Displaying items by tag: pasaban

Pasaban Upgrades Papel Aralar's Non-woven Paper Winder

Paper and board sheeters and winders more than 10 years old, usually need to be refurbished in order to improve their efficiency. For this reason, upgrading this type of machines is the best option, as the return on investment is short-term.

“The upgrade has been a complete success. Thanks to the automations installed, format changing times and reel loading times have been significantly reduced.” These are the words of satisfaction for the work carried out at the Basque mill Papel Aralar. One of the first manufacturers in the world to produce 100% flushable paper, which is natural, biodegradable and can be flushed down the toilet.

In 2015 Pasaban supplied a BM3600 winder for the non-woven paper production line. After 6 years of operation, and after having seen the need to automate several of the machine groups, the areas of improvement have consisted in; automating the longitudinal cut to save time in format changes and installing an automatic empty pope reel ejector, allowing time-saving when loading new reels.

At Pasaban we are proud to collaborate with our clients on innovative projects, especially those that are focused on sustainability and respect for the environment. This is why we would like to thank Papel Aralar for the trust placed in us.

For more information on Pasaban Upgrades service please contact us through the website or call us on +34 943 65 16 32.

Pasaban Service | fast and efficient service at your disposal.

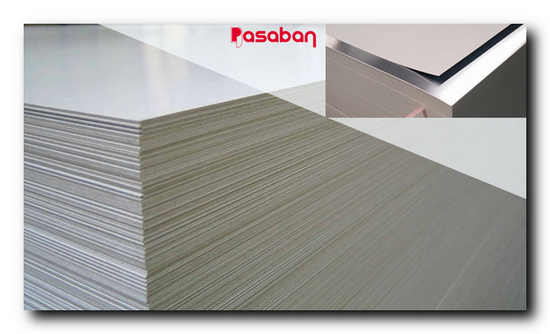

Pasaban Focuses On Upgrades Of Paper And Cardboard Sheeters And Winders

Pasaban Upgrades, the ideal solution to get the best out of your paper and cardboard converting equipment.

Upgrading sheeters and winders is essential if you want to increase the life of old machines and improve their performance.

The benefits of this type of maintenance include increasing the availability and the performance of the machine and improving the quality of the finished product. In turn, you will increase productivity, mitigate obsolescence and enable the automation of some of the machine's processes.

This is why we believe it is essential for companies that have acquired Pasaban machines or machines from other brands such as Jagenberg or Bielomatik to continue to get the most out of these great machines.

Our expertise in the world of converting machines enable us to suggest the best improvement proposals or technological adaptations. Usually by adding new controls, HMIs and simplifying the use and maintenance of old equipment. In this way, we can refurbish, modernize or upgrade the sheeters and winders to the current needs of the customer.

Our commitment is to exhaustively analyse all possible options to improve the performance of your converting machines.

Pasaban Upgrades is part of Pasaban Service, which offers a series of services aimed at manufacturers, converters and packagers or printers. These include Remote support, Maintenance service, online spare parts store and machine relocations.

Finally, and in order to continue offering the best possible service to our customers, we have compiled an up-to-date Upgrades catalogue available at your disposal.

For more information, contact the Pasaban Service department at This email address is being protected from spambots. You need JavaScript enabled to view it., call one of our specialised technicians on +34 943 65 16 32 or send a message to one of our worldwide agents.

COMART installs a new Pasaban paper sheeting machine to increase its cutting capacity

Comart, a specialised distributor in the supply of paper cardboard and flexible films has the largest private warehouse in Spain with a permanent stock of more than 10.000 tonnes of rolls and sheets. It is one of the few distributors that can guarantee a 24-hour supply service in Spain, France and Portugal.

To provide a highly efficient service that covers all the needs of the packaging & graphic industries, Comart offers a wide variety of folding, recycled boards, kraftliner and coated papers. With a workforce of more than 100 people, its 30.000m2 of offices, warehouses and production centres are located in Barcelona, Girona and Toledo (Spain).

