Displaying items by tag: Metso Group

Metso supplies a recovery boiler to Grasim Industries in India

Metso will supply the Harihar Polyfibers unit of Grasim Industries Limited with a recovery boiler to replace the two existing recovery boilers at the rayon grade pulp mill located in Kumarapatnam, Karnataka state, India. Start-up of the boiler is scheduled for the Q3 of 2012. The value of the order is not disclosed. The order is included in Energy and Environmental Technology’s Q4/2010 orders received.

Metso’s delivery includes the main equipment and piping and standard equipment for the recovery boiler as well as field instruments.

The new recovery boiler will improve steam generation and help lower operating and maintenance costs over the mill’s two present bidrum recovery boilers. “We entered into a contract with Metso for a new recovery boiler as replacement for existing boilers for ensuring safe and reliable operation and enhanced environmental performance. This recovery boiler project is prestigious for Harihar plant”, says Mr. Rajendra Jain, Executive President, Harihar Polyfibers.

Metso’s Power business line established its operation in India in 2008, and since then the business operation has scaled up as a regional center to cater to the regional market. In 2009 India was the Metso Group’s 11th largest country in terms of orders received with EUR 117 million. India was also 12th largest country in terms of Metso Group’s net sales with EUR 131 million. The Metso Group has altogether about 700 employees in India.

Grasim Industries Limited, part of Aditya Birla Group, is the largest exporter of Viscose Rayon Fiber (VSF) in India, with an aggregate capacity of 333,975 tpa. The Harihar Polyfibers unit houses facility for manufacture of both VSF and rayon grade pulp, the basic raw material for VSF.

Metso supplies pulp mill equipment for Eldorado Celulose e Papel in Brazil

Metso will supply a new recovery boiler and evaporation plant for Eldorado Celulose e Papel S.A.’s new greenfield pulp mill investment in Três Lagoas, Brazil. The value of the order is not disclosed. The order will be included in Energy and Environmental Technology’s Q4/2010 orders received. The start-up of the new plant is scheduled for Q4/2012.

The recovery boiler will be the largest on the American continent, with capacity of 6.800 tons of dry solids per day (tDS/day) and steam generation of 308 kg/s. The evaporation plant will be the largest single line evaporation plant in the world, with 6 thermal stages and capacity of 1600 tons per hour.

“The definition and dimension of the equipment supplied by Metso, shows a concern not only with the return on investment, but also with the search for solutions that add high technology to sustainable industrial processes. An example is the recovery boiler supplied by Metso, it is part of the process generating clean energy, obtained from the renewable raw material, in this case, the biomass residue of eucalyptus,” says Carlos Monteiro, Industrial Director, Eldorado Celulose e Papel S.A.

Eldorado Celulose e Papel S.A. is a newly established pulp company and a newcomer in the pulp and paper industry, but already has plans to build three parallel pulp lines to produce a total of 5 million tons per year when the project is complete. The company is owned by J&F Holding and MCL Enterprises, most notably known for business in the food segment.

Metso supplies a wash press to Mondi Richards Bay in South Africa

Metso will supply a new wash press to Mondi’s Richards Bay mill in South Africa. The Mondi Richards Bay mill, commissioned in 1984, produces more than 720,000 tonnes of bleached pulp per year, using mainly eucalyptus from own plantations as raw material. Start-up of the new wash press is scheduled for end of 2011. The value of the order will not be disclosed.

Metso’s delivery will include a TwinRoll Evolution wash press, basic and detail engineering and site services. The new wash press will allow Mondi to improve the existing brown stock washing process at the mill.

Mondi is an international paper and packaging company, with production operations across 31 countries and revenues of EUR 5.3 billion in 2009. The Group's key operations are located in central Europe, Russia and South Africa and employed 31,000 people on average in 2009.

Metso-supplied fine paper line starts up at Shandong Huatai Paper in China

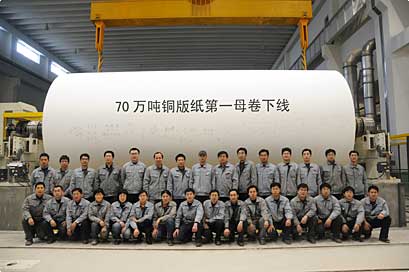

The Metso-supplied coated fine paper production line, PM 8, of Shandong Huatai Paper Co. Ltd came successfully on stream on Jan 18, 2011 in Dong Ying City, Shandong Province, China.

The 8.1-m-wide PM 8 has an annual dimensional production capacity of close to 700,000 tonnes of coated and uncoated fine papers within the basis weight range of 80 to 200 g/m2. The paper machine design speed is 1,800 m/min and the coater design speed is 2,000 m/min.

Metso's delivery included a complete Metso OptiConcept paper machine from headbox to reel. The paper machine line also comprises a re-reeler and an off-machine coater with coating stations, off-machine OptiLoad multinip calenders, winders, a parent reel handling system and a comprehensive Metso automation system package. The production line was started up with a Metso wet end machine clothing package.

