Ian Melin-Jones

Rottneros Appoints New CFO

Tomas Hedström (MBA) will take up his appointment as CFO for Rottneros AB on 1 May 2010. Tomas Hedström, who has among other things been engaged as an accountant at PricewaterhouseCoopers, is coming to us from the SCA Group where he was responsible for the Corporate Finance Department. Prior to this, he held various financial posts within SCA's Swedish and global operation.

Tomas Hedström replaces Karl Ove Grönqvist, who decided to leave Rottneros in May.

For further information please contact: Ole Terland, CEO, +46 8 590 010 00

Rottneros discloses the information provided herein pursuant to the Securities Markets Act and/or the Financial Instruments Trading Act. The Information was submitted for publication on Thursday 25 March 2010 at 12.30 CET.

SKS Vision Systems Oy and Opto-Control Oy joining forces

SKS Vision Systems Oy has announced 15.3.2010 the acquisition of all business operations of Opto-Control Oy. The business will be operated under the name SKS Vision Systems Oy.

The incorporation of these two companies with decades of expertise in optoelectronics, as well as measuring and quality control systems based on machine vision gives SKS Vision Systems the opportunity to offer fully comprehensive service providing the widest range of products.

- Business acquisition strengthens our product range in optical measurement, detection application and sensor technology. Through the acquisition, additional outlets and resources will be available. This will create new growth opportunities in international markets, SKS Vision Systems Oy Kari Rahkola says.

The managing director of Opto-Control Oy, Mr. Lars-Erik Lindelöf will operate as SKS Vision Systems Oy Sales Manager.

Further information is given by Managing Director Kari Rahkola, int. +358 207 648 971, mobile +358 400 641 349 or email address This email address is being protected from spambots. You need JavaScript enabled to view it. or Sales Manager Lars-Erik Lindelöf, int. +358 50 596 0643.

SKS Vision Systems Oy

Kari Rahkola

Managing Director

Duroblade®-Velvet™: More softness, more bulk, lower costs

The newest member of BTG's Duroblade family delivers extra-soft, extra thick tissue in both wet and dry creping applications.

BTG's Duroblade-Velvet™ has been specially developed to meet the needs of mills working in one of today's fastest-growing, most competitive markets. As global demand for tissue continues to grow steadily, thanks to new applications in segments like personal care and household cleaning, consumers are constantly on the look-out for softer, more luxurious products.

BTG customers working with both wet crepe and dry crepe machines are already reporting significant benefits in trials of Duroblade-Velvet, in terms of both product quality and overall production costs. Two test-bed mills both improved tissue bulk without any other changes to their production process, with one of them also able to reduce their fiber costs without any loss of product quality.

In dry creping, a mill which was already using Duroblade-Softcrepe™ blades was looking to further improve blade lifetimes and chip-resistance, while boosting tissue softness. BTG field engineers conducted a comparative trial with Duroblade-Softcrepe and Duroblade-Velvet set at a 75° bevel, retaining the same basis weight of 14.2 g/m2 and the same process conditions. The result was an 8% increase in tissue bulk, with Duroblade-Velvet delivering sheet thickness of 117.3 against the Softcrepe blade's 108.4. Chipping was reduced, and the end product retained its exceptional hand feel softness.

Cut back on furnish costs

In addition to improving tissue quality, Duroblade-Velvet gives manufacturers the option of lowering the basis weight of the paper, for significant potential savings on furnish costs as well as the ability to increase machine speed to boost output.

For applications where higher bulk is not needed, setting a 5° sharper blade bevel can achieve the same bulk level with a finer creping structure – a useful option for further improving hand feel softness and smoothness without any loss of bulk.

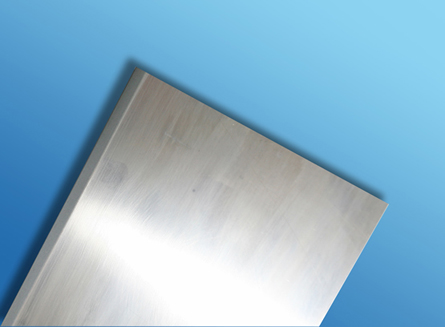

Figure 1: BTG's new creping doctor: Duroblade-Velvet

Top-performing choice

Meanwhile, another BTG customer using a wet crepe machine to manufacture different towel grades (22-48 g/m2) and napkins (18-19.5 g/m2) wanted to retain the high bulk his products require while significantly improving blade lifetimes and quality consistency.

