Displaying items by tag: sca

SCA relies on latest digitalization and lifecycle management solutions from Voith and BTG along the entire paper machine to save resources

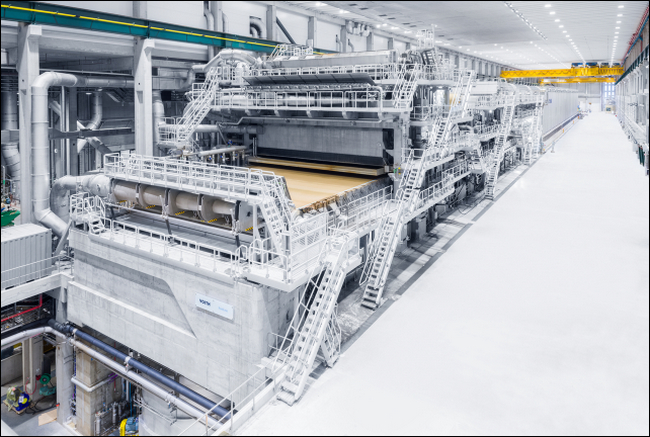

SCA is successfully utilizing Voith's digital and automation solutions with the aim of optimizing the production efficiency of its new XcelLine PM 2. Last year, the leading full-line supplier Voith successfully commissioned the paper machine at its Obbola site. The high-performance machine produces 725,000 tons of kraftliner annually with basis weights between 100 and 200 gsm and has a design speed of 1,400 meters per minute.

- SCA uses digitalization and automation solutions from the Papermaking 4.0 portfolio of Voith and BTG across the entire paper machine

- In addition, Voith works closely with SCA after installation as part of an Efficiency Partnership

- Solutions lead to significant resource savings in paper production

“The journey for SCA and Voith together has only just begun,” says Gustaf Nygren, Mill Manager Obbola at SCA. “We have a long-term partnership in place with the target of reaching the common vision of PM 2 in Obbola becoming the new reference for safety, efficiency and digitalization.”

To achieve its goals, SCA is using more than 10 innovative digitalization and automation solutions across the entire paper machine from the Papermaking 4.0 portfolio of Voith and its subsidiary. For example, solutions from the OnEfficiency family help increase line efficiency and stabilize product and process quality. The increased efficiency also contributes to more sustainable and resource-saving paper production. SCA also uses applications from the OnCare family to monitor productivity and take optimization measures quickly.

Machine availability is further increased by digital services such as the OnCall.Video remote maintenance service. The Voith Paper Webshop enables fast ordering of spare and wear parts as well as services. The digital portfolio is made available on Voith’s IIoT dataPARC cloud platform, which is characterized by the highest security standards.

“With the PM 2, we will take our next steps in the digitalization journey. The applications provided by Voith will help us to monitor the process and make the right decisions,” confirms Niclas Ahnmark, Paper Mill Manager at SCA.

SCA has also signed a long-term service agreement with Voith subsidiary BTG for process control. BTG's Lifecycle program ensures optimal consistency accuracy and control by providing preventive maintenance services for the entire consistency sensors install base, including regular calibration and routine checks. BTG Field Service Engineers assist in the planning, implementation and coordination of the various maintenance services, maximizing machine uptime and stability while maintaining SCA's high safety standards.

The collaboration with SCA is long-term and is particularly evident through the Efficiency Partnership. Throughout the process, the teams work closely together to ensure that the solutions are used optimally. Stephan Sicking, Vice President Sales FRS EMEA at Voith Paper, explains, "As part of a digitalization roadmap, we have defined common goals and KPIs in a cross-functional team, developed a customized concept and are now providing support for successive installation and employee training. Already, the benefits from this collaborative approach are clearly demonstrated." Learn more on our Voith website: Containerboard mill Obbola PM 2 | Voith.

About SCA

The core of SCA’s business is the growing forest, Europe’s largest private forest holding. Around this unique resource, we have built a well-developed value chain based on renewable raw material from our own and others’ forests. We offer packaging paper, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2022 the forest products company SCA had approximately 3,300 employees and sales amounted to approximately SEK 21 bn. SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. More information at http://www.sca.com.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

SCA acquires wind farm in Markbygden

SCA has acquired its first wind farm with the purchase of 36 wind turbines in Markbygden in Piteå municipality, northern Sweden. The acquisition is in line with the company’s previously stated goal of becoming one of the Sweden’s leading providers of fossil-free electricity generated by wind power. Twenty per cent of Sweden's installed wind power capacity is currently located on land owned by SCA.

"This is an important first step for SCA, and we’re now considering options to upgrade the wind farm over time, so that each turbine multiplies the amount of power produced on land that is already in use," says Ulf Larsson, SCA President and CEO.

