Displaying items by tag: Runtech Systems

The Switch direct-drive, high-speed turbo technology becomes industry standard

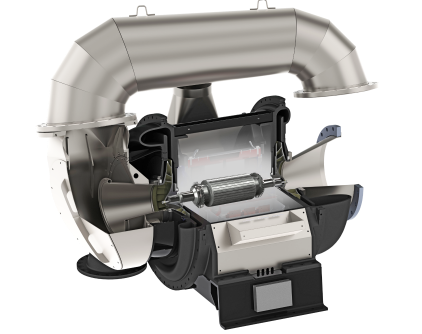

Finland-based Runtech Systems has placed its largest multi-million-euro order for high-speed turbo motors from The Switch for use in its turbo vacuum blower systems for paper machines. Using direct-drive technology developed jointly by both companies since the early 2000s, these turbos have now become widely accepted in the paper industry thanks to their superior advantages. Along with being a reliable, long-lasting solution, they bring customers unmatched simplicity and energy efficiency.

Years of product development and unrelenting sales work are now paying back for Runtech Systems with their unique turbo vacuum pump systems specifically designed to replace the poorly performing water ring pumps in paper mills. Runtech has superior competence in analyzing and designing efficient paper manufacturing processes. Together with The Switch, the company harnessed the built-in power of direct-drive, high-speed turbo technology to create a radical solution that has recently become the new industrial standard. The turbo vacuum blower is now a key component in the optimum solution when retrofitting existing paper machines or designing new ones.

Runtech Systems placed its largest multi-million-euro order with The Switch for turbo motors to be used in their vacuum pump systems that have now become the papermaking industry standard.

Breaking through to standard

“We’ve finally made an industrial breakthrough with our turbo vacuum blower systems, which are fully and widely accepted as a viable, long-lasting solution in the papermaking industry. Today, our customers see us a trusted and preferred supplier when it comes to providing energy efficiency,” says Jukka Lehto, President and CEO of Runtech Systems.

“Another major step for us in attaining this position has been in strengthening our global sales network. We can now be in closer touch with local paper mills through our sales representatives. Although Europe still represents the largest market for us in total, China and Asia in general are growing the fastest for these products,” he says.

Exceptional savings

The undisputable main benefit of Runtech’s vacuum blower system is its power savings. Results show that mills can save between 30–60% in energy while increasing vacuum speed. Additionally, the solution is water-free, giving mills a 100% savings in water costs, which are exceptionally high in papermaking. Payback time is normally one to three years.

“Environmental savings are also important benefits as regulations are becoming more stringent,” Jukka adds. “A recent study proves that electrical machines can increase system efficiency as well as reduce CO2 emissions in both energy production and energy consumption.”

Simplicity facilitates uptake

“Now we have an optimum and proven solution that works at the natural speed of the blowers of up to 10,000 rpm to achieve the optimum vacuum for the process,” says Jukka-Pekka Mäkinen, President and CEO of The Switch. “The simplicity of the solution means that extra parts like the gearbox can be avoided, along with any associated cooling and lubrication. The motor offers a much smaller and lighter footprint. And it is all self-contained; only minimum on-site installation is required.”

“With Runtech, we have had a dedicated partner that truly understands the applications and complete paper mill process. Now it is exciting to see them break through with great results,” he continues. “In the future, we see that that our turbo technology can bring advantages to a wider range of industrial applications, such as oil and gas, where we already have experience with high-speed solutions.”

Latest high-performance turbo models

Deliveries of the newest motors will start in September 2016 and include higher power motors that match Runtech’s new models.

“In certain cases, there has been a clear need for greater capacity. Instead of delivering five vacuum pumps for a paper machine, these new higher-performing units allow us to deliver only four. What’s more, we do not need to dimension the capacity too tightly for the prevailing conditions with these new units,” Jukka states.

The new turbo models are exactly the same physical size as the current ones, which enables Runtech to offer a more powerful turbo solution rebuilt for some of their existing units.

About Runtech

Runtech Systems provides energy-efficient and innovative solutions for the global paper industry. The majority of business comes from vacuum systems for the paper industry, where Runtech is globally one of the leading suppliers with its very energy-efficient Ecopump technology. The other main businesses are in doctoring products and tail threading products for paper, board, tissue and pulp machines. Since being founded in 1989, Runtech has provided the best and most innovative solutions for its customers with many cutting-edge technologies. For more information, visit www.runtech.fi.

