Kastamonu Entegre Ağaç Sanayi ve Ticaret A.Ş. (KEAS) started up its new fiber preparation line for MDF (Medium Density Fiberboard) production at its mill in Balikesir, Türkiye. KEAS is the largest wood panel producer in Türkiye and now successfully operates three production lines supplied by ANDRITZ.

Hasan Akpinar, Global Investment and Projects Director of KEAS, says: “We have relied on ANDRITZ MDF technology and service for many years and are very satisfied with the results. Our new line from ANDRITZ is equipped with a pressurized refining system for low electricity and thermal energy consumption. This perfectly contributes to our sustainability strategy.”

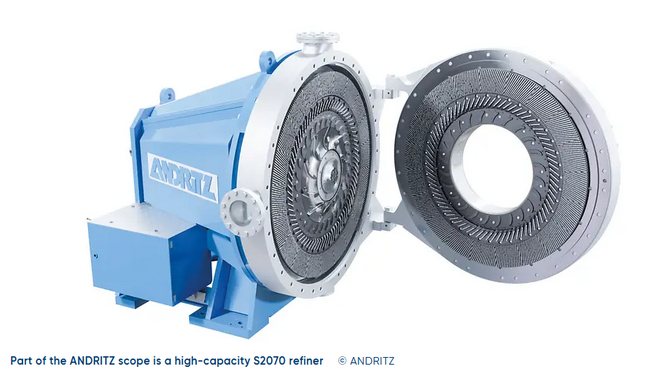

The new line has a capacity of 60 t/h and processes pine, beech and oak wood. Its centerpiece is the pressurized refining system, which includes a 24” plug screw feeder and a high-capacity S2070M refiner. The high dewatering efficiency of the plug screw feeder ahead of the high-pressure zone ensures low thermal and electrical energy consumption, which is one of the major benefits of the ANDRITZ pressurized refining system.

ANDRITZ’s scope also included supply of a gravity-fed HQ-Chipper, a chip bin discharger and a digester, as well as supervision of mechanical installation and start-up.

KEAS, part of Hayat Holding, was established in 1969 and specializes in the production of wood-based panels for the furniture, interior decoration, and construction industries. It has more than six locations in Türkiye and several manufacturing plants worldwide.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,700 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.