Displaying items by tag: Runtech Systems

Runtech Systems signs a RunCare Agreement with Levent Kâğıt

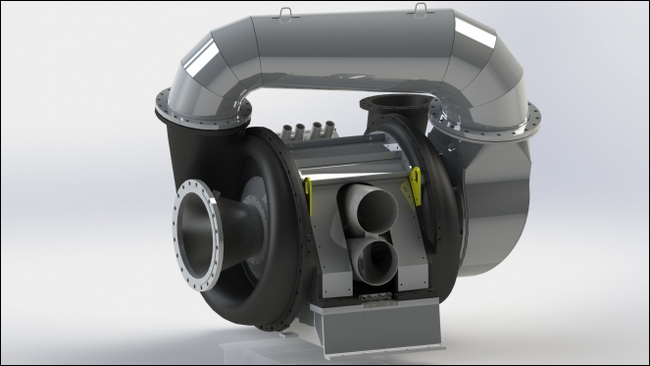

Runtech Systems and Levent Kâğıt San. ve Tic. A.S PM2 in Kemalpasa, Izmir, Turkey, have signed a 5-year RunCare Agreement. The agreement includes all needed maintenance actions and an extended warranty for the recently commissioned RunEco Vacuum System with EP600 Turbo Blower, EcoDrop water separator and EcoFlow multi dewatering measurement.

“Our target is to make life better for our customers. By providing ready maintenance plans for EP Turbo Blowers, we reduce administrative work in customer’s maintenance and purchasing teams. The RunCare Agreement is an easy way for the customers to make sure that the vacuum system is used and working properly. An agreement also strengthens the cooperation between the parties,” says Lari Lampila, Sales & Aftermarket Manager, Runtech Systems.

About RunEco Vacuum System and RunCare Agreement

RunEco offers a sustainable and energy-efficient vacuum solution designed specifically for industrial paper machine applications. This water-free system ensures reliability while significantly reducing CO2 emissions and minimizing the carbon footprint.

EP Turbo Blowers are advanced blowers equipped with integrated high-speed motors controlled by a frequency converter. This innovative technology allows for precise adjustment of rotation speed and vacuum level to meet the specific requirements of the papermaking process. With RunCare, we plan and schedule the maintenance actions according to the mill’s production plan requiring minimal time and effort from the customer organization.

The RunCare Agreement is a long-term partnership, featuring an extended warranty for the first five years. The typical length of the turbo blower service agreement is 5–10 years. Individual maintenance does not need to be ordered separately. With comprehensive reporting and feedback on the serviced equipment and 24/7 on-call assistance mills can be sure that the RunEco Vacuum System is working at the optimum settings.

About Levent Kâğıt

Levent Kâğıt is specialized in manufacturing tissue papers such as napkin, towels and toilet papers in reel using both cellulose and recycled paper pulp. Reels are sold to converters for domestic and non-domestic use. The mill also produces MG (single-glazed) paper, with a production range of 17-120 gr/m2. With a trim width of 446 cm, PM2 produces over 20,000 tons of paper annually.

Read more about RunEco solution https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech Systems delivers ropeless tail threading to Munksjo Caieiras Ltda, Brazil

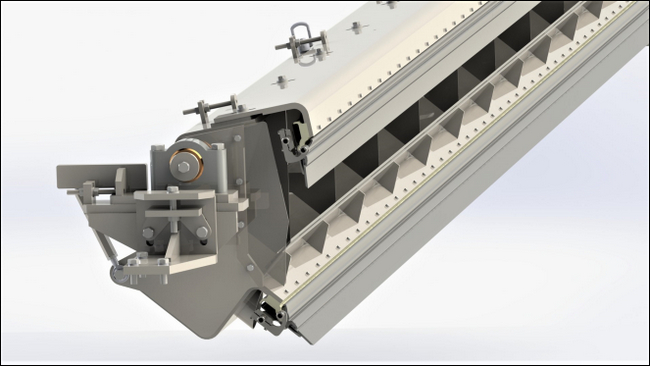

Runtech delivers a ropeless tail threading systems to Munksjo Caieiras Ltda, Brazil. The delivery includes Runshooter technology with detailed engineering and startup support. With the upgrade Caieiras targets more fluent and faster tail threading and improved operator safety.

