Displaying items by tag: recard

Recard delivers Meghna Pulp & Paper Mills its second turnkey plant

In June, Meghna Pulp & Paper Mills Ltd and Recard S.p.A. signed a contract for the delivery of a brand new tissue and MG paper production plant.

For the second time, this important client from Bangladesh chose Recard for the delivery of a plant.

The new turnkey plant includes three preparation lines for pulp where also waste paper can be used as raw material.

The paper machine with fourdrinier formation section is designed to reach a max operating speed of 1000 mpm and a production rate of 70 tpd. The plant features all the auxiliary equipment, from the vacuum system and recovery boiler to the water distribution system and full DCS and electrical system installation.

A special rewinder – suitable for both crepe papers and smooth papers like the MG – completes the plant.

Installation and start-up are scheduled for September 2022.

Recard will be in charge of all plant engineering, project management, installation supervision, start-up support, training, and post-start-up babysitting.

Meghna Pulp & Paper Mills Limited is a unit of Meghna Group of Industries, one of the largest conglomerates in Bangladesh, with over 35000 employees and a turnover of 2.5 Billion dollars.

The Greek company MAXI S.A. has chosen Recard S.p.A. to supply a complete new tissue production plant.

Earlier this year Recard S.p.A. signed a contract with the Greek company MAXI S.A. for the supply of a second complete turnkey plant for the production of Tissue Paper. Installation and start-up are scheduled for 2021. For MAXI this will be PM2 but for the owners of MAXI this is the third plant ordered from Recard (the first was Papyros PM1, installed in 2006), as they were the founders and previously main shareholders of Papyros Paper Mill, nowaday belonging to an international Group.

With regards to this project the Chairman of the Board and CEO Mr. William Papadopoulos said: “Following the recent completion of a new investment in Tissue Roll Converting with the installation of a new Perini line for consumer products, MAXI has ordered a complete new Tissue Plant from Recard S.p.A, the supplier who already delivered two successful turnkey plants in Katerini in 2006 and 2010 and that we are willing to entrust again with this milestone project.”

The signing of the contract. From left: Spyros Deliadis - Recard Area Agent; William Papadopoulos - Chairman of the Board and CEO MAXI SA; Silvio Renieri - Shareholder of Recard S.P.A.

The signing of the contract. From left: Spyros Deliadis - Recard Area Agent; William Papadopoulos - Chairman of the Board and CEO MAXI SA; Silvio Renieri - Shareholder of Recard S.P.A.

The new production line will be installed at the Katerini factory, where MAXI PM1 built by Recard has already been in production for some years

The new turnkey plant includes a Crescent Former Tissue Machine which will produce 115 tonnes/day and reach a speed of 1,850 metres/min. With this new production plant, the Greek company will increase its total production from the current 28,000 tonnes per year to approximately 68,000 tonnes.

The second Recard Tissue plant actually operating at MAXI company.

The second Recard Tissue plant actually operating at MAXI company.

The turnkey plant includes 3 stock preparation lines for long, short fibres and broke/rejects from the converting area.

The delivery scope also covers all machine auxiliaries, including the latest generation of recovery boiler and a top performance 4-ply hydraulic Rewinder.

In terms of services Recard will be responsible for all plant engineering, project management, goods transportation till mill site, full mechanical and electrical installation, plant commissioning, machine start up and post start up baby sitting.

About MAXI S.A.

1988 marked the company’s foundation as a commercial business for the sale of sanitary household products under the name MAXI S.A.

Three years later, in 1991, the small scale production of Toilet Paper, Kitchen Towel and Napkins began with a work force of eight employees in a factory located at the 1st kilometre of the old Katerini – Thessaloniki motorway, where it remains until today.

Today, MAXI S.A. is a leading force in Paper production and converting, running several high speed lines and producing a great variety of Tissue products.

With customer satisfaction as a priority, the company continues to develop a wide variety of prime quality products, investing in a highly trained workforce and state-of-the-art machinery.

Following the recent completion of a new investment in Tissue Roll Converting with the installation of a new Perini line for consumer products, MAXI have placed the order for a complete second Tissue Plant from Recard S.p.A, the supplier who also delivered the first successful turnkey plant in Katerini in 2010 and who they choose to entrust again with milestone project.

About Recard S.p.A.

Founded in 1962 Recard Spa has attained industrial dimensions all the while maintaining its philosophy of a “craft laboratory”, a working philosophy that guarantees top production efficiency and allows placing the customer always at the centre of attention.

The watchword at Recard SpA is “customization”, for this reason the Italian company is specialized in designing, manufacturing, shipping and installing of complete Tissue plants from stock preparation to paper machine, slitting rewinder and finished roll handling, including every process system required inside the production building.

