Ian Melin-Jones

Kipaş Kağıt is counting on Voith's XcelLine at its Söke production facility

A consistently high quality for all basis weights and low energy consumption were the two main requirements to be met by the new PM 1 at Kipaş Kağıt. This is why the Turkish paper manufacturer opted for an XcelLine system from Voith featuring a high degree of automation.

- Efficient production of high-quality board and packaging papers

- Basis weights from 90 to 400 g/m2 possible

- Automation package guarantees process reliability

At the end of September 2017, Voith won a contract from Turkish paper manufacturer Kipaş Kağıt to build the PM 1 at the company's mill at Söke in Western Turkey. The company will use the XcelLine facility to produce around 700,000 metric tons per year of high-quality board and packaging papers with basis weights of 90 to 400 grams per square meter. Kipaş Kağıt is planning to run at a production speed of 1,200 meters per minute. The wire section has a flexible design allowing the production of two-ply and three-ply paper.

At the end of September 2017, Voith won a contract from Turkish paper manufacturer Kipaş Kağıt to build the PM 1 at the company's mill at Söke in Western Turkey. The company will use the XcelLine facility to produce around 700,000 metric tons per year of high-quality board and packaging papers with basis weights of 90 to 400 grams per square meter. Kipaş Kağıt is planning to run at a production speed of 1,200 meters per minute. The wire section has a flexible design allowing the production of two-ply and three-ply paper.

One of the key priorities for the Turkish papermaker was high paper quality with high machine efficiency even in the case of low grammages. In addition, the machine should be particularly energy efficient, i.e. use less power, water and steam. XcelLine meets both these criteria thanks to its perfectly matched components.

In the stock preparation unit of the PM 1, for example, various products of the BlueLine family reduce the costs for energy, fresh fiber treatment, water and maintenance. In four stock preparation lines featuring processing technology specially designed for various recovered papers and pulp and with a total production capacity of more than 3,000 t/day, the conditions have been created for manufacturing high-quality paper products. Apart from the process machines, Voith will also supply the complete water, sludge and reject system and the main components for the effluent treatment plant.

Stock distribution is done via three MasterJet Pro headboxes. The OnQ ModuleJet dilution water system, which is integrated into the headbox for the middle ply, allows the dilution water to be dosed directly into the intermediate layer. This results in a uniform distribution over the entire height of the layer. The system improves the accuracy of the control response in the paper web by over 50 percent compared with conventional systems, allowing optimum CD profiles and an excellent fiber orientation to be achieved.

A key element of the Combi DuoRun dryer section are the EvoDry steel cylinders which allow the number of drying cylinders in the pre-dryer and after-dryer sections to be reduced. This reduces the weight of the dryer section and saves investment and electricity costs, without compromising the quality of the products.

In addition, the PM 1 will be fitted with a Tandem NipcoFlex shoe press with four felts and a downstream third press to improve smoothness, a SpeedSizer AT film applicator unit and an EcoCal Hard and EcoCal Soft nip calender. If the paper is to be coated this is done using up to three DynaCoat AF coaters and a DF Coat unit for direct coating. Non-coated papers are transferred via an intermediate Sirius winding system directly to the two VariFlex winders with two-drum winder technology. Voith will also supply the complete initial clothing for the PM 1 and three further clothing sets.

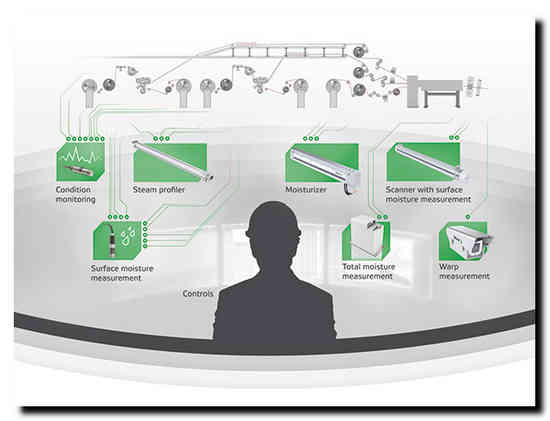

A comprehensive automation package consisting of OnControl process control system, OnQ quality control, OnView information system and OnCare CM condition monitoring increases process reliability and allows preventive maintenance. Interminable and costly machine shutdowns can therefore be avoided. Moreover, the OnV energy management system that is also integrated into the PM 1 identifies, localizes and visualizes all energy consumptions during ongoing paper production and offers the user numerous options for improvement. In this context, the entire machine air system, which guarantees high heat recovery rates and operational reliability, makes an especially important contribution to energy saving and economic efficiency.