The Skogberget wind farm was commissioned in 2014 and was acquired with the purchase of 100 % of the shares in Skogberget Vind AB from Enercon for approximately SEK 800 million.

The Skogberget wind farm was commissioned in 2014 and was acquired with the purchase of 100 % of the shares in Skogberget Vind AB from Enercon for approximately SEK 800 million.

The park is located in Markbygden in Piteå municipality, which has been designated by the Swedish Energy Agency as a national interest for wind farms and consists of a total of 36 turbines with a total installed capacity of about 85 MW. The annual electricity production from the site is estimated at close to 200 GWh.

Of the 36 wind turbines, 15 are located on SCA land. The remaining 21 wind turbines are operated under agreements with about 10 landowners that are valid until 2062.

"The wind farm has great potential for increased electricity production through upgrading, so-called re-powering. Through re-powering, production capacity can be increased by replacing existing turbines with new ones with several times greater power per turbine," says Larsson.

With today's transaction, SCA has initiated its Renewable Energy business area strategy to transform its wind power business model from being lease-based to also acquiring, developing, building, and managing wind farms on its own land.

SCA publishes 2021 annual and sustainability report

SCA has just published its annual and sustainability report for 2021. In the report, SCA describes the company's work to contribute to a fossil-free society. SCA's climate benefit in 2021 amounted to 10.5 million tonnes of carbon dioxide based on the forest's net carbon sequestration, substitution effect and reduced fossil emissions.

SCA has just published its annual and sustainability report for 2021. In the report, SCA describes the company's work to contribute to a fossil-free society. SCA's climate benefit in 2021 amounted to 10.5 million tonnes of carbon dioxide based on the forest's net carbon sequestration, substitution effect and reduced fossil emissions.

The annual report is available on the SCA website at www.sca.com. The printed annual report will begin to be distributed to shareholders and other stakeholders from March 25 2022.

The annual report is published in accordance with the reporting requirements of the European Single Electronic Format (ESEF). In accordance with the requirements of the ESEF, the year-end report has been provided with XBRL tags. The ESEF files, in Swedish, can be downloaded at sca.com

SCA appoints new CFO

Andreas Ewertz as its new CFOSCA has appointed Andreas Ewertz as its new CFO. Ewertz has worked at SCA since 2017, where he has been responsible for investor relations and served as head of business control for business areas Publication Paper and Pulp, respectively.

Andreas Ewertz as its new CFOSCA has appointed Andreas Ewertz as its new CFO. Ewertz has worked at SCA since 2017, where he has been responsible for investor relations and served as head of business control for business areas Publication Paper and Pulp, respectively.

Ewertz, who will become a member of SCA group management, will take up the position as CFO on May 1, 2022. Prior to his employment at SCA, Ewertz worked in a number of different roles at Handelsbanken Capital Markets. Ewertz, born in 1987, holds a Master’s degree in Industrial Engineering and Management from Linköping University.

Ewertz replaces current CFO, Toby Lawton, who is leaving his position for personal reasons.

SCA and St1 enter joint venture to produce and develop liquid biofuels

SCA and St1 have entered a joint venture to produce and sell liquid biofuels. SCA will supply tall oil to the joint venture and will invest approximately SEK 0.6 billion in the company. SCA and St1 will be equal shareholders of the joint venture, which will itself have a 50% share in the St1 Gothenburg Biorefinery, which is now making an investment in a biorefinery with total capacity of 200,000 tonnes of liquid biofuels, estimated to a total investment cost of SEK 2.5 billion. The new biorefinery will be operational in Q2 2023.

“Partnership with SCA is a key element in the implementation of our renewable fuels investment program and it secures the supply of renewable feedstock materials to meet the ambitious Nordic climate targets for 2030”, says Henrikki Talvitie, CEO of St1 Nordic Oy.

“In line with our communicated long term strategy, we will now with the joint venture with St1 go from being a supplier of tall oil to the chemical and fuel industries to becoming active in the further refining of our renewable raw materials”, says Ulf Larsson, President and CEO of SCA. “We will continue to develop the business potential of the renewable by-products we have from our forests and industries in order to further develop our value chain and to contribute to the EU’s ambitious climate strategy.”

“In line with our communicated long term strategy, we will now with the joint venture with St1 go from being a supplier of tall oil to the chemical and fuel industries to becoming active in the further refining of our renewable raw materials”, says Ulf Larsson, President and CEO of SCA. “We will continue to develop the business potential of the renewable by-products we have from our forests and industries in order to further develop our value chain and to contribute to the EU’s ambitious climate strategy.”