Recard, a new successful startup in Sweden for Klippans Bruk AB

Recard was successfully started-up the new plant PM11 for Klippans Bruk in Sweden the last 19th august 2019. This new machine will add an annual capacity of 30.000 tonnes/year of coloured and white high quality tissue to the market.

The Recard’s supply, based in a turn key project, includes a Tissue Machine Crescent Former with a maximum operating speed of 1.700 mpm, trim at reel by 3.200 mm and with a gross production capacity of 110 tpd. Auxiliaries systems serving the machine are duo system hood, steam and condensate system, vacuum system, mist removal system and dust suction system.

The scope of supply includes a stock preparation system for 100% pre-dried virgin pulp, broke line, approach flow system, fiber recovery system and water distribution. The supply for Klippan Mill comprises also a high performing slitting rewinder with 3 unwind stands.

The Recard team and the first Jumbo reel during the start up at Klippan Bruck

The Recard team and the first Jumbo reel during the start up at Klippan Bruck

To complete the Turn Key also the plant electrification have been supplied including mainly MCC, Drives, AC motors and power and signal cables and DCS and QCS are also included in the scope.

Turn Key Recard’s Services include full detailed engineering, mechanical erection, supervisions, start up assistance and personnel training.

“This is the 138th start-up for us, - declared Recard's Managing Director, Ing. Riccardo Campo - but the excitement and satisfaction for women and men of Recard seeing the first Jumbo reel made by our tissue machine is always unique. The plant was built with a turnkey contract signed with Klippan Bruk, an historic paper mill that blends well with the tradition of Recard to build unique machinery as each component is designed and built with artisan care to achieve the performance required by the customer”.

With Klippan’s PM11, continues the series of Recard successful start-up’s in which the first reel is perfect and ready to the market.

Recard guarantees high performances, user friendliness and energy saving. The accuracy of the project, the manufacturing quality and the care give to the installation, ensure the respect of all customer’s targets.

Klippans Bruk AB History

Klippans Bruk AB has a long tradition of papermaking. It began in 1573 when renowned astronomer Tycho Brahe´s uncle started producing paper near the monastery at Herrevadskloster. In 1832 the country’s first paper machine was installed at Klippan Mill.

Through the years the paper products have varied following the markets requests.

From 1962 the production of tissue for napkins started at Klippan Mill and with more than 50 years’ experience of producing it Klippans Bruk AB is today one of the world´s leading producers of deep-coloured tissue.

Recard, a new successful startup in Sweden for Klippans Bruk AB

Recard announces the successful start up of PM11, the new plant of Klippan Bruk in Sweden that took place on August 19, 2019.

The new PM increases the annual capacity by 30.000 tonnes of coloured and white high quality tissue.

Recard supplied the client with a Turn Key Project including a Tissue Machine Crescent Former with a maximum operating speed of 1.700 mpm; trim at reel by 3.200 mm and with a gross production capacity of 110 tpd. Auxiliaries systems serving the machine are duo-system hood, steam and condensate system, vacuum system, mist removal system and dust suction system.

The Recard team and the first Jumbo reel during the start up at Klippan Bruck

The Recard team and the first Jumbo reel during the start up at Klippan Bruck

The scope of supply includes a stock preparation system for 100% pre-dried virgin pulp, broke line, approach flow system, fiber recovery system and water distribution. The supply for Klippan Mill comprises also a high performing slitting rewinder with 3 unwind stands.

To complete the Turn Key also the plant electrification have been supplied including mainly MCC, Drives, AC motors and power and signal cables and DCS and QCS are also included in the scope.

Turn Key Recard’s Services include full detailed engineering, mechanical erection, supervisions, start up assistance and personnel training.

“This is the 138th start-up for us, - declared Recard's Managing Director, Ing. Riccardo Campo - but the excitement and satisfaction for women and men of Recard seeing the first Jumbo reel made by our tissue machine is always unique. The plant was built with a turnkey contract signed with Klippan Bruk, an historic paper mill that blends well with the tradition of Recard to build unique machinery as each component is designed and built with artisan care to achieve the performance required by the customer”.

With Klippan’s PM11, continues the series of Recard successful start-up’s in which the first reel is perfect and ready to the market.

Recard guarantees high performances, user friendliness and energy saving. The accuracy of the project, the manufacturing quality and the care give to the installation, ensure the respect of all customer’s targets.

Klippans Bruk AB History

Klippans Bruk AB has a long tradition of papermaking. It began in 1573 when renowned astronomer Tycho Brahe´s uncle started producing paper near the monastery at Herrevadskloster. In 1832 the country’s first paper machine was installed at Klippan Mill.

