Displaying items by tag: Voith Group

Increase in orders received, profitability and cash flow – Voith Group gets off to a good start in fiscal year 2023/24

The Voith Group performed well in the first six months of the current fiscal year 2023/24 (October 1, 2023 to March 31, 2024) despite major uncertainties in the markets. The company's focus was on further improving profitability: Voith was able to increase both the operating result and the net income in the reporting period. Net liquidity and orders received also improved.

- Significant increase in orders received; orders on hand at record level

- Cash flow significantly increased to €159 million

- Group sales down slightly as expected due to decline in sales in the Group Division Paper

- Hydrogen activities strengthened with new “Voith HySTech” unit

As forecast, Group sales amounted to €2.64 billion, which was slightly lower than in the previous year (€2.75 billion). At €3.62 billion, orders received were significantly higher than in the previous year (€2.95 billion) – in particular due to a major order won by the Group Division Voith Hydro. Accordingly, the orders on hand reached a record level of €8.13 billion as of March 31, 2024 (previous year: €7.02 billion). The operating result (EBIT) improved again in the first half of the year to €129 million (previous year: €123 million) – as did the net income at €38 million (previous year: €29 million). The cash flow from operating activities (ONCF) showed a clearly positive development and amounted to €159 million, compared to €35 million in the same period of the previous year.

“Voith performed well in the first half of the year despite continued major uncertainties in the markets. In particular, we were able to significantly improve cash flow and profitability. This means that Voith remains in a resilient position both operationally and financially and has the necessary resources to invest in its future,” explains Dr. Toralf Haag, CEO of the Voith Group.

Investments in innovative, future technologies

Voith continues to invest in climate-friendly technologies. In the area of mobility, alternative drive solutions are being moved forward, particularly in the field of hydrogen. In April of this year, “Voith HySTech GmbH” was founded. As an expert in carbon composite materials combined with many years of experience in industry and the automotive sector, Voith has a high level of knowledge in the field of hydrogen tank systems. On this basis, a ready-to-install Plug & Drive hydrogen storage system for heavy-duty vehicles was developed. The integrated 700-bar hydrogen tanks have had the road approval required for marketing in Europe since the end of 2023.

To advance the decarbonization of the paper industry, Voith is working with Essity, a leading global hygiene and healthcare company, on an innovative concept that enables CO2-neutral paper production. To further research this new approach, a pilot plant has been installed at Voith's headquarters in Heidenheim, Germany. This project is being funded with around €14.5 million as part of the “Decarbonization in Industry” program of the German Federal Ministry for Economic Affairs and Climate Protection (BMWK) and the EU fund “NextGenerationEU.”

A major focus continues to be on the automation of rail freight transport. Voith has developed the CargoFlex digital automatic coupler for this purpose. It forms the basis for shifting freight transport to rail and makes a significant contribution to reducing rising CO2 emissions and achieving the goals of the European Green Deal.

Sustainability as a business model

In January 2024, Voith realigned its climate protection strategy and committed to the Science Based Targets initiative (SBTi). The goal is to make further progress in reducing greenhouse gas emissions. Voith is also committed to the ten globally applicable principles of the Global Compact, which includes the areas of human and labor rights, diversity, and anti-corruption.

“Voith’s Corporate Board of Management is committed to continuing to make sustainability the basis for strategic decisions and to consistently drive forward our sustainability activities worldwide,” says Dr. Toralf Haag.

Good developments in the three Group Divisions of the Voith Group

In the first six months, the Group Division Hydro recorded an increase in sales of 4 percent compared to the previous year at €587 million. Orders received rose to €1.51 billion resulting from a major order in West Africa. At €6 million, the operating result was stable, but not yet satisfactory.

With sales of €1.04 billion, the Group Division Paper recorded a year-on-year decline (previous year: €1.18 billion). Orders received fell to €1.04 billion in the same period (previous year: €1.26 billion). The operating result remained stable and amounted to €76 million (previous year: €77 million).

The Group Division Turbo increased its operating result to €48 million (previous year: €33 million). Sales amounted to €977 million (up 2 percent), while orders received fell slightly to €1.03 billion (previous year: €1.05 billion).

Outlook: Voith expects an increase in orders received and profitability for the remaining fiscal year

In the second half of the current fiscal year 2023/24, Voith expects volatile markets and a global economy that will continue to be characterized by high interest rates and low economic growth. Nevertheless, Voith expects to achieve its targets for the fiscal year and is sticking to its targets for orders received, sales and earnings.

