Displaying items by tag: södra

Södra to implement unique infrastructure initiative with RME

As an alternative to diesel, Södra is introducing the fossil-free fuel RME, rapeseed methyl ester, for its own timber trucks, loaders and fork lift trucks in Sweden at five of its fuelling stations. At the same time, transport companies which have agreements with Södra are being offered the opportunity to fill up with RME at the stations.

"The objective is to reduce overall fuel costs for Södra and at the same time provide a more eco-friendly fuel," said Henrik Brodin, project manager for Södra's RME initiative.

The introduction of RME is very much in line with the Södra business model, where the use of fossil-free and renewable products is a key issue," said Klara Helstad, Sustainability manager at Södra.

Södra has entered into agreements concerning the supply of RME manufactured in Sweden with BioFuel Express in Landskrona and Ecobränsle in Karlshamn. "We are seeing greater demand for RME, and so Södra's RME initiative is very timely. Being a selected supplier and helping to develop RME provides us with great impetus," said Clemen Rasmussen, CEO of BioFuel Express.

"Thanks to this agreement, we provide Södra with an excellent product in terms of both quality and the environment, and thanks to our close proximity to Södra's fuelling stations we are also able to provide an excellent service and fast, secure supplies," said Claes Ramel, CEO of Ecobränsle.

From June, RME will be available alongside diesel at Södra's five biggest fuelling stations in Mönsterås, Mörrum, Värö, Kinda and Långasjö.

"Fuelling stations supplying RME have been available in just a few locations throughout the country to date, but Södra is working on changing that now. By offering RME at our fuelling stations in various geographical locations throughout southern Sweden, we will allow this renewable fuel to be used just as much as diesel," said Henrik Brodin.

Södra's aim is for RME to account for at least half of all the fuel used by Södra in Sweden within a year.

Södra: Looking ahead

A lot is happening, both locally and elsewhere in the world, which is having an impact on Södra. In a large company, rapid changes do sometimes take place in terms of both organisation and production. Gunilla Saltin, temporarily holding the position of CEO of the Södra Group, explains:

We have made a number of rapid changes of late, but now we have reached the point where we want to be, to allow us to focus on the right things and face the future.

We have made a number of rapid changes of late, but now we have reached the point where we want to be, to allow us to focus on the right things and face the future.

Historically, the pulp market has always been sensitive to economic conditions. Bad times mean less advertising, less printed information and less packaging. At present, we can see that Europe, Södra Cell's domestic market, is hesitant. A number of major economies are experiencing problems. Furthermore, electronic media are taking over in many instances and replacing paper as a carrier of information. All this means that we are facing an unprecedented combination in Europe of a hesitant market combined with structural change.

Despite this, both long and short fibre pulp prices have increased since the start of the year. Asia has China, with its stable economic development and an increasing need for paper pulp. Prices in China have also increased, although they remain lower than in Europe. Our overall assessment is that Södra Cell has every chance this year of meeting its return requirement of 10%.

Södra Cell launched two new products last year, Durapulp, and textile pulp at Mörrum. When we asked for investment funding for this product, we thought we would need three years in which to achieve full production from both a marketing and a production standpoint. Production has gone better than expected and customers are showing a lot of interest. They perceive Södra to be a stable, long-term supplier with a good environmental profile and a quality product based on raw material from sustainable forestry. A month or so ago, we decided to produce only textile pulp on one of the Mörrum lines. The change went more quickly than we envisaged, and so we are already at the point that we thought we would reach in three years.

Looking ahead, Södra is now into the final sprint for the current strategy period, which will be completed in 2014. We have a number of strategic targets that we have to have met by then:

Our pulp production must be fossil-free. This means that we will not be using any oil for normal operations. This is the right thing to do, regardless of whether or not you believe carbon dioxide helps to bring about climate change. We are being cautious with a scarce resource which can be used for better purposes, and we are saving money: squeezing out those last few drops of oil is an expensive enterprise!

Another target is for us to implement an established productivity culture. What does this involve? It goes without saying that we should continue doing what we were doing before, but doing it better now, working together and systematically coming up with new solutions. We have been working in this way since 2000, so our target is very much in sight. But a culture is something that we have to cherish and develop if we are not to lose it, and this is our priority just at the moment. Productivity involves working with development. Of course, anything which does not develop will be superseded. Development will involve us working on changing and improving the products we have at present and finding new product options. Södra Interiör is something of a role model in this regard. It is constantly coming up with new products in order to maintain an attractive product range.