“Safety issues are getting more and more important in Brazilian markets as well as everywhere else. With our ropeless tail threading system Munksjo is not only lowering significantly risk of injuries, but at the same time increasing efficiency on paper machine by reduced downtime,” says Lari Lampila, Sales and Aftermarket Manager, Runtech Systems.

Runtech’s composite products are manufactured in Kolho facility, Finland.

Runtech’s composite products are manufactured in Kolho facility, Finland.

Runtech Systems’ ropeless tail threading technology provides numerous benefits. It improves operator safety significantly while also shortening tail threading time during web breaks by up to 80% to increase production. In many cases, the technology enables mills to increase machine speed, which would not be possible with manual tail threading without risking operator safety. Also, thanks to the automated process, operators can focus on other tasks. All these benefits are reflected in a short payback time.

About Munksjö

Munksjö is the first international manufacturer solely dedicated to decor paper. Through investments, Munksjö aims to reduce their CO2 emissions by 25% per ton of paper by 2030 and achieve net zero emissions latest by 2050. Munksjö has 11 paper machines and a production capacity of 250,000 tons per year. Caieiras mill produces over 46,000 tons of decor paper annually.

Read more about RunPro solutions https://www.runtechsystems.com/en-fi/paper-machine-runnability-and-tail-threading

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech Systems delivers vacuum system to Sonoco, Indonesia

Runtech Systems delivers a RunEco vacuum system rebuild to Sonoco Products Co. Subang mill in Indonesia. The delivery includes a RunEco EP600 Turbo Blower with EcoDrop water separator and EcoFlow dewatering measurements.

“Our EP Turbo Blowers are ideal for rebuilds as they are compact and easy to install and very economical to own and operate. Upgrading the vacuum system not only saves energy but also brings flexibility. With our turbo blower technology, the turbo speed is automatically adapted to the needed vacuum level,” says Hannu Kääriä, Sales Director, Runtech Systems.

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

RunEco EP Turbo Blower

RunEco EP Turbo Blower

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About Sonoco Products Co.

Since 1899, Sonoco has partnered with customers to provide dependable service and quality products. Today, the team includes approximately 22,000 employees working in 300+ operations around the world.

More information:

Hannu Kääriä, Sales Director, Asia-Pacific; This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +358 40 828 6840

Read more about RunEco solution https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech Systems delivers a vacuum system to Sonoco Stainland

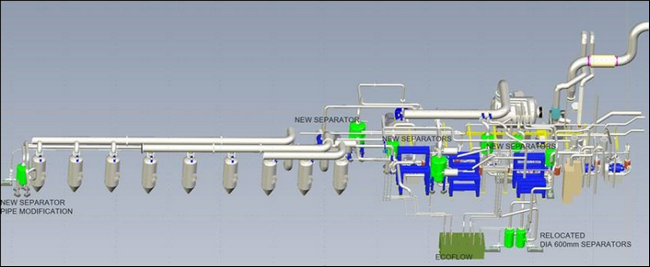

Runtech Systems delivers a RunEco vacuum system rebuild Sonoco Cores and Paper Limited Stainland mill in United Kingdom. The delivery includes a RunEco EP600 Turbo Blower with ABB motor and drive, transformer, new EcoSep pre-separators, EcoFlow dewatering measurements and detailed engineering.

“With today’s energy challenges and the aim to lower carbon footprint it is even more important that our Turbo Blowers are very economical to own and operate. A tailored solution with flexible and variable capacity can help balance supply and demand, leading to optimized dewatering and minimized power consumption,” says Jussi Lahtinen, Sales Director, Runtech Systems.