Customer challenge.

With the inclusion of Spirax and Sumapel, the new facilities in Barcelona were opened in 2015. Since then, COMART has acquired the latest generation paper sheeting machines, paper winding machines and ream wrappers.

“Within our growth strategy, we saw the need to increase our cutting capacity and widen our range of formats to continue facing up to the challenges of a very competitive market.” Ernest Ginjaume, CEO.

To achieve these objectives and with the clear intention of improving the conversion quality and operations, they contacted Pasaban to jointly study a solution.

The Solution.

To provide the optimum solution Pasaban carried out an extensive analysis of the current situation. The factory required a new machine to substantially increase their cutting capacity and to widen the range of sheet formats. It is for this reason that a turnkey project was proposed with two main actions.

One action was the design and manufacture a new wider-width sheeter with automatic pallet change; the second was to automate the pile delivery system so to transfer the piles of paper to the loading and unloading bays.

The KB 2300 paper sheeting machine is able to manage a wide range of formats with an operating speed of 350 m/min. Equipped with an automatic splicing unwind stand, the sheeter is also capable of changing pallets at maximum speed.

This new paper sheeting machine has allowed COMART to improve the flexibility of the factory.

On the other hand, in order to automate the output of the different sheeting machines several conveyors were installed. Now, the piles of paper leaving the sheeting machines are able to automatically enter into the baler and are directly transferred to the loading and unloading bays.

Thanks to this improvement, the overall efficiency of the plant has been improved. “Pasaban has given us the solution we needed to make the necessary improvements to our factory in Barcelona” Ernest Ginjaume, CEO.

“We are extremely happy with the results achieved. Thanks to this investment we will continue to be a benchmark in the conversion and distribution of paper in southern Europe”, Ernest Ginjaume, CEO

“The continuous investment in automating the factory allow us to improve the internal logistics. It directly impacts on improved speed, efficiency and service quality”, states Lluís Mª Ginjaume, chairman and company founder.

Pasaban, trust and professionalism.

At Pasaban we firmly believe we must continuously offer our customers high quality machines and solutions alongside with an impeccable service to gain their trust. Meeting these requirements is what makes us leaders in the design and manufacturing of machinery for the conversion of paper and cardboard.

Fully customized turnkey projects like the one for Comart are only possible thanks to the know-how of our engineers and a close cooperation with our customers.

Pasaban upgrades one of OKAB Group’s cardboard sheeters

Pasaban upgrades the electrical cabinets of a cardboard sheeter for Okab in order to improve the machine’s performance.

The Okab Group has been providing cardboard and paper converting services to European market since 1969. It originally started converting envelopes, cutting paper sheets and currently provides tailormade converting services such as, sheeting, rewinding and ream wrapping across the entire continent from its plants in France, Germany and Sweden.

Pasaban has been working with the Okab group designing and manufacturing their paper and cardboard sheeting machines for more than two decades. During this time, we have manufactured more than 10 machines, just two of which are now more than 15 years old. That is the case of the KDD 1700, designed to work with high quality coated cardboard.

After analysing the possibilities for upgrading the sheeter, it was decided to update the electronic components. The PLCs, the hardware of the machine’s computer, and the electrical cabinets were replaced.

With this update, all the Okab’s sheeters now use the same technology.

For more information about upgrades to improve your old paper converting equipment performance, check our Upgrades section table at www.pasaban.com

PAPELEIRA COREBOARD acquires a Pasaban BM 2600 Winder

Papeleira Coreboard S.A., a company that produces 220 tons per day of cardboard for the paper core and angle manufacturing industry, has acquired a BM 2600 Paper Winder as part of its machinery and facilities upgrade project.

Papeleira Coreboard is part of a group that includes Spiralpack and the paper core manufacturer Cicarsa. After a period of heavy investments to optimize their manufacturing process, they have become the benchmark for recycled paper in Portugal.

