Metso's New DNA applications for power generation industries: Using automation to increase efficiency, operational knowledge and control

Metso is again breaking new ground by introducing advanced power plant applications that enhance both efficiency and environmental performance.

The Metso DNA automation system has now been strengthened to include new control applications for steam and gas turbines, pulverized coal-fired combustion optimization, and overall machine condition monitoring. The DNA system is also pioneering usability applications in process control work.

"With Metso DNA, you can now have one system for power producers that includes energy management, plant information management, controls for the boiler, turbine and Balance of Plant, as well as safety integrated systems and emissions management," said Edward Coll, regional vice president for Metso Automation Energy and Process Systems.

Turbine control for steam and gas turbines

The integration of applications for turbine control, protection and management into the Metso DNA automation system provides customers with an easy and cost-efficient method to get all turbine functionality in one common system, Coll said.

Functions included for turbine control are auto turbine startup, full arc to partial arc transition, MW control, and several protection features, including over-speed and power load imbalance. Further, an operator training simulator and turbine performance monitoring are also available in the integrated DNA package.

"This level of integration will improve plant responsiveness and lower maintenance and spare parts costs," Coll said.

Pulverized coal-fired combustion optimization

Metso DNA Pulverized Coal Combustion Manager optimizes control reactions to dynamic upsets, such as changes in pulverizer configuration, load demand, or fuel variability, ensuring correct fuel and air flow into the entire furnace. This optimization of the fuel and air mix maximizes combustion efficiency while minimizing emissions. Metso further enhances the reliability of this application by housing it in rugged, and easily redundant, real-time process controllers, rather than a network-based PC.

Overall, plants using the DNA Coal Combustion Manager consume less fuel and decrease emissions and emission adsorbents usage, Coll said.

Machine condition monitoring

Another new DNA application is machine condition monitoring, and Metso is the first to integrate this function within the process controls. The application provides real-time condition monitoring of rotating machines, such as fans, pumps and turbines, and it allows the operator to see condition monitoring alarms in the same interface with process alarms. Condition monitoring has traditionally been a separate system, mostly utilized by maintenance specialists. Now, with the Metso DNA Machine Monitoring application, both monitoring and process alarms can be shared with operators in the control room. This "advance warning system" reduces the likelihood of unscheduled outages and improves maintenance efficiency by alerting operators to potential problem areas before a breakdown occurs.

Sootblowing optimization

The Metso DNA Sootblowing Manager calculates, stores and displays boiler heat transfer characteristics that indicate fouling and deposit accumulation on heat transfer surfaces. It also defines the economically optimal sootblowing sequence and location. By optimizing the sootblowing process, a plant can improve efficiency by lowering soot losses, and also improve reliability by reducing unnecessary sootblowing cycles.

Enhancing usability by increasing operator knowledge and control

Metso is also pioneering "usability" in process control work, providing operational information in both real time and retrospectively, which allows system operators to have much greater insight into processes over time which, in turn, enhances their control.

"Despite being fact-based by its nature, process control work at power plants also includes a lot of interpretation and real-time problem-solving," said Jaakko Oksanen product manager for the Metso DNA automation business line. "When all the aspects of business and production processes are visible and under control, stress is reduced, and people make better decisions because they are in control of their work. It's the perfect combination of artificial and human intelligence coming together to solve problems."

An example of usability: Metso DNA is the only system in the world from which the user receives process data in real time and retrospectively, from the same user interface, using the same graphic displays, with one push of a button.

"The user can easily access all the data collected during his or her absence, for example, over the weekend," Oksanen said. "Traditionally, the history of this information required separate applications, and data analysis was difficult. Here, we have taken usability into consideration to enhance operator control and create a more knowledgeable, positive user experience."

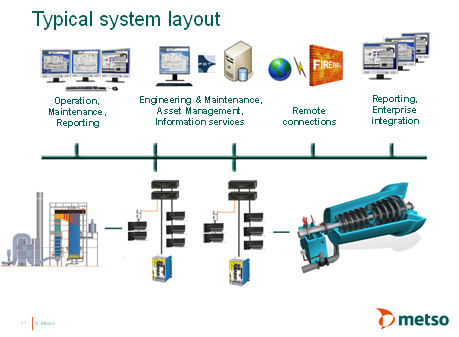

Lower operating costs based on Metso life cycle support

Metso DNA is supported by a global network of local experts who provide customer service on-site and through remote connectivity. In addition to product support, the portfolio of Metso services includes training, process improvement services and assured upgrade capability. The single system architecture of Metso DNA enables lifelong compatibility and upgrading options. As a result, Metso customers have confidence that their investment will pay dividends for the long-term because the system provides step-by-step upgrade paths that facilitate future system improvements according to changing process and functionality needs.

One system for all

The Metso DNA system enables power plants to integrate all operations into a single plant-wide, or even corporate-wide entity, enabling easy access to information for comparing and combining process data. Operators only need to know one system, and customers also benefit from having a single source for global system support, updates and spare parts. The result is a power plant that has lower fuel costs, reduced emissions and higher availability.