“Runtech vacuum system concept is very interesting for us because by using Ecoflows we can actually see how much vacuum is needed. We started the project by doing a Runtech vacuum audit and after that pre-engineering including the 3D scan and 3D modelling of the existing vacuum system. Pre-engineering gave us all necessary information to calculate the project costs and ROI accurately. Now we are able to execute the project much quicker when a big part of the engineering is already done so good pre-engineering saves also time,” says Peter Donnelly, Mill Manager, Sonoco Board Mill, Stainland, Halifax.

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About Sonoco Products Co.

Since 1899, Sonoco has partnered with customers to provide dependable service and quality products. Today, the team includes approximately 22,000 employees working in 300+ operations around the world.

More information:

Jussi Lahtinen, Sales Director, Runtech Systems; This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +358 40 079 0950

Read more about RunEco solution https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech rebuilds vacuum system at Enstra Paper, South Africa

Runtech Systems rebuilds vacuum system and improves dewatering at Enstra Paper (Pty) Ltd PM6, South Africa. The delivery includes two low vacuum blowers, three EP600 Turbo Blowers with EcoDrop and EcoSep water separators and an EcoFlow dewatering measurement system for couch save-all and full press section. The new RunEco system replaces 16 liquid ring pumps, which significantly reduces both energy and water consumption. Delivery also includes new double doctor for 1st press bottom roll and suction roll save-all with integrated double doctoring.

“We selected Runtech because their vacuum system is compact, simple and flexible. Runtech understands full paper making process so they were capable of offering a total solution that includes doctors and dewatering measurements in addition to turbo blowers. Measuring water flow accurately is essential for optimizing vacuum levels,” says Nic Campher, Head of Paper, Enstra Paper.

“In case of a bigger rebuild it is essential that vacuum system has flexibility so that vacuum levels can be optimized after the start-up. In many cases machine suppliers oversize the vacuum systems by 30-50% so by selecting an unsuitable supplier, end customers will pay extra operating costs. Difference in vacuum system power consumption is easily 25-30%.

Combining dewatering improvement and EcoFlow system with vacuum system rebuild often brings very significant benefit. We have seen up to 1.5% increase in dryness after press and 20-30 m/min increase in machine speed. Optimized vacuum level will reduce vacuum system power consumption even further as well as press section drive loads,” says Jussi Lahtinen, Sales Director, Runtech Systems.

About RunEco vacuum system

RunEco vacuum system is developed specially to take into account the challenges and demands related to the dewatering and runnability of paper machines. EP Turbo Blowers are designed to operate efficiently across a wide range of vacuum levels and air flows allowing paper mills to optimize vacuum levels. High speed motors, driven by frequency converters, allow a typical EP Turbo Blower to provide vacuum levels between 30 and 70 kPa. A wide range of impeller designs allows highly efficient levels across the operating range.

The EP Turbo Blower's water-free design not only reduces water and chemical consumption within the vacuum system but also eliminates the need for water-related equipment like cooling towers and circulating pumps. Nip dewatering, combined with doctoring, significantly improves energy efficiency and machine performance. A well-designed and operated dewatering and doctoring system is crucial for both energy consumption and paper quality. Runtech’s EcoFlow, save-alls, and double doctors offer a tailored approach to meet these needs.

About Enstra Paper

The Enstra Paper site is based in Springs close to Johannesburg. With over 60 hectares of manufacturing space, Enstra Paper is not only strategically located in South Africa with regards to proximity to the largest waste paper supply, but also the biggest market for recycled paper. Due to these factors Enstra is a leading producer of recycled wastepaper grades in the country. With two uniquely capable paper mills on site, Enstra is positioned for the growing consumer market. Enstra produces high quality security paper and packaging paper products for use throughout the industry. PM6 produces Containerboard and PM2 Bag Grades and other specialty grades. Drawing upon a successful history of over 75 years, the name “Enstra” is derived from its chief raw material: Enterprise Straw. Enstra is part of the Corruseal Group.

