Ian Melin-Jones

Demag Cranes equips new paper roll shipping store in China

Demag Cranes has been awarded a further contract to supply the entire equipment for a paper roll shipping store in China. The contract by the Chinese paper manufacturer Liansheng Paper (Longai) Co. Ltd includes the delivery of five identical fully automated Process Cranes with the latest generation of mechanical grippers and a warehouse management system. The material will be carefully stored and staged ready for shipping to schedule in the automated paper roll store, which will accommodate the production of two paper machines with an annual capacity of some 800,000 tonnes of paper. The cranes will be fitted with mechanical grippers that can pick up individual rolls of paper, or sets of up to four rolls simultaneously, to provide a significant increase in handling rates.

Chen Yan Yang, General Manager of Liansheng Paper, emphasises: “As part of our planned growth strategy, we are investing in new production and storage technologies at our location in Longhai in Fujian province. In Demag Cranes, we have found a reliable partner that will support us with all of its expertise. Thanks to the automated storage solution, we are able to save some 40 per cent of the space required compared to the originally planned manually operated store. Besides the large number of Demag paper roll stores installed worldwide, we were impressed by the newly developed gripper technology.”

Thomas H. Hagen, Member of the Management Board of Demag Cranes AG and COO: “The contract awarded by Liansheng Paper underlines once again our leading role in the automated paper roll store sector. In addition to cranes, which we have successfully supplied with vacuum systems worldwide, we are increasingly utilising mechanical gripper systems with which our customers can also safely and reliably store packed rolls of paper.”

Additional information:

Innovative gripper technology for Liansheng Paper

The first stage of development of the automated paper roll store operated by Liansheng Paper consists of two parallel bays, measuring 189 and 139 metres in length. Five fully automated Process Cranes with spans of 35.5 metres and load capacities of four tonnes pick up the rolls of paper and stack them up to a height of 14 metres. The cranes are equipped with mechanical grippers that can also transport sets of rolls.

To pick up the rolls of paper, a Process Crane is positioned by the warehouse management computer exactly above the centre of the roll. The six arms of the mechanical gripper gently enclose the rolls of paper, which, in this store, measure between 800 and 2,600 millimetres in length and between 1,000 and 1,300 millimetres in diameter. The ability to lift a set of up to four rolls simultaneously, measuring 3,600 millimetres in length, will result in a significant increase in handling speeds. The compact design of the mechanical roll gripper also makes it possible to achieve a tight storage pattern and, therefore, optimum utilisation of the space available in the automatic store. With a theoretical 100-per cent fill rate of 70,000 tonnes with specified roll diameters, the store operated by Liansheng Paper will be one of the largest paper roll stores in the world.

High safety standards

The handling of rolls in sets and the required subsequent separating of the paper rolls can only be achieved with a gripper that is specially developed for this application. The gripper is designed in such a way that the rolls of paper are safely and reliably held, even if rolls with differing diameters are picked up. Additionally integrated safety circuits – such as the redundantly designed sensors installed in the gripper – provide for reliable handling of rolls in automated storage processes.

About Liansheng Paper

Liansheng Paper Industry (Longhai) Co., Ltd., is a subsidiary of Fujian Liansheng Paper Co., Ltd. The company, which is based in Fujian province in southeast China, is specialised in the production of board and kraft packing papers. Paper machines PM 5 and PM 6 are currently being installed at the Longhai City plant and are due to enter service in the first quarter of 2012 with a production capacity of 800,000 tonnes per year. In the next five years, Liansheng Paper Industry (Longhai) Co., Ltd. plans to install four further paper machines with dedicated shipping stores at this new location.

About Demag Cranes

The Demag Cranes Group is one of the world’s leading suppliers of industrial cranes and crane components, harbour cranes and terminal automation technology. Services, in particular maintenance and refurbishment, are another key element of the Group’s business activities. The Group is divided into the business segments Industrial Cranes, Port Technology and Services and has strong and well-established Demag and Gottwald brands. Demag Cranes sees its core competence in the development and construction of technically sophisticated cranes and hoists as well as automated transport and logistics systems in ports and terminals, the provision of services for these products and the manufacture of high-quality components.

As a global supplier, Demag Cranes manufactures in 16 countries on five continents and operates a worldwide sales and service network that is present in over 60 countries through its subsidiaries such as Demag Cranes & Components GmbH and Gottwald Port Technology GmbH, agencies and a joint venture. In financial year 2009/2010, the Group, with its 5,711 employees, generated revenue of EUR 931.3 million. Since August 2011, the Terex Group in the United States (www.terex.com) has held a majority share in the company.