The good experience that Kipaş Kağıt had with Voith in the past during the construction of the new stock preparation unit in 2013 was the reason the company decided from the very outset that the new facility had to come from one source. The Turkish paper manufacturer was more than satisfied with the performance and reliability of the stock preparation unit and therefore decided to award Voith the entire contract for the PM 1 and also entrust the technology leader from Heidenheim with the complete planning of the facility. As part of its Process Line Package, Voith assumes total responsibility for the project and guarantees scheduled completion of the system at the agreed price.

Moreover, Kipaş Kağıt is planning to work with Voith again to build another paper machine for non-coated packaging papers in the same width and with a similar production capacity at the same location.

About Voith Paper

Voith Paper is a Group Division of Voith and the leading partner and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About Voith

For 150 years, Voith technologies have been inspiring its customers, business partners and employees all over the world. Founded in 1867, Voith today has around 19,000 employees and earns 4.3 billion euros in sales. It has locations in more than 60 countries and is one of the largest family-owned companies in Europe. As a technology leader, Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets.

Valmet's IQ Moisturizers start up and improve corrugated box quality at Dunapack Mosburger in Austria

The three Valmet IQ Moisturizers delivered to Dunapack Mosburger's corrugated line in Strasswalchen, Austria, have been successfully started up. With the new solutions, the plant will be able to improve corrugated box quality and plant performance.

Since 2012-2013, Dunapack Packaging has invested more than EUR 30 million in its Mosburger Strasswalchen production site, including a new 2.8-meter-wide corrugated line.

"Higher quality, more diverse papers together with improved production and smaller, just-in-time orders make it more and more challenging to act against warp with standard temperature, speed and glue settings. We were looking for a device to do it. When Valmet presented its control technology that is widely proven in paper production, we were convinced that this will work on our corrugated line, too," says August Hauser, Corrugated Line Manager at Dunapack Mosburger Strasswalchen.

"Valmet's IQ quality control solutions are established on paper machines worldwide. However, it takes innovative people to adopt them in the converting and corrugated industry, too. Innovation is definitely an attitude shown by the Dunapack Mosburger team," summarizes Christian Kallich, Country Manager, Austria and Eastern Europe, Automation, Valmet.

Technical information about Valmet IQ Moisturizer

The Valmet IQ Moisturizer profiler is used to correct all kinds of warping, decrease cracking tendency and optimize glue consumption by adding a fine and controlled water mist onto the liners with 60 mm or 120 mm resolution in a cross direction. IQ Moisturizer's two-stage spray head contributes to a balanced and application-matched mixture of air and water. The system is used via an IQ Moisturizer operator interface and integrated into the existing process controls.

Information about the customer Dunapack Packaging

Dunapack Packaging is part of the Austrian family-owned Prinzhorn Group. With more than 6,000 people in 15 countries, Prinzhorn Group is one of the European market leaders in the recycling, paper and packaging industry with an annual turnover of approximately EUR 1.2 billion.

Dunapack Packaging operates at 18 sites in 10 different countries and has an annual sales volume of 1.9 billion m² of corrugated board, mainly made from recycled papers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