Fast and easy rebuild of existing cleaner systems: New AdaptClean technology ensures optimized cleaning process

Based on many years of experience in cleaner technology, Voith introduces the AdaptClean rebuild kit, the latest optimization option within its BlueLine product range. The AdaptClean technology enables a quick and easy conversion of existing low consistency cleaners from a diameter of 105 mm. The upgrade involves removing all parts below the headstock. A Voith cleaner cone and the Easy EcoMizer are then attached to the existing headpiece using an adapter. A dilution water line with pump makes the system ready for use again within a few hours.

- The new AdaptClean system leads to efficiency increases as well as significant fiber and energy savings for existing low consistency cleaner with a diameter of 105 mm or more

- The rebuild kit consists of an adapter, the tried and tested cones in various material designs, and the Easy EcoMizer

- The modernization is possible for most plants worldwide, regardless of manufacturer

"With the new AdaptClean system, we now offer an efficient and fast rebuild worldwide and independent of manufacturer for existing cleaner systems," explains Elmar Ott, Product & Service Manager at Voith Paper. "Due to the optimized service lives and higher plant efficiency, customers thus achieve cost savings every day through the modernization, even for originally non-Voith cleaners. The ROI of the AdaptClean system is therefore less than one year."

To realize the best cost-benefit combination, the new AdaptClean system is available in a wide range of cone materials. The proven Easy EcoMizer enables clog-free operation with optimal fiber backflushing, significantly reducing fiber losses compared to conventional systems. By reducing the amount of fiber, a significant increase in ash content in the rejects can be realized. In addition, increased inlet stock consistency achieves further energy savings.

Voith also supports its customers with suitable spare parts after the rebuild. In addition to the AdaptClean concept, Voith offers many additional services and individual measures to optimize processes and plant efficiency. Thanks to worldwide service locations and the OnPerformance.Lab remote service center, customers can receive competent support at any time and from any location. Find more information here.

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith’s PapermakingAcademy contributes to successful start-up of SCA’s PM 2 in Obbola

Voith delivered effective commissioning trainings for the November 2022 start-up of the world’s largest kraftliner machine, SCA’s PM 2 in Obbola, Sweden. Thanks to Voith's PapermakingAcademy and comprehensive documentation, the SCA team was optimally prepared for operation of its new state-of-the-art facility.

- Effective commissioning training provided by the PapermakingAcademy to ensure successful start-up of SCA’s PM 2 in November 2022

- PapermakingAcademy bundles Voith’s training offerings along the entire life cycle of a plant

- Customers benefit from in-depth expert know-how and application-oriented training courses

“A key factor to the successful start-up here in Obbola has been the training given to the employees,” says Lisa Lundström Hämälä, Process Engineer at SCA. “Voith prepared extensive training materials, and Voith and SCA together made sure there were several occasions for each training so employees could attend while also running our old, now closed paper machine.”

Voith is a leading provider of comprehensive expert training for the papermaking industry. With the PapermakingAcademy, the company offers target group-specific training programs and courses that cover the entire life cycle of a paper machine and the plant’s components. The PapermakingAcademy enables customers to use and operate their paper machines to their optimal capacity. During commissioning, this results in a faster take-over. At the same time, Voith supports papermakers with in-depth expert knowledge to drive forward efficiency and lift their plants to the next level of performance.

Training offerings of the PapermakingAcademy cover the entire life cycle of a paper machine

“The new training modules include all sections of the paper machine and cover its entire life cycle,” says Zahida Sakic-Kramer, Director Design Main Sections at Voith Paper, describing an important aspect of the PapermakingAcademy. “This allows us to support customers precisely where and when they need it – and with the help of new, digital tools.”

“With the PapermakingAcademy, we are expanding the previous training offered by the Voith PaperSchool, which primarily covered service-related topics,” adds Stefanie Schmied, Concept Manager Digital Training at Voith Paper. “Voith Paper now offers a comprehensive course catalog – from basic training units on our new machines and commissioning to in-depth, application-oriented expert training of specific service activities.”

The PapermakingAcademy course catalog gives information about all courses, the respective learning objectives and the recommended target groups. This ensures that participants get the maximum benefit from training in homogeneous learning groups and that customers can make use of a comprehensive and unique training offering to educate their personnel in the best possible way.

For further information on the PapermakingAcademy and the current course catalog, please visit: www.voith.com/papermakingacademy

Visit our website to learn more about SCA’s PM 2 in Obbola: www.voith.com/corp-en/industry-solutions/papermaking/obbola-pm-2.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith, Visy and Appita hold joint energy summit on decarbonization in paper production

The leading full-line supplier Voith, in collaboration with its customer Visy, a global packaging and resource recovery company, held a two-day workshop on decarbonization in papermaking last week in Melbourne. This event was supported by Appita, the leading Australasian pulp and paper technical association. The Energy Summit brought together leaders and experts to discuss the latest solutions and proven technologies for energy efficiency, cost savings and operational improvements.