With the cardboard production machine upgraded, the Pasaban BM winder contributes significantly to meeting the objectives set by the company: to produce and convert safely and efficiently 220 tons per day of recycled cardboard.

The winder is an off-line pope winder equipped with 39 automatically positioned slitters. It converts the cardboard produced by the main PM into narrow reels that will later be used to make “Coreboard” and “Coretissue” cardboard cores. And it has the capacity to process 180 to 700 gsm cardboard at an operating speed of 1500 m/min.

At Pasaban we continue to meet our commitment to provide our customers with customized solutions that help then position themselves as a quality benchmarks in their sector.

Pasaban supplies 2 new paper sheeters to Asia Symbol (Guangdong) in China

Asia Symbol Paper Company has once again entrusted Pasaban with the design and manufacture of 2 paper sheeting machines which will become a part of the paper converting equipment at one of its plants.

This is not the first time that Pasaban manufactures a folio sheeter for this factory located in the province of Guangdong, south-east of China. Therefore, for one of their latest projects (PM12), the factory has once again chosen Pasaban's technology and machinery.

The Guangdong factory belongs to the April group, one of the largest cellulose and paper manufacturers in the world. It has a cut-size conversion line for the production and sale of high-quality copy paper. In 2017, due to the purchase of a new paper machine capable of producing 1,700 tons of paper a day, they found it necessary to complete the equipment with the latest technology conversion machinery that ensured a high-quality finished product.

Pasaban's KB sheeters are the right solution for paper and cardboard factories.

For the design of the cutters for the Asia Symbol factory, the characteristics of the manufactured paper were considered; high-quality copy and offset paper of 50 to 150 gsm. The result, a solution tailored to their needs, 2 KB 2000 cutters with 8 unwinders capable of producing at a speed of 320 m/min.

Once again Asia Symbol banks on Pasaban's paper converting equipment in order to continue offering a high-quality product that places them among the world's largest cellulose and paper producers.

Pasaban upgrades a laminating line and a cartonboard sheeting equipment for an important packager in France

The laminating line is now able to produce either laminate paper rolls or sheets depending on customer’s demand.

With the objective of improving the performance of one of their laminating lines and their Pasaban KDD 1500 paper sheeter, Pasaban Upgrades service carried out two different projects.

On the one hand, a new configuration for the laminating line was designed by adding two new pieces of equipment; a rotary unwinder and a rewind stand. On the other hand, an electrical upgrade of the sheeter was carried out, adapting it to work both OFFLINE and INLINE with the laminator.

Both the rotary unwind stand and the rewinding station installed on the laminator allow automatic splicing at maximum speed, capable of reaching 200 m/min. The two systems have electrical motors and everything is controlled by a high-performance PLC.

Regarding the sheeter upgrade, it was necessary to carry out improvements to the electrical system for which Pasaban drives and PLCs were used.

Currently, after the changes have been made, the sheeter can be fed by either its unwinders or by the laminator working INLINE. The sheeter is prepared to cutting in register on printed mark.

These solutions have enabled or customer to adapt the performance of their equipment to their specific needs, giving option to several configurations.

The project although complex due to space problems, it has been satisfactory and both the customer and ourselves are satisfied with the final result.

For more information regarding our Upgrades service, click here

Iggesund UK renews its finishing area with Pasaban machinery

The two KB2300 board sheeters will contribute to the British plant to continue offering a high-quality product alongside impeccable service.

Iggesund, an important Swedish group and a benchmark in the board mills on a global scale, produces two of the highest quality paperboard products in the market. In their Workington (UK) plant they make “Incada” folding box board. The brand is used for packaging in sectors with high quality requirements, such as the food, cosmetics, electronics and the pharmaceutical.

The factory’s finishing area is one of the fundamental areas of its production process. For 20 years, they have entrusted Pasaban with the supply and service of some of their paperboard cutting machines, this way offering them a total solution.