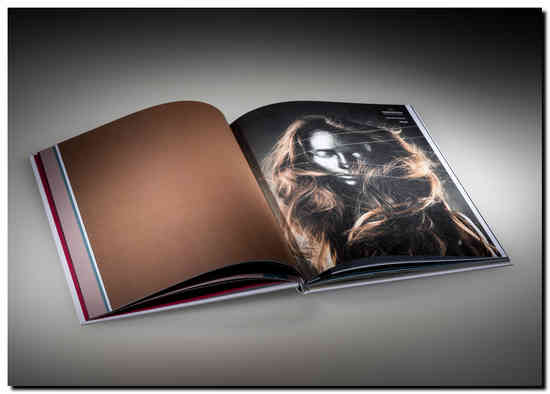

Mondi to showcase professional printing papers at Frankfurt Bookfair

Mondi, the international packaging and paper Group, will exhibit its wide range of professional paper solutions for book printing at the Frankfurt Bookfair held from 11 to 15 October in Frankfurt, Germany. The Mondi booth is located in Hall 4 / Booth F94. As a professional printing paper manufacturer, Mondi offers sustainable paper solutions for all printing technologies and needs. Book printing customers will find more than they expect at the Mondi booth.

Johannes Klumpp, Marketing & Sales Director at Mondi Uncoated Fine Paper, explains, “We can offer the right solution for any printing technology – whether digital, hybrid, offset, HP indigo or high-speed inkjet. At the Frankfurt Bookfair, customers can explore the quality of Mondi’s design papers, tinted portfolio and our high-speed inkjet papers.”

‘Paper for Perfectionists’ in graphic design and fine printing

PERGRAPHICA® design papers – exhibited for the first time at the highly renowned Frankfurt Bookfair – complement Mondi’s offering at the high end of its professional print portfolio. It is called ‘Paper for Perfectionists’ because it fulfils the most demanding requirements for sophisticated and elegant printed documents – ideally suited for book printing projects. Graphic designers, advertising agencies and fine book publishers are just a few of the creative industries that will appreciate PERGRAPHICA®’s variety of options: two textures (Rough and Smooth), three shades (High White, Classic and Natural) and six grammages between 90 and 300 g/m2.

As a hybrid paper, PERGRAPHICA® works well with all printing technologies. It delivers consistent, high-quality results whether used for offset or digital printing. It is also well-suited to a variety of post-print processing such as cellophaning, embossing, creasing, die-cutting and more.

NEUJET®, Mondi’s newest high-speed inkjet paper

The NEUJET® portfolio will also be presented at the Frankfurt Bookfair. It represents Mondi’s next generation of high-speed inkjet papers optimized for medium to heavy color book printing applications. The portfolio is offered in two quality levels, standard and premium, and two surface finishes, matte and silk, closing the gap to coated offset printing. Publishers and book printers will be able to see books printed on DNS® high-speed inkjet and DNS® premium – testament to our wide paper portfolio dedicated for inkjet printers.

IQ color – an extensive colour range

The IQ color range encompasses 36 standard colors, from soft pastels to bright neons and bold black. Book printers can experience the superb colour uniformity and consistency of IQ color in the new Visual Book – the “Art of Seeing” – with its smooth surface and even fibre distribution for high-quality printing and itself a piece of art. It invites people to take a journey through colour and explore visual phenomena and perception. Mondi’s tinted papers achieve top print results whether using digital laser, hybrid or offset printing technologies. IQ color also features a high degree of light-fastness for a print product that will last for years. “IQ color delivers better print quality and more flexibility than you expect – the possibilities are endless”, added Klumpp.

Jutta Wacht, Art Director at the creative agency Say Say Say, Inc., which designed the book, was impressed by the variety of weights and formats in which IQ color is available, from A4 and A3 to folio sheets and reels. “The great number of formats and different grammages show that IQ color is perfectly suited to professional printing. Its good printability showed us that you can easily use colourful paper for a book project or a catalogue,” she said.

Sustainable. Every day.

“Customers have peace of mind knowing that all Mondi papers are environmentally certified, so they have the best paper solutions combined with proven, environmentally sound production. Hence sustainability is one of the key drivers of Mondi’s business”, underlines Klumpp. All Mondi uncoated fine paper branded products are part of Mondi’s Green Range, meaning that they are FSC® or PEFC™ certified, 100% recycled or totally chlorine free bleached (TCF). Mondi continually invests in making its mills and production plants as energy efficient and sustainable as possible. For Mondi, sustainability makes good business sense - every day.

Get in touch with Mondi.

To meet Mondi during Frankfurt Bookfair, please stop by in hall 4 at booth F94.