- Experts present leading technologies and solutions

- The companies cooperate on decarbonization workshop for sustainable paper production

- During a World Café, topics such as customized rebuild solutions, service activities, as well as efficient spare and wear parts packages were discussed

The summary was positive throughout, as Jean-Yves Nouaze, Executive General Manager at Visy Pulp & Paper, also confirmed in his opening speech on Visy's decarbonization strategy: "We have a relentless focus on energy efficiency across our pulp and paper factories and developing our own energy supply through on-site clean energy plants. The Energy Summit is an important way for us to stay up to date with state-of-the-art solutions and proven technologies to further drive energy efficiency. By bringing experts together in one room, we have been able to generate new insights and share expertise.”

During the event, various Voith experts showed leading technologies as well as international perspectives that promote energy efficiency in papermaking. On the first day, Michael Weiss, CTO at Voith Paper, presented current research and development work at Voith Paper on decarbonization and minimization of energy consumption and gave an insight into the energy situation in the German and European paper industry. In addition, Mark Grenning, Director of Policy and Regulation of the Energy Users Association of Australia (EUAA), presented current developments and challenges in the Australian energy market for large energy users in his keynote speech.

"The Energy Summit builds on a very good partnership with Visy and is a great example of how we can work together to drive decarbonization and energy efficiency in paper manufacturing," emphasizes Michael Weiss. "With our holistic approach and forward-looking solutions, we are aiming for CO2-neutral production by 2030 and are committed to a sustainable future."

Dieter Wenninger, Regional President Products & Services Asia at Voith Paper: "The Energy Summit was a remarkable platform for the exchange of innovative solutions and proven technologies. We also explored efficient rebuild concepts that make a significant contribution to sustainability in paper production. The event not only strengthened our very good partnership with Visy, but also helped to further drive our spare and wear parts business as well as service activities in the region."

On the second day, Voith experts presented opportunities for energy savings along Voith Paper's full-line portfolio as part of a World Café. Topics such as efficient spare and wear parts packages, suitable service and maintenance concepts, as well as analyses of energy consumption and audits were discussed by the mixed groups consisting of representatives from Voith and Visy. The latest developments in digital transformation and automation were also presented. The Voith subsidiary Meri also presented efficient water management concepts that can lead to further resource savings.

Papermaking for Life sustainability program

As part of the innovation and development initiative "Papermaking for Life," Voith Paper presents versatile technologies and solutions that lead to more efficient and sustainable processes in papermaking. The emphasis is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. https://voith.com/Papermaking-for-Life/Energy

About Visy

Visy is a global leader in packaging and resource recovery and has been a pioneer in sustainability since its inception. The innovation, production and logistics capabilities are organized around an integrated, closed-loop approach. Together, they give rise to customized solutions that deliver lasting value to our customers, partners and communities. We have been in business for over 70 years and have more than 140 sites across Australasia, as well as commercial offices in Asia and Europe. With over 7,000 employees, our innovative approach provides end-to-end solutions for our customers' needs in paper, primary packaging, fiber packaging, packaging materials and consumables, point-of-sale displays, automation, material handling, logistics and recycling. https://www.visy.com.au/

About Voith Paper

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

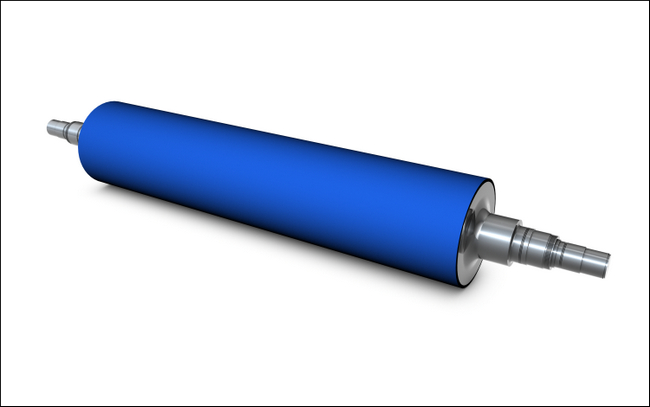

OceanCoat P: Voith launches new coater backing roll cover

As an addition to the proven OceanCoat roll cover, Voith has now developed the OceanCoat P. The new coater backing roll cover is specially made for high-demand positions in blade coater applications. Due to its new polyurethane chemistry and unique filler concept, OceanCoat P is optimized to meet the requirements of stable profile conditions and highest wear resistance.

- Optimally designed for high-demand positions in blade coater applications

- Meets the requirements of stable profile conditions and highest wear resistance

- Made with a new polyurethane chemistry and unique filler concept

OceanCoat P is confirmed to be very resistant to over pressing. Due to the resistant polymer matrix enhanced with fillers, a constant cover surface including very high abrasion resistance can be ensured. This is an important advantage in coater backing roll applications, as paper breaks may lead to over pressing on standard covers and can shorten the cover lifetime. Another decisive advantage of OceanCoat P is its high chemical resistance. All features increase the running time of the roll, simplify work processes, and thus increase the machine’s productivity.

