Displaying items by tag: metso

Metso's new Valve Technology Center in Finland opens with strong demand in valves globally

The new facility is in line with the company's long-term strategy to invest in quality and delivery capabilities globally for Metso's valve customers

The new Valve Technology Center in Finland covers an area of 23,000 m2. The adjoining 12,300 m2 office building houses domestic sales, project management, research and development, global service development, training facilities as well as the management and administration of Metso's Flow Control business unit. The location is logistically ideal. It is close to the Port of Helsinki, airport and main highways. Energy efficiency meets the standards set by BREEAM, which is the world's foremost environmental assessment method and rating system for buildings. Both buildings have been built according to the latest Finnish regulations.

Metso's new Valve Technology Center in the Helsinki region, Finland, is officially opened today. The office building and purpose-built factory are home base to 800 automation professionals. Production is working in two shifts on a record pace.

"Our current deliveries have increased by half compared with the corresponding period in the previous year. Production is more than 2,500 valves monthly, and volumes will be further increased order to meet the growing global demand.'' tells Markku Simula, President of Flow Control business in Metso's Automation business line.

Metso develops valve services globally

The fastest growing markets of the technology center specialized in manufacturing of engineered industrial valves are Middle East and China. ''Especially companies in Middle East, Brazil and in China have recently invested at an accelerating pace to new production facilities" explains Simula. The customers include major global companies, such as Saudi Aramco, ExxonMobile, Petrobras and Stora Enso.

Building a new facility in Finland is in line with Metso's investment decisions of previous years to develop Metso's valve services globally. In 2010, Metso opened a state-of-the-art facility in Shanghai, China, and is currently expanding its valve production premises in the US. Metso also has high-class industrial valve facilities in Brazil and Germany.

"Metso is the leading valve solutions and services provider. We have a strong, established market position in the oil & gas, pulp & paper, refining and chemical/petrochemical industries. Our new production and testing facilities allow us to further improve our services to our customers with faster deliveries as well as with a wider product and application scope," Markku Simula summarizes.

Long-term strategy for developing operational capabilities

The investment decision for the Helsinki center was made in 2008 when the market situation looked uncertain. "Nevertheless, we went ahead with our plans in Finland and China. This is a strong message for our  customers globally: We are in the business with a long-term strategy to continuously improve our products and services," Markku Simula emphasizes.

customers globally: We are in the business with a long-term strategy to continuously improve our products and services," Markku Simula emphasizes.

The decisions have proved to be excellent. The newly started facility in Finland reaches record level production, and the Shanghai center has been operating for more than one year also at record level, as it is located in the midst of the world's fastest growing valve market," Simula continues.

New facility enhances research and development

"Our customers are facing increasing operating pressures and more advanced applications. We have a long tradition to supply valves for tough conditions, so we are ready to meet this demand," Markku Simula ascertains. The new Helsinki facility further improves Metso's possibilities for product development. For example, there is a new flow laboratory for valve testing and a new expanded cryogenic testing facility for the LNG industry.

Metso is the leading supplier of control, on-off and emergency shutdown (ESD) valves and intelligent positioners and condition monitoring. "We just launched stainless steel versions of all our Smart products for safety and automated on/off use. Stainless steel products are aimed at the oil & gas market, which is very important for us. Clearly within these industries, there was room especially for safety products, because we have received very positive feedback from our customers so far," Simula says proudly.

Due to Metso's strong position in advanced valves technology, services are becoming a larger business for Metso. In addition to 31 service centers around the globe, a new service center will be opened in India within the next six months. As examples of the growth in services, the major Brazilian oil company Petrobras recently awarded Metso a service contract that covers the supply of spare parts and maintenance services for 11 refineries in Brazil.

Invitation to a pre-silent Q&A session with Metso’s management

Metso’s management will host a pre-silent Q&A session regularly prior to stepping into silent periods during 2011. The purpose of these sessions is to serve all financial community parties equally and increase understanding of earlier stated information by giving an opportunity to set questions to our management. No new information will be disclosed but the aim is to clarify information on our operations and operating environment. Therefore, we don’t intend to publish separate releases in connection with these events. Each event will be webcasted and an on-demand recording will be available on our website.

