater connectivity.

Operational Game Changers

- Change drivers such as sustainability — including the need to ditch single-use plastics, its implications through the supply chain and the potential gains from upgrading.

- Assessing the return on investment of upgrading America’s tissue-making assets.

- Managing change – from evolving routes to market to technological adaptation imposed by such external factors as legislation and customer demand.

Buyer Expectations

- Trends and forecasts.

- The contrasting shopper propositions of in-store vs. online.

- AfH – the rise of e-commerce and the challenge of cut-price entrants.

For more information about Tissue World Miami 2020, visit:

Registration: https://www.tissueworld.com/miami/en-us/register

Exhibitor List: https://exhibitors.informamarkets-info.com/tissue-world-miami-2020/

Conference Sessions: https://www.tissueworld.com/miami/en-us/conferencesessions

BillerudKorsnäs postpones the annual maintenance shutdown at Gruvön

Due to current circumstances regarding the Covid-19 virus, BillerudKorsnäs postpones the major parts of the maintenance shutdown initially planned to be held week 13, 2020 at Gruvön.

– We have decided that during the current circumstances it is not possible to follow through the maintenance shutdown as initially planned. Further, we must also consider the risk of infection for our employees, but also the many suppliers and contractors who were scheduled to come to Gruvön, says Ivar Vatne, CFO at BillerudKorsnäs.

– We have decided that during the current circumstances it is not possible to follow through the maintenance shutdown as initially planned. Further, we must also consider the risk of infection for our employees, but also the many suppliers and contractors who were scheduled to come to Gruvön, says Ivar Vatne, CFO at BillerudKorsnäs.

The additional negative financial effects of postponing the maintenance shutdown is calculated to MSEK 40-100 for the full year of 2020. BillerudKorsnäs closely monitors the development and is now planning, together with contractors, to carry out the maintenance shutdown in Gruvön during the third quarter of 2020.

The ramp-up of KM7 continues to be BillerudKorsnäs’ number one priority for 2020. An additional consequence of the postponed maintenance shutdown is that BillerudKorsnäs adjusts the previously communicated negative earnings interval by MSEK 100 to MSEK 250-450 for the full year 2020. Focus remains on producing coated material and we expect to launch the process of certifying materials during the second quarter of 2020.

Other financial effects related to Covid-19 have so far been fairly limited. At this stage, it is too early to estimate to what extent Covid-19 will affect BillerudKorsnäs long-term.

ABB to upgrade paper machine drives, motors and electrical control systems at WestRock mill in Washington, USA

Leading US paper and packaging producer looks to increase reliability and performance with dry end drive system replacement.

WestRock Company—a leading provider of differentiated paper and packaging solutions—has selected ABB to replace its dry end drive system. This includes upgrades to its PM12 paper machine drives, motors and the installation of the ABB Ability™ System 800xA control system at its mill in Longview, Washington, USA. Installation and commissioning of the project is planned for completion by year-end 2020.

WestRock Company—a leading provider of differentiated paper and packaging solutions—has selected ABB to replace its dry end drive system. This includes upgrades to its PM12 paper machine drives, motors and the installation of the ABB Ability™ System 800xA control system at its mill in Longview, Washington, USA. Installation and commissioning of the project is planned for completion by year-end 2020.

“ABB was chosen for this project based on the customer’s positive experience with our drives systems at its Longview mill and other WestRock sites,” said Steve St. Jarre, Head of Business Development, Pulp and Paper, Process Industries, ABB. “We were able to provide a cost-effective, phased approach to this upgrade project. We set up a new 800xA system to control both existing and new drives. The existing drives can be replaced as needed and use the same control platform as the mill evolves.”

The new ABB drive system will have a smaller footprint and require minimal parts. The modular drives are extremely compact, but with all of the parts easily accessible. This not only reduces interruption to production for planned and unplanned maintenance, but also reduces spare part inventories.

“With our aim of improving reliability and productivity, without the need for extensive downtime during installation, ABB offered a practical approach to achieve our goals,” said Rick Siragusa, Project Manager at WestRock. “We look forward to moving forward with the replacement.”

The Annual General Meeting of Metso Corporation postponed due to coronavirus outbreak

Due to the current coronavirus outbreak, the Finnish government has announced its intention to issue a presidential decree to commission the Emergency Powers Act (Valmiuslaki 1552/2011, as amended) on Tuesday, March 17, 2020, adopting multiple restrictive measures, including the prohibition of public gatherings of over 10 people. Due to this, as Metso takes the threat of the coronavirus seriously, Metso’s Board of Directors has decided to postpone the Annual General Meeting, which was scheduled to be held on Friday, March 20, 2020. The Annual General Meeting will be held as soon as permitted by future developments concerning the coronavirus outbreak. A notice to the Annual General Meeting will be issued at a later stage.