OceanCoat P

OceanCoat P

“We are extremely satisfied with the OceanCoat P. After six months in operation, the roll is still in very good condition,” confirms Markus Krall, Production Manager Coating & Finishing Line 4 at Norske Skog Bruck. “The runtime, which is usually 180 days in this position and shows wear especially in the edge area, was achieved without difficulty. OceanCoat P shows no wear and is used without regrinding.”

Voith offers the best solution for demanding coater backing roll applications and is an expert in the whole process. Especially when combined with ceramic coated high-performance blades, OceanCoat P offers the potential to reduce overall production costs for the customer.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Stora Enso commissions Voith to convert a former paper machine into Europe's largest board machine at its Oulu site in Finland

Stora Enso has entrusted the leading full-line supplier Voith with the conversion of a former paper machine. The machine at the northern Finnish site in Oulu previously produced coated graphic papers. After the successful conversion, the machine will produce high-quality folding boxboard and coated kraft back (CKB). With a production volume of 750,000 tons per year, the plant will be the largest board machine in Europe. Start-up is scheduled for early 2025.

- With an annual production volume of 750,000 tons of folding boxboard and coated kraft back (CKB), the machine will be one of the largest of its kind in Europe after conversion

- The tailor-made full-line scope of supply includes state-of-the-art solutions that enable maximum production and resource efficiency with a minimum CO2 footprint

- The renewed line will utilize Voith’s technologically leading solutions

It was important to Stora Enso that the converted line offers optimal production efficiency while meeting the highest environmental standards, especially excellent heat recovery. With the converted line, the company can achieve the highest production capacity in Europe for high-quality packaging made of folding boxboard and CKB.

"We are very pleased that Stora Enso has chosen our full-line solution," says Dr. Michael Trefz, President Projects at Voith Paper. "The order builds our existing partnership with Stora Enso further. After the conversion, the board machine will be a high-tech plant with the latest standards to produce high-quality board packaging."

To achieve the high production volume, Voith together with Stora Enso developed a tailor-made concept that maximizes both efficiency and sustainability along the entire paper machine. The scope of supply includes a new, three-layer wire section with the DuoFormer D II. The high-performance Triple NipcoFlex shoe press concept will enable maximum production output at the highest quality level. At the same time, the efficient technology will minimize specific energy and production costs. The machine will also feature maximum flexibility and top product quality thanks to a SpeedSizer system and four DynaCoat AT coating units with JetFlow F applicators. The SpeedSizer as well as the DynaCoat AT are partly made of carbon fiber to ensure stable cross sections at all grades and speeds. In addition, Voith's bulk-saving EcoCal HiBulk calender will provide excellent stiffness, outstanding smoothness and printability.

To achieve the high production volume, Voith together with Stora Enso developed a tailor-made concept that maximizes both efficiency and sustainability along the entire paper machine. The scope of supply includes a new, three-layer wire section with the DuoFormer D II. The high-performance Triple NipcoFlex shoe press concept will enable maximum production output at the highest quality level. At the same time, the efficient technology will minimize specific energy and production costs. The machine will also feature maximum flexibility and top product quality thanks to a SpeedSizer system and four DynaCoat AT coating units with JetFlow F applicators. The SpeedSizer as well as the DynaCoat AT are partly made of carbon fiber to ensure stable cross sections at all grades and speeds. In addition, Voith's bulk-saving EcoCal HiBulk calender will provide excellent stiffness, outstanding smoothness and printability.

For ideal energy efficiency, Voith experts are also extensively rebuilding the existing dryer section. The high operating dew point of up to 65°C in the EcoHood 65 dryer hood lowers the supply and exhaust air volumes and thus reduces power and steam consumption. The CombiDuoRun drying concept efficiently dries the web on both sides, preventing curl even at high operating speeds. Finally, two VariFlex Performance winders will be installed. In addition, Stora Enso relies on Voith's leading digitalization and automation expertise. Thus, Voith will implement the OnControl.Machine MCS for the automation of the board machine, the OnQuality quality control system, and the OnCare.Health condition monitoring solution. The dataPARC cloud serves as the IIoT platform.