Pre-silent Q&A session before Q3/2011 result publication

will be held on Tuesday, October 4 at

3.00 p.m. EET (Helsinki),

1:00 p.m. GMT (London),

2:00 p.m. CET (Paris),

8:00 a.m. EDT (New York).

Metso’s President and CEO Matti Kähkönen and CFO Harri Nikunen will be present answering the questions. Marja Mäkinen, Investor Relations Manager will act as a moderator in the session.

The Q&A session can be participated through live webcast or conference call (please see the details below). Questions can be presented through both channels or by sending questions in advance via email to This email address is being protected from spambots. You need JavaScript enabled to view it. by Monday, October 3 by 12:00 p.m. EET (Helsinki).

Live webcast at www.metso.com/webcasts.

Conference call participants are requested to dial in few minutes prior to the start of the teleconference

• US: +1 334 323 6201

• Other countries: +44 (0)20 7162 0025 or +44 (0)20 7162 0077

• Access code: Metso

A replay of the conference call will be available for 14 days until October 18, 2011 on the following phone numbers:

• US: +1 888 365 0240

• Other countries: +44 (0)20 7031 4064

• Access code: 885 219

A transcript of the event will be available on our website at the latest on Thursday, October 6, 2011.

Welcome to our pre-silent Q&A session!

Metso Corporation

Metso's new control applications improve pulp and paper mill operations

Again Metso DNA is leading the way by introducing first in the world new control applications enhancing productivity and profitability. Metso DNA is now strengthened with new control applications, such as the winder controls, power plant turbine controls and machine condition monitoring. Metso is also pioneering usability in the process control work.

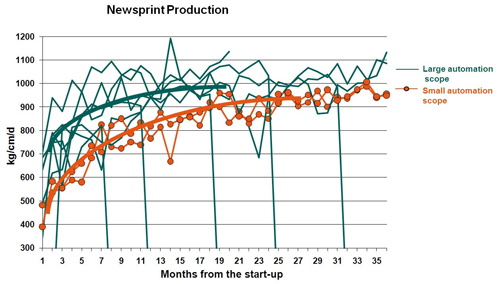

The chart shows the correlation between start up of the paper machine and scope of Metso automation system delivery. The largest scope results clearly the fastest start-up for new paper machine.

Metso DNA offers now pulp and paper makers a single system for all controls, from the fiber line to baling information, and from head box to winder.

Winder controls

''The renewed Metso DNA offers now winder controls, which increase the transparency between the winding process and papermaking process controls. "The new winder controls enable following paper profiles through the winder controls, which improves both runnability and productivity of the winding process," says Mika Lehmusvaara, Technology Manager, Automation Sales, Metso Paper.

Machine condition and runnability monitoring

Another new application is machine condition and runnability monitoring which Metso is first to integrate within the process controls. The operator sees condition monitoring alarms in the same interface where process alarms. Condition and runnability monitoring has traditionally been a separate system mostly utilized by maintenance specialists. Thanks to Metso DNA Machine Monitoring, the same information can be shared with machine operators in the control room.

Turbine control

Integration of turbine control, turbine protection and turbine management applications into Metso DNA automation system provides customer with easy and cost efficient maintenance and reliability based redundant process controllers. The Metso DNA turbine automation consists of special turbine control features like fast governor control and integrated simulator. Protection functions include over speed protection and machine protection. Tools for mechanical condition and turbine performance monitoring are also included.

Good usability enables positive emotions and feelings

Metso is also pioneering usability in the process control work. Metso DNA takes a new approach to usability by taking emotions and feelings a part of the process control work. "Despite fact-based by its nature, process control work at pulp and paper mills includes a lot of feelings connected with solving situations. When all the aspects of business and production processes are under control, people in various tasks can enjoy feeling of control in their work," explains Jaakko Oksanen, Product Manager for Metso DNA.

An example about usability is that Metso DNA is the only system in the world, where the user receives the process data in real time and retrospectively from the same user interface, with one push of a button.

''The user can easily access all the data collected during his/ her absence, for example, over the weekend. Traditionally, the history of this information requires separate applications and data analysis is difficult. This is one example of how we have usability and the subsequent positive emotions and positive user experience taken into account, ''Jaakko Oksanen explains.