Södra Skog has faced a number of challenges of late. Production at our pulp mills has not been as envisaged, and we have large stocks of pulp wood. Acquiring raw materials for the sawmills has been a challenge, and so market premiums have been introduced in some areas. Despite this, the situation is not satisfactory. Increased domestic hardwood supplies, monitoring of the transfers of ownership and pre-commercial thinnings are all focal points for forestry operations over the coming period.

The uncertainty in the global economy is also apparent at Södra Interiör. Sales volumes to date this year have been lower than anticipated. Profitability at the hardwood sawmills continues to be something of a challenge. As far as products are concerned, solid flooring with a new surface treatment and new parquet floor ranges are being launched.

The market conditions for sawn timber products are tough. Weak economic development in many countries is resulting in low construction rates. Market conditions contributed to a very weak result of SEK -307 million last year, and profitability has not improved over the first four months of the year. The accumulated result for the period January to April stands at SEK -108 million. In a situation such as this, it is natural for the CEO to throw open his or her position and hand over to someone else. We need to focus on the profitability of the sawmills. Håkan Svensson, the Acting CEO of Södra Timber, has put together a team of people to work on increasing income and reducing costs.

Södra Timber and Södra Interiör share a number of customers. As part of the efforts to increase revenues, Håkan has worked in cooperation with Ulf Edman (the new CEO of Södra Interiör) to launch a joint sales organisation. This will make things easier for customers who want to buy from both Södra Timber and Södra Interiör, so allowing us to be perceived as a more attractive supplier and giving us the opportunity for additional sales. Sales, sales, sales - that's the name of the game.

We have a successful productivity programme in place at all Södra units, and Södra Timber is no exception to this. But now that we have been seeing negative results for such a long time, extraordinary efforts are required. We are mustering all our available resources so as to completely screen all expenses at all sawmills and propose measures in order of priority, all under Håkan's management. Stoppages will not reduce expenses. Therefore, we have reversed the decision we made to implement stoppages in the summer.

We now have an organisation in place which is working hard to focus on the most important thing: reversing the trend at Södra Timber.

Södra's CEO to leave - President of Södra Cell Gunilla Saltin to take over temporarily

The Board of Directors at Södra has decided to start searching for a new CEO and Group President.

As the Board of Directors and CEO have differing views regarding the ongoing development of the company and what is required in the form of leadership and clarity, the Board has decided to terminate the employment of CEO Leif Brodén with immediate effect. At the same time, a decision has been made to extend temporarily the responsibilities of the President of Södra Cell Gunilla Saltin to also include the role of CEO for the entire Södra group. Recruitment of a new CEO will begin immediately. Until a new CEO is appointed, Board Chairman Christer Segerstéen will extend his involvement in the company and take over as Acting Chairman. In this role, he will mainly assist the Acting CEO with ownership and industry issues.

Leif Brodén has been employed by Södra since 1999, initially to head Södra Cell, Södra's biggest subsidiary, and then as CEO and Group President. Södra has developed very strongly during this time, to the benefit of its 51,000 members. Under sometimes very stressful conditions, such as when dealing with the consequences of the Gudrun storm, Leif Brodén has very professionally and successfully led and expanded Södra's industrial operations, forming a group which is financially very stable. Södra has a very strong foundation on which to stand, both financially and in terms of expertise, which will permit ongoing successful development and active participation in future structural changes. However, the Board has arrived at the conclusion that it is time for a new type of leadership, and for a new CEO to work together with the Board to produce and then implement the strategy to follow Södra's current long-term plan, which will remain in force until 2014.

Gunilla Saltin has been the President of Södra Cell, Södra's biggest business area, since 2008. She joined Södra in 2000, and she has previously held the position of Plant Manager at Södra Cell Värö.

"Business at Södra subsidiaries Södra Cell, Södra Timber, Södra Interiör and Södra Skog is successful in their respective areas. This guarantees that Södra will not suffer any adverse effects in the limited time it is estimated to take to find a new CEO," commented Christer Segerstéen, Chairman of Södra.

Södra Timber imposes market shutdown

Price levels for sawn timber products have been increasing slowly during the second quarter of 2012. At the same time, however, the construction market remains weak almost everywhere for Södra's products, not least in the Netherlands and Denmark, which are important to Southern Sweden. No improvement is expected until 2013 at the earliest.