About Stora Enso

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2022 were EUR 11.7 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Combined competencies of Voith and Meri lead to significant water savings in paper production

The global interest of papermakers in water-saving solutions has steadily increased, with the effective use of water as a resource is an essential lever for sustainable paper production. To support papermakers in securing their future competitiveness, Voith and its subsidiary Meri have been developing tailored new innovations in the areas of water, sludge and residual materials for more than 25 years. Mutual understanding of the product portfolio, very close coordination in every project phase and many successfully completed projects characterize the partnership of the companies. As Axel Gommel, Global Product Manager Fiber Systems at Voith Paper, explains: "Over the years, we have developed unique process know-how. Combined with our highly efficient technologies, this makes Voith a strong full-line partner for manufacturers of all paper grades who want to take their operations to the next level of performance in the area of sustainability."

In successful cooperation, Voith and Meri experts offer fresh water treatment and conditioning as well as internal cleaning of process water streams. In addition to process and disposal machines, their extended portfolio also consist of wastewater treatment including primary, secondary and tertiary treatment via chemical or physical stages. These are combined with anaerobic and aerobic biological processes and sludge treatment. Customers also benefit significantly from Voith and Meri's water and wastewater balances. Furthermore, Meri offers optimized solutions for the rejects recovery process stages, such as transport, handling and conditioning, and waste-to-energy processes.

In addition to the optimized product portfolio and close cooperation, global presence is also a key success factor, as Henning Laubrock, Head of Sales & Technology at Meri, adds: "Thanks to the combined synergies of Voith and Meri, we are very well positioned and networked internationally." Voith now boasts more than 110 OCC stock preparations with a total production capacity of more than 40 million tons per year over the past 20 years. Meri has realized more than 5,000 installations and supplied more than 300 subsystems. With the opening of another site in Kunshan, China, Meri strengthened its local footprint in the APAC region, supplying efficient water, sludge and reject (WSR) and wastewater systems to Chinese and other Asian customers, among others.

According to Laubrock, a major milestone of Voith and Meri was the joint development of the sustainable water management system AquaLine. Following the official launch of the system in 2021, the AquaLine, AquaLine Flex and AquaLine Zero system variants are already in use at several well-known manufacturers of packaging paper. Among others, the North American paper manufacturer Green Bay Packaging uses the AquaLine Flex system variant at its PM 4 in Wisconsin. Equipped with a "biological kidney," the process water can be treated and part of the purified process water fed back into the production process. The amount of wastewater is thus reduced to up to 3.5 liters per kg of paper produced. Compared to similar production plants, Green Bay Packaging with an annual production volume of 621,422 tons and a design speed of 1,200 m/min saves fresh water amounting to 2,271 m³ per day. Comparable process values and savings can also be found in the plant of Turkish paper manufacturer Kipaş Kağıt, which started up in mid-2022. In addition, Kipaş Kağıt produces around 90 MW of electrical energy from biogas produced in Meri's anaerobic wastewater treatment plant and fed directly into the public grid.

Axel Gommel sums up: "The AquaLine Flex system variant has now become state of the art in the production of packaging papers. In addition, under certain conditions it is possible to operate plants with the closed, technologically very complex water circulation system AquaLine Zero, in which the process wastewater is reduced to zero liters." In the future, Voith will continue to develop the individual concept variants so that closed water circuits can increasingly be used throughout the paper industry. In addition, as part of Voith’s Papermaking for Life sustainability program, the company is also working on new, disruptive solutions to significantly reduce fresh water consumption.

Papermaking for Life sustainability program

Resource efficiency is a key focus of the Papermaking for Life sustainability program. As part of its innovation and development offensive, Voith Paper is presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in paper production. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Learn more about the focus topic water here: www.voith.com/papermaking-for-life/water.

About Meri

The MERI Group, a wholly owned subsidiary of Voith Paper, is a global environmental technology company specializing in industrial applications, particularly for the paper industry and food & beverage. Due to the global market trend towards "online shopping", the market of Meri's customers in the recovered paper/recycled based packaging paper industry will continue to grow in the coming years. MERI Group has been a leader in the relevant environmental technology field for the paper industry for years. With offices in Germany, USA, China and Brazil Meri realizes in the application fields: Residual and Fuel Processing, Material Handling, Reject and Sludge Dewatering, Water Treatment, Recirculating Water Purification and Wastewater Treatment single machine projects, upgrades and new construction of complete plants. With over 5000 units installed, Meri has been a reliable partner for customers in the global paper industry for many years, as well as for the market-leading parent company Voith Paper. Tel: +49 89 59 33 44 | Email: This email address is being protected from spambots. You need JavaScript enabled to view it. | https://www.meri.de/