One system for all controls

The new Metso DNA provides pulp and paper makers with measurements, analyzers and a complete selection of state-of-the-art advanced process controls.

Having all controls for machine, process, quality and drives within the same system gives the customers several benefits.

One systems enables pulp and paper mills to integrate all operations into one mill-wide or even corporate-wide entity enabling easy access to information for comparing and combining process data. The operators need to know only one systems. Metso DNA customers also benefit from having a single source for global system support, updates and spare parts.

In new machine installations, Metso control system allows for quick start-ups.

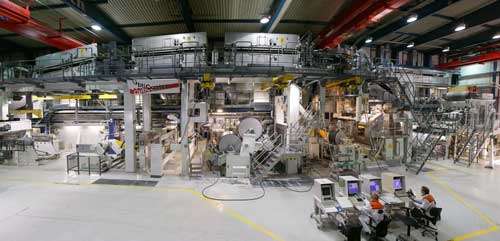

The world's fastest and most demanding coating machine starts up with Metso drive controls reaching record speed

The benefit of using a single control system was again proved in Järvenpää, Finland, when the restart of Metso’s Järvenpää Pilot Coater immediately reached a new world record speed of 3,160 m/min.

Restart of Metso's Järvenpää Pilot Coater immediately reached a new world record speed of 3,160 m/min.

The restart took place on September 1 after an automation upgrade. The new 35 group drive is controlled directly by Metso DNA automation system in which the drive controls are integrated with the machine control system. Tension controls are implemented with a new multivariable control, developed by Metso, to achieve more accurate tension management in dynamically changing coater conditions.

The pilot coater can run basis weights of 25 – 350 g/m2. Available coating technologies are OptiSizer film sizing, OptiCoat Duo double backing roll coating, OptiCoat Jet nozzle coating, OptiBlade short dwell coating, OptiLayer curtain coating and ValSpray spray sizing.

One system, several benefits for customers

Metso DNA offers pulp and paper makers a single system for all controls, from fiber line to baling information, and from headbox to winder enabling faster startups. It provides pulp and paper makers with measurements, analyzers and a complete selection of state-of-the-art advanced process controls.

Having all controls for machine, process, quality and drives within the same system gives customers several benefits. In new machine installations, the Metso control system allows for quicker startups. One system enables pulp and paper mills to integrate all operations into one mill-wide or even corporate-wide entity, enabling easy access to information for comparing and combining process data. Operators only need to learn to use one system. Metso DNA customers also benefit from having a single source for global system support, updates and spare parts.

Metso launches new OptiConcept M paper and board making line

Metso has launched a new, modular paper and board making line, called OptiConcept M. A member of the well-proven OptiConcept production line family, the new OptiConcept M optimizes machine investment in line with each mill’s capacity needs. OptiConcept M paper and board making lines are specifically designed for mills in growing markets to ensure optimized productivity at minimal operating costs.

High productivity at low operating costs

Savings in operating costs are achieved through precise dimensioning of processes, proven technological solutions, optimal running parameters, effective maintenance operations and fully integrated automation solutions. These OptiConcept M features result in minimized cost per ton produced and shorter investment payback periods.

The proven technology utilized in OptiConcept M and the integrated processes enable high-quality production with lower-quality raw materials and lighter basis weights, yet with equal strength properties and high raw material efficiency.

The new OptiConcept M paper and board making line stands for economy, safety and usability.

Safety, usability and optimized environmental performance

OptiConcept M has been designed both visually and physically with the requirements of its users in mind. For example, the design of the machinery allows for easy and safe changing of rolls and wear parts, thus reducing the total duration and cost of maintenance shutdowns.

Optimized processes, innovations, smart controls and accurate dimensioning decrease the use of steam, gas, electricity, water, chemicals and other raw materials, and reduce emission levels. The new OptiConcept M production line meets and exceeds environmental regulations.

Metso to supply coated board line to International Paper & Sun Cartonboard in China

Metso will supply a coated board production line to International Paper & Sun Cartonboard Co., Ltd in China. The value of the order will not be disclosed. A typical value of this kind of a production line is EUR 90–120 million, depending on the scope of the delivery and the production output.