Demag Cranes AG. We Can Handle It.

Metso's new control applications improve pulp and paper mill operations

Again Metso DNA is leading the way by introducing first in the world new control applications enhancing productivity and profitability. Metso DNA is now strengthened with new control applications, such as the winder controls, power plant turbine controls and machine condition monitoring. Metso is also pioneering usability in the process control work.

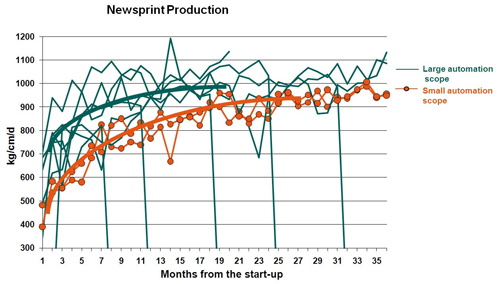

The chart shows the correlation between start up of the paper machine and scope of Metso automation system delivery. The largest scope results clearly the fastest start-up for new paper machine.

Metso DNA offers now pulp and paper makers a single system for all controls, from the fiber line to baling information, and from head box to winder.

Winder controls

''The renewed Metso DNA offers now winder controls, which increase the transparency between the winding process and papermaking process controls. "The new winder controls enable following paper profiles through the winder controls, which improves both runnability and productivity of the winding process," says Mika Lehmusvaara, Technology Manager, Automation Sales, Metso Paper.

Machine condition and runnability monitoring

Another new application is machine condition and runnability monitoring which Metso is first to integrate within the process controls. The operator sees condition monitoring alarms in the same interface where process alarms. Condition and runnability monitoring has traditionally been a separate system mostly utilized by maintenance specialists. Thanks to Metso DNA Machine Monitoring, the same information can be shared with machine operators in the control room.

Turbine control

Integration of turbine control, turbine protection and turbine management applications into Metso DNA automation system provides customer with easy and cost efficient maintenance and reliability based redundant process controllers. The Metso DNA turbine automation consists of special turbine control features like fast governor control and integrated simulator. Protection functions include over speed protection and machine protection. Tools for mechanical condition and turbine performance monitoring are also included.

Good usability enables positive emotions and feelings

Metso is also pioneering usability in the process control work. Metso DNA takes a new approach to usability by taking emotions and feelings a part of the process control work. "Despite fact-based by its nature, process control work at pulp and paper mills includes a lot of feelings connected with solving situations. When all the aspects of business and production processes are under control, people in various tasks can enjoy feeling of control in their work," explains Jaakko Oksanen, Product Manager for Metso DNA.

An example about usability is that Metso DNA is the only system in the world, where the user receives the process data in real time and retrospectively from the same user interface, with one push of a button.

''The user can easily access all the data collected during his/ her absence, for example, over the weekend. Traditionally, the history of this information requires separate applications and data analysis is difficult. This is one example of how we have usability and the subsequent positive emotions and positive user experience taken into account, ''Jaakko Oksanen explains.

One system for all controls

The new Metso DNA provides pulp and paper makers with measurements, analyzers and a complete selection of state-of-the-art advanced process controls.

Having all controls for machine, process, quality and drives within the same system gives the customers several benefits.

One systems enables pulp and paper mills to integrate all operations into one mill-wide or even corporate-wide entity enabling easy access to information for comparing and combining process data. The operators need to know only one systems. Metso DNA customers also benefit from having a single source for global system support, updates and spare parts.

In new machine installations, Metso control system allows for quick start-ups.

Stora Enso orders a compact approach flow system from POM Technology Oy Ab for its Ostroleka Mill

POM Technology Oy Ab has received an order for the supply of a compact approach flow system for Stora Enso’s new testliner machine in Ostroleka Mill in Poland. The start-up is scheduled for the first quarter of 2013.

At a wire width of 8,600 mm and a design speed of 1,800 m/min, the new Narew PM5 project will produce 455,000 metric tons of testliner per year. The new paper machine is designed for the production of lightweight testliner and recycled fluting in a basis weight range of 65-140 g/m².

The POM compact approach system delivery includes: two POMix Stock Processors for efficient stock mixing, three POMp Degassers for white water dearation, two POMlock suction leg sealing units as well as compact process solutions and engineering for whole approach flow system. Stora Enso’s focus of this investment was on operational savings from improved drainage, cleanliness and quality as well as on space and especially energy cost savings, which all are met by POM System applications and principles.