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

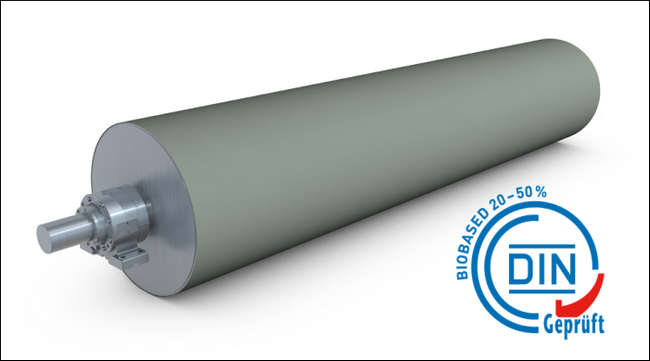

Sustainable fabrics and roll covers from Voith ensure significant energy and cost savings

Various factors support more sustainable paper production. Fabrics and roll covers, for example, can contribute to improved resource efficiency by directly optimizing production efficiency and because they are themselves sustainably manufactured. Based on many years of experience, Voith offers specific solutions for sustainable paper production, the advantages of which are proven by many positive customer references. A German graphic papers manufacturer, for example, reported that Voith's SolarPress roll covers have enabled energy savings due to a 1.5 percentage point higher dry content after the press section. Efficiency add-ons for press fabrics are another example. In particular, +Peak technology, a specially developed elastomer material, optimizes nip dewatering and increases the service life of a press fabric. For one paper producer, +Peak resulted in higher dry content in the tandem press and reduced the average amount of steam by 11 percent, from 1.6 t/ton to 1.43 t/ton. In addition to energy savings, significant water savings are also enabled. For example, customers worldwide benefit from HydroSeal, the modern version of sealing strips for suction rolls. At a board mill in the USA, HydroSeal reduced water usage by 80 percent and saved the papermaker more than $30,000 per year in sealing strip lubrication.

- Positive feedback from many customers confirms more sustainable production thanks to wear parts from Voith

- Research and development team is working on bio-based materials for the production of wear parts

- Voith focuses on the entire life cycle of wear parts, from production and use in operation to material recycling

"In addition to production that conserves resources as much as possible, it is important that the products themselves are also manufactured sustainably," emphasizes Lidia Loskan, R&D Project Manager Sustainability at Voith Paper. Here, it is important to be able to offer the same product properties as with petroleum-based roll covers and fabrics.

To further optimize the product portfolio in terms of sustainability, Voith's R&D team is working on new possibilities with the help of life cycle analyses (LCAs). As an example, Dr. Robert Hilbing, Senior Vice President R&D FRS at Voith Paper, mentions the newly launched roll cover AiroGuide Tune Green. The innovative roll cover is certified according to the international DIN CERTCO standard for bio-based products. The fiber composite roll cover is manufactured with bio-based raw materials and was specially developed for the wet-end section. It also has improved corrosion properties and a long service life. This makes AiroGuide Tune Green the first DIN CERTCO-certified sustainable roll cover on the market with the same performance data as the petroleum-based alternatives.

Furthermore, Voith is increasingly focused on the entire manufacturing process of wear parts. The company has already been systematically measuring its own energy, water and waste volumes since 2012 and reducing them in a targeted manner. Measures include the use of renewable energies and the establishment of material recycling processes at Voith locations. For example, the unavoidable waste produced during the surface treatment of QualiFlex press sleeves is recycled. For this purpose, the Voith team, together with partners, implements a special thermal treatment process for polyurethanes. Subsequently, the production waste is used again in the manufacture of other products and reduces the company’s carbon footprint.

"As part of Voith Paper's sustainability program Papermaking for Life, Voith is working intensively on sustainable solutions to strengthen the circular economy and reduce its carbon footprint," summarizes Dr. Hilbing. "Our goal is to offer our customers an optimal portfolio of fabrics and roll covers that increases performance and sustainability while reducing operating costs."

Sustainability program Papermaking for Life

As part of the innovation and development offensive "Papermaking for Life," Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The emphasis is on the topics of water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: voith.com/papermaking-for-life.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

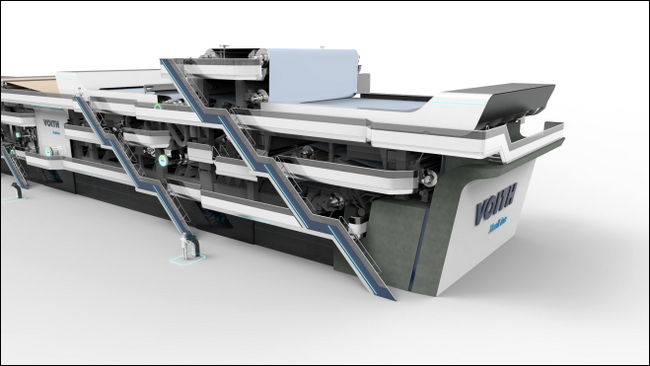

Voith's XcelLine paper machine nominated for German Sustainability Award

For the 16th time, the jury of the German Sustainability Award (DNP) has nominated outstanding innovations in the field of sustainability. Out of more than 1,000 applicants, Voith's XcelLine paper machine is a finalist in the "Design" competition in the "Vision" category. With eight competitions, the high number of applicants and more than 2,000 guests at the award’s closing events, the DNP is the most comprehensive award of its kind in Europe. The award is based on the goals of the 2030 Agenda and thus on the key transformation fields such as climate, biodiversity, resources, supply chain and society.