Due to the current coronavirus outbreak, the Finnish government has announced its intention to issue a presidential decree to commission the Emergency Powers Act (Valmiuslaki 1552/2011, as amended) on Tuesday, March 17, 2020, adopting multiple restrictive measures, including the prohibition of public gatherings of over 10 people. Due to this, as Metso takes the threat of the coronavirus seriously, Metso’s Board of Directors has decided to postpone the Annual General Meeting, which was scheduled to be held on Friday, March 20, 2020. The Annual General Meeting will be held as soon as permitted by future developments concerning the coronavirus outbreak. A notice to the Annual General Meeting will be issued at a later stage.

METSO CORPORATION

Valmet completes the co-determination negotiations in the Fabrics Business Unit

Valmet has completed the co-determination negotiations in the Fabrics Business Unit’s operations in Tampere, Finland. The negotiations were started on January 21, 2020. The target is to ensure the unit’s profitability and future competitiveness.

Valmet will relocate the dryer fabric and wide filter fabric production from Finland to Portugal. As a consequence of the relocation and re-organizing of the work, the need for workforce reduction in Tampere will be 78 persons mainly during 2021. In addition, the possibility for temporary lay-offs and part-time work remains if capacity adjustments need to be done later this year. For those affected by the reductions, Valmet will provide support measures like support for studies and re-employment.

Valmet will relocate the dryer fabric and wide filter fabric production from Finland to Portugal. As a consequence of the relocation and re-organizing of the work, the need for workforce reduction in Tampere will be 78 persons mainly during 2021. In addition, the possibility for temporary lay-offs and part-time work remains if capacity adjustments need to be done later this year. For those affected by the reductions, Valmet will provide support measures like support for studies and re-employment.

Earlier Valmet estimated that the co-determination negotiations would lead to a workforce reduction of 90 persons at the maximum and possible lay-offs and part-time work.

Fabrics Business Unit employs altogether approximately 500 persons in Tampere. Fabrics develops and manufactures press felts, shoe press belts, dryer fabrics and wide filter fabrics in Tampere. Valmet’s location in Portugal, to which the dryer fabric and wide filter fabric production is relocated, develops and manufactures filter fabrics and other industrial textiles.

The winning design of the Better with Less – Design Challenge presents an ecological alternative to single-use plastic

Metsä Board is delighted to announce the winner of its international packaging design competition the Better with Less – Design Challenge. ‘Expandable Eco Street Food Ware’ is a smart and ecological solution that addresses the growing demand for street food packaging and to find an alternative to the use of plastic. This year sustainability, and the dual role of packaging, played an especially strong role among the participating designs.

The winner is a highly adaptable plastic-free packaging solution that can provide a simple and trendy alternative to plastic and styrofoam containers which are typically used to serve fast food. The paperboard container is 10 inches in diameter when laid flat and can be folded up to eight different ways ranging from a cone to a plate. The simple design therefore has many applications and can accommodate many types of food.

Besides saving material, the design minimises the space occupied by the container during storage as well as in disposal and recycling. The Expandable Eco Street Food Ware was designed by Christine Gamboa, a Senior Art Director, and Gaudy Danao III, an Associate Creative Director, both from the Philippines. Christine and Gaudy will receive the main prize of 7,000 euros.

“The winning design is a simple, smart and practical solution offering high variability with minimal material use – reflecting “Better with Less” at its best. It provides a good user experience and is truly environmentally friendly and economical. Made of a plastic-free barrier board it is easily recyclable, compostable and biodegradable,” says the competition’s chairman, and the member of the jury, Ilkka Harju, Packaging Services Director at Metsä Board.

The winner of the second prize, 2,000 euros, is ‘Bruk’, a sustainable beverage carton that can be easily recycled with reduced plastic content, designed by Eric Smith from the United States. The third prize, 1,000 euros, went to ‘Razor’ that replaces standard plastic packaging by a minimalist paper box that covers only the razor heads while leaving the handles uncovered. The design was created by Magdalena Schmitz, Sarah Redlich, Mikayla Just and Alejandro Don Flores, all students in product design at the Münster School of Design.

“In the winning designs sustainability and circular economy aspects were well considered and innovatively implemented, and the competition between the top three was very tight. There were many inspiring solutions reflecting a shift in consumer trends from plastic towards more sustainable packaging materials. In some designs, the packaging had a dual role, becoming a part of the product when using it, which further strengthens the circularity of packaging,” says Ilkka Harju, Packaging Services Director at Metsä Board.

Metsä Board also offered an additional prize of an internship for one student at its new upcoming Paperboard and Packaging Excellence Centre in Finland. ‘Reload’ that allows the storage and sorting of full and empty batteries in the same package won the judges over in the student category. The package is designed by Hamzeh Za’balawi, Franziska Prior, Marcel Diederich and Oliver Ricker. In addition, an honorary mention went to Jasper Chou’s Project FF that is a sustainable glueless container for French fries and ketchup.

The international packaging design competition Better with Less – Design Challenge 2019–2020 was organised by Metsä Board, part of Metsä Group. The competition was arranged to challenge designers to create more environmentally friendly solutions for some of the most frequently used consumer packaging. As many as 146 entrants from 28 countries joined with their ideas. The jury included packaging design influencers from around the world.

Learn more about the winning design and the finalists from the competition website, betterwithless.org