More information:

Jussi Lahtinen, Sales Director, Runtech Systems; This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +358 40 079 0950

Read more about RunEco solution: https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech Systems and Nash tighten their cooperation in Europe

To better serve customers in Pulp & Paper industry, Ingersoll Rand brands Runtech Systems and Nash are joining their sales activities in Europe. With a unique offering portfolio for paper machine dewatering and vacuum systems and extensive papermaking knowhow, Runtech Systems can provide optimal solution for all paper mills, from service and rebuilds to completely new papermaking lines.

“We are the only company globally who can offer both liquid ring and dry turbo blower technology – or a combination of both. With this portfolio we can always find a perfect fit for customer’s demands, needs and budget. Combining our sales teams also provides more comprehensive service to our customers and better reach on the market,” says Gerhard Göller, Industry Manager, Pulp & Paper.

“The combination of doctors, save-alls and vacuum system equipment topped with papermaking knowhow enables us to provide a holistic view over the paper machine dewatering and energy efficiency. Customers have now one contact point to get full vacuum system and dewatering audits from vacuum experts,” says Jussi Lahtinen, Sales Director, EMEA and Americas, Runtech Systems.

A unique vacuum system and dewatering offering

RunEco EP Turbo Blowers are the first variable speed and variable capacity turbo blowers available. With more than 800 units sold, they offer a proven, energy-efficient, completely water-free vacuum solution with significant heat recovery potential for paper, board and tissue machines. Nash is the leading manufacturer of liquid ring vacuum pumps, compressors, and engineered-to-order systems with more than 100 years of experience and an extensive installed base.

Runtech’s offering includes also save-alls, doctoring, forming and dryer section cleaning systems and EcoFlow dewatering measurement, which significantly improve dewatering, doctoring and cleaning processes enabling increased dryness after the press section.

Gardner Denver Acquires Runtech Systems

Gardner Denver Holdings Inc. (NYSE: GDI), a leading global provider of mission-critical flow control and compression equipment, announced that it has acquired Runtech Systems Oy for a net purchase price of approximately $93 million funded by cash on hand. Based in Kolho, Finland, Runtech is a leading global manufacturer of turbo vacuum technology systems and optimization solutions for use in a variety of process-oriented industrial end markets. Runtech will be part of Gardner Denver’s Industrials Segment.

“Runtech is a market-leader with a history of innovation, excellent customer relationships and strong talent with deep market expertise,” said Vicente Reynal, Gardner Denver’s CEO. “This transaction is aligned with our strategy of leveraging core, mission-critical technologies to drive growth and build additional value at acquired companies. Runtech’s technology will enable expansion into new and attractive markets. It is a great addition to the Gardner Denver family,” added Reynal.

“Runtech is a market-leader with a history of innovation, excellent customer relationships and strong talent with deep market expertise,” said Vicente Reynal, Gardner Denver’s CEO. “This transaction is aligned with our strategy of leveraging core, mission-critical technologies to drive growth and build additional value at acquired companies. Runtech’s technology will enable expansion into new and attractive markets. It is a great addition to the Gardner Denver family,” added Reynal.

“This is an exciting time for our customers and employees,” said Kimmo Loippo, Chairman and co-founder of Runtech. “Both companies are aligned, with an entrepreneurial mindset and a passion for developing innovative customer-focused solutions,” added Loippo. Juha Karvinen, co-founder and developer of EcoFlow™ and Eco-Pump™ said, “Together our combined capabilities will further expand the technology to broader flow control, vacuum and pressure solutions for the betterment of our customers.”

For more information, visit: www.gardnerdenver.com

Europac Viana PM4 vacuum system is fully installed

Europac Viana PM4 vacuum system is fully installed and fulfills all guarantees. This turn-key vacuum system rebuild project includes five (5) Ecopump Turbos, one low vacuum EP Blower, new Ecodrop water separators and full Ecoflow system. Turnkey delivery includes equipment, mechanical installation, piping, automation and installation supervision.

Old vacuum systems had 10 liquid ring pumps and 2 blowers. Total power consumption of the vacuum system was 3900 kW and SEC was 76 kWh/t. Now after short optimization period total energy consumption is 1800 kW / SEC 35 kWh/t. Total energy saving is over 17 GWh/year or 1,7 MEUR/a.