- The XcelLine paper machine has been nominated for the German Sustainability Award (DNP) in the Design competition, Vision category

- Decisive for the jury was the optimized design, measurable resource efficiency and innovative strength of the XcelLine

- The DNP is one of the most important sustainability awards in Europe

"Making it to the finals makes us very proud and confirms our ambition as a leading full-line supplier to provide our customers with the most sustainable and efficient paper production," says Dr. Michael Trefz, President Projects Voith Paper. "In addition to technical performance, the development of the XcelLine paper machine also focused on resource efficiency, which is made possible by an optimized design. Compared to conventional systems, the XcelLine paper machine features reduced energy consumption, optimal fiber utilization and lower water consumption."

Thanks to the modular design of the XcelLine, highly individualized production lines can be put together for almost any application. All individual components are perfectly coordinated to achieve outstanding results over the decades-long life cycle of the paper machine. The XcelLine portfolio today covers machine widths of up to 11 meters. Depending on the grade, speeds of up to 2,000 m/min can be achieved. The increasing production width and speed of the lines optimize productivity and thus reduce specific consumption data.

Award-winning excellence of the XcelLine in design, performance and sustainability

Voith's future and design study "Papermaking Vision" contributed significantly to the DNP nomination in the Design competition, Vision category. Dr. Christoph Lapp, Senior Vice President Product Management at Voith Paper, comments: "The jury evaluated both the current status and our innovative strength and research and development work. With our Papermaking Vision last year, we presented a long-term, visionary concept that goes far beyond the current state of the art."

In the overall concept, Voith takes into account all aspects of paper production. Maintenance and operation of the system are simplified, efficiency and safety are increased, interfaces are reduced through a higher degree of networking, and an attractive design ensures a uniform appearance. Another focus of the Papermaking Vision is the implementation of the "Clean Design" concept throughout the line. By increasing cleanliness, the risk of unplanned downtime is reduced. This improves operational reliability and machine efficiency and ensures a trouble-free production process. Aspects of this vision are being successively integrated into equipment that is already being delivered to customers today.

The optimized design of XcelLine paper machines also leads significantly to improved resource efficiency. "Our ‘Papermaking for Life’ sustainability program goes hand in hand with our Papermaking Vision design study," confirms Dr. Michael Weiß, CTO at Voith Paper. "For this, we invest around 100 million euros per year in the development of sustainable and efficient solutions." As part of its sustainability program, Voith aims to achieve completely CO2-neutral paper production by 2030 through the use of energy-optimized products, digital solutions and renewable energies. In recent years, the implementation of various individual measures has already helped to reduce thermal and electrical energy requirements by 5 to 15 percent, depending on the paper grade. In addition to energy, water is another precious resource. As part of the XcelLine product family, Voith has developed the first completely closed water cycle in paper production together with Meri.

Another important lever for increasing sustainability is the optimization of paper quality. Reducing process fluctuations enables more efficient use of the fiber material. In this way, fibers can be saved and resources conserved. At the same time, the integration of automation and digitalization solutions from the Papermaking 4.0 portfolio enables further increases in the efficiency of the XcelLine. The applications, such as intelligent process controls, are often implemented quickly and pay for themselves in less than a year. The digital solutions are expected to be able to save up to 15 percent of production costs in the future.

Sustainability also plays a key role for Voith in its own activities. For example, Voith pays attention to the durability of components, avoids critical substances when selecting materials, and promotes the recyclability of its own products as part of its circular economy concept. In addition, active supplier management ensures efficient sourcing strategies. As a measure, for example, transport routes for components have been significantly reduced and supplier chains improved.

Further information on the XcelLine can be found here: https://voith.com/corp-en/components-papermaking/xcelline.html and on the Papermaking Vision design concept here: https://voith.com/corp-en/industry-solutions/papermaking/papermaking-vision.html.

German Sustainability Award (DNP)

Since 2008, the German Sustainability Award Foundation has been awarding the DNP in cooperation with, among others, the German government, civil society organizations and research institutions, thus honoring companies that promote sustainability as part of their business model. The winners of the DNP will be announced on December 2 at the awards ceremony in Düsseldorf, which will also be attended by German Chancellor Olaf Scholz. More information about the DNP can be found here: https://www.nachhaltigkeitspreis.de/en/.