The new Stora Enso Ostroleka PM5 order continues Stora Enso’s orders to POM Technology Oy Ab. POM Tehnology has successfully delivered several POM Degassing solutions to Stora Enso Varkaus and Imatra Mills in Finland. POM Technology Oy Ab will become part of Aikawa Fiber Technologies (AFT) at beginning of year 2012.

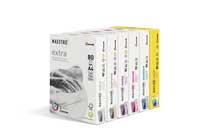

Mondi launches a new package design for IQ and MAESTRO® reams

The new packaging displays a contemporary design that highlights key product features.

September 20, 2011, Vienna – Today Mondi announces a new package design for its most popular office paper brands IQ and MAESTRO®. The design provides a more contemporary look that draws attention to the characteristics and environmental accreditations specific to IQ and MAESTRO® and their sub-brands.

“The impetus for the new package design came from customers wanting straightforward product information that could be accessed quickly in a busy office environment. Therefore, we increased the visibility of all environmental accreditations so they appear on the front, back and sides of IQ and MAESTRO® packaging, as well as key product characteristics,” says Johannes Klumpp Marketing and Sales Director for Mondi Uncoated Fine Paper.

On the back side of each package of IQ and MAESTRO®, customers will find a table that concisely describes the entire brand portfolio, providing the range of grammages available, formats, and recommended applications. Furthermore, logos are accompanied by explanations about each label and certification, such as Green Range, FSC®, ColorLok® or TRIOTEC®.

IQ

IQ

The colour-coding and motifs for all IQ sub-brands have remained the same. However, in place of the narrow colour band that ran across the top of IQ packages, customers will now find a bold swatch of colour – gold (IQ selection smooth), brown (IQ premium), orange (IQ appeal), blue (IQ allround) red (IQ economy) – and the sub-brand name wrapping around the upper right corner and down the side for easy identification. The same holds true for IQ color, Mondi’s tinted range that is available in a transparent plastic wrapper to reveal the colour of the paper. A horizontal strip of colour along the bottom right corner of the ream also displays the grammage, sheet count, format, and printer suitability.

MAESTRO®

MAESTRO® customers know this brand as the high performance paper for business users and the new packaging now better reflects this concept. Using consistent  MAESTRO® sub-brand colours – gold (MAESTRO® supreme), silver (MAESTRO® extra), purple (MAESTRO® bulky), red (MAESTRO® special) and blue (MAESTRO® standard) – the new wrapper image combines the MAESTRO® logo with a close-up view of hands typing on a computer keyboard. On the transparent package for the tinted MAESTRO® color, the logo is multicoloured, echoing the 29 shades available.

MAESTRO® sub-brand colours – gold (MAESTRO® supreme), silver (MAESTRO® extra), purple (MAESTRO® bulky), red (MAESTRO® special) and blue (MAESTRO® standard) – the new wrapper image combines the MAESTRO® logo with a close-up view of hands typing on a computer keyboard. On the transparent package for the tinted MAESTRO® color, the logo is multicoloured, echoing the 29 shades available.

In addition to IQ premium, IQ selection smooth, MAESTRO® extra and MAESTRO® supreme, customers can now find the ColorLok® logo on packages of IQ appeal and MAESTRO® bulky. The primary benefits of ColorLok® Technology are realized with inkjet printing and result in brighter images and graphics, crisp text with bolder blacks, and less smears due to rapid drying. To promote the extended paper range with ColorLok® Technology, Mondi will launch a ColorLok® campaign toward the end of 2011.

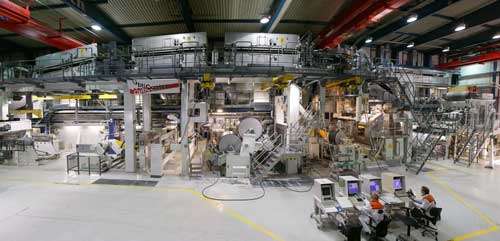

The world's fastest and most demanding coating machine starts up with Metso drive controls reaching record speed

The benefit of using a single control system was again proved in Järvenpää, Finland, when the restart of Metso’s Järvenpää Pilot Coater immediately reached a new world record speed of 3,160 m/min.

Restart of Metso's Järvenpää Pilot Coater immediately reached a new world record speed of 3,160 m/min.