Metso’s delivery will include a complete coated board machine from headbox to winders, including stock preparation and approach flow systems, hoods with machine ventilation and coating color preparation systems. Additionally, the full-scope automation delivery will include process, machine and quality controls, web break monitoring and web inspection as well condition monitoring. The main part of the order is included in Paper and Fiber Technology’s third quarter 2011 orders received and the automation delivery in Energy and Environmental Technology’s third quarter 2011 orders received.

International Paper & Sun Cartonboard Co., Ltd. is a joint venture co-established by International Paper and Sun Paper Group. The joint venture combines International Paper’s management and technology experience with Sun Paper Group’s local resources and in-depth understanding of local market. The combined capacity of its three machines is 850,000 t/y and the net sales in 2010 were about EUR 530 million (USD 700 million).

Metso to deliver biomass boiler for We Energies in Wisconsin, USA

Metso will supply a biomass boiler for the We Energies/Domtar Biomass Energy Project owned by We Energies. The biomass boiler is a key component of a major investment to build a new biomass-fueled cogeneration power plant which will be located at the Domtar Mill in Rothschild, Wisconsin, USA. The value of the order will not be disclosed.

Metso will supply a biomass boiler for the We Energies/Domtar Biomass Energy Project owned by We Energies. The biomass boiler is a key component of a major investment to build a new biomass-fueled cogeneration power plant which will be located at the Domtar Mill in Rothschild, Wisconsin, USA. The value of the order will not be disclosed.

The biomass boiler plant will utilize circulating fluidized bed (CFB) technology and will use waste wood from logging and mill activity, tree trimming and sawdust as the main fuel. The plant will produce approximately 50 megawatts of renewable electric power and provide process steam to the mill.

"We chose Metso for our biomass project based on their proven biomass experience and robust boiler design features, coupled with their strong organizational commitment to sustainable technologies. "We fully expect to realize the project goals of cogenerating cost-effective renewable electric power and process steam , while reducing overall emissions at the Domtar Rothschild mill", says Al Mihm, project director at We Energies.

"Metso is proud to be chosen by We Energies for such an industry-leading collaboration. This order continues to reinforce Metso's commitment to be the pre-eminent supplier of bioenergy plants", says Robert Deneault, General Manager Capital Sales at Metso's Power business line in North America. "Once built, this boiler will join a fleet of 33 Metso CFB boilers already operating in the US, and this one will be the largest and most efficient biomass-fired boiler of them all", adds Dave King, President at Metso's Power business line in North America.

The commercial operation of the plant is scheduled for 2013. The value of the order is included in the Energy and Environmental Technology's second quarter 2011 orders received.

The We Energies/Domtar Biomass Energy Project is owned by We Energies, an investor-owned electric utility company based in Milwaukee, Wisconsin, USA. We Energies serves more than 1.1 million electric customers in Wisconsin and Michigan's Upper Peninsula and more than 1 million natural gas customers in Wisconsin. We Energies is the trade name of Wisconsin Electric Power Company and Wisconsin Gas LLC, the principal utility subsidiaries of Wisconsin Energy Corporation (NYSE: WEC). Visit the We Energies website at www.we-energies.com. Learn more about Wisconsin Energy Corporation by visiting www.wisconsinenergy.com.

Metso strengthens its automation foothold in Finnish bioenergy production

Metso will supply advanced automation systems and solutions to two new bioenergy power plants currently under construction in Finland, while receiving another replacement order.

Porvoon Energia Oy has ordered a Metso DNA automation system including safety automation for its new biomass-fired power plant located in Tolkkinen, about 50 km northeast of Helsinki. Representing the latest know-how and technology, the plant has a capacity of 12 MW of electricity and 38 MW of thermal heat that will be used for district heating in the town of Porvoo. The boiler will be supplied by MW Power Oy, a company co-owned by Metso and Wärtsilä. The delivery also includes an electrostatic precipitator controlled with Metso DNA. The plant, which will be started up in early 2013, will be fueled by forest residues, bark and sawdust.

