Super User

Metsä Group to draw up biodiversity plans for its mill areas – Kemi the first in line

Metsä Group plans to boost biodiversity on its land areas in Kemi. Covering more than 650 hectares, the designated site encompasses Metsä Group’s mill area and other areas in the Kemi urban environment. Metsä Group’s operations in Kemi include a bioproduct mill, currently under construction, and a paperboard mill. The company aims to increase regional biodiversity at all its mill locations across Europe, which number more than 20.

The goal is to modify land use on the Metsä Group Kemi site to improve the state of nature in the industrial environment. The special features of local nature will be taken into account in the project, and the living conditions of endangered species will be improved. Biodiversity in the area will be increased experimentally and by adopting new operating methods.

For example, more than 12 hectares of meadows and sunlit habitats will be added to the Kemi mill area. Only local vegetation will be used in establishing open habitats, and these habitats will be made suitable for endangered species. Various other approaches to increasing the biodiversity of industrial environments will also be tested on the mill site.

The biodiversity plans will also extend outside the mill site to land areas owned by Metsä Group that belong to the Kemi built environment. Residents use these areas for recreational purposes. New ways to increase biodiversity are being developed collaboratively with the town of Kemi.

“Improving the state of nature is one of the goals of Metsä Group’s regenerative forestry approach, and the Kemi pilot project will expand its scope from the forest to the mill area and urban environments. Their biodiversity can also be improved if you have the will and competence and if things are done together. This could be a course adopted industry-wide,” says Ilkka Hämälä, Metsä Group’s President and CEO.

Metsä Group’s collaborative network will grow as the project progresses. One of the key partners is the Villi Vyöhyke association, a leading expert in the biodiversity of the built environment.

“Metsä Group is showing courage, as well as an impressive and high ambition in protecting biodiversity in Kemi. The scope of the new nature targets is exceptionally wide and varied, encompassing the built environment as part of regenerative land use. Metsä Group is a big operator, which gives our actions greater leverage for a wider cultural change towards the international mainstream of biodiversity protection,” says Jere Nieminen, Chair of Villi Vyöhyke.

“Metsä Group’s initiative is important for the town of Kemi. Together, we can develop and strengthen the pioneering role that the Sea Lapland region plays in protecting our nature. The coexistence of industry and nature benefits all of us,” says Matti Ruotsalainen, Mayor of Kemi.

The Kemi pilot project is now underway. The various measures concerning other Metsä Group mills will be carried out gradually over the next few years, using the operating models developed in Kemi.

Metsä Group intends to make the mill areas’ biodiversity plans part of the environmental reporting of mills. In the next few years, the company also plans to collaborate with its stakeholders to develop the plans for the built environment into internationally approved criteria and standards.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in around 30 countries. We promote a culture of diversity, equality and inclusion. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by over 90,000 forest owners.

Energy savings and decarbonization are key topics of Voith's research and development work

At the end of April, Voith unveiled a completely new disruptive concept for paper manufacturing in collaboration with hygiene and healthcare company Essity. This concept enables CO2-neutral paper production as well as fresh water savings of up to 95 percent and energy savings of up to 40 percent. Currently, Voith and Essity are working on a pilot plant in Heidenheim, Germany. In addition to the disruptive concept, Voith is also focusing its research and development on other promising solutions. The leading full-line supplier invests around 100 million euros annually in the development of more efficient and sustainable solutions to drive decarbonization in paper production.

- Voith and Essity work on an innovative concept for CO2-neutral paper production

- For the electrification of paper drying, Voith is developing various concepts to avoid fossil fuels and reduce CO2 emissions

- Voith is involved in various industry initiatives, such as the ‘Modellfabrik Papier’, to promote the decarbonization of paper production using completely closed systems

An important field of action for decarbonization is the drying of paper, as this is where the greatest energy consumption occurs. Drying cylinders are typically heated with steam, which is often generated by burning fossil fuels. In order to dispense with the use of fossil fuels, Voith is working intensively on concepts for the electrification of paper drying. In the process, various technologies are evaluated to determine their potential and identify suitable solutions depending on the energy source at the site. This leads to significant reductions in CO2 emissions at the paper mills.