We are Mondi: IN TOUCH EVERY DAY

Mondi is an international packaging and paper Group, employing around 25,000 people across more than 30 countries. Our key operations are located in central Europe, Russia, North America and South Africa. In 2016, Mondi had revenues of €6.7 billion and a return on capital employed of 20.3%.

We are fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and compound plastics, to developing effective and innovative industrial and consumer packaging solutions. With over 100 products customised into more than 100,000 solutions, we offer more than you may expect. Leading brands around the world rely on our innovative technologies and products across a variety of industries such as agriculture; automotive; building and construction; chemicals and dangerous goods; food and beverages; graphic and photographic; home and personal care; medical and pharmaceutical; office and professional printing; packaging and paper converting; pet care; retail and e-commerce; and shipping and transport.

We believe sustainable development makes good business sense. It's integral to our responsible and profitable growth, and embedded in everything we do, every day. We continue to look for ways to do more with less, promote the responsible management of ecosystems, develop and inspire our people, and enhance the value that our sustainable product solutions create.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for Mondi Limited under the ticker code MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker code MNDI. We have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

About Mondi Uncoated Fine Paper

Mondi Uncoated Fine Paper is part of Mondi Group. In 5 paper mills in Austria, Slovakia, Russia, and South Africa Mondi Uncoated Fine Paper produces environmentally sound office and professional printing papers tailored to the latest professional digital print technology. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSC® or PEFC™ certified, 100% recycled or bleached entirely without chlorine.

Its renowned brands such as Color Copy, DNS®, IQ, MAESTRO®, NAUTILUS®, BIO TOP 3®, PERGRAPHICA® or Snegurochka are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication.

UMV to supply coaters to OOO Mayak-Technocell (MTC), Penza Russia

Joint venture OOO Mayak-Technocell (MTC) have selected UMV Coating Systems to supply key components for their new PM6 in Penza Russia.

The contract contain state of the art coating units for surface treatment of both top- and reverse side of the paper.

The new PM 6 will produce décor- and non-woven wallpaper base and production start is scheduled to the first quarter of 2018

For more information please contact:

Daniel Ragnarsson, Executive VP Sales

This email address is being protected from spambots. You need JavaScript enabled to view it.

+46 522 982 81

ANDRITZ with successful upgrade of two screw presses for Metsä Board Joutseno

International technology Group ANDRITZ has successfully started up another upgraded screw press installed at the Joutseno mill of Metsä Board, Finland. This upgrade follows a separate screw press rebuild for Metsä Board Joutseno that was completed successfully in late 2016.

The rebuild of both screw presses (#21 and #22) included installation of a new Low-Energy Screw Shaft (LESS) as well as split grooved baskets for the medium-pressure zone in order to widen the operating window of the presses and allow higher production rates. The design of the LESS enables a new compression curve, resulting in a higher throughput at the same installed power.

Screw press #21 at Metsä Board’s Joutseno mill after upgrade by ANDRITZ. © ANDRITZ

Screw press #21 at Metsä Board’s Joutseno mill after upgrade by ANDRITZ. © ANDRITZ

The screw press upgrades are part of the step-by-step optimization of the BCTMP (bleached chemi-thermomechanical pulp) process that is currently in progress, with the overall aim of improving the availability of the plant. Press #21 is used as a wash press, and press #22 acts as a secondary stage in the washing process.

Metsä Board is a leading European producer of premium fresh fiber paperboards, including folding boxboards, food service boards, and white kraftliners. The company is part of Metsä Group, a Finnish forest industry group that operates in some 30 countries. The Joutseno mill produces BCTMP for Metsä Board’s own board mills and has a production capacity of 320,000 t/a.

The ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metalworking and steel industries, and for solid/liquid separation in the municipal and industrial sectors as well as for animal feed and biomass pelleting. Other important business segments include automation and service business. In addition, the international Group is also active in the power generating sector (steam boiler plants, biomass boilers, recovery boilers, and gasification plants) and in environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard as well as recycling plants. The publicly listed technology Group is headquartered in Graz, Austria, and has a staff of approximately 25,400 employees. ANDRITZ operates more than 250 sites in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Improved presence for Metso's flow control business thanks to new distribution agreement with Croatia-based Eco Consult

Metso is expanding the coverage of its flow control solutions with a distribution agreement with the Croatia-based company Eco Consult d.o.o. The agreement was signed in 2017, and orders have already been placed for refinery and geothermal projects.