Profitability remains weak as a consequence of depressed demand and overcapacity of timber construction products in Southern Sweden.

As a result, Södra Timber is reducing its production. The planned holiday downtime at its sawmills in Ramkvilla and Torsås will be extended as an initial measure. Sawmill production will stop on 4 June and resume on 27 August, extending the planned holiday shutdown by two months. Sawmill production at the sawmill in Långasjö will be reduced from a three-shift pattern to a two-shift pattern over the same period. All sawmills will remain open for deliveries throughout the summer.

The situation at Södra Timber's sawmills will be evaluated in May.

"We are monitoring market development closely. The sawmills have now seen a fairly long period of no profitability, and we have to create a balance between production and demand in order to place ourselves back in a reasonable situation," said Peter Nilsson, President of Södra Timber.

"We hope that these measures will improve the situation. But at the same time, we are not ruling out further action in the future," Nilsson added.

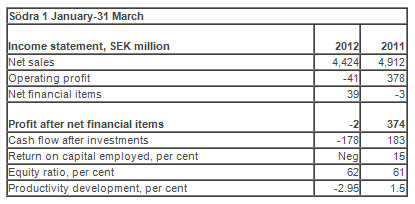

Södra's income statement for the first quarter of 2012

Södra's operating profit for the first quarter of 2012 amounted to SEK -41 million. Profit after net financial items amounted to SEK -2 million. Reduced production and a number of market stoppages characterised the first quarter of the year.

"We started the year with most of our sawmills implementing market stoppages, while production at two of our Norwegian pulp mills was down for much of the quarter. Production at our pulp mills was just 73 per cent of our normal capacity. For the sawmills, the corresponding figure was a low 70 per cent," said Group Chief Executive Leif Brodén. Together with the first quarter of 2009, this is historically the lowest level of capacity utilisation the company has seen. January and February experienced the lowest production figures, but they also mark the turning point. All production units have been back to normal production capacity since 20 March.

"We are seeing a recovering pulp market and anticipating economic recovery," said Brodén. Price announcements have been accepted, and as of 1 April the price of NSBK is USD 870 per tonne. We are now seeing strong increases in volumes to China, which up to now has been more or less solely responsible for the increase. We are expecting to see higher prices for sawn timber products over the course of the year, but only small volume increases. Viewed from a new development perspective, it seems that 2012 will be another lost year. The sawmill structure will probably need further streamlining.

"For the rest of 2012, we will see normal capacity utilisation, and we think we will see a profit for the year which is just below last year's result, along with a 7 to 8 per cent return on capital employed," said Brodén.

The pulp market started to show signs of recovery during the first quarter of 2012. The world market price of bleached softwood sulphate pulp went up as inventories decreased.

Pulp production at Södra's five mills over the period amounted to 380,000 tonnes, compared with 522,000 tonnes over the same period last year. This reduction is due to the market stoppages which took place at Södra Cell Tofte and Södra Cell Folla.

Textile pulp is now being produced at Södra Cell Mörrum. Annual production is expected to reach 170,000 tonnes, which will give Södra a competitive textile pulp product based on hardwood.

Production of DuraPulp is ongoing at Södra Cell Värö. This is a material which has attracted significant attention due to its unique properties, combined with the fact that it is renewable and biodegradable. DuraPulp is made up of a specially selected pulp from Södra Cell and a renewable biopolymer. On further processing, these two components provide special properties such as moisture resistance, strength and hardness. For the most part, a lamp and a children's chair have been in the spotlight to date, and work is now ongoing with a number of partners which are testing the material at their production facilities.

The market for sawn timber products remains weak, although supply and demand remain balanced. High raw material prices combined with the weak market are having an adverse impact on profitability.

Södra produced 371,000 m3 of sawn timber products over the period, compared with 391,000 m3 over the same period last year. Production at the new sawmill in Värö is continuing to develop positively towards stable, high production levels as planned.

The market for interior products is hesitant in Sweden and remains weak in Denmark, but both sales and earning capacity are strong in Norway.

Over the quarter, Södra Interiör acquired parquet flooring manufacturer Berg & Berg in Kallinge, employing around 90 staff. The company produces more than 500,000 m2 of high quality parquet flooring per year, with net sales of around SEK 130 million. This acquisition will further increase the range of products available to Södra Interiör's customers, while at the same time providing good opportunities for synergies between the businesses in fields such as marketing, logistics and product development.