In addition to electrification, heat pumps for heat recovery are included in the development approaches to further improve the sustainability balance. Digital solutions, intelligent control systems and innovations in the area of fabrics and roll covers offer additional efficiency benefits.

Voith is a member of various industry initiatives to drive forward the decarbonization of paper production. One such initiative is the ‘Modellfabrik Papier’, in which companies along the value chain work with research institutes and higher education institutions on pre-competitive basic research.

Dr. Lada Bemert, Vice President New Business and Research at Voith Paper and Deputy Chairwoman of the shareholders’ committee of the Modellfabrik Papier, confirms the positive impact of the initiative. "With the help of completely closed systems, no more unused energy should escape from the process in the future,” explains Bemert. “Building on our research results, our aim is to make the technologies available to industry as quickly as possible. In doing so, we are setting an important course for the future."

Sustainability program Papermaking for Life

As part of the "Papermaking for Life" innovation and development offensive, Voith Paper is presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: www.voith.com/papermaking-for-life/innovation. For more information on the Modellfabrik Papier, click here: https://modellfabrikpapier.de/en/home-en/.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Emerson’s New Engineering Software Accelerates Plant Modernisation Using Artificial Intelligence

REVAMP simplifies and speeds transition to a modern automation architecture, reducing capital costs by up to 15%

Global technology and software leader Emerson (NYSE: EMR) is helping customers more quickly and efficiently transition legacy technology to modern DeltaV™ automation architecture that modernises and digitises operations. Emerson’s REVAMP advanced software solution uses cloud computing and artificial intelligence (AI) to automate up to 70% of system configuration, reduce errors and manual conversion work, and slash capital costs by up to 15%.

“Modernisation projects too often surprise teams late in the process with cumbersome, unanticipated work and errors from manual conversion,” said Claudio Fayad, vice president of technology for Emerson’s process systems and solutions business. “Emerson’s REVAMP helps project engineering teams modernise their systems more easily, on time and within budget, while also minimising errors and disruptions to production.”

Organisations seeking to modernise control and safety systems often start with decades-old code that must be transitioned to current software. Manually converting and documenting this code is an arduous process that dramatically increases the time and capital requirements for these projects.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

REVAMP is a groundbreaking, cloud-based, advanced software solution that manages the transition of legacy applications to optimal control.

Emerson’s REVAMP advanced software combines an extensive knowledge base from similar modernisation projects with Emerson’s experience library to develop continuously updating AI models. Each modernised control system feeds back into the REVAMP software, creating learning algorithms that perpetually get smarter and faster at converting legacy code.

The applied AI in REVAMP informs project teams of the engineering requirements before migration projects even begin, making planning easy. The AI engine analyses native files from the existing distributed control systems, safety instrumented systems or programmable logic controller back-ups while using a global library of thousands of successful projects to sort, select and automate engineering tasks. The modernisation project is automatically fully documented, and significant portions can be generated in the DeltaV control system, enabling the latest capabilities and using modern standards.

Emerson project teams around the world have access to the most recent functionalities and libraries of this secure, cloud-native tool. And with embedded machine learning, the libraries grow and improve as projects become more efficient over time.

Learn more at Emerson.com/revamp.

About Emerson

Emerson (NYSE: EMR) is a global technology and software company providing innovative solutions for the world’s essential industries. Through its leading automation portfolio, including its majority stake in AspenTech, Emerson helps hybrid, process and discrete manufacturers optimise operations, protect personnel, reduce emissions and achieve their sustainability goals. For more information, visit Emerson.com.

Nordic Paper decides on strategic investments for Bäckhammar

The Board of Directors of Nordic Paper has decided to invest approximately SEK 850 m at the Bäckhammar mill. The investment will further improve sustainability performance and strengthen the competitiveness of the plant. An important component of the investment is a new wood room providing for both strategic flexibility in raw material sourcing and efficiency gains in the production. The emissions of dust to air will be reduced by more than two thirds through an installation of a new electrostatic filter. The investments are expected to add about SEK 100 m annually to Nordic Paper EBITDA. Further, the investments set the foundation for future growth in production output.

The investments of today’s decision are approved under the current, existing, production permit. A new production permit was granted for the Bäckhammar mill on 31 January 2023. The new production permit was appealed by a third party and has as of today not gained legal force.

The investments of today’s decision are approved under the current, existing, production permit. A new production permit was granted for the Bäckhammar mill on 31 January 2023. The new production permit was appealed by a third party and has as of today not gained legal force.

- Bäckhammar is a highly competitive production unit. It is also one of the most climate efficient production plants in the global kraft paper industry. With these investments, we further strengthen the competitiveness of the plant at the same time as we improve our environmental performance. The investment decision has been made considering our strong balance sheet and opportunities for organic growth in Bäckhammar in the future, says Nordic Paper CEO Anita Sjölander.

The investments will be carried out 2023-2025 and will be financed through existing credit facilities. The main cash flow effect from these investments will occur in 2024 and 2025 with more than SEK 300 m each year. There will also be a cash flow effect in 2023 most of which in Q4, as well as a minor effect in 2026. The additional EBITDA of about SEK 100 m from the investments will have full effect from 2026.

At Bäckhammar, Nordic Paper manufactures unbleached kraft papers of different qualities primarily for packaging end-uses. The raw material is pulpwood from sustainably managed forests in mid-Sweden as well as sawmill chips. Products made from paper from Bäckhammar include for example sacks for flour, carrier bags and bread pouches. The main market is in Europe but the papers are shipped all over the world.

Nordic Paper is a leading specialty paper producer with its base in Scandinavia. We have been manufacturing top-quality kraft papers and natural greaseproof papers since the 19th century. Our products are based on renewable raw material from local forests. From our five paper mills, four in Scandinavia and one in Canada, we supply customers in 85 countries. Nordic Paper had in 2022 net sales of SEK 4,440m, about 670 employees and is listed on Nasdaq Stockholm. www.nordic-paper.com

ANDRITZ wins 9th shoe press order from Lee & Man Paper

International technology group ANDRITZ has received the ninth order for a PrimePress X shoe press from Lee & Man Paper Manufacturing Ltd., China. It will help to save energy and further improve paper quality at the company’s Best Eternity Recycle Technology mill in Banting, Malaysia. Start-up is planned for end of 2024.

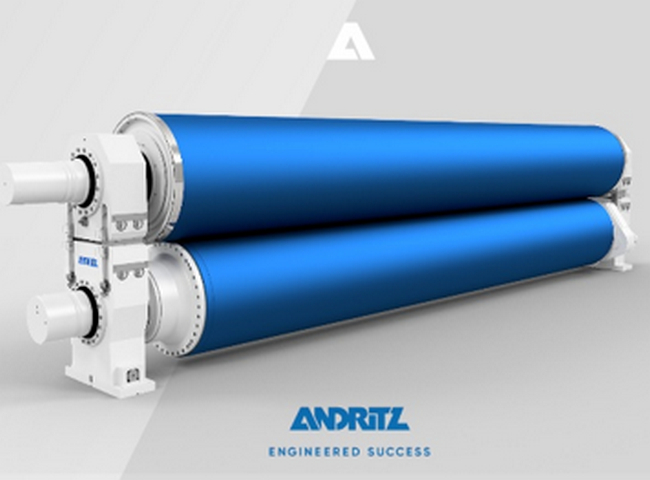

The newly ordered shoe press will be installed in the PM26 containerboard machine that runs at a design speed of 1,000 m/min and produces high-quality Testliner of 70 – 160 gsm basis weight. The PrimePress X shoe press will replace the existing conventional third nip in the center roll-based concept. Equipped with an ANDRITZ PrimeRoll X and a PrimeRoll HV-Smart anti-deflection roll as well as an Impulse grooved shoe press belt, it will raise the line load to 1,250 N/mm and further increase the off-press dryness of the paper web. This will result in significant energy savings, improved machine runnability especially at lower basis weights, and enhanced final paper strength properties.

This repeat order further strengthens the very close and successful cooperation between Lee & Man and ANDRITZ. Three PrimePress X shoe presses, installed in 2020, 2021 and 2022, are already operating at the Banting mill, with two recently ordered ones scheduled to start up during the next few months. Another three shoe presses from ANDRITZ have been in operation at Lee & Man’s Dongguan mill in China for several years.

PrimePress X shoe press for gentle dewatering at high nip loads. "photo Andritz"

PrimePress X shoe press for gentle dewatering at high nip loads. "photo Andritz"

Established in 1994, Lee & Man Paper produces linerboards and corrugating medium for various industrial packaging purposes. The group runs five paper mills and one pulp mill in China as well as several production bases in Vietnam, Malaysia and other countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Toscotec to supply forming section rebuild to Gulf Paper Manufacturing

Toscotec will supply a forming section rebuild of PM2 to Gulf Paper Manufacturing at their Mina Abdullah paper mill in Kuwait. PM2 machine produces tissue from 100% virgin fibres, and it is scheduled for rebuild at the end of 2023. This is a repeat order for Toscotec who in 2019 successfully delivered a major dryer section rebuild of Gulf Paper’s packaging paper machine (PM1).

The project aims to improve PM2’s paper formation and basis weight cross direction (CD) control through an approach flow system upgrade and the installation of a state-of-the-art TT Headbox. The new headbox will be designed to match the high quality requirements for facial tissue in the Middle Eastern market.

Toscotec and Gulf Paper Manufacturing (GPM) at Paper One Show in UAE (from right to left): Marco Dalle Piagge, Sales Director Tissue Toscotec; Fabio Bargiacchi, Sales Manager Toscotec; Tareeq Al Moasherji, CEO GPM; Ghaleb Alhadhrami, Projects & Development Manager GPM; Ahmed Kasim, Plant Manager GPM; Enrico Fazio, Sales Director P&B Toscotec.

Toscotec and Gulf Paper Manufacturing (GPM) at Paper One Show in UAE (from right to left): Marco Dalle Piagge, Sales Director Tissue Toscotec; Fabio Bargiacchi, Sales Manager Toscotec; Tareeq Al Moasherji, CEO GPM; Ghaleb Alhadhrami, Projects & Development Manager GPM; Ahmed Kasim, Plant Manager GPM; Enrico Fazio, Sales Director P&B Toscotec.

Ghaleb Alhadhrami, Gulf Paper Manufacturing Projects & Development Manager, says, “With Toscotec’s rebuild of our packaging paper machine in 2019, we achieved a substantial production increase, reduced sheet breaks by over 80%, and improved paper quality especially in the moisture profile and hand feel. We are confident that Toscotec will deliver on this new upgrade of our tissue machine as successfully as they did two years ago. This new headbox and approach flow system are also fit for a future rebuild into crescent former configuration.”

Fabio Bargiacchi, Sales Manager at Toscotec, says, “A rebuild is always a challenge, as it requires strong engineering skills, experience, and flexibility. We are delighted that our tailor made solution was selected for this project. Our technology will support Gulf Paper to improve product quality and strengthen their tissue business. Toscotec consolidates its position in the Middle East, which includes 4 projects for super-soft facial tissue production awarded over the last two years.”

About Gulf Paper Manufacturing

Established in 1978, Gulf Paper Manufacturing was the first company to start manufacturing paper in the Gulf region in 1981. Owned by two families of Kuwaiti entrepreneurs, it operates three production lines at its Mina Abdullah paper mill in Kuwait: PM1 produces packaging grades, mainly Fluting medium, Test liner and white top liner, using 100% recycled paper; PM2 manufactures tissue from 100% virgin pulp; the third is a tissue converting line. The company’s current capacity is 70,000 tons, with 70% of its packaging grades being destined for export to GCC (Gulf Cooperation Council) countries and chiefly Saudi Arabia, and the domestic market accounting for approximately 30% of its business.

Contact

Fabio Bargiacchi

Sales Manager, Tissue division Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet to deliver a complete atmospheric diffuser rebuild to Billerud’s Skärblacka mill in Sweden

Valmet will deliver a complete atmospheric diffuser rebuild to Billerud’s Skärblacka mill in Sweden. The delivery is scheduled to take place in May 2024.

The order was included in Valmet's orders received of the second quarter 2023. The value of the order will not be disclosed.

Skärblacka mill’s original washer was delivered by Valmet in 1973. The rebuild will secure the washer’s performance and availability for years to come and prepare the mill for future capacity increases.

“We have established a long-lasting relationship with Valmet and have learned to trust their expertise. We have confidence in Valmet’s technology and found their solution superior to the alternatives,” says Samuel Wirzén, Project Manager at Billerud’s Skärblacka mill.