The company operates particularly in Eastern Europe and already has a 13-year history of cooperation with Metso.

"We are excited to take our cooperation to the next level. Sustainability is the key for us, and Metso's high-quality, proven valve solutions are a match for us and our customers. As a distributor, we can now provide an impressive range of Metso valves combined with our knowledge and extensive experience of them," says Goran Pavlovic, CEO of Eco Consult.

Eco Consult has a strong presence in the power, oil and gas industries, and it also serves e.g. other process industries, energy projects and steel production.

"This agreement allows us to extend the availability of our solutions vastly in Europe and provide comprehensive solutions to customers as an addition to our local services," says Robert Prinz, Director for Central and Eastern Europe of Flow Control at Metso.

Metso's wide product scope for demanding conditions include Neles® linear globe valve (left), Neles® R-series V-port segment valve (middle) and Neles® Neldisc high performance triple eccentric disc valve (right).

Metso's wide product scope for demanding conditions include Neles® linear globe valve (left), Neles® R-series V-port segment valve (middle) and Neles® Neldisc high performance triple eccentric disc valve (right).

First orders received

The first order for control valves, received in Q1, was for a refinery expansion project in Russia. Eco Consult was able to offer Metso's comprehensive variety of valves, resulting in a one-stop-shop solution that saved time and resources for the customer. The order included Neles® globe and segment valves, all with Metso's actuator and ND positioner. Metso's Neles® standard and severe service globe valves are designed to operate at extreme pressures and temperatures.

The second order was received in Q2 for a geothermal project in Croatia for Neles® control valves, all in a high-alloy material that ensures corrosion resistance and very high mechanical strength.

The valves in a geothermal power plant must endure demanding process conditions, such as high pressure differences, flashing and silica scaling, and they must meet all safety requirements. Today, Metso has the widest product scope with an extensive pressure rating for the wellhead phase in the process.

Distribution channel expansion calls for recognized partners

Developing the distribution channel globally is one of the most important strategic growth initiatives of Metso's Flow Control business. By partnering with the top distributors, Metso improves its presence in the traditional core areas, as well as in new markets, to serve its customers better.

Eco Consult d.o.o. is an international company, based in Croatia with a goal of designing, implementing and operating sustainable, energy efficient solutions. www.ecoconsult.hr

Metso is a world-leading industrial company serving the mining, aggregates, recycling, oil, gas, pulp, paper and process industries. We help our customers improve their operational efficiency, reduce risks and increase profitability by using our unique knowledge, experienced people and innovative solutions to build new, sustainable ways of growing together.

Our products range from mining and aggregates processing equipment and systems, to industrial valves and controls. Our customers are supported by a broad scope of services and a global network of over 80 service centers and about 6,000 service professionals. Metso has an uncompromising attitude towards safety.

Metso is listed on the Nasdaq Helsinki in Finland and had sales of about EUR 2.6 billion in 2016. Metso employs over 11,000 people in more than 50 countries. Expect results.

PCMC names Dave Wall as Value Stream Leader of flexographic printing

Wall brings in-depth knowledge and years of experience serving customers to his new role

Paper Converting Machine Company (PCMC)—a division of Barry-Wehmiller and a leading supplier of high-performance converting machinery for the tissue, nonwovens and package-printing industries worldwide—is pleased to announce that Dave Wall has accepted the position of Printing, Coating and Laminating Value Stream Leader.

In this role, he will provide overall leadership for PCMC’s printing, coating and laminating (PCL) value stream, focusing on everything from sales support and project management, to acceptance of equipment in customers’ facilities.

In this role, he will provide overall leadership for PCMC’s printing, coating and laminating (PCL) value stream, focusing on everything from sales support and project management, to acceptance of equipment in customers’ facilities.