Since 2008, the German Sustainability Award Foundation has been awarding the DNP in cooperation with, among others, the German government, civil society organizations and research institutions, thus honoring companies that promote sustainability as part of their business model. The winners of the DNP will be announced on December 2 at the awards ceremony in Düsseldorf, which will also be attended by German Chancellor Olaf Scholz. More information about the DNP can be found here: https://www.nachhaltigkeitspreis.de/en/.

Papermaking for Life sustainability program

As part of the "Papermaking for Life" innovation and development offensive, Voith Paper is presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: www.voith.com/papermaking-for-life/innovation.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Sustainable investment decisions pay off in daily stock preparation operations

Sustainable production in stock preparation is not a vision for the future but already a reality today. Many existing plants benefit from solutions from Voith's leading BlueLine stock preparation portfolio. In the last five years, Voith experts have commissioned more than 30 plants with a total production capacity of 12.8 million tons per year. Voith has also launched more than 20 new innovative machines in recent years. Based on its experience, Voith is characterized by in-depth know-how and reliable, optimized process standards. In addition, the development of new solutions is part of Voith's sustainability program “Papermaking for Life.” Every year, the technology company invests around 100 million euros in research and development of impetus-giving innovations that are intended to further increase sustainability and efficiency.

- Based on profound know-how and many years of experience, Voith offers the most sustainable and efficient solutions for stock preparation

- Already today, optimized solutions can achieve efficiency increases of between 20 and 30 percent

- Sustainability and efficiency lead to significant cost savings and maximized output

"As the leading full-line supplier, we not only focus on the individual machine components but also on the entire stock preparation process," confirms Andreas Heilig, Vice President Products Fiber Systems at Voith Paper. "Our BlueLine stock preparation portfolio is used in new plants worldwide. But upgrading existing plants to our solutions also pays off – both economically and in terms of sustainability and efficiency."

Falk Albrecht, Head of Process Technology Fiber Systems at Voith Paper, mentions, among other things, pump energy, which accounts for up to 50 percent of the energy consumption of a stock preparation system. There is great potential for optimization here, especially with existing, older systems. In order to minimize energy consumption, Voith solutions strive for the highest possible consistency level of the achievable quality parameters with the same technological performance. Savings of between 20 and 30 percent are already possible through this measure. At the same time, great attention is given to low pressure levels. Another product example for increasing energy efficiency is Voith's LowEnergyFlotation technology (LEF). Through its use, energy savings of up to 50 percent can be achieved in the flotation pumps, without negatively affecting the technological result.

Customers also benefit from significantly lower water and energy consumption with the AquaLine water and wastewater management system, which is well thought-out in all aspects. The system, developed and optimized by Voith and Meri over many years, treats the process water biologically and thus reduces the COD and calcium content in the water. This saves fresh water and reduces the consumption of additive materials on the paper machine. The AquaLine Flex system variant enables fresh water consumption to be reduced to less than 5 liters per kg of paper produced. With the very technologically advanced AquaLine Zero solution, fresh water consumption is reduced to 1.5 liters per kg of paper produced. The use of the biogas produced as a substitute fuel for fossil fuels also led to a CO2 reduction of around 10 percent in one German installation.

In addition to water management, high-performance process components are important in stock preparation. Modern disc filters produce excellent filtrate qualities that can be fed directly to biological treatment. Additional primary clarification is no longer required, which has a very positive effect on yield, investment costs and the environment. Significant energy savings can also be achieved with the new InduraClean heavy-weight cleaning system compared with conventional solutions. As part of the BlueLine stock preparation family, Voith presented the system, which consists of an improved cleaner bank, the new InduraClean IDC-4 and the optimized InduraClean IDC-5. Depending on requirements, the modular cleaning technology can be configured for significantly increased production, a high specific energy reduction of up to 50 percent, or significantly improved separation efficiency.

The OnView.MassBalance digitalization solution is another example of how sustainability and efficiency are combined in Voith's product portfolio. The innovative digital tool displays losses in stock preparation in real time, allowing the operator to identify optimization opportunities in specific areas at a glance and initiate appropriate countermeasures. In this way, high losses can be avoided, which is why the solution pays for itself after less than a year. In the future, stock preparation will become even more digitalized and autonomous. Voith experts are working on 24/7 real-time analysis of complex system interactions, which will allow automatic adaptation of process parameters to individual situations. At the same time, the need for manual intervention is reduced to a minimum. In addition, Voith is developing self-optimizing control systems that enable an optimal balance between production volume, efficiency and quality while maintaining the highest reliability based on daily updated cost models.

Sustainability program Papermaking for Life

As part of the innovation and development offensive "Papermaking for Life," Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The emphasis is on the topics of water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: voith.com/papermaking-for-life/innovation.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.