Displaying items by tag: AFT

AFT delivering new approach flow system to Smurfit Kappa Mexico

AFT is set to deliver a complete approach flow system to the Smurfit Kappa board mill in Cerro Gordo, Mexico. Representatives from the mill visited AFT’s Varkaus Service Center to tour the facility and inspect their equipment – including a new MaxFlow™ HB 2200 headbox screen and POMp™ degassers. “Everything we saw was great. We really liked the quality of manufacture, welding, and design”, remarked Alberto Monterrubio, Process Engineer (Projects & Engineering) for Smurfit Kappa Mexico.

In addition to the new approach flow system, AFT is also supplying system engineering, conceptual 3D layout and piping, and on-site services. Designed with ease of maintenance, process optimization, and reduced power consumption in mind, all AFT products are supported by a global team of process and service experts.

In addition to the new approach flow system, AFT is also supplying system engineering, conceptual 3D layout and piping, and on-site services. Designed with ease of maintenance, process optimization, and reduced power consumption in mind, all AFT products are supported by a global team of process and service experts.

AFT is pleased to have been selected for this project and looks forward to bringing the new equipment online safely and efficiently for Smurfit Kappa, a leading global provider of sustainable packaging solutions.

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT supplying POM approach system to Papeles y Conversiones de Mexico containerboard mill

AFT will be supplying a new POM thin stock approach system to the Papeles y Conversiones de Mexico containerboard mill in Monterrey, Nuevo Leon, Mexico. PCM is a leading Mexican company in the manufacture, conversion and marketing of high quality printing and packaging products.

The project will consist of two POMp degassers, two POM Dynamix static mixers, two POMlock seal tanks, two POM headers, and two POM head tanks for PCM’s two-ply PM2, along with accompanying spare parts and system engineering.

The POMp degasser provides a compact and efficient solution at the beginning of the white water handling process, requiring fewer and smaller silos and tanks downstream. By removing air before the paper machine headbox, the short circulation system will promote better machine runnability with fewer sheet breaks, faster start-ups and grade changes, reduced chemical and water use, and greater system cleanliness.

“We appreciate our continued partnership with PCM and look forward to a successful start-up later this year”, Sven Girschner, Regional Manager – Americas, Process & Equipment Solutions.

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT supplying POMix stock processors to new Pratt Industries board machine

AFT is supplying two POMix stock processors to Pratt Industries for the new PM18 board machine in Henderson, Kentucky. The POMix units will deliver uniform top- and bottom-ply stock distribution to the machine headbox. The mill will use 100% recycled paper to produce corrugating medium and linerboard grades. PM18 is scheduled to start-up in fall of 2023.

AFT’s POMix stock processor is a compact, patented mixing solution that replaces conventional large mixing chests and machine chests. Its small volume results in a highly responsive and stable operation – an efficient "just-in-time" approach to feeding the paper machine that minimizes grade change time and off-grade paper.

“AFT is excited to be part of this project for one of the world’s most advanced, environmentally friendly recycled paper mills”, says Sven Girschner. “We are looking forward to a successful start-up in 2023.”

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

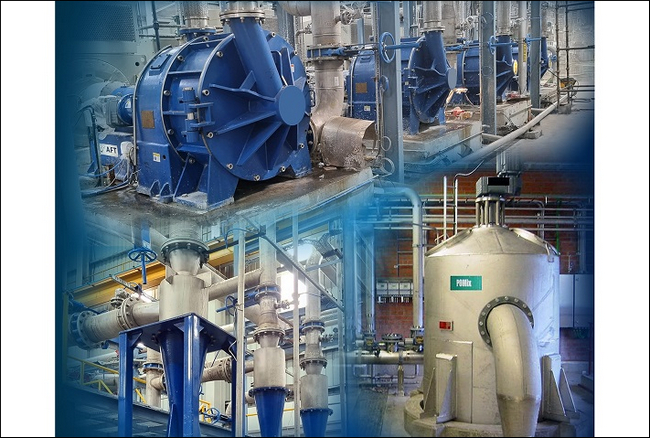

AFT ANNOUNCES SALE OF POM SYSTEM FOR KIVANC GREENFIELD PROJECT

Kıvanç Tekstil may be new to packaging, but their broad experience applying innovative and environmental approaches in their textile and energy businesses is also a focus in their containerboard venture. This greenfield 1,000 tpd recycled containerboard and special packing grade board machine will utilize a wet end system with AFT’s most advanced POM® technology. This technology choice was essential to enable faster grade shifts with less waste for the multiple grades planned for the new paper machine.

The system includes a complete screen room with MaxFlow screens, a POMix stock processor to feed the paper machine, POMp degassing, and POMLock drop legs. The mill’s sustainable focus will benefit from this system, which is more compact, more flexible, and results in a cleaner operation with less waste and down time.

Compared to traditional systems, the POM paper machine wet end and headbox screening system has a smaller footprint, and the option to have no basement below the paper machine - thus simplifying construction and environmental permits. All this leads to enhanced paper making performance with high quality and greater production efficiency.

AFT Pom degasser

AFT Pom degasser

About Kivanç

Kıvanç Tekstil operates as one of the main woven fabric suppliers of the European and American apparel market, including famous local and global fashion brands, by producing an annual capacity of 18 million meters on a wide mix of fabric blends weighing between 100 g/m2 to 500 g/m2. Kıvanç Tekstil is an integrated woven fabric producer based in Adana, South Central Turkey. The company was founded by Hacı Mustafa KIVANÇ in early 1950 and since then has grown to become a vertical fabric producer covering all crucial woven textile production steps from spinning to finishing.

Kıvanç Tekstil targets and currently supplies high quality and innovative fabrics for business and classic apparel both for menswear and womenswear. The company’s innovative approach and know-how in the industry leads to long-term collaborations with fashion retail brands by producing best quality fabrics with a professional work ethics.

About AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end-product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT refining with IoT integration at BillerudKorsäs Skärblacka

AFT recently had another successful refiner start-up with the BillerudKorsnäs group, world leader in packaging grades. Our new pulp mill reject refiner started-up in December at the 460 000 t/d Skärblacka mill in Sweden, designed to defiberize knots, shives and fiber bundles coming from pulp screening. Combined with Finebar® technology, AFT refiners deliver optimized performance and energy savings which will help support BillerudKorsnäs’ sustainability goals through resource-efficient production.

AFT refining at BK Skarblacka

AFT refining at BK Skarblacka

The Skärblacka installation also includes an AFTLinx integration unit for monitoring refiner performance remotely. Our optional IoT gateway collects equipment-specific operating data to address customer needs for remote product support and service. The data access allows AFT specialists to assist with start-ups, conduct comprehensive real-time machine diagnostics, and provide advice for optimized refiner operation.

About AFT:

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application, and the end-product being produced in order to optimize their return on investment.

For more on AFT refining products and services, contact us at http://ow.ly/6u4m50HtSAb

AFT SUPPLYING POM SