Super User

ANDRITZ to increase mechanical pulp production at Dezhou Taiding with another high-performance line

International technology group ANDRITZ has received an order from Dezhou Taiding New Material Science and Technology Co., Ltd., China, to deliver a second chemi-thermomechanical (P-RC APMP) line to the mill in Pingyuan County, Dezhou City, Shandong Province, China. The ANDRITZ fiberline already installed at the mill supplies the company’s paper machines producing printing and writing paper and board grades. It has been operating successfully since 2021.

Zhang Qingchao, Vice General Manager of Production, Dezhou Taiding, says: “The ANDRITZ P-RC APMP line at our mill has consistently shown top fiber quality, remarkably low energy and chemical consumption, and high operational reliability. It was clear for us to partner with ANDRITZ again for our capacity increase.”

The new line with a capacity of 400 admt/d will process poplar wood chips into high-quality mechanical pulp. ANDRITZ will furnish the fiberline with its state-of-the-art key equipment, covering all stages from chip washing to pulp storage. The scope of supply also comprises the basic engineering and on-site services including installation, commissioning, and start-up supervision. Start-up is scheduled for the beginning of 2025.

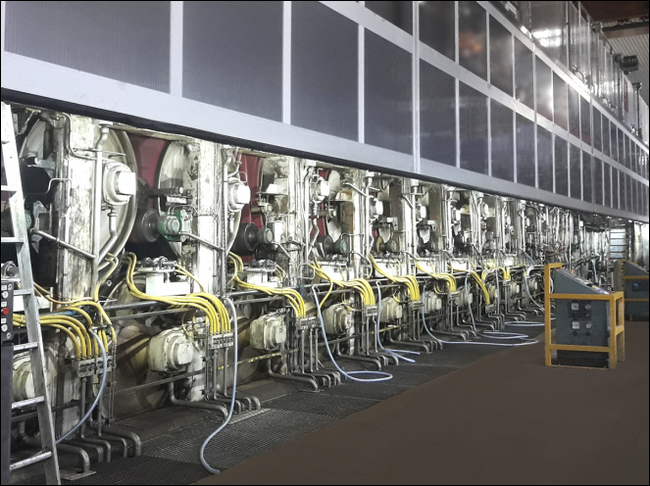

ANDRITZ PrimeMSD Impressafiner and vertical Impregnator running in Taiding mill. Photo Andritz

ANDRITZ PrimeMSD Impressafiner and vertical Impregnator running in Taiding mill. Photo Andritz

Dezhou Taiding is a joint-stock company focusing on the pulp production, papermaking and thermo-electricity business. It is one of the most important players in the paper industry in the Shandong region, China.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

PULP & BEYOND 2024 CONFERENCE -PROGRAM IS RELEASED

The Pulp & Beyond 2024 Conference will bring together key people in the forest industry on 9 April 2024 at the Helsinki Expo and Convention Centre. The program for the three-part conference has now been published, focusing this time on innovative wood-based products, carbon zero future mills, and international control systems.

The conference opening will highlight the forest industry contributing on global responsibility. The Pulp & Beyond Conference will take place on Tuesday 9 April 2024 as part of the leading international forest industry event, Pulp & Beyond 2024, which runs from Wednesday to Thursday, 10-11 April 2024 at the Helsinki Expo and Convention Centre. On Friday 12 April 2024 there will also be excursions for professionals to Central Finland and for university students to Stockholm.

The panel discussion at the opening of the Pulp & Beyond 2024 Conference will feature Michael Carus, the founder and CEO of Nova-Institute, discussing the role of wood in the renewable carbon concept. Tiina Pursula, SVP Sustainability, Division Packaging Materials, Stora Enso, will provide insights from the perspective of forest companies on responsibility, and Lyndsey Parette, Nestlé Nespresso's Nordic Environmental Sustainability Manager, will share a brand owner company’s perspective on global responsibility and the forest industry’s role therein. The panel will be moderated by Andre Noël Chaker.

After the opening, the conference program will be divided into three tracks including presentations from top experts. Each track will feature four or three presentations from three different perspectives or themes. The complete program is published on the www.pulpandbeyond.com website. The main partner for the conference is ANDRITZ, and other partners are Cargill and Sulzer.

Innovative wood-based products, carbon zone future mills, and control systems

The track dedicated to innovative wood-based products includes three themes. The "New Cellulose-based Textiles Changing the Fashion Business" theme explores the challenges, opportunities and the future of cellulose-based textile fibers, how consumers perceive the differences between wood fibers versus recycled plastic, the case TreeToTextile on new biodegradable fibers with responsible resource stewardship, and projects for developing new textile products with partners. Speakers include Aspi Patel, Group Chief Technology Officer of ABG, CEO of Aditya Birla Science and Technology Company and Olli Ylä-Jarkko, CEO of TreeToTextile. The theme "Creating New Innovative Bioproducts from Wood and Process Side Streams" discusses wood as a versatile raw material bank with vast opportunities, long-term lignin application development, sustainable battery materials from lignin, and microfibrillated cellulose. Speakers include PhD Professor Orlando Rojas from The University of British Columbia and, Canada Excellence Research Chair and Scientific Director, Bioproducts Institute, and R&D Executive Manager Heloisa Ramires from Suzano. The theme "Solving Global Challenges with Renewable Packaging Materials and Barrier Products" covers the future of packaging in light of EU PPWR, developing sustainable cushioning product innovations with foam-laid forming technology, the re-thinking of paper packaging, and the latest developments in cellulose-based food packaging. Speakers include Gustavo Duerte, Manager Competence Centre Functional Papers Solutions at Sappi Europe, and Professor Julien Bras, Cellulose Vallery chair holder, Grenoble INP Pagora – LGP2.

The track dedicated to innovative wood-based products includes three themes. The "New Cellulose-based Textiles Changing the Fashion Business" theme explores the challenges, opportunities and the future of cellulose-based textile fibers, how consumers perceive the differences between wood fibers versus recycled plastic, the case TreeToTextile on new biodegradable fibers with responsible resource stewardship, and projects for developing new textile products with partners. Speakers include Aspi Patel, Group Chief Technology Officer of ABG, CEO of Aditya Birla Science and Technology Company and Olli Ylä-Jarkko, CEO of TreeToTextile. The theme "Creating New Innovative Bioproducts from Wood and Process Side Streams" discusses wood as a versatile raw material bank with vast opportunities, long-term lignin application development, sustainable battery materials from lignin, and microfibrillated cellulose. Speakers include PhD Professor Orlando Rojas from The University of British Columbia and, Canada Excellence Research Chair and Scientific Director, Bioproducts Institute, and R&D Executive Manager Heloisa Ramires from Suzano. The theme "Solving Global Challenges with Renewable Packaging Materials and Barrier Products" covers the future of packaging in light of EU PPWR, developing sustainable cushioning product innovations with foam-laid forming technology, the re-thinking of paper packaging, and the latest developments in cellulose-based food packaging. Speakers include Gustavo Duerte, Manager Competence Centre Functional Papers Solutions at Sappi Europe, and Professor Julien Bras, Cellulose Vallery chair holder, Grenoble INP Pagora – LGP2.

The track Carbon Zero Future Mills is approached through three themes. Under the theme "Breakthrough Energy Solutions in the Forest Industry," topics include hydrogen as gamechanger in energy markets, the case of Kemi bioproduct mill – how to take steps toward fossil-free pulp mills, breakthrough energy solutions in the forest industry, and improving energy efficiency through digitalization as well as the future of electrification of European industries and its implications on the forest industry. Speakers include Simo Säynevirta, Head of ABB Green Electrification Ecosystem and Chair of Hydrogen Cluster Finland, and Matti Toivonen, Vice President of Technology at Metsä Fibre. The theme "On the Path Towards World-Class Process Safety" includes discussions on the implementation of process safety management systems from the mill perspective, process safety and production of chemicals, optimizing the mill site development by fitting new processes into old mill sites, and the developing of world-class process safety and enhanced energy efficiency with digitalization. Speakers include Mika Ristimäki, Area Director of Process Safety at Stora Enso Pulp Competency Centre, and Jaakko Nousiainen, Technology Director at UPM Biofuels. The theme "Developing Material Efficiency in Future Carbon Zero Mills" highlights stepping into a new level in smart material usage with the Emission Free Pulping project, carbon zero future for pulp, paper, and board, smart utilization of carbon dioxide at pulp mills, and radical reduction of water usage in pulp making. Speakers include Atte Virtanen, Vice President, Biomaterial processing and products at VTT Technical Research Centre of Finland Ltd, and Petri Vasara, Vice President at AFRY.

As part of the Pulp & Beyond Conference 2024 is the International Control System Conference 2024, which focuses on international control systems through Pulp Mill Modelling and Control, Advances in Quality Control Systems, and Millwide Applications for the Future.

Pulp & Beyond, the new era for PulPaper

The next generation for PulPaper, Pulp & Beyond 2024 is the leading forum bringing together the latest forest-based bioeconomy innovations, products, services and technologies as well as key people throughout the ecosystem. It offers new encounters, inspiration, networking and business possibilities for marketing global and sustainable solutions. The event provides the widest available showcases on the latest trends, and supports learning, employer branding, and competence development. The new event format will put a strong focus on sustainability, efficiency and functionality.

Pulp & Beyond will be arranged for the first time on 10-11 April 2024 at Helsinki Expo and Convention Centre in Finland. The Pulp & Beyond Conference will take place on 9 April 2024, and the event continues on 12 April 2024 with excursions targeting industry companies in the Jyväskylä region in Central Finland. This time, the destinations include Metsä Group's Äänekoski bioproduct mill, Suzano Finland’s textile MFC plant, VTT's technical research facility, and Aisti, a company producing wood based acoustic panels. From Thursday 11 April to Saturday 13 April, a day cruise to Stockholm is organized for university students, including visits to Stora Enso's and AFRY's offices. Reservations: www.pulpandbeyond.com.

Pulp & Beyond is the new Nordic innovation hub for forest industry

Pulp & Beyond offers exhibitors an easy and sustainable way to participate in one of the leading and most influential forest industry events in the world. For visitors, the event is a great place for networking and learning. The new efficient event concept will focus on easiness, time saving, sustainability and high impact. Companies can choose between four different turn-key participation packages, including everything needed for the participation. The stand constructions are completely made of sustainable and recyclable materials. In addition to sustainability, turn-key packages also mean efficiency and easiness for the event partners. As the organizer takes care of all practical matters, the event partners can fully focus on networking and business. Sustainability will also play a central role when it comes to catering and travelling. Visitors will have the possibility to compensate possible travelling emissions and only responsibly produced food will be served.

The event venue features two program stages. The main stage hosts keynote speakers and top-level panel discussions. Presentations by event partners are at the Speaker’s Corner. The event is filled with various active engagements – discussions, forums, meetings, and networking opportunities. Visitors will have access to meeting spaces, remote work areas, and meeting points. Additionally, there will be evening programs as part of the event.

The Pulp & Beyond 2024 Conference (450 € + VAT) will be held on 9 April 2024 at the Helsinki Exhibition and Convention Centre. The conference is followed by the leading event within the forest industry, Pulp & Beyond 2024 (free for visitors) on 10-11 April 2024. Both events are organized by Helsinki Expo and Convention Centre. Pulp & Beyond 2024 excursions to Jyväskylä (250 € + VAT) will take place on 11-12 April 2024. ChemBio Finland 2024 and Helsinki Chemicals Forum 2024 will also be held at the Helsinki Expo and Convention Centre on 10-11 April 2024.

Helsinki Expo and Convention Centre organizes the Pulp & Beyond 2024 event in cooperation with the Finnish Forest Products Engineers’ Association (PI).

#pulpandbeyond www.pulpandbeyond.com

Valmet reaches two significant milestones in its Climate Program

Valmet’s Climate Program – Forward to a carbon neutral future – was launched in 2021. The program covers the entire value chain and includes four key targets for the supply chain, Valmet’s own operations and the use of Valmet’s technologies by its customers for 2030. Year 2023 marks two significant milestones for the program.

Carbon neutral production enabled for pulp and paper industry customers

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

Valmet has estimated that around 95 percent of its carbon footprint originates from the use phase of Valmet’s technologies by its customers and the program emphasizes this part of the value chain with two targets: to enable 100 percent carbon neutral production for all pulp and paper industry customers and to improve the energy efficiency of Valmet’s current technology offering by 20 percent by 2030. Valmet has now reached the first one of these two targets.

“When it comes to the first target, we have had excellent progress as we already reached our goal this year. We now offer carbon neutral production opportunities for our pulp, paper, board, and tissue customers, with the precondition that the customer has bioenergy or carbon neutral electricity in use. Carbon neutral production can be achieved by combining the best available technologies, optimizing mill design and selecting the right automation, Industrial Internet and service solutions,” says Janne Pynnönen, VP, R&D at Valmet.

“Among the key innovations in reaching this final stage has been the development of electrical heating of paper and board coating machines, while for tissue machines we have developed a fossil-free alternative for Yankee cylinder and Hood heating,” he continues.

Furthermore, many of Valmet’s customers’ chemical pulp mills using the company’s technologies are bioenergy self-sufficient, enabling carbon neutral pulp production and even selling of excess renewable energy.

“Lime kilns are typically the biggest source of fossil CO2 in pulp mills. Over the years, we have developed and delivered several fossil-free lime kilns based on biomass gasification or wood powder firing,” says Ari Saario, VP, Strategy and R&D, Pulp & Energy at Valmet.

For energy customers, Valmet has already long enabled carbon neutral heat and power production with biomass-based energy solutions.

100 percent carbon neutral electricity purchases reached in Finland and Sweden

In its own operations, Valmet targets to reduce CO2 emissions by 80 percent by 2030. The emissions from fuels, heating and electricity have already been reduced by 50% since the baseline year 2019. A major new milestone will be achieved by end of 2023 as Valmet reaches 100% carbon neutral electricity purchases in Finland and Sweden.

“The impact is significant, as these countries represent 60% of Valmet’s total electricity consumption and about 30% of the company’s total CO2 emissions from electricity usage. Through this, we are saving a total of 32,000 tonnes of CO2 annually, which is equivalent to driving almost 223 million kilometers by car,” says Victoria Larsson, VP, HSE at Valmet.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

AFT delivering new approach flow system to Smurfit Kappa Mexico

AFT is set to deliver a complete approach flow system to the Smurfit Kappa board mill in Cerro Gordo, Mexico. Representatives from the mill visited AFT’s Varkaus Service Center to tour the facility and inspect their equipment – including a new MaxFlow™ HB 2200 headbox screen and POMp™ degassers. “Everything we saw was great. We really liked the quality of manufacture, welding, and design”, remarked Alberto Monterrubio, Process Engineer (Projects & Engineering) for Smurfit Kappa Mexico.

In addition to the new approach flow system, AFT is also supplying system engineering, conceptual 3D layout and piping, and on-site services. Designed with ease of maintenance, process optimization, and reduced power consumption in mind, all AFT products are supported by a global team of process and service experts.

In addition to the new approach flow system, AFT is also supplying system engineering, conceptual 3D layout and piping, and on-site services. Designed with ease of maintenance, process optimization, and reduced power consumption in mind, all AFT products are supported by a global team of process and service experts.

AFT is pleased to have been selected for this project and looks forward to bringing the new equipment online safely and efficiently for Smurfit Kappa, a leading global provider of sustainable packaging solutions.

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

Successful start-up of Asia Symbol's Rugao board machine 13

At the end of October, Voith successfully started up Asia Symbol's BM 13 at Rugao, 180 km north of Shanghai, China. The state-of-the-art machine is 8.16 m wide with a design speed of 1,400 m/min and an annual capacity of around one million tons. It mainly produces high-quality white folding boxboard in the basis weight range of 170 to 400 gsm.

- Asia Symbol's Rugao BM 13 starts up successfully and will produce one million tons of high-quality white folding boxboard per year

- The full line was supplied by Voith and is characterized by excellent performance in terms of product quality, production efficiency, and operating and maintenance costs

- Project reflects important partnership between Voith and Asia Symbol and reinforces the strategic alliance of both companies in the paper industry

“Voith has always been a reliable partner for us. Thanks to Voith's full-line package, the Rugao BM 13 achieves excellent results in terms of product quality, production efficiency, and operating and maintenance costs, which further strengthens our competitive advantage in the market,” says Eric Xu, General Manager Rugao BM 13 of Asia Symbol.

“I thank both teams for the successful start-up! Asia Symbol is a partner that always sets new goals to achieve excellence. We look forward to deepening our business relationship in the future,” says Carlos Lin, Senior Vice President Order Execution and Operations, Voith Paper Asia.

The full-line solution supplied by Voith for the Rugao BM 13 includes a wide portfolio of state-of-the-art solutions, from BlueLine stock preparation and intelligent XcelLine paper machine to two VariFlex Performance winders with a fully automated Flying Splice reel change. For the plant, Voith and Asia Symbol placed a special focus on sustainable and efficient solutions. In addition to the resource-saving Triple NipcoFlex press, an energy-efficient EcoHood dryer hood, ropeless transfer in the dryer section and contactless qDry Pro drying with the HelioX infrared emitters are installed. Voith also supplied a comprehensive wear parts package and a wide range of automation solutions, including the OnControl MCS, DCS, Drive Control, OnQuality MD/CD Control and the OnCare Health condition monitoring system.

Successful project despite challenges

Despite a tight timeframe, complex tasks and challenging conditions due to the global pandemic, the project was successfully implemented. The project team benefited from mutual trust based on many years of successful cooperation. The Voith and Asia Symbol team worked cross-nationally with the local teams and enabled a smooth execution of the project through very close and committed cooperation from planning to implementation.

The commissioning of Rugao BM 13 now strengthens Asia Symbol's market position and reinforces its supply chain. The line supports Asia Symbol's goal of reducing CO2 emissions from paper production and promoting the joint development of local upstream and downstream industries. The start-up has laid a solid foundation for future cooperation and development between the two parties, which aim to further deepen their collaboration in the fields of technological innovation and sustainable development.

About Asia Symbol

Asia Symbol is a world leading producer of pulp and paper under the RGE Group. Its main products are BHKP, NBKP, DP, liquid packaging board, high grade ivory board and uncoated wood-free printing and office paper. The products are sold at home and abroad. Asia Symbol is committed to sustainable development and the exploration of long-term renewable resources for paper production to facilitate regional economic development and the welfare of the local community. The company's principle is to operate in a manner that creates value for the community, the country, the climate, the customer and the company.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Toscotec supplied a dryer section rebuild to Les Papeteries de Clairefontaine

Graphic paper manufacturer Les Papeteries de Clairefontaine started up PM6 after a dryer section rebuild supplied by Toscotec at its Etival Clairefontaine mill in France. The machine produces graphic paper in the basis weight range from 60 to 100 gsm.

The project was focused on PM6’s pre-dryer section for which Toscotec supplied TT SteelDryers designed for an operating steam pressure of 10 barg, as well as an upgrade of the machine frame. The associated services included the complete erection with supervision, commissioning, and start-up assistance.

The rebuild has achieved the target of increasing PM6’s drying face length without changing the overall width of the machine frame.

PM6’s dryer section at Les Papeteries de Clairefontaine’s Etival Clairefontaine mill in France.

PM6’s dryer section at Les Papeteries de Clairefontaine’s Etival Clairefontaine mill in France.

Julien Courant, Production Engineer at Les Papeteries de Clairefontaine, says, “The project had a positive outcome. We have enhanced our paper quality by improving the moisture profile in cross direction.”

Giancarlo Gianlorenzi, Sales Manager at Toscotec, says, “Through the cooperation with a well-established player such as Les Papeteries de Clairefontaine, Toscotec strengthens its presence in the French market. We were very happy to support the mill in the coordination of the project. Based on our vast experience in dryer section rebuilds, we are well positioned to continue serving this market area effectively.”

About Les Papeteries de Clairefontaine

Les Papeteries de Clairefontaine is a subsidiary of the Exacompta-Clairefontaine group, which is comprised of over fifty companies and employs over 3,200 staff, including 580 people at Les Papeteries de Clairefontaine. They are a well-established market player and produce a wide range of office and graphic papers.

GUTEX produces first fibers for insulation board with new ANDRITZ fiber preparation system

Wood fiber insulation board manufacturer GUTEX has successfully produced first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

Oliver Bauch, Plant Manager, GUTEX, says: “The new line will perfectly support the environmentally friendly production approach for our ecological insulation board products. Thanks to the excellent cooperation and the great effort of the whole ANDRITZ team we were able to produce first fibers even ahead of schedule.”

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, ANDRITZ. Photo " Andritz "

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, ANDRITZ. Photo " Andritz "

Michael Rupp, Vice President for Panelboard Systems, ANDRITZ, adds: “We are proud that GUTEX again chose to collaborate with us and that we had the opportunity to provide them with our complete front-end technology.”

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work. The highly efficient system processes softwood chips as raw material and features the following technological highlights:

- ANDRITZ RotaBarker debarking system and horizontally fed HHQ-Chipper for consistently good chip quality at high production rates

- Fully automatic chip storage system with reclaiming and screening equipment

- High-consistency pressurized refining system to obtain high fiber quality and low specific energy consumption

- Steam Recovery System (SRS) for efficient recovery of surplus steam and greater thermal efficiency of the fiber preparation system

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Toscotec to supply a complete drying section rebuild to Rexcell in Sweden

Toscotec will supply a complete rebuild of PM1’s drying section to Rexcell Tissue & Airlaid at its Skåpafors mill in Sweden. Planned for the second half of 2024, the project aims to support Rexcell to achieve substantial energy consumption reductions as part of its strong commitment to sustainability.

Energy Saving Customized solution

Toscotec will supply a customized solution designed to deliver substantial gas consumption reductions, as well as a significant increase in machine run-ability.

The scope includes a press section upgrade, a latest generation TT SYD Steel Yankee Dryer with new steam and condensate system, and a high efficiency TT Hood with a complete air system. The latter features various steps of heat recovery and an advanced BMS (Burner Management System) to optimize combustion efficiency through precise control of the combustion air, where the burners are fit to make an efficient use of LPG first and biomethane in the near future. The hood plant is also equipped with TT Drying Equilibrium, a reliable system that automatically regulates the air balance in the hoods, thereby ensuring maximum drying efficiency, faster basis weight changes, and a production increase.

Rexcell Tissue & Airlaid’s production facility at Skåpafors in Sweden.

Rexcell Tissue & Airlaid’s production facility at Skåpafors in Sweden.

Two-fold target

The rebuild aims to considerably reduce PM1’s thermal energy consumption through the use of state-of-the-art drying technology designed for energy efficiency, and to increase the machine speed and production capacity in the future.

Lars Andersson, CEO at Duni Rexcell, comments, “At Rexcell we take global environmental challenges very seriously. As a part of Duni AB, we share the same vision to be Net Zero 2030 along with considerable energy reductions. This machine upgrade is a strategic investment that perfectly fits into this vision. Toscotec’s energy efficient technology will take us a step closer to realizing maximum energy savings and minimal material footprint.”

Riccardo Gennai, Sales Manager at Toscotec, says, “It is a pleasure for Toscotec to cooperate with Rexcell who is on track to operationalize its transition from fossil-based to fossil-free sources. By developing a customised solution for the new drying section of their PM1, we will ensure the highest possible energy efficiency, as well as substantial energy savings compared to the present configuration.”

About Rexcell Tissue & Airlaid AB

Rexcell, a wholly owned subsidiary of Duni Group, operates one of the most advanced paper mills in Europe for the production of specialised tissue. Located in Skåpafors, Sweden, the mill started production in 1898 with their first paper machine. Through continuous innovation, today Rexcell produces Airlaid, Tissue and Evolin products in a variety of colours.

GUTEX produces first fibers for insulation board with new ANDRITZ fiber preparation system

Wood fiber insulation board manufacturer GUTEX has successfully produced first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

Oliver Bauch, Plant Manager, GUTEX, says: “The new line will perfectly support the environmentally friendly production approach for our ecological insulation board products. Thanks to the excellent cooperation and the great effort of the whole ANDRITZ team we were able to produce first fibers even ahead of schedule.”

Michael Rupp, Vice President for Panelboard Systems, ANDRITZ, adds: “We are proud that GUTEX again chose to collaborate with us and that we had the opportunity to provide them with our complete front-end technology.”

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work. The highly efficient system processes softwood chips as raw material and features the following technological highlights:

- ANDRITZ RotaBarker debarking system and horizontally fed HHQ-Chipper for consistently good chip quality at high production rates

- Fully automatic chip storage system with reclaiming and screening equipment

- High-consistency pressurized refining system to obtain high fiber quality and low specific energy consumption

- Steam Recovery System (SRS) for efficient recovery of surplus steam and greater thermal efficiency of the fiber preparation system

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ plant will prepare date palm waste for fiberboard production

International technology group ANDRITZ will supply a complete fiber preparation line for a greenfield plant in the Toshka area in the south of Egypt. The pioneering and eco-friendly plant will produce high-density and medium-density fiberboard (HDF/MDF) from date palm fronds, a material normally considered farm waste.

ANDRITZ will execute this order in cooperation with the engineering, procurement and construction (EPC) specialist WESER Industrie- und Anlagentechnik GmbH and DIEFFENBACHER GmbH Maschinen- und Anlagenbau, a leading manufacturer of press systems and complete plants for the wood-based panel industry. On behalf of Egypt’s National Service Projects Organization (NSPO), the German company WESER is acting as the general contractor for this turnkey project.

Michael Frint, Director Technology Panelboard Systems at ANDRITZ says: “Alternative raw materials, in particular from waste streams, are becoming increasingly important in the panel industry. Participating in this innovative and sustainable NSPO project is an important milestone for us.”

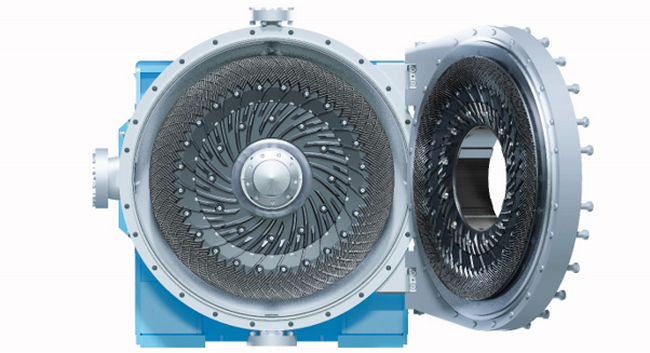

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

The ANDRITZ line, with a capacity of up to 14 bdmt/h, will process date palm fronds from a nearby 40,000-acre date farm. It includes a system to wash and condition the chips from the palm frond stems, and a pressurized refining system with a well-proven refiner to process the washed and conditioned chips into high quality fibers at very low energy consumption. The fibers will be used to produce high quality fiberboards, mainly for the flooring and furniture industries. The plant is scheduled to commence production in the autumn of 2025.

About Andritz

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.