The mill manufactures towel grades using CTMP plus broke, and uses 100% virgin pulp for all other grades. Its regular 90° steel and long life creping blades could only deliver lifetimes of 6-12 hours, necessitating frequent blade changes and lost production time. Add to that the fact that the production process is a little different from a standard wet crepe application, and it was clear an innovative solution was called for.

BTG engineers' goal was to find a solution that could deliver at least 30 hours' blade lifetime, with high bulk, stable quality consistency, and good machine runnability. They chose to trial both Duroblade-Standard blades and Duroblade-Velvet blades in 90°, alongside the mill's standard steel blades – an inspired choice, since Duroblade-Velvet blades had not previously been used in wet creping.

The result: Duroblade-Velvet not only achieved 50 hours' blade life with very stable runnability, it delivered the best bulk results of all three blades tested, allowing the mill to reduce Basis Weight by 3% (1.3g), and to use 50% more broke in the mix without any loss of bulk compared with production using steel blades. That 3% reduction has resulted in huge savings on fiber costs – and one very happy customer.

CTS Engtec gains Membership of Russian SRO

CTS has got a membership of SRO for practicing design activities in Russia. Scope of this engineering license covers company´s earlier Russian engineering licenses.

The earlier license obtaining practice has been changed at the end of year 2009 to a system where companies apply for membership of so called self-regulated organizations (SRO) which have been established especially for this purpose. Federal environment and technology organization Rostechnadzor has given for particular, non commercial organizations a right to grant certificates for practicing design activity in Russia.

The certificates can be granted without time limitations for activity for both domestic and foreign companies.

CTS Engtec has a lot of experience in the design of demanding paper, board and pulp mill projects as well as in the design of energy systems for paper, pulp and the mechanical forest industries in Russia. The company has an excellant technical knowledge of renewable energy sources e.g CHP- plants (combined heat and power) and bioenergy plants.

The company can provide Russian clients conceptual study, pre-study and pre-engineering, basic and detail engineering, environmental technology services, project management and maintenance engineering.

CTS's flexible organization and working methods are particularly adapted for implementing rebuild projects as well as green field mill projects in Russia and around the world.

m-clean opens project office in Shanghai, China

In order to support our expanding business in China and Asia m-clean papertech AB opened a project office in Shanghai 2010-03-01. In addition to project handling this will also be our Asian center for service and after market with stock of most common spare parts. The office is already in full operation and welcomes all your inquiries.

Contact information:

Miikka Salonen

Regional Manager Asia – Pacific

+86 138 1727 8002

Bobbie Xu

Aftermarket support and service China

+86 139 1868 9221

Metso’s high speed all-in-one tissue sensor goes non-nuclear

After extensive field testing in tissue mills, Metso is now delivering a new all-in-one sensor which measures tissue fiber weight and moisture simultaneously in the PaperIQ Select quality control system. The new sensor, called IQFiber, measures fiber weight and moisture on the same spot of paper using a multi-channel infrared detector. The need for a traditional basis weight sensor with a nuclear source has been eliminated. Therefore, the time and costs involved in nuclear safety training, nuclear licenses and specialized service and safety requirements have been eliminated.

IQFiber is installed in numerous tissue mills using virgin pulp or 100% recycled furnish. Users of the IQFiber sensor report lower maintenance and cleaning requirements, leading to increased productivity. Also, with more precise control over dry fiber weight, tissue makers have been able to reduce target sheet weight at the same quality, thereby saving valuable fiber furnish.

The speed of response and signal to noise ratio of the IQFiber measurement are significantly better than traditional nuclear sensors, making it most appropriate for the detection of transient or cyclical variations and allowing more precise control. The MD variability in the sheet is detected at a very fast 1 kHz sampling rate and the CD streak resolution is 5 mm. The signature frequency components of these fast-responding online measurements are determined by the spectral analysis capability built into the PaperIQ Select system. This high speed measurement analysis adds a significant troubleshooting capability to the system, making it possible to perform detailed online variability studies and to make process improvements.

For further information, please contact: Seyhan Nuyan, Director, Paper Applications, tel. +1 678 575 0448

50th Annual Survey of Paper, Paperboard and Pulp Capacity

The American Forest & Paper Association (AF&PA) today released its 50th Annual Survey of Paper, Paperboard, and Pulp Capacity, which reported that U.S. paper and paperboard capacity declined 2.5 percent in 2009 to 93.9 million tons. The decline took place against a backdrop of a severe global economic recession. Paper and paperboard production is rebounding from the recession-induced lows reached in early 2009.