Photo: Billerud's media portal

Photo: Billerud's media portal

“We are happy that Skärblacka chose Valmet to supply washer technology. We believe that our solution will be both valuable to the mill and prolong the lifespan of their machine,” says Lennart Montonen, Sales Manager, Pulp Solutions, EMEA Area at Valmet.

Technical information about the delivery

The rebuild will include a complete technology upgrade and an installation of a Valmet Atmospheric Diffuser Kit, leading to optimized washing and increased capacity.

About the customer Billerud

Billerud provides paper and packaging materials made from virgin fiber – passionately committed to sustainability, quality, and customer value. The Skärblacka mill produces white machine glazed kraft paper, brown sack paper and fluting and runs two laboratories specialized in developing packaging for food and medical products. The company has ten production units in Sweden, the USA and Finland with around 6,100 employees in over 13 countries and customers in over 100 countries. Billerud has an annualized turnover of approximately SEK 42.6 billion.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our 17,500 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Former Voith Paper CEO Dr. Hans-Peter Sollinger turns 70

Dr. Hans-Peter Sollinger, CEO of Voith Paper from 2005 to 2014, turns 70. In his more than 30 years of service at Voith, Sollinger played a key role in shaping the company and made a significant contribution to its success.

“On behalf of Voith Paper, I would like to congratulate Hans-Peter Sollinger on his 70th birthday,” says Andreas Endters, current President & CEO Voith Paper. “As our former CEO, Mr. Sollinger had a massive impact not just on our organization but also on the people who worked with him. We would like to thank him most sincerely for his more than three decades of loyal service and wish him all the very best!”

Sollinger began his career at Voith in 1982 as a project planning engineer and subsequently held various management roles. As a member of the Management Board of the Voith Paper Division, he assumed responsibility for the Paper Machine segment in 1994. In the same year, he was appointed as a Member of the Board of Management of Voith Paper. In 2000, Sollinger joined Voith’s Corporate Board of Management. As CEO of Voith Paper, he managed the company’s entire paper machine business from 2005 to 2014.

Sollinger began his career at Voith in 1982 as a project planning engineer and subsequently held various management roles. As a member of the Management Board of the Voith Paper Division, he assumed responsibility for the Paper Machine segment in 1994. In the same year, he was appointed as a Member of the Board of Management of Voith Paper. In 2000, Sollinger joined Voith’s Corporate Board of Management. As CEO of Voith Paper, he managed the company’s entire paper machine business from 2005 to 2014.

Under Sollinger’s leadership, Voith Paper evolved to become one of the world’s foremost technology suppliers. The strategic acquisition of the paper technology operations of the British Scapa Group in 1999 underpinned this development. Moreover, Sollinger was behind the successful development and expansion of the automation business. Early on, he also recognized the importance of the efficient use of resources in paper manufacturing and established this as a focus area of Voith Paper. The internationalization of the paper business, in particular the expansion of business operations in China through the establishment of the Voith Paper City in Kunshan, also bears his signature. And ultimately, he initiated the realignment of Voith Paper in the face of fundamental structural changes in the global paper markets.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 21,000 employees, sales of € 4.9 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and supports customers in significantly reducing their carbon footprint. With its comprehensive automation products and leading digitization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art, digital technologies to increase the availability and efficiency of their systems in all areas of the production process.

Voith and partners announce FOREST initiative: Research project aims to develop digital framework for optimizing energy and material flows in paper production

Voith, the leading global technology group for the paper industry, has launched a new research project called FOREST together with partners from industry and research. The goal of the project is to develop a fully comprehensive digital map for papermaking processes that can capture energy and material flows, as well as CO2 flows and footprints, down to the sub-process and sub-product level. The digital framework identifies multiple optimization opportunities that promote a targeted acceleration of the paper industry's transformation toward climate neutrality.

- FOREST research project launched in cooperation with renowned partners from industry and research

- Goal is to build a digital framework that will enable effective process optimization and predictive benefit assessment

- Project aims to support the paper industry's transformation towards climate neutrality

By visualizing the actual state of the production facilities, all stakeholders gain a deeper understanding of the processes. In particular, the innovative solution makes it possible to identify plant areas with high optimization potential during ongoing operation using current data. With the help of the digital framework, for example, the optimum settings for minimized CO2 emissions can be determined and the benefits of rebuild measures can be estimated in advance. In addition, the digital framework supports the definition of requirements for future developments. In this way, the influence of new framework conditions, such as changes in energy supply or costs, can be modeled.

After the first kick-off meeting, the project team is now working to define the requirements and interfaces for the framework and derive a requirements catalog. In addition to a physical basic model, this framework also includes specific, more detailed modeling of individual sub-processes, which are also being developed by Voith as part of the project. In the next step, Voith will test the digital framework together with the other research partners on various pilot installations.

The research project was approved by the project management organization Jülich as of April 1, 2023. The project involves cooperation between Voith and Modellfabrik Papier gGmbH, the Institute of Textile Technology at RWTH Aachen University (ITA), the NOWUM-Energy Institute at FH-Aachen University of Applied Sciences, the Chair of Wood Technology and Fiber Materials Technology at TU Dresden, the Paper Technology Foundation (PTS), ABB AG and associated partners such as Felix Schoeller GmbH & Co. KG, Sappi Ehingen GmbH, Schoellershammer GmbH and WEPA Group.

About the FOREST research project

FOREST stands for “Framework fOr Resource, Energy, Sustainability Treatment” in paper production. The work is funded by the German Federal Ministry of Economics and Climate Protection as part of the German government's 7th Energy Research Program. Further information can be found at: BMWK - Energy Research and Innovation.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of €4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Toscotec delivers a press section rebuild to ETAP in Egypt

Egyptian linerboard manufacturer ETAP started up PM2 at its Borg Elarab mill, following a press section rebuild successfully carried out by Toscotec. PM2 produces testliner, kraftliner, top kraftliner and white top in the range from 125 to 240 gsm. In 2018, the machine had already been modified by Toscotec who entirely rebuilt its Fourdrinier wire section in stainless steel.

Toscotec successfully replaced an existing plain press in the first part of PM2’s press section with a new bi-nip concept press, which has achieved a two-fold target. First, the increase of post-press dryness; and second, an efficiency increase of the entire press section through a substantial reduction of paper breaks.

Mohamed Ashour, Managing Director at ETAP, says: “On our second major rebuild with Toscotec, we are once again very satisfied with their ability to effectively manage the project from inception to completion. ETAP has increased its production capacity taking advantage of Toscotec’s advanced technology.”

ETAP and Toscotec teams during the start-up of PM2 at ETAP mill in Egypt: (from left to right) Marco Del Chiaro, Project Manager Toscotec; Vedran Simic, Mechanical Supervisor Toscotec; Mohamed Ashour, Managing Director ETAP; Sameh Habib, CEO Chemitex Egypt for Trading & Agencies; Luca Nesi, Design Engineer Toscotec; Flavio Biondi, Automation Supervisor.

ETAP and Toscotec teams during the start-up of PM2 at ETAP mill in Egypt: (from left to right) Marco Del Chiaro, Project Manager Toscotec; Vedran Simic, Mechanical Supervisor Toscotec; Mohamed Ashour, Managing Director ETAP; Sameh Habib, CEO Chemitex Egypt for Trading & Agencies; Luca Nesi, Design Engineer Toscotec; Flavio Biondi, Automation Supervisor.

“ETAP is an important customer for Toscotec in Egypt and in the Middle Eastern market” comments Enrico Fazio, Sales Director Paper & Board division Toscotec. “We had a very positive cooperation four years ago, and we are very satisfied to carry on our collaboration with this project and to continue supporting them with Toscotec’s expert services in the future.”

Sameh Habib, CEO at Chemitex Egypt for Trading & Agencies S.A.E., says, “The partnership with ETAP has been successful for over two decades and we are very proud to contribute again to ETAP’s growth by successfully landing their latest rebuild in collaboration with Toscotec. We look forward to more success with upcoming projects.”

About ETAP

Established in 1990, ETAP is a family business that has grown to become one of the leading manufacturers of high quality linerboard in Egypt. Its production facility is located in Borg Elarab, Alexandria, where it operates two paper machines with an annual production capacity of approximately 120,000 tpy. Their product range includes top kraftliner and testliner1 that are distributed in the local and export markets.

Contact

Enrico Fazio

Sales Director, Paper & Board division Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.