The restart took place on September 1 after an automation upgrade. The new 35 group drive is controlled directly by Metso DNA automation system in which the drive controls are integrated with the machine control system. Tension controls are implemented with a new multivariable control, developed by Metso, to achieve more accurate tension management in dynamically changing coater conditions.

The pilot coater can run basis weights of 25 – 350 g/m2. Available coating technologies are OptiSizer film sizing, OptiCoat Duo double backing roll coating, OptiCoat Jet nozzle coating, OptiBlade short dwell coating, OptiLayer curtain coating and ValSpray spray sizing.

One system, several benefits for customers

Metso DNA offers pulp and paper makers a single system for all controls, from fiber line to baling information, and from headbox to winder enabling faster startups. It provides pulp and paper makers with measurements, analyzers and a complete selection of state-of-the-art advanced process controls.

Having all controls for machine, process, quality and drives within the same system gives customers several benefits. In new machine installations, the Metso control system allows for quicker startups. One system enables pulp and paper mills to integrate all operations into one mill-wide or even corporate-wide entity, enabling easy access to information for comparing and combining process data. Operators only need to learn to use one system. Metso DNA customers also benefit from having a single source for global system support, updates and spare parts.

DS Smith PLC – Disposal Of Higher Kings Mill Paper Mill

DS Smith Plc (DS Smith) announces that its DS Smith paper business has entered into a binding legal agreement for the sale of its Higher Kings Mill paper mill in the United Kingdom to Asia File Corporation Berhad, for an enterprise value of £4.6 million payable in cash on completion. As at 30 April 2011, the net assets of the Higher Kings Mill business (on a cash and debt free basis) were £3.8 million and gross assets were £8.0 million. Higher Kings Mill is a leading European producer of filing and educational papers, producing 34 thousand tonnes of paper per annum. The sale is expected to be completed on 30 September 2011.

This transaction marks a further development in the execution of DS Smith’s strategy to focus on recycled packaging for consumer goods and to reduce paper manufacture that does not directly support the packaging business. This transaction follows the announcement on 23 June 2011 of the intention to close the Hollins paper mill, which produces 95 thousand tonnes per annum. This reduction in DS Smith’s exposure to paper manufacturing will help DS Smith achieve its goal of delivering higher returns on capital with reduced cyclicality.

Sale of the Business and Operations of NewPage Port Hawkesbury Corp.

NewPage Port Hawkesbury Corp. ("NPPH") filed for and obtained protection under the Companies' Creditors Arrangement Act ("CCAA"). Pursuant to an Order of the Court dated September 9, 2011 (the "Initial Order"), Ernst & Young Inc. ("E&Y") was appointed as Monitor (the "Monitor") in the CCAA proceedings. Documents relating to the CCAA proceedings can be obtained from the Monitor's website at http://www.ey.com/ca/npph.

NPPH operates a paper mill on Cape Breton Island, owns approximately 50,000 acres of timberland and manages 1.5 million acres of licensed crown timberland in Nova Scotia. The NPPH mill consists of one newsprint paper machine and one supercalendered paper machine with a combined annual production capacity of 545,000 metric tonnes. Supercalendered paper is a form of enhanced newsprint that is a value added grade of paper used in catalogues, magazines, inserts and flyers. Additionally, NPPH's mill operates a thermo-mechanical pulp operation to provide the bulk of its fibre requirements.

On September 9, 2011, NPPH obtained a court order authorizing NPPH and the Monitor to implement a sales process ("Sales Process Order") to sell NPPH's assets and business. Sanabe & Associates LLC has been retained by NPPH to assist in the sales process. The assets offered for sale include the property and assets, and any liabilities required to be assumed in connection with the purchase of the business of NPPH, (the "Assets").

The sale of the Assets is on an "as is, where is" basis and without surviving representations and warranties of any kind to the purchaser. Subject to order of the Court, all rights, title and interests of NPPH in and to the Assets will be sold free and clear of all claims. In addition, a sale will be subject to court approval.

The deadline for submission of a non-binding letter of intent ("LOI") is 5:00 pm EST on September 28, 2011. Information which must be included in the LOI and information on the process for submission can be found in Schedule "A" of the Sales Process Order which can be found on the Monitor's website at http://www.ey.com/ca/npph.

Continued efficiency enhancements and growth top agenda

SCA hosted the Capital Markets Day in Stockholm on the 19th September. The strategy of recent years of focusing on costs, cash flow, capital efficiency and innovation remains firmly in place. Increased growth was added to the Group’s strategic agenda in 2010.