About The Switch

The Switch, a Yaskawa company, is a pioneer in advanced drive train technology. The company has an installed base of over 11 GW of megawatt-class permanent magnet machine and converter packages. The main focus areas are wind, marine and special industrial solutions. The company’s innovative drive trains make an impact on profitable power generation and energy use, with the ultimate goal of lowering the cost of energy and operations. Starting in 2006, The Switch reported net sales of EUR 37.1 million in 2014. The company employs approximately 175 persons. The Switch is headquartered in Helsinki, Finland. For more information, visit: www.theswitch.com.

Runtech Ecopump TurboTM new factory inauguration, Kotka, Finland

Runtech Systems Oy, together with 80 global customer representatives, celebrated its Ecopump TurboTM new factory inauguration in Kotka, Finland, June 2, 2014

Ribbon Cutting Ceremony

Technical Seminar

Ecopump TurboTM is Runtech patented technology, which offers a water free, flexible and energy efficient vacuum system solution for pulp, tissue, paper and board machines. It is the first energy efficient variable speed turbo blower in the world.

Ecopump Turbo Factory Tour

“As a revolutionary innovation, Ecopump TurboTM saves 30-70% energy and 100% water comparing with traditional vacuum systems like liquid ring pumps and fixed speed turbo blowers”, says Jukka Lehto, CEO of Runtech Systems Oy.

Since the first installation in 1999, Ecopump Turbo has been successfully delivered to over 100 main paper makers globally, including machines producing all paper and board grades, as well as tissue and pulp.

Saving energy and resources is the global trend in the pulp and papermaking industry, “Ecopump Turbo, not only save energy and water, but also very importantly, helps us to improve the runnability and efficiency of the paper machines”, says Peter Demcak, PM 1,16,17,18 Manager, Mondi Ruzomberok, Slovakia.

“To meet with the increasing demand, and to catch the opportunities in global market, Runtech Systems Oy invested its new Ecopump Turbo factory in Kotka. It will significantly shorten our delivery time, serve our customers faster and help our customers run a more profitable business”, says Kimmo Loippo, Chairman & Founder of Runtech systems Oy.

Runtech Systems Ltd purchases Selotek Ltd

Runtech Systems Ltd has purchased the entire share capital of Selotek Ltd and has announced plans to build a Vacuum System Competence Center in Kotka, Southern Finland.

Selotek Ltd provides maintenance services for the paper industry, for example for liquid ring pumps and multi stage blowers. Selotek also offers service and repair work during shutdowns and is a subcontractor for many well-known companies.

Runtech Systems Ltd is a leader in the paper industry, recognized for its energy-efficient Ecopump Turbo Blowers and energy optimization expertise and is renown for investing heavily in the development of energy efficient paper industry vacuum systems. With this acquisition Runtech Systems Ltd will be in a position to offer more extensive service packages, utilizing Selotek?s expertise in maintenance, service and repair work.

Runtech?s new Vacuum System Competence Center will provide the customer with a total service package, regardless of the system being used. This service package will include the maintenance of vacuum equipment including spare parts and the planning or optimization of your vacuum system, including process optimization aimed at maximizing the dry content after the press section, thereby minimizing steam consumption. As well, new Ecopump Turbo blowers with separators will still be available as a complete delivery, including installation.

Stora Enso orders EP Turbo Systems for a new machine

Stora Enso orders Runtech vacuum system for the new machine to Poland. Delivery includes 7 pcs Ecopump Turbo blower, water separators and Ecoflow system.

Stora Enso orders Runtech vacuum system for the new machine to Poland. Delivery includes 7 pcs Ecopump Turbo blower, water separators and Ecoflow system.

Wire width of the new machine is 8,600 mm and a design speed of 1,800 m/min, the Narew PM 5 will produce 455,000 metric tons of testliner per year. The new paper machine is especially designed for the production of lightweight testliner in a basis weight range of 65-140 g/m2. Storas Enso's focus of this investment was on low operating costs as well as a resource-efficient overall concept above all. The start-up is scheduled for the first quarter of 2013.

For more information please contact This email address is being protected from spambots. You need JavaScript enabled to view it.