The new biorefinery is under construction on the St1 refinery site in Gothenburg and will have a total capacity of 200,000 tonnes of liquid biofuels. It is designed to optimize production of renewable HVO diesel and biojet fuel and to use tall oil-based feedstock. The joint venture will have access to SCA’s tall oil, a by-product from the kraft pulp production at SCA’s mills in Östrand, Obbola and Munksund. The biorefinery will also be capable of using a wide range of other feedstocks and is expected to be operational in Q2 2023.

As part of the agreement, St1 also becomes a 50% owner of SCA Östrand Biorefinery. The Östrand biorefinery project has recently received environmental permits for the production of 300,000 tonnes of liquid biofuels based on black liquor (a by-product from kraft pulp production) and solid biomass (such as sawdust or bark). The biorefinery in Östrand is a development project where a number of technological challenges remain to be solved before a project design can be finalized.

St1 Nordic Oy is a Nordic energy group whose vision is to be the leading producer and seller of CO2-aware energy. The Group researches and develops economically viable, environmentally sustainable energy solutions. St1 focuses on fuels marketing activities, oil refining and renewable energy solutions such as waste-based advanced ethanol fuels and industrial wind power. The Group has 1250 St1 and Shell branded retail stations in Finland, Sweden and Norway. Headquartered in Helsinki, St1 employs currently more than 1000 people. www.st1.com

The core of SCA’s business is the growing forest, Europe’s largest private forest holding. Around this unique resource, SCA have built a well-developed value chain based on renewable raw material from the company’s own and others’ forests. SCA offer packaging paper, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2020 the forest products company SCA had approximately 4,000 employees and sales amounted to approximately SEK 18.4 bn (EUR 1.8 bn). SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. For more information, visit w.sca.com

ABB/Voith alliance helps SCA to drive bold investment program forward

ABB’s appointment by Voith to deliver end customer electrification package enables SCA to transform kraftliner production capabilities at Swedish pulp and paper mill

ABB has been contracted by machine supplier Voith to deliver drives and electrification to support the build of SCA’s new kraftliner machine PM2 at its Obbola mill in Umeå, Sweden.

The contract is in addition to an automation and control system upgrade based on the ABB Ability™ System 800xA distributed control system (DCS), drives and instrumentation package that SCA awarded to ABB for the brownfield expansion, complementing ABB’s existing installed base and long-standing service agreement.

The installation of a new machine, infrastructure and optimized capabilities means that SCA’s annual production at Obbola will increase from the current 450,000 tonnes of kraftliner to 725,000 tonnes. The feat of bringing a brand new, large and wide machine online will meet the growing demand for renewable packaging with higher production capacity and efficiency.

“Increased focus on sustainable packaging and e-commerce is boosting demand for high-quality packaging paper,” said Per Strand, Project Director at SCA. “The new machine from Voith and the associated ABB product selection will allow substantial increases in production and will allow the Obbola mill to meet increased market demands.”

Voith, as a full-line supplier, is taking responsibility for the entire papermaking process and project handling of the new Obbola mill. ABB’s scope includes sectional drives suitable for high power and high power density machines as well as specialized motor requirements, ABB Ability ™ System 800xA drive control system with ABB Ability ™ Data Logger tool and Safety PLC solution for the drive system safety functions.

“This contract allowed the opportunity to demonstrate ABB’s willingness to share a project scope with OEMs like Voith and serve the end customer in a way that harnesses our local presence and global know-how,” said Per-Inge Bengtsson, Sales Manager for ABB Pulp & Paper, Sweden.

“We are able to work closely with contracted parties to offer a more agile management style that enables us to better mitigate risks and balance expectations for both the OEM and customers.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

SCA to increase Kraftliner price by €50 per tonne

SCA will increase the price of White and Brown Kraftliner by €50 per tonne. The new price is valid for deliveries from February 1, 2021.

“The market is characterized by a very strong demand for Kraftliner” says Mikael Frölander, Vice President Sales & Marketing Containerboard.

“The market is characterized by a very strong demand for Kraftliner” says Mikael Frölander, Vice President Sales & Marketing Containerboard.

For further information, please contact:

Björn Lyngfelt, SVP Communications, tel, +46 70 626 82 23

Mikael Frölander, VP Sales & Marketing Containerboard, tel +46 70 616 81 10

The core of SCA’s business is the forest, Europe's largest private forest holding. Around this unique resource, we have built a well-developed value chain based on renewable raw material from our own and others’ forests. We offer paper for packaging and print, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. 2018 the forest products company SCA had approximately 4,000 employees and sales amounted to approximately SEK 1617 bn (EUR 1,8 bn). SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden. More information at www.sca.com.

Renewcell establishes textile recycling at SCA’s industrial site Ortviken

SCA and the textile recycling company Renewcell have signed an agreement for Renewcell to establish textile recycling at SCA’s industrial site Ortviken in Sundsvall. The operation is expected to create one hundred new jobs.