“Dave has a proven track record of successfully aligning internal operations to exceed customer expectations and enhance their trust,” said Bart Hardy, PCMC’s Vice President of Major Machinery. “His leadership skills and knowledge of the PCL product line make him an asset to the value stream.”

Wall has been part of PCMC’s PCL value stream for 25 years. He started as an Electrical Engineering Co-op in 1992 while attending the University of Wisconsin-Madison, and worked as an Electrical Engineer for 12 years. Wall was an integral part of PCMC’s first gearless press developments, and has continued to accept increasing levels of responsibility. For the past 13 years, he has been an Engineering Leader in the PCL group.

Wall will operate from PCMC’s headquarters in Green Bay.

ABOUT PAPER CONVERTING MACHINE COMPANY (PCMC)

Paper Converting Machine Company (PCMC) specializes in the design and manufacture of high-performance converting machinery for the tissue, nonwovens and package-printing industries worldwide. Our comprehensive product offerings include rewinding, laminating, printing, embossing, perforating and packaging equipment for tissue and towels; folding and converting machines; and a complete range of flexographic printing presses, serving the flexible-packaging, prime-label and carton-converting industries. For more about PCMC, which is part of Barry-Wehmiller, go to pcmc.com

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2.8 billion organization with more than 11,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com

Valmet reconfirmed as a constituent of the Ethibel Sustainability Index Excellence Europe

Valmet has been reconfirmed as a constituent of the Ethibel Sustainability Index (ESI) Excellence Europe since 20 September 2017. The index contains 200 of the European stock listed companies that display the best performance in terms of corporate social responsibility (CSR).

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

Ethibel is constantly looking out for companies which may be eligible for ethical investments and to be included in its ethical investment register. From the investment register 200 of the best companies are selected to the Ethibel Sustainability Index. Main areas of assessment are human capital, environmental management, market ethics, governance, social impact and human rights. The assessment is based on external information sources such as sustainability reporting and company web sites.

"The reconfirmation as a constituent in the Ethibel Sustainability Index is a recognition of Valmet's strong focus and consistent progress in sustainability. For investors Valmet's inclusion in this index provides further assurance of the company as an ethical investment target. In its assessment, Ethibel is using only external information sources, and thus the inclusion in the index is also a recognition for Valmet's transparent and comprehensive reporting and communications around sustainability," says Anu Salonsaari-Posti, SVP, Marketing, Communications and Sustainability at Valmet.

In September 2017, it was announced that Valmet was included in the Dow Jones Sustainability World and Europe indices for the fourth consecutive year. Valmet is also included in the CDP Climate A-list for its actions and strategy to mitigate climate change.

About the Ethibel Sustainability Index Excellence Europe

The Ethibel Sustainability Index Excellence Europe includes the 200 best performing European companies in the field of corporate social responsibility. The analysis is based on research carried out by the rating agency Vigeo Eiris. Ethibel actively promotes socially responsible investing and corporate social responsibility on the financial markets. Read more

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Smithers Pira forecasts nonwovens as fastest growth area for fluff pulp over the next ten years

Global fluff pulp consumption in 2017 is 5.8 million air-dried and has value of $4.6 billion according to the latest exclusive research from Smithers Pira.

Smithers’ in-depth market analysis shows how this demand will increase by 3.7% per year to reach 7.0 million air-dried tonnes in 2022. Value growth will be slower, and yield a market value of $5.3 billion by the end of the study period, with a series of emergent opportunities for fluff pulp suppliers and users fueling worldwide expansion.

Historically, the hygiene segment - diapers/nappies, feminine hygiene pads, and adult incontinence products – has consumed the majority of the fluff pulp globally, and driven overall growth 2012, hygiene end uses accounted for 90.3% of world fluff consumption By 2022, though, these end uses will consume only 89.5% of the world fluff pulp; a small drop in market share, but an indicator of longer-term trends that have been place for Several years.

Historically, the hygiene segment - diapers/nappies, feminine hygiene pads, and adult incontinence products – has consumed the majority of the fluff pulp globally, and driven overall growth 2012, hygiene end uses accounted for 90.3% of world fluff consumption By 2022, though, these end uses will consume only 89.5% of the world fluff pulp; a small drop in market share, but an indicator of longer-term trends that have been place for Several years.