Another Metso DNA system including safety automation, field design as well as information and reporting applications will be delivered to a bioenergy plant built by Hämeenkyrön Voima Oy in Hämeenkyrö, located about 220 km northwest of Helsinki. The BFB boiler plant will run on forest residues and other wood-based fuels, with peat as auxiliary fuel. It will produce electricity and process heat for the nearby M-real Kyro paper and board mill, as well as electricity and district heat for Leppäkosken Sähkö Oy, a local electricity company. When started up in the fall of 2012, it will have an electricity capacity of 12 MW and thermal capacity of 55 MW.

Additionally, Metso has received an order from Helsinki Energy, one of the largest energy companies in Finland, for a Metso DNA system to replace an existing automation system in its 118 MW Kellosaari reserve power plant. With the modernized system, the plant ensures that electricity will be available for the Helsinki region in case of sudden nationwide disturbance situations. The delivery also includes safety interlockings, field design, field devices, an information management application and integrated vibration monitoring. The new system will be integrated with the Metso DNA system already used at the Salmisaari power plant, which runs the Kellosaari plant. The renewed automation will be started up in February 2012

Industrie Cartarie Tronchetti starts up a Metso-supplied tissue production line in France

The Metso-supplied tissue line at Industrie Cartarie Tronchetti (ICT) in Montargis, France, successfully started up on July 15, 2011.

Metso’s delivery comprised a complete tissue production line with complete stock preparation equipment including OptiFiner RF refiners and an Advantage DCT 200 tissue machine. The tissue machine features an OptiFlo II TIS multi-layer headbox, a Metso Yankee cylinder, an Advantage AirCap hood, an Advantage WetDust dust management system and an Advantage SoftReel reel. Also included was the first installation of Metso’s new OptiThick DF disc filter. The production line is optimized to enhance final product quality and save energy. The delivery also comprised an extensive automation package including Metso DNA machine, process and drive controls, as well as a Metso IQ quality control system with non-nuclear Metso IQ Fiber Weight Measurement.

With a large width and an operating speed of 1,900 m/min, the new production line will produce 70,000 tons a year of high-quality facial, toilet and towel grades. The raw material for the new line will be virgin pulp.

Industrie Cartarie Tronchetti is headquartered in Lucca, Italy, and operates mills in Italy, Spain and Poland with a combined capacity of 400,000 tons a year, has a turnover of more than EUR 500 million and around 1,200 employees. The group has been present in France since 1999 through its sales organization based in Paris.

Metso Kappa Q Analyzer to improve fiberline control at Södra Cell's Mörrum mill

Upgrading to Metso Kappa Q technology provides existing users of Metso Kappa Analyzers with both new and faster measurement possibilities.

Södra Cell's Mörrum mill in southern Sweden is currently installing a new Metso Kappa Q analyzer. It will replace one of three analyzers operating on the mill's two fiberlines where Metso's Kappa analyzer technology has been in use since 1994.The new analyzer with 7 sample points in the ECF fiberline will measure pulp lignin content and brightness as well as shive content for improved process optimization and quality control. Start-up of the analyzer on fiberline 2 will be completed during September 2011.

"With 400 delivered, Metso Kappa Analyzers have gained a solid reputation for reliability around the world and this latest repeat order is further proof of our customers' confidence in Metso technology," says Jarmo Koskinen, Business Manager, Metso Pulp Analyzers. "Many of the new features and measurements have been developed with help from mills like Mörrum and it is especially satisfying to see them reaping the rewards of our continuing cooperation."

The Metso Kappa Q utilizes patented sweep technology to measure kappa and brightness with a unique two-point calibration method. The fast and accurate Kappa and brightness measurement provides mill with new possibilities for profitable and sustainable pulp production. The addition of shive analysis has provided a valuable diagnostic tool that helps to produce more uniform pulp and gives the mill precise information of grade differentiation for premium pricing potential.

Mörrum produces 425,000 tonnes per year of hardwood and softwood pulp on two fiberlines. Much of the pulp produced at Södra Cell in Mörrum is exported to paper mills in Europe to manufacture paper which may become magazines, books, tea bags and many other products. The Mörrum mill is also the source of green electricity and district heating used to heat houses in the Karlshamn municipality.