As a consequence of the sawmill and pulp mill stoppages, the volumes handled by Södra Skog over the first quarter were 800,000 m3 lower than at normal capacity. The price of softwood pulp timber was reduced by SEK 25 on 16 January to SEK 300 per cubic metre sub (solid volume under bark). Since the end of the quarter on 13 April, the price of softwood pulp timber and the assortment mixed hardwood has been reduced by SEK 20 to SEK 280 per m3sub. At the same time, the price of aspen pulp timber went up by SEK 25 to SEK 325 per m3sub.

Over the period, Södra has installed and commissioned a new machine for applying wax protection to its bare root saplings and "plug plus one" saplings as an effective, non-toxic means of protecting against pine weevil damage. This machine is the first of its type. The wax makes it difficult for pine weevils to gnaw their way through to the bark and has been specially developed for high elasticity. This project is a cooperation between Södra Skogsplantor, Ramlösa Plantskola and Sundins Skogsplantor.

The forestry plans, with a newly prepared plan, have been available online to Södra members since March thanks to a newly developed function on Skogsägarnätet, the forest owners' network. The Skogsägare - forest owners - app was launched at the same time, making it possible to access the forestry plans on the iPhone and iPad.

Productivity improvement within the group continues apace, mainly due to ideas contributed by staff.

"We have implemented 1,281 suggested improvements over the quarter. These ideas will improve our profits by a total of SEK 32 million per year. However, overall productivity fell by 2.95 per cent over the quarter, mainly due to the fact that this figure is calculated on the basis of volumes supplied. March saw the marking of the 20,000th idea implemented since we started our systematic productivity programmes in 2000," added Brodén.

Södra Cell begins commercial production of DuraPulp

"A large number of companies have been in touch and are interested in this material. We are currently working with a number of partners who are testing DuraPulp as part of their production processes," said Henrik Wettergren, Business Area Manager for graphic paper and speciality paper.

Production of the new composite material DuraPulp is now beginning at Södra Cell in Värö. This new biodegradable and renewable material has huge potential as an alternative to plastic.

Production of the new composite material DuraPulp is now beginning at Södra Cell in Värö. This new biodegradable and renewable material has huge potential as an alternative to plastic.

DuraPulp has been in the spotlight for a couple of years within Södra because of its exciting combination of a renewable, biodegradable material which is also very strong. A lamp and a children's chair have already been made out of DuraPulp attracting huge interest, and commercial production of the new composite has now begun.

"A large number of companies have been in touch and are interested in this material. We are currently working with a number of partners who are testing DuraPulp as part of their production processes," said Henrik Wettergren, Business Area Manager for graphic paper and speciality paper.

DuraPulp is the result of several years of collaboration between Södra and the research company Innventia. The starting point for the work was to create a new, fibre-based material which could be a biodegradable alternative to plastic.

DuraPulp is made up of a specially selected pulp from Södra Cell and a biopolymer. On further processing, these two components take on special properties such as moisture resistance, strength and hardness.

DuraPulp was exhibited for the first time at the Milan Furniture Fair in 2009 as part of the Parupu children's chair developed by design company Claesson Koivisto Rune. The latter has also used DuraPulp to create its award-winning w101 lamp.

Managers in new positions at Södra

Klara Helstad, Ulf Edman, Magnus Olsson and Stefan Sandberg are taking up new positions at Södra now that Urban Eriksson, President of Södra Interiör, and Per Braconier, Director of Communications, have decided to leave Södra.

Klara Helstad, Ulf Edman, Magnus Olsson and Stefan Sandberg and are taking up new positions at Södra now that Urban Eriksson, President of Södra Interiör, and Per Braconier, Director of Communications, have decided to leave Södra.

Ulf Edman, currently President of Södra Cell International, will be taking over asPresident of Södra Interiör from Urban Eriksson, who has decided to leave the group in order to start up a consultancy. Urban will be staying with the group until the end of June so as to hand over his responsibilities to his successor. Ulf Edman is 55 years old and has worked for Södra since 1997, when he was employed as the Director of Marketing for Södra Cell. Prior to this, Ulf Edman was the CEO of MoDo Paper Ltd in the UK.