Through the years the paper products have varied following the markets requests.

From 1962 the production of tissue for napkins started at Klippan Mill and with more than 50 years’ experience of producing it Klippans Bruk AB is today one of the world´s leading producers of deep-coloured tissue.

New succesfull startup of Recard turnkey plant for Drenik ND Serbia

PM3 was successfully started-up on 19 September 2018.

This turn-key plant is the 3rd one supplied by Recard to Drenik ND after PM1 (2004) and PM2 (2008). An identical plant will be supplied to Drenik Hungary in 2019.

The Recard’s supply included a Crescent Former machine in a 1850-mpm speed and 2850-mm format with a production capacity of 120 tpd, will be fed by two stock preparation lines for virgin fibers and equipped with two rewinders (one pneumatic with one backstand and one hydraulic rewinder with 4 backstands), complete electrical plant, DAF system, integrated recovery boiler, mist and dust extraction systems and hall ventilation.

Belgrade, 19 September 2018. Startup PM3 of Drenik DN. The Recard’s Team with the first master roll.

Belgrade, 19 September 2018. Startup PM3 of Drenik DN. The Recard’s Team with the first master roll.

“Drenik Sebia PM3 synthetizes all Recard’s features: Hi performances, user friendliness and energy saving.” says Mauro Michelini – General Manager of Recard “With this tissue plant continues the series of Recard successful start-up in which the first reel is perfect and sellable. The accuracy of our projects, the manufacturing quality and the care we give to the installation, ensure the respect of all customer’s targets.”

DRENIK is one of the largest manufacturer of tissue paper in Southeast Europe and consists of a group of industrial and commercial companies in the field of tissue products. Actually the group Drenik DN has more than 700 employees and operates in the two factories: DRENIK Belgrade and DRENIK Hungary.

Besides the Drenik's production and development of the brand's PERFEX and Boni the factory also produce the private label products for renowned wholesalers, trading companies and retail chains in Southeast Europe.

Speed record for a Recard machine: 2150 m/min

Speed record attained: 2150 m/min! Holder of this record is the machine owned by M.C. Tissue produced by Recard for Cartiere Carrara for the Tassignano (Lucca) plant. A figure very close to the world record.

Already just 3 months after start-up, M.C. Tissue’s PM5 – the seventh machine supplied by Recard to the Lucca-based group and started up in the summer of 2017 – had shown great performance, running at 2130 m/min for 24 hours. The 2150 m/min were reached in February 2018 and there is ample margin to be able to exceed not just this personal record, but the world record, too.

Klippans Bruk AB chooses Recard for its facilities in Sweden

Recard will supply the new 30,000-tpy tissue machine to the historic company Klippans Bruk AB for its Klippan facilities in Sweden. Start-up of the complete turnkey plant, in a 3200-mm format and a speed of 1700 m/min, is scheduled for summer 2019.

The Klippan mill is specialized in the production of paper for colored table napkins that it supplies to customers worldwide. With the addition of the new machine by Recard – that will flank another machine already in operation – production will increase fourfold. A 15-million euro investment that will allow boosting the mill’s staff by 20-25 new employees and to strengthen the position of the Swedish company in the market.

For Recard, this is a great event, since it is the first tissue machine order signed for Sweden.

About Klippans Bruk AB

Klippan nurtures a long tradition of papermaking. It began in 1573 when renowned astronomer Tycho Brahe´s cousin started producing paper near the monastery at Herrevadskloster. In that time this area of Sweden belonged to Denmark and the mill was in fact Denmark’s very first paper mill. In 1658 it became Swedish through the peace at Roskilde.

In the 1700s the mill moved to new premises by the river Rönne, where it remains still today. In 1832 the country’s first paper machine was installed at Klippan Mill. It was soon followed by several more. Through the years the paper products have varied following the markets requests. Newspaper quality, paper for stamps, copy paper etc have all been produced here.

In 1962 the production of tissue for napkins started at Klippan Mill and with more than 50 years’ experience of producing it Klippans Bruk AB is today one of the world´s leading producers of deep-coloured tissue.

Drenik renews its trust in Recard for the fourth time

Drenik ND d.o.o., a company headquartered in Belgrade and very strong not only on the Serbian market but also in the Balkan and Eastern European territories, renews its trust in Recard for the fourth time with the order of PM3: a complete turnkey plant with a production capacity of 120 tpd.

Drenik ND d.o.o., a company headquartered in Belgrade and very strong not only on the Serbian market but also in the Balkan and Eastern European territories, renews its trust in Recard for the fourth time with the order of PM3: a complete turnkey plant with a production capacity of 120 tpd.