"The PM 8 start-up was successful thanks to the state-of-the-art equipment supplied by Metso and the strong co-operation between Huatai's and Metso's project teams. Based on the good experience with Metso Huatai looks forward to producing high-quality art paper in the near future," states Wei Lijun, General Manager of Huatai PM 8 art paper line.

The first parent roll from the Metso-supplied coated fine paper production line PM 8 of Shandong Huatai Paper on January 18, 2011. Photo: courtesy of Shandong Huatai Paper.

Shandong Huatai Paper Co. Ltd. is a member of the Huatai Group. The Huatai Group has five production bases, Huatai Green Industry Park, Huatai Qinghe Green Ecology Industry Park, Rizhao Huatai Pulp & Paper Industry Park, as well as Guangdong Huatai and Anhui Huatai Industrial Parks, with an annual capacity of around 3 million tonnes.

Metso-supplied tissue making line starts up in Mexico

The Metso-supplied tissue making line of SCA in Mexico came successfully on stream on November 15, 2010, at SCA’s greenfield mill site in Ciudad Sahagún, Hidalgo State, close to Mexico City. The new PM 1 line has an annual production capacity of 60,000 tonnes of high-quality facial, toilet and towel grades.

Metso’s scope of delivery comprised a complete turn-key tissue production line. The production line is fully Metso-engineered and optimized with regard to energy savings, production efficiency and quality. The scope of supply included a tissue machine, deinking plant, effluent plant, stock preparation system, a mill-wide automation package, and also all other auxiliary equipment and systems needed for the mill. Transport, installation, training, start-up and commissioning were also included in the delivery. The combination of Metso’s wide hardware portfolio and extensive know-how and project services has created a highly competitive production unit.

“Within Metso we have the best professionals and very committed people to make such an extensive project as this possible. The installation at the site was finalized timely with high quality and in flawless cooperation with the SCA project team,” says Dan Finnerman, Vice President, Project Management, Tissue business line, Metso.

The civil engineering and building construction was handled by SCA. Special attention was paid to the interaction between the civil engineering and Metso’s plant design.

”Metso supplied a very complete solution for the tissue mill. The SCA project team worked closely with Metso throughout all phases of the projects. Support and cooperation from Metso was excellent. The tissue machine start-up went very smoothly,” said James Haeffele, Vice President, Tissue Technology for SCA North America and Project Director for the Sahagún greenfield tissue mill project.

Metso Corporation's Financial Statement 2010

Metso Corporation's Financial statements will be published on Thursday, February 3, 2011 at about 12:00 p.m. Finnish time/EET (10:00 a.m. GMT, 11:00 a.m. CET, 5:00 a.m. EST)

The news conferences

Metso will hold two news conferences in Helsinki on Thursday, February 3, 2011

• The press conference for media in Finnish will be arranged at 1:30 p.m. - 2:15 p.m. Finnish time

• The news conference with live webcast and conference call for investors and analysts in English will be arranged at the following local times:

• 03:00 p.m. EET (Helsinki)

• 01:00 p.m. GMT (London)

• 02:00 p.m. CET (Paris)

• 08:00 a.m. EST (New York)

Both events will take place at Metso Group Head Office, Fabianinkatu 9 A, Helsinki, Finland.

The news conference in English can also be followed through a live webcast at www.metso.com/investors or through a simultaneously arranged conference call. Due the live webcast, we are kindly asking those attending the news conference starting at 3:00 p.m. EET, to be present 5 minutes prior the start of the event.

Conference call details

Conference call participants are requested to dial in a few minutes prior to the start of the teleconference

• US: +1 334 323 6201

• other countries: +44 20 7162 0025 or +44 20 7162 0077

• please quote: : 885192

A replay will be available for 7 days until midnight on February 11, 2011 on the following phone numbers:

• US: +1 954 334 0342

• other countries: +44 20 7031 4064

• access code: 885192

After the news conference there will be an audio file (mp3) available for downloading and at the latest on Monday, February 7 also a transcript of the event at www.metso.com/Investors.

The presentation material will be available after the publishing of Metso Corporation's Financial Statements 2011 at www.metso.com/Investors.

You are most welcome to participate in these events.

Metso Corporation

Metso to rebuild M-real’s board machines at Simpele and Kemiart Liners mills in Finland

Metso will rebuild two board machines for M-real in Finland to increase capacity and improve quality: the cartonboard machine at the Simpele mill and the kraftliner machine at the Kemiart Liners mill in Kemi. The start-up of the rebuilt Simpele machine is scheduled for the second quarter of 2011 and that of the rebuilt Kemiart Liners machine for the third quarter of 2011. The combined value of the orders is below EUR 20 million. The order is included in Paper and Fiber Technology’s Q4 orders received.

Metso's delivery to the Simpele mill will include a rebuild of the forming section, press section including a new shoe press and the dryer section. After the rebuild, the annual capacity of the Simpele mill will be approx. 300,000 tonnes, making the Simpele machine the biggest folding boxboard machine in Europe.

Metso’s delivery to the Kemiart Liners mill will include a coating section rebuild. Additionally, a coating drying rebuild will replace old gas infrared dryers with energy efficient high-drying-capacity air dryers. The rebuild will further improve the coated white top liner quality produced.