In the Workington Mill, Iggesund already has a KDD-2600 board sheeter which, together with an old Jagenberg and a Pasaban board winder, they have been some of the key machines in the paperboard finishing area. However, they are currently immersed in a machinery renewal process for which they have once again trusted in Pasaban. We will substitute the old equipment for two KB-2300 sheeters with highly automated rotary unwind stands able to process 170 to 400 gsm folding box board (FBB).

We are proud to be able to continue to satisfy our customer needs and to continue being a benchmark in the market. In this case being a part of the manufacturing process of 'Incada' and 'Ivercote' FBB.

VIDEO: The Making of Incada here

Once again, the quality of Pasaban machines, services and customised solutions make it a reliable brand for the world's leading paper and board manufacturers.

Emreser shows its continued confidence in Pasaban for the supply of a paper and board winder

The winder will significantly increase production capacities, helping to improve delivery times for its customers.  Manipulados Emreser S.L., one of Pasaban’s committed customers, has once again trusted Pasaban for the supply of a BM-2600 board and paper winder. This converter, located in Murcia (Spain), offers solutions aimed at satisfying the carton requirements for the manufacture of all types of casing, display stands and packaged products, amongst others.

Manipulados Emreser S.L., one of Pasaban’s committed customers, has once again trusted Pasaban for the supply of a BM-2600 board and paper winder. This converter, located in Murcia (Spain), offers solutions aimed at satisfying the carton requirements for the manufacture of all types of casing, display stands and packaged products, amongst others.

For over 20 years, Pasaban has provided them with the necessary machinery, such as several folio sheeters, in order to offer a high added value product.

Due to having recently expanded their facilities, they have entrusted us with the design and manufacturing of a winder which will reliably cut their high-quality cartons: folding FBB, craft, recycled, cardboard, coated and liner.

The winder has a width of 2600 mm and it is designed for cartons from 250 to 500 g/m2. It is prepared to handle both input and output reels of large diameters (2100 mm/1800 mm) at speeds of up to 1500 m/min. And It incorporates an automatic blade positioning system together with the last control improvements developed with the IK4-Tekniker technology centre.

With this project, we have contributed to Emreser reaching their objective of increasing the factory’s production and, consequentially, improving their delivery times.

Pasaban manufactures two new paper sheeters for the Naini Group paper mill

Mr. Pawan Agarwal, Managing Director of the Naini Group and Chairman of the Indian Pulp and Paper Technical Association (IPPTA) has once again chosen Pasaban sheeters to meet his objective of providing a quality finish to the paper produced in the company’s two plants; Naini Tissues and Naini Papers.

Naini Group belongs to the medium-size pulp and paper manufacturing sector. Four years ago it hired Pasaban to design and manufacture a paper sheeting equipment in order to provide a higher quality finish to the paper it produces. The good results achieved were key to the manufacture and commissioning of two more high output sheeters.

Naini Group belongs to the medium-size pulp and paper manufacturing sector. Four years ago it hired Pasaban to design and manufacture a paper sheeting equipment in order to provide a higher quality finish to the paper it produces. The good results achieved were key to the manufacture and commissioning of two more high output sheeters.

To the 8 unwind stand KB 2400 sheeter, another KB 1900 was added. Including an automatic pallet change at maximum speed and a 6 unwind stand Compact CX145 sheeter with low speed pallet change without sheet reject. Those machines are to be the perfect complement to the first KB.

As for the type of paper, the sheet cutting machines are designed for sheeting 70 and 80 g/m2 light-weight printing and writing papers.

Mr Agarwal describes his experience with Pasaban with these words in an article for the Papermart magazine:

[…] Naini then shifted its focus to finishing paper. It installed a Synchro Fly Sheeter from Pasaban in 2014 for giving a quality finish to the paper it produced.

“We felt sheeting was not as per the market requirement and there were certain wastages at the end of the end-consumers. All this was because of not so good quality of sheeting. Installation of Pasaban sheeter again was an instant hit and we got very good new customers. So, that was again a turning point for us”.

Pasaban is committed to providing customers with customised products that contribute to positioning their companies as a benchmark for quality and as market leaders.