Worldwide there is an expected rapid growth of paper as in the past paper demand grew more rapidly than Gross National Product and has been unaffected by the often predicted “paperless office”. Covering this huge demand only by using fresh fibre pulp would lead to en overexploitation of forest resources. Therefore it has mainly to be covered by recycling of used paper products.

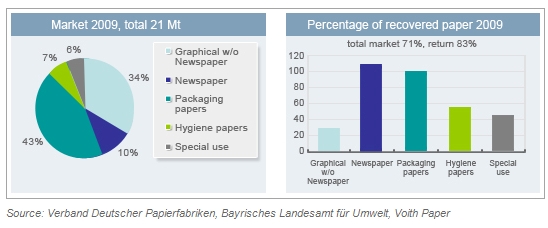

Even though 80% of used paper is collected still only 70% of it is recycled even though recycling is economically very attractive. 30% of paper is still made out of virgin fibres.

Why don′t we recycle all of the paper we collect? During the recycling process paper is ground. Its fibres are shortened and hence the stability of the paper is reduced making it unsuitable for many applications. We have to consider that “70% recycled” also means 50% has been recycled more than once, leading to a further deterioration in performance. To compensate this 30% of fresh fibres are added to the paper. Particularly graphical papers have a very low content of recovered material.

With our viscose fibres we were able to achieve an increase of paper quality demonstrated by e.g. higher double fold numbers and tear lengths by adding only 2–3% of our short cut viscose fibres to the pulp. With these short cut fibres it is possible to use nearly 100% of the cheaper recycled pulp. Instead of adding 20–30% of fresh fibre pulp there is only a need to add 2–3 % of viscose fibres such as Bellini.

This means that resource consumption can be reduced by up to 90%. Furthermore savings can be made on the raw material price because adding 2–3 % of viscose fibres is still cheaper than adding 20–30% of virgin pulp.