The new President of Södra Cell International will be Magnus Olsson, currently the Plant Manager at Södra Cell Mörrum. Magnus is 48 years old and joined Södra in 2006 after working as the CEO of Stora Enso Nymölla.

The new Plant Manager for Södra Cell Mörrum will be Stefan Sandberg, 46, who is currently Head of HR at Södra Timber. Stefan was formerly Head of HR and Head of Purchasing at Södra Cell Värö. He joined Södra in 2003.

Our present Director of Communications, Per Braconier, will be leaving Södra in order to take up a new position as Director of Communications for the Swedish Forest Industries Federation. Per has worked for Södra since 2005, joining us from Dagens Industri. Klara Helstad, who was recently appointed as the Sustainability Director, will be taking over from Per and operating as our Director for sustainability and communication. Klara Helstad is 34 years old and a Doctor of Forestry. Prior to taking on this position, she worked as the Environmental and Quality manager at Södra Skog.

All these changes will be implemented on 15 May.

"We thank all five of these staff members for their efforts and wish them every success in their new jobs," says Leif Brodén, CEO at Södra.

A forestry first: Non-toxic wax protection treatment for saplings begins at Södra

Södra has now installed the new machine for applying wax protection to its saplings as an effective, non-toxic means of guarding against pine weevil damage. This machine is the first of its type.

"Forestry operations at Södra focus on balancing profitability with environmental protection. Reducing the use of chemicals and investing resources in the development of non-toxic methods is entirely in line with this," said Göran Örlander, Chief Forester at Södra.

The machine has been on trial at Södra Skogsplantor in Falkenberg for a couple of weeks, and it is calibrated for future large-scale production. The wax protection will initially be used on bare root saplings and "plug plus one" saplings. The wax makes it difficult for pine weevils to gnaw their way through to the bark and has been specially developed for high elasticity. This means that the wax holds together even when the sapling grows during its first delicate growth season.

"The tests carried out by both Södra and the Swedish University of Agricultural Sciences have shown that this wax protection is very effective. Failing to protect saplings from pine weevil damage is a costly exercise, as on average more than half of unprotected saplings die as a result of the attack. This is why around 90 per cent of all saplings sold nowadays are protected, but by means of chemicals. Being able to offer a non-toxic yet effective alternative to chemical protection is eagerly awaited," commented Andreas Alvehus at Södra Skogsplantor.

This project is a cooperation between Södra Skogsplantor, Ramlösa Plantskola and Sundins Skogsplantor.

Södra textile pulp production in progress

Under full operation, annual production is expected to amount to 170 000 tonnes, and the investment in Mörrum will give Södra competitive textile pulp production based on hardwood.

Production of textile pulp at Södra Cell Mörrum has now begun. Under full operation, annual production is expected to amount to 170 000 tonnes, and the investment in Mörrum will give Södra competitive textile pulp production based on hardwood.

Södra made a decision to invest in the production of textile pulp back in December 2010. The Group is anticipating strong market development for textile pulp as it is renewable and timber-based, and it will replace oil-based and cotton fibres. Since this decision was made, implementation of the investment and development of a new market organisation for the new customer segment have been taking place in parallel.

"We are focusing on textile pulp as this is a growing market to which we can supply a certified, renewable forest raw material," says Gunilla Saltin, president of Södra Cell.

"For Södra Cell Mörrum, this is an important step in the reinforcement of the profitability and competitiveness of the mill," says Magnus Olsson, Site Manager for Södra Cell Mörrum.

Södra's executive committee has also made a decision in principle about an appropriation limit for production of textile pulp on a further pulp line at one of the company's pulp mills. A definitive decision on a second textile pulp line at Södra will be made in 2012.

Södra reduces price of softwood pulp timber

The 16th of January Södra reduced the price of its softwood pulp timber by SEK 25 per m3sub. This price reduction is also applicable to the pulp timber element of its storm range. The price of all hardwood pulp timber ranges will remain unchanged for the time being, however.

A contract adjustment concerning small sawn timber and hardwood and softwood pulp timber will be taking place at the same time. As of 1 February, customers will be given the opportunity to use the applicable price for these ranges at the time of contracting.

"This adjustment will make it easier and clearer for forest owners to work out what price they will receive for their timber, and it will give us better sale options than before, and that is why this change is logical," concluded Håkan Svensson.

The new softwood pulp timber price is SEK 300 per m3sub, while the price of hardwood pulp timber will remain at SEK 350 per m3sub.