Displaying items by tag: universal converting equipment

Universal Converting Equipment appoint top slitter sales executive

Universal Converting Equipment are pleased to announce the appointment of Mike Wilkinson as Sales Executive. Mike has a wealth of experience in the converting industry having worked in senior sales and general management roles for Titan, Atlas, Comexi and Kampf.

Commenting on the appointment, Alan Jones, Managing Director said, “Mike is one of the top salespeople in the industry. His experience and knowledge are second to none. He was responsible for Titan during its rapid growth phase and most recently he has worked for Kampf who are probably the largest worldwide supplier of slitting and rewinding machines. We have ambitious growth plans over the next three years and Mike will help us reach our targets.”

Mike Wilkinson added “When I first visited Universal, I was excited by the potential of their machine range and in particular, their X6 slitter rewinder. I could see the investment that has taken place particularly in the machine and control system design. It was good to see features being incorporated to simplify the operation and maintenance of the machines which others have talked about but Universal Converting Equipment has actually done. Although Universal has always had a reputation for high quality machines its sales effort has been limited. I intend to help Universal grow to be a major worldwide supplier of slitter rewinders.”

Universal Converting Equipment are a fast growing manufacturer of slitter rewinders, rewinding machines, hot melt coating equipment, core cutters and other ancillary systems used in the converting industry. These machines are sold globally. The Universal X6 slitter rewinder is a machine with a compact footprint that has proved particularly successful as a high performance yet cost effective slitting machine for slitting flexible materials. It incorporates automatic knife setting, core alignment, closed loop tension control, additional tension zone through slitting and constant geometry contact rollers to allow high speed operation, minimising changeover time, with consistent high quality output.

For further information contact Alan Jones, (Managing Director) on +44 (0) 1473 403333, This email address is being protected from spambots. You need JavaScript enabled to view it. or online at www.universalconvertingequipment.com

Universal Converting Equipment complete Phase 2 of their expansion strategy

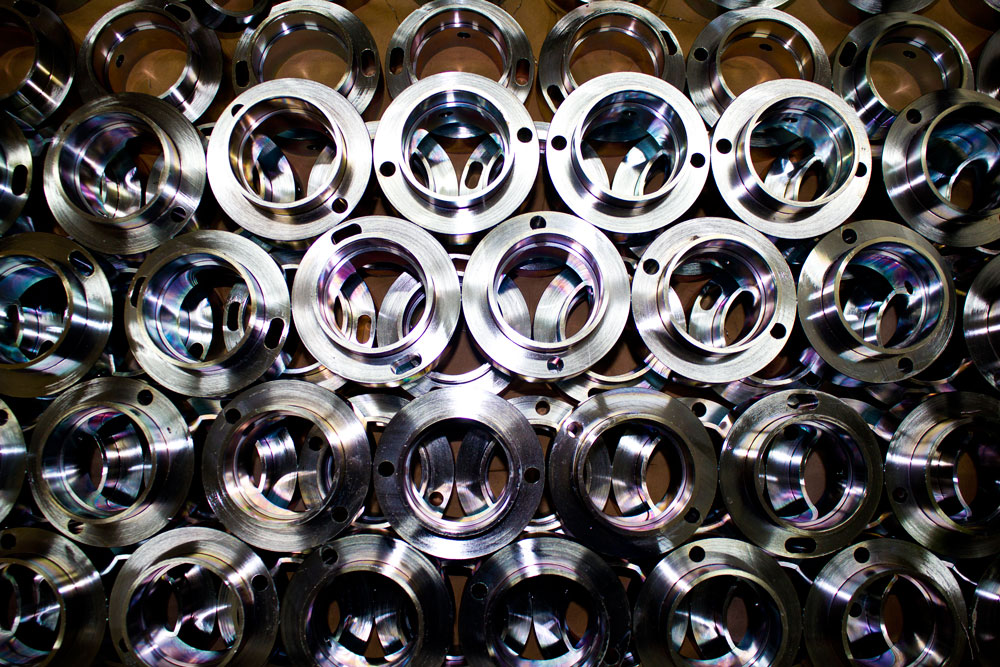

In the last two years, Universal Converting Equipment has doubled its turnover. To support this turnover growth, Universal invested in additional manufacturing space, designers and assembly staff (Phase 1). However, Universal found that the business was being held back by the lack of capacity of its sub-contractors to meet their increased demands. In the last 12 months Universal undertook an ambitious plan to install its own machine shop so it could be self-sufficient in machined mechanical parts. This Phase 2 investment plan is now complete following the installation of £1m in CNC controlled machine tools. The investment has included a CNC mill for the manufacture of machine side-frames, a CNC lathe for production of rollers, PC controlled roller balancing equipment and a range of CNC machining centres for the manufacture of other parts. Special foundations were built for some of the equipment. For example, the large mill sits on a solid reinforced concrete base over 1000mm deep. Levelling the machine bed to the tolerances required took a specialist team over a week to achieve.

In the last two years, Universal Converting Equipment has doubled its turnover. To support this turnover growth, Universal invested in additional manufacturing space, designers and assembly staff (Phase 1). However, Universal found that the business was being held back by the lack of capacity of its sub-contractors to meet their increased demands. In the last 12 months Universal undertook an ambitious plan to install its own machine shop so it could be self-sufficient in machined mechanical parts. This Phase 2 investment plan is now complete following the installation of £1m in CNC controlled machine tools. The investment has included a CNC mill for the manufacture of machine side-frames, a CNC lathe for production of rollers, PC controlled roller balancing equipment and a range of CNC machining centres for the manufacture of other parts. Special foundations were built for some of the equipment. For example, the large mill sits on a solid reinforced concrete base over 1000mm deep. Levelling the machine bed to the tolerances required took a specialist team over a week to achieve.

Commenting on the investment, Alan Jones, Managing Director of Universal Converting Equipment said “We have been using 3D CAD systems to design our machines for the last 10 years. We have now invested in CAM software systems so that the part drawings can be converted into files that can be downloaded directly into the CNC machine tools. This prevents errors caused with manually controlled machines and eliminates data entry mistakes. The CAM system ensures we have consistently high quality components with the minimum of downtime when new designs are entered. Since installing this equipment, we have changed the design of some components so that the machining time can be reduced resulting in cost savings that can be passed onto our customers. We have used our own resources to fund this investment without the need for borrowings, increasing the financial strength and stability of the company. We are now commencing Phase 3 to increase our global sales and support infrastructure.”

Universal Converting Equipment are a manufacturer of slitter rewinders, rewinding machines, hot melt coating equipment, core cutters and other ancillary systems used in the converting industry. These machines are sold globally. The Universal X6 slitter rewinder is a machine with a compact footprint that has proved particularly successful as a high performance yet cost effective slitting machine for slitting flexible materials. It incorporates automatic knife setting, core alignment, closed loop tension control, additional tension zone through slitting and constant geometry contact rollers to allow high speed operation, minimising changeover time, with consistent high quality output.

For further information contact Alan Jones, (Managing Director) on +44 (0) 1473 403333, This email address is being protected from spambots. You need JavaScript enabled to view it. or online at www.universalconvertingequipment.com