The Survey also reported that 14 U.S. mills were permanently closed in 2009, shutting down 16 paper and paperboard machines, and an additional 11 machines were permanently shut down at other mills. Furthermore, several mills and machines have been indefinitely idled in response to weak market conditions, but have not been removed from the Survey base because they may be restarted at some future date.

According to data reported to the Survey, total paper and paperboard capacity is expected to decline 3.4% in 2010 and then remain essentially stable in 2011 and 2012.

The Survey reports U.S. industry capacity data for the years 2009 through 2012 for all major grades of paper, paperboard, and pulp, based on a comprehensive survey of all U.S. pulp and paper mills. Survey respondents represent about 90 percent of the U.S. industry capacity.

The complete Survey with detailed tables can be purchased for $1,650 by contacting Michelle Gaskins at AF&PA (202-463-5162, This email address is being protected from spambots. You need JavaScript enabled to view it.).

For More Information:

This email address is being protected from spambots. You need JavaScript enabled to view it.

SCA one of the world’s most ethical companies

For the third consecutive year, SCA has been named one of the world’s most ethical companies by the Ethisphere Institute. According to the Institute, the ranking list recognizes companies that go beyond making statements about doing business “ethically” and actually translate those words into action.

Of the 3,000 companies worldwide that took part in the survey, only 100 made the 2010 list.

Says Ulf Söderström, Senior Vice President for Business Development and Strategy at SCA, who is responsible for the Group’s sustainability work:

"We are pleased to have qualified as one of the most ethical companies in the world for the third consecutive year. The award is a recognition of how the Group's employees are successful at managing our extensive operations in a responsible way, and how we let our core values of Respect, Excellence and Responsibility guide us in everything we do."

Read more at www.ethisphere.com/wme2010. For further information about SCA’s sustainability work, visit www.sca.com/sustainability, where you can download the Group’s latest sustainability report.

For additional information, please contact

Jörgen Olsson, Press and Media Officer, +46 8 788 51 29

Chinese Rayon Producer Buys Minority Interest in Neucel Specialty Cellulose

Chinese Rayon Producer Buys Minority Interest in Neucel Specialty Cellulose

Zhejiang Fulida Ltd. has taken a direct minority investment in Neucel Specialty Cellulose Ltd. and signed a long-term supply agreement to procure Neucel's chemical cellulose product. Fulida is one of the leading producers of rayon in the world.

Neucel plans to use the investment to accelerate its capital plan targeted mainly at capacity expansion in addition to cost and quality improvements.

"This partnership will enable us to gain an improved market presence in China and solidify our strong position in both the viscose and specialty markets," said Bob Taylor, president and CEO of Neucel.

"Viscose rayon fibre production capacity has increased greatly in China and competition has become intense. With the relationship with Neucel, Fulida gains a smooth and stable supply of dissolving pulp materials," said Jainer Qi, CEO of Fulida.

Neucel plans to deploy the available capital immediately to keep pace with the high customer demand in the chemical cellulose market. The company notes that this capital will complement the funding provided by the Government of Canada's Pulp and Paper Green Transformation Program to further reduce its energy consumption.

Metso to supply board making technology to Cheng Loong Corporation in Taiwan

Metso will supply board making technology for Cheng Loong Corporation for their new containerboard production line at Hou-Li paper mill in Taiwan. The production line is scheduled to start up in the second quarter of 2011. The value of the order exceeds EUR 20 million. The order is included in Paper and Fiber Technology's Q1 orders received.

Metso's delivery will include three headboxes for the 3-ply liner machine with a dilution profiling system for the back ply, a press section and a film size press. The dryer section will be equipped with a moisturizing unit for web moisture profile control.

Established in 1959, Cheng Loong Corporation has four paper mills and five paper box plants in Taiwan. The company's annual production capacity of paper and paperboard is approx. 1.8 million tons.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press, please contact:

Hannu T. Pietilä, Vice President, Sales, Paper business line, Metso

Tel. +358 40 503 4085

Further information for investors, please contact:

Johanna Henttonen, Vice President, Investor Relations, Metso Corporation, tel. +358 20 484 3253