“We are glad that Renewcell chooses Ortviken as the site for this investment”, says Ulf Larsson, SCA’s President. “We know that Ortviken is a very attractive industrial site with excellent infrastructure, including first class logistic solutions.”

“We are glad that Renewcell chooses Ortviken as the site for this investment”, says Ulf Larsson, SCA’s President. “We know that Ortviken is a very attractive industrial site with excellent infrastructure, including first class logistic solutions.”

SCA will discontinue the production of publication paper at Ortviken and will thereafter make room for Renewcell’s operations, where one of SCA’s paper machines is currently located. SCA has also started the investment to produce chemically pretreated thermomechanical pulp, CTMP, on the site.

SCA will rent out the space for Renewcell’s operations and will supply utilities such as steam, water treatment and other services.

SCA discontinues publication paper and invests in pulp production

SCA has decided to discontinue the production of publication paper and to invest SEK 1,45bn in the production of chemically pre-treated thermo-mechanical pulp (CTMP) at the Ortviken industrial site in Sundsvall. The decision has been preceded by consultations with employee representatives.

SCA has decided to discontinue the production of publication paper and to invest SEK 1,45bn in the production of chemically pre-treated thermo-mechanical pulp (CTMP) at the Ortviken industrial site in Sundsvall. The decision has been preceded by consultations with employee representatives.

The proposed restructuring plan for Ortviken paper mill was announced on August 26. Following the conclusion of negotiations with employee representatives regarding the closure of publication paper production, consultations will now commence regarding the consequences of this closure for the employees. Approximately 800 employees are affected, most of whom are located at the Ortviken paper mill.

“Publication paper is a product with a declining market and we now entirely leave this product area, this enables us to focus on products with healthy growth and good prospects for the future,” says Ulf Larsson, SCA’s CEO. “The plans we are now carrying out will have significant impact and now, together with representatives of our employees, we will seek the best possible solutions for those affected.”

SCA intends to invest in pulp production and initiates consultations to discontinue publication paper

SCA intends to invest SEK 1,45bn in the production of chemically pre-treated thermo-mechanical pulp (CTMP) at the Ortviken paper mill in Sundsvall. In parallel, SCA is initiating consultations with trade unions and employee representatives to discontinue the production of publication paper at the mill.

SCA intends to invest to achieve an annual production volume of 300,000 tonnes of CTMP pulp at Ortviken, using the existing infrastructure. The investment is expected to give a positive EBITDA-effect of approximately SEK 0.3bn per annum. Expected start of production in the new mill is the beginning of 2023. SCA today has a production capacity of 100,000 tonnes of CTMP pulp at the Östrand pulp mill. This production will be phased out when the new line starts up, which will allow a future increase in the production of kraft pulp at Östrand Pulp mill.

“Our pulp customers want us to grow with them in product segments such as packaging board and hygiene products, segments with healthy growth,” says Ulf Larsson, SCA’s CEO. “In line with our strategy, we have gradually reduced our exposure to publication paper. We now initiate negotiations to leave this product segment completely.”

“Our pulp customers want us to grow with them in product segments such as packaging board and hygiene products, segments with healthy growth,” says Ulf Larsson, SCA’s CEO. “In line with our strategy, we have gradually reduced our exposure to publication paper. We now initiate negotiations to leave this product segment completely.”

Currently, SCA produces coated and uncoated publication paper on three paper machines at Ortviken paper mill with annual sales of approximately SEK 4bn. Demand for publication paper in Western Europe has declined by approximately 5% per year since 2008. During the coronavirus pandemic, demand for publication paper decreased by a further 30-40% and production at Ortviken paper mill has been adapted to the weak order level. This low demand, combined with a weak price development, results in a negative profitability for the operation.

The closure of publication paper manufacturing at Ortviken paper mill proposed by SCA will affect about 800 employees, primarily at Ortviken paper mill, but also in other parts of SCA’s operations. The closure would result in non-recurrent costs with cashflow effects which are estimated not to exceed SEK 0.9bn and an impairment of about SEK 1.1bn.

“Through today’s proposals, we intend to continue to develop a strong, sustainable and profitable industry based on our renewable forest raw materials”, says Ulf Larsson. “This will have a significant impact on many people and we will in a responsible way seek the best possible solutions for those affected.”

Negotiations under the Co-determination at Work Act (MBL) with trade unions will now begin regarding the plans to discontinue paper production at Ortviken paper mill, the investment in CTMP production at Ortviken and the impact on other SCA operations. In other jurisdictions affexcted employees and their representatives will be informed and consulted in line with the legal framework.