M-real is Europe’s leading primary fibre paperboard producer and a major paper supplier. The company’s customers include brand owners, carton printers, converters, publishers, printing houses, merchants and office suppliers. In 2009, the company’s sales totalled EUR 2.4 billion, and it has approximately 4,700 employees. M-real is part of the Metsäliitto Group.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

For further information for the press, please contact:

Mikko Tani, Vice President, Sales, Paper business line, Metso, tel. +358 40 564 2007

Metso wins Best Automation Award from Brazilian Technical Association of the Pulp and Paper Industry

ABTCP, the Brazilian Technical Association of the Pulp and Paper Industry, has chosen Metso to be the best company of the Automation category in 2010. The award was granted to Metso on October 5, 2010 at the ABTCP congress and exhibition in Sao Paulo, Brazil.

The main criteria for the selection were the innovativeness of the automation supplier, the latest technology, the level of service and industry performance.

Metso has been on the Brazilian market since 1975. The country is currently a growing market for new investments. Metso has been able to win significant orders from the pulp and paper as well as the oil and gas industries. For example, Klabin, Celulose Nipo-Brasileira S.A. (Cenibra) and Suzano,Papel e Celulose S.A. are relying on Metso’s automation technologies.

During the years, Metso’s product range has been developing toward a comprehensive product offering, from process audits to life cycle performance agreements. Today, the main emphasis is on offering results that decrease raw materials, maintenance costs, chemical and energy consumption as well as support the environmental issues with high reliability. Metso’s automation based on a single platform approach with common hardware saves money for customers. All the different types of controls are within the same platform. This results in one user interface. No links are necessary between the systems.

ABTCP, the Brazilian Technical Association of the Pulp and Paper Industry, arranges a pulp and paper related congress and exhibition every year. The events organized are well established in the field; every year about 15,000 professionals visit the exhibition. This year saw the celebration of the 43rd event. More than 160 exhibitors were present.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press, please contact:

Marcelo Motti, Vice President, Sales & Service, South America, Metso, Tel. +55 15 2102 9708, This email address is being protected from spambots. You need JavaScript enabled to view it.

Aija Kalander

Communications Director

Energy and Environmental Technology

Metso Corporation

Lentokentänkatu 11, P.O. Box 237, 33101 Tampere, Finland

Tel. +358 20 483170, mobile +358 40 555 1637

This email address is being protected from spambots. You need JavaScript enabled to view it.

Metso to supply tissue line to ICT in France

Metso will supply a complete tissue production line to the Italian Industrie Cartarie Tronchetti group. The tissue line will be installed at Montargis in France. The line will be started up in the second quarter of 2011. The value of the order that was received in April will not be disclosed.

Metso's delivery will comprise a complete tissue production line with stock preparation equipment and an Advantage DCT 200 tissue machine including an OptiFlo II TIS multi-layer headbox, a Metso Yankee cylinder, an Advantage AirCap hood, an Advantage WetDust dust management system and an Advantage SoftReel reel. The production line will be optimized to enhance final product quality and save energy. The delivery will also comprise an extensive Metso automation package including metsoDNA machine, process and integrated drive controls, as well as a PaperIQ Select quality control system with an IQScanner-i scanner and an IQFibre sensor.

With a width of 5.6 m and an operating speed of 1900 m/min, the new production line will produce 60-70,000 tons/yr of high-quality facial, toilet and towel grades. The raw material for the new line will be virgin pulp.

Industrie Cartarie Tronchetti is headquartered in Lucca, Italy, and operates mills in Italy, Spain and Poland with a combined capacity of 400,000 tons a year, has a turnover of more than €500 million and around 1000 employees. The group has been present in France since 1999 through its sales organization based in Paris.

Metso Group to donate funds to Finnish universities

Metso Corporation's Annual General Meeting on March 30, 2010 authorized the Board of Directors to decide on a donation of a maximum of EUR 2.5 million to universities.

On the basis of the decision made by the Annual General Meeting, Metso has decided to grant a donation of EUR 1.9 million to Aalto University Foundation. Metso is directing donations to other universities as follows:

- Tampere University of Technology's TUT Foundation EUR 350,000

- University of Jyväskylä EUR 100,000

- Åbo Akademi University EUR 50,000

- Lappeenranta University of Technology EUR 50,000

- University of Oulu EUR 50,000

With these decisions, the donation authorization granted by the Annual General Meeting has been exercised in full.

"Metso appreciates its cooperation with frontline universities around the world. These donations strengthen the new financing model aligned together by the Finnish government and the economic life to support the ability of Aalto University and four other Finnish universities to provide internationally competitive research and education” assesses Metso's President and CEO Jorma Eloranta.

Metso is a global supplier of sustainable technology and services for mining, construction, power generation, automation, recycling and the pulp and paper industries. We have about 27,000 employees in more than 50 countries. www.metso.com

Further information for the press, please contact:

Jukka Seppälä, Vice President, Stakeholder Relations and Trade Policy, Metso Corporation, tel. +358 (0)20 484 3106

Further information for investors, please contact:

Johanna Henttonen, Vice President, Investor Relations, Metso Corporation, tel. +358 20 484 3253