The Crescent Former, in a 1850-mpm speed, 2850-mm format, will be fed by two stock preparation lines for virgin fibers and equipped with a hydraulic rewinder with 4 backstands, complete electrical plant, all ancillary equipment, DAF system, mist and dust extraction systems and hall and roof ventilation.

Recard thus confirms itself sole provider of PMs for the Serbian company. In 2004 it had installed PM1 for Drenik, later modified by Recard at the company’s request to increase its speed and production capacity and started up in February 2017, while in 2007 it manufactured PM2 for the company.

Agreement between Recard and Grand Bay Paper and Care Products Group

Agreement between Recard and Grand Bay Paper and Care Products Group for the installation of a new paper mill in Guatemala

To be able to meet the growing demand in the different markets of the Latin-American area and pursue a regional growth plan, the Grand Bay Paper and Care Products Group has stipulated an agreement regarding the installation of a new paper mill for the production of soft papers (toilet rolls, table napkins, facial tissue, kitchen towels) with the Italian company Recard.

This new investment will be set up in Guatemala, in Central America, through the branch company Papelera Internacional S.A., and will constitute the basis for the expansion of the activities in the region of Central America and the Caribbean.

The new machine, whose start-up is scheduled for mid-October 2018, boasts a drying capacity of 120 t/d and a maximum speed of 2000 m/min. The machine will run on 100% virgin fiber or 100% secondary fiber. Recard will supply a turnkey service that includes 3 pulp preparation lines for long fibers, short fibers and broke, approach flow system, related ancillary equipment and complete mechanical and electrical assembly.

The new machine, whose start-up is scheduled for mid-October 2018, boasts a drying capacity of 120 t/d and a maximum speed of 2000 m/min. The machine will run on 100% virgin fiber or 100% secondary fiber. Recard will supply a turnkey service that includes 3 pulp preparation lines for long fibers, short fibers and broke, approach flow system, related ancillary equipment and complete mechanical and electrical assembly.

“This new order by Painsa”, commented Mauro Michelini, General Manager, “is a great reason for pride for us because it allows us to work once again with people with whom we have established a great rapport, and this is foundational in order to pursue satisfactory technical results”.

The Grand Bay group

The Grand Bay group is a Latin-American consortium with over 65 years’ experience in the area. Present in the markets of Central America, the Caribbean and the Andean region, it carries out its activities directly from the facilities located in Venezuela, Colombia, Trinidad, Panama and Guatemala, and is specialized in the production and sale of soft papers (toilet rolls, table napkins, facial tissue, kitchen towels), directly serving over 20 countries in Latin-America.

With this new investment, the Grand Bay Group intends improving the service standards available to customers and offering high quality products that meet the increasingly pressing demands of consumers in the region, maintaining its leading position from a technological point of view and with a focus on responsible, efficient and ecosustainable management of the resources.

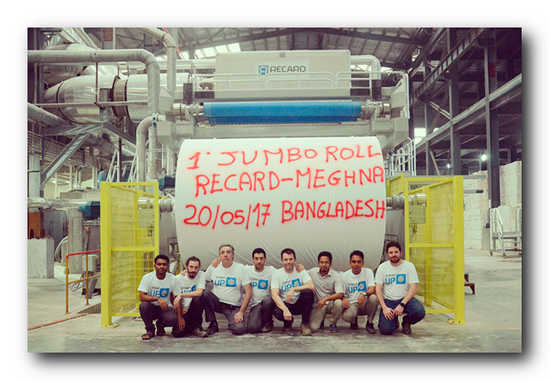

Two new startups in Bangladesh and Mexico for Recard

From the end of May to the beginning of June 2017, Recard was involved in two new startups outside national boundaries.

From the end of May to the beginning of June 2017, Recard was involved in two new startups outside national boundaries.

As scheduled, the Easy Crescent plant for Meghna Group of Industries was started up in Bangladesh on May 20th. PM1 (sheet width 2850 mm, production capacity 50 ton/ day, speed 1200 m/min) produced its first reel of high quality paper immediately upon startup, which took place smoothly and with no interruptions. Recard thus strengthens its presence in the country after the plant supplied to another customer, Bashundhara Paper Mills, which was started up in 2010.

Another welcome return was Mexico for the startup of the machine supplied to Convertipap: the turnkey plant (sheet width 2850 mm, production capacity 90 ton/day, speed 1500 m/min) was successfully started up on June 2nd.

The machine began producing 24/7 immediately and after a week attained maximum guaranteed speed. Since 1992, Recard has installed four machines in Mexico and a total of eighteen throughout Latin America, underscoring once again that this is an important reference market for the Lucca company.