Volume growth in hygiene will follow the market average, but the fastest expanding end-use application will be nonwovens, where consumption for the next 5 years is forecast to increase at 5.5% per year.

‘These new markets will evolve alongside developments in the supply of fluff pulp’. Phil Mango, author of the Smithers report, says: ‘The trend in fluff pulp production is expansion in South America and North America, while Europe has concentrated on modifying pure fluff-producing mills to biorefineries. A biorefinery uses biomass as the input, and produces a wide variety of products and energy. In the fluff pulp biorefinery, wood is input and chemicals, pulp, and even energy are produced. This is not only more sustainable as a process, but improves the profitability of the mill, especially one with marginal profitability.’

Geographically, the fluff pulp is relatively mature in North America and Western Europe, meaning these regions will have the lowest growth rates for fluff pulp. While Asia, South America, and Eastern Europe will increase relative market share.

The competitive landscape for fluff pulp is dominated by large pulp and paper companies headquartered in North America. This is due mainly to the presence of the most optimal wood species for fluff pulp in North America. The three largest fluff pulp producers are International Paper, Georgia-Pacific, and Domtar. These three producers account for about 4.9 million air dried tonnes, or 80% of all fluff pulp production in 2017.

The short growing seasons in northern Europe and Asia, and sub-optimal soil and climate conditions in most of southern Asia, have reduced the potential of these regions. Infrastructure issues in South America and Russia continue to retard progress in these regions.

Brazil: Production and exports of forest products grow in 2017

The results for exports and production from the planted tree sector are positive for the first eight months of 2017. In comparison with this same period last year, exports of pulp rose 4.9%, wood panels 30.4%, and paper 0.6%. This performance led to growth in the production of pulp and paper, on the order of 3.6% and 0.4%, respectively. For wood panels, the good news is that the domestic market for this product is beginning to thaw, with sales 1% higher than during the same period in 2016.

Continue reading below about the performance indicators for the planted tree industry in the 40th edition of Cenários Ibá, the monthly bulletin of the Brazilian Tree Industry (Ibá).

Continue reading below about the performance indicators for the planted tree industry in the 40th edition of Cenários Ibá, the monthly bulletin of the Brazilian Tree Industry (Ibá).

Export revenue – From January to August of 2017, revenue from exports reached US$ 5.5 billion (+9.6%); of this total, US$ 4.1 billion (+12.4%) came from sales of pulp abroad, US$ 1.2 billion (-0.3%) came from paper sales, and US$ 191 million (+23.2%) was the result of wood panels sales. As a result, the trade balance in the sector was positive, with a value of US$ 4.85 billion during the first eight months of the year (+11.4% compared to 2016).

Export destinations – Latin American countries continued to be the main markets for paper and wood panels during the first eight months of the year, with export revenues of US$ 806 million (+11.2%) and US$ 100 million (+20.5%), respectively. China continues to be the main destination for pulp produced in Brazil, accounting for 40.2% of these exports and revenues of US$ 1.6 billion (+22.0%). The second largest destination for pulp is Europe, which during this period was responsible for 31.5% of exports, corresponding to US$ 1.3 billion (+3.9%).

Export volume – 8.9 million tons of pulp were exported (+4.9%), the paper segment traded 1.4 million tons (+0.6%), and 840,000 m³of wood panels were sold (+30.4%) between January and August of this year.

Production – Brazilian pulp production reached 12.7 million tons (+3.6%) and paper surpassed the 6.9 million ton mark (+0.4%).

Domestic sales – Between January and August of 2017, domestic sales of paper reached 3.5 million tons (-0.8%), while the wooden panel sector registered internal sales of 4.2 million m³ (+1.0%).

ABOUT IBÁ

The Brazilian Tree Industry (Ibá) is the association responsible for institutionally representing the planted tree production chain, from the fields to the factory, with its main stakeholders. Launched in April 2014, it represents 55 companies and nine state entities for products originating from planted trees (wood panels, laminate floors, pulp, paper, energy forests and biomass) in addition to independent producers of planted trees and institutional investors. Learn more at www.iba.org