Europac Viana do Castelo mill is located in North parts of Portugal. Viana PM4 is one of the bigger virgin fiber krafliner machines in Europe. Machine is 6,4-meter-wide and produces almost 400 000 t kraft paper a year.

About Runtech

Runtech is your reliable partner, whenever you are looking for solutions to improve the runnability and efficiency of your tissue, board, paper and pulp machines.

With our patented solutions in vacuum system energy saving and system optimization, press section and forming section dewatering and doctoring optimization, as well as ropeless tail threading you can understand and control your paper machine operation conditions in the most cost-effective way.

The Runtech story started from a group of paper making professionals. It dates back to 1989, when Ecopump Oy started paper machine optimization services. In 1997, Runtech Systems Oy was established and later on in 2008 Ecopump Oy was merged to Runtech Systems. Selotek Oy was acquired in 2011.

Smurfit Kappa Cali PM4, Tail threading rebuild project has started up extremely well

Smurfit Kappa Cali PM4, Columbia. The delivery includes TailBlade M units for the pre- and post-dryers and the ropeless Clupak area.

Cali PM4 makes both sack paper and linerboard, so it was necessary to implement a solution to bypass the Clupak process. Now the operator can select the tail threading path from a switch, making the transfer from sack to liner very quickly. Previously, this required a longer machine stop and re-routing the ropes.

The average threading time per sheet break has dropped by 35%. Earlier, the mill lost Clupak ropes 3 to 4 times per month, which caused additional downtime and lost production.

This challenging project has fulfilled all the targets set for it, and the customer is very pleased with the results. The customer has already placed another order to rebuild the tail threading in the reel area.

At the same time as this rebuild, Runtech delivered a new save-all for the PU roll and Ecoflow measurements for the press section. The customer has reported lower steam consumption on the dryer section thanks to the improved doctoring.

About Runtech

Runtech is your reliable partner, whenever you are looking for solutions to improve the runnability and efficiency of your tissue, board, paper and pulp machines.

With our patented solutions in vacuum system energy saving and system optimization, press section and forming section dewatering and doctoring optimization, as well as ropeless tail threading you can understand and control your paper machine operation conditions in the most cost-effective way.

The Runtech story started from a group of paper making professionals. It dates back to 1989, when Ecopump Oy started paper machine optimization services. In 1997, Runtech Systems Oy was established and later on in 2008 Ecopump Oy was merged to Runtech Systems. Selotek Oy was acquired in 2011.

http://www.runtech.fi/en/ Vege PM1. A RunPress project started up in Turkey

The project scope included one EP500-700-D10 Turbo, Ecoflow systems for the press section and new doctoring for the combi press and 3rd press rolls.

The PM1 vacuum system was fully rebuilt with all 7 vacuum pumps stopped and replaced by one EP500-700-D10 Turbo. The machine is now operating without a couch roll vacuum. Yet thanks to the improved doctoring, specific steam consumption has come down from 1.66 t/t to 1.5 t/t. At the same time, there are fewer sheet breaks.

The vacuum system power consumption is now 330 kW, representing a project energy saving of 600 kW. And for this size of machine, the SEC is of world-record class at 30 kWh/ton! Water savings is also very significant: 60,000 m3/year less water goes to into the wastewater treatment plant. Total project ROI is expected to be less than 2 years.

About Runtech

Runtech is your reliable partner, whenever you are looking for solutions to improve the runnability and efficiency of your tissue, board, paper and pulp machines.

With our patented solutions in vacuum system energy saving and system optimization, press section and forming section dewatering and doctoring optimization, as well as ropeless tail threading you can understand and control your paper machine operation conditions in the most cost-effective way.

The Runtech story started from a group of paper making professionals. It dates back to 1989, when Ecopump Oy started paper machine optimization services. In 1997, Runtech Systems Oy was established and later on in 2008 Ecopump Oy was merged to Runtech Systems. Selotek Oy was acquired in 2011.

http://www.runtech.fi/en/