A consortium has received a £150,000 grant to develop a plentiful source of renewable chemicals, currently seen as a waste product of the paper industry, to help break our dependence on oil-based plastics.

The grant, which forms part of the Technology Strategy Board’s ‘Sustainable high value chemical manufacture through industrial biotechnology’ technical feasability competition, will help a research team led by Biome Technologies to develop a new source of organic chemicals for the production of bioplastics, that could accelerate growth in the market and lead the way for a bio-based chemicals industry.

Using biological materials to make industrial products is recognised by the UK government as a promising means of developing less carbon-intensive products and processes, with an estimated value to the UK of between £4bn and £12bn by 2025.

Although present-day bioplastics are based on natural materials, some oil-based chemicals are widely used in their manufacture to provide qualities such as mechanical strength, tear resistance and durability.

Phasing these out and providing them instead from natural materials could, the researchers believe, significantly reduce costs, expand functionality and increase performance in bioplastics, enhancing their ability to compete with, and ultimately replace, conventional oil-based plastics.

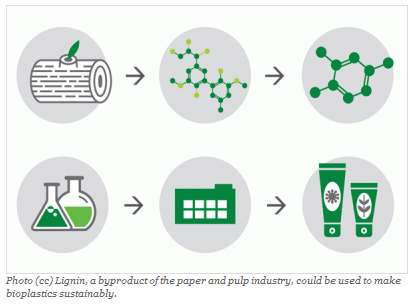

One such source is lignin, a complex hydrocarbon that helps to provide structural support in all plants, but which is currently seen as a waste product of the pulp and paper industry.

It is therefore a potentially abundant feedstock.

Biome has partnered with the University of Warwick’s Centre for Biotechnology and Biorefining that is pioneering academic research into lignin degrading bacteria, to develop methods to control the lignin breakdown process to determine whether these chemicals can be extracted in significant quantities.

“The environmental and social concerns surrounding the use of fossil fuels and food crops make lignin a compelling target as a source of chemicals,” explained Professor Tim Bugg, director of the centre.

“Often considered a waste product, it may provide a sustainable source of building blocks for aromatic chemicals that can be used in bioplastics”.

The TSB grant will support a feasibility project to isolate a chemical from lignin to replace the oil-derived equivalent currently used in a polyester that conveys strength and flexibility in some of Biome’s products.

If successful, Biome will explore the possibilities for deriving a wider selection of bio-based aromatic chemicals from lignin.

“The bioplastics market remains small compared to that of fossil-based polymers," comments Biome Bioplastics CEO Paul Mines. “Growth is restricted by the price of bioplastic resins being two to four times that of their petrochemical counterparts. We anticipate that the availability of a high performance polymer, manufactured economically from renewable sources would considerably increase the market”.