“SCA has implemented key efficiency-enhancement measures and boosted the pace of its new product launches. We have managed to grow both in mature and emerging markets. Our global TENA and Tork brands, which each generate more than EUR 1 billion in annual sales, have strengthened their market shares. To capitalise on the growth opportunities in the hygiene operation, we have conducted acquisitions and investments in a number of growth markets, including Brazil, Russia, Turkey, Mexico and Argentina,” said Jan Johansson.

“SCA has implemented key efficiency-enhancement measures and boosted the pace of its new product launches. We have managed to grow both in mature and emerging markets. Our global TENA and Tork brands, which each generate more than EUR 1 billion in annual sales, have strengthened their market shares. To capitalise on the growth opportunities in the hygiene operation, we have conducted acquisitions and investments in a number of growth markets, including Brazil, Russia, Turkey, Mexico and Argentina,” said Jan Johansson.

Jan Johansson pointed out that the completed action programmes have reduced the cost base and made SCA a stronger company than it previously was. Focusing on cash flow has led to lower net debt and improved the debt payment capacity, giving SCA better means to grow.

SCA will grow by reinforcing existing and establishing new market-leading positions. The aim is to reduce the number of local brands and increase the number of global brands.

“SCA is currently the world’s third largest hygiene company and hygiene products now account for 60% of the Group’s sales. The aim is to continue to grow by capitalising on the growth opportunities created by the global population increase, improved prosperity, an aging population and greater market penetration. We can also see a rising consumer interest in convenience and sustainability,” said Jan Johansson.

In the short term, it is difficult to assess the impact of the global economic situation. Today, no changes can be seen among our customers. Demand is strong in all business areas.

SCA’s Group-wide financial target of a return on capital employed of 13% over the course of an economic cycle remains in place.

Attached documents

- CMD on efficiency enhancements and growth (PDF, 18 kB)

- Read SCA capital market day 2011 agenda (pdf)

- Watch SCA capital market day 2011 webcast (flash) (Flash)

- Watch SCA capital market day 2011 webcast (wm) (Flash)

- Download SCA capital market day 2011 press images (flickr) (Photos)

Metso launches new OptiConcept M paper and board making line

Metso has launched a new, modular paper and board making line, called OptiConcept M. A member of the well-proven OptiConcept production line family, the new OptiConcept M optimizes machine investment in line with each mill’s capacity needs. OptiConcept M paper and board making lines are specifically designed for mills in growing markets to ensure optimized productivity at minimal operating costs.

High productivity at low operating costs

Savings in operating costs are achieved through precise dimensioning of processes, proven technological solutions, optimal running parameters, effective maintenance operations and fully integrated automation solutions. These OptiConcept M features result in minimized cost per ton produced and shorter investment payback periods.

The proven technology utilized in OptiConcept M and the integrated processes enable high-quality production with lower-quality raw materials and lighter basis weights, yet with equal strength properties and high raw material efficiency.

The new OptiConcept M paper and board making line stands for economy, safety and usability.

Safety, usability and optimized environmental performance

OptiConcept M has been designed both visually and physically with the requirements of its users in mind. For example, the design of the machinery allows for easy and safe changing of rolls and wear parts, thus reducing the total duration and cost of maintenance shutdowns.

Optimized processes, innovations, smart controls and accurate dimensioning decrease the use of steam, gas, electricity, water, chemicals and other raw materials, and reduce emission levels. The new OptiConcept M production line meets and exceeds environmental regulations.

Metso to supply coated board line to International Paper & Sun Cartonboard in China

Metso will supply a coated board production line to International Paper & Sun Cartonboard Co., Ltd in China. The value of the order will not be disclosed. A typical value of this kind of a production line is EUR 90–120 million, depending on the scope of the delivery and the production output.

Metso’s delivery will include a complete coated board machine from headbox to winders, including stock preparation and approach flow systems, hoods with machine ventilation and coating color preparation systems. Additionally, the full-scope automation delivery will include process, machine and quality controls, web break monitoring and web inspection as well condition monitoring. The main part of the order is included in Paper and Fiber Technology’s third quarter 2011 orders received and the automation delivery in Energy and Environmental Technology’s third quarter 2011 orders received.

International Paper & Sun Cartonboard Co., Ltd. is a joint venture co-established by International Paper and Sun Paper Group. The joint venture combines International Paper’s management and technology experience with Sun Paper Group’s local resources and in-depth understanding of local market. The combined capacity of its three machines is 850,000 t/y and the net sales in 2010 were about EUR 530 million (USD 700 million).