International technology group ANDRITZ has received an order from Tamil Nadu Newsprint and Papers Limited (TNPL) to supply a complete recovery island for its mill in Mondipatti Village, Tamil Nadu, India. Start-up is scheduled for early 2021.

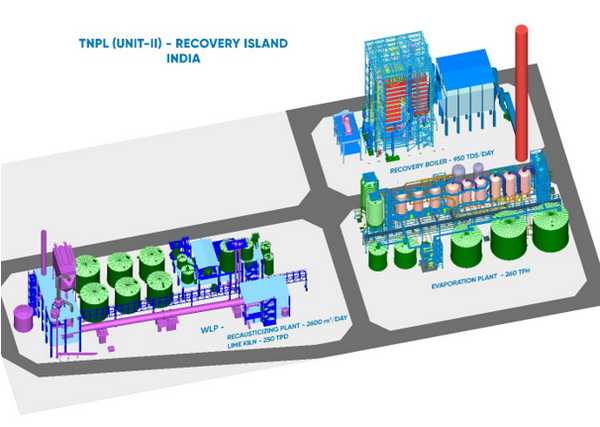

ANDRITZ recovery island with evaporation plant, recovery boiler and white liquor plant “Photo: ANDRITZ”.

ANDRITZ recovery island with evaporation plant, recovery boiler and white liquor plant “Photo: ANDRITZ”.

The ANDRITZ scope of supply includes:

- A HERB recovery boiler with a capacity of 950 tds/d on EPC basis, with a provision for upgrade to 1,100 tds/d in the future

- An evaporation plant with a capacity of 260 t/h on EPC basis, which will concentrate black liquor to a final dry solids content of 75%

- A white liquor plant containing

- A recausticizing plant (2,600 m3/day white liquor production) on EPS basis

- A lime kiln (250 t/d) on EPC basis.

This investment is part of TNPL’s mill expansion plans to further strengthen its position in the printing and writing paper segment. TNPL is a leading producer of paper and board based on bagasse – a sugar cane residue. The mill’s “Unit II” produces multi-layer coated board for use in pharmaceutical, health care, food, cosmetics and consumer packaging applications.

The recovery island to be supplied by ANDRITZ incorporates state-of-the-art technologies, thus ensuring highest energy efficiency and optimum environmental protection. ANDRITZ HERB recovery boilers maximize the use of thermal energy while efficiently recovering cooking chemicals. The latest ANDRITZ technology for evaporation plants ensures optimum reuse of condensates with minimum energy consumption, while the white liquor plant will recycle and reuse the mill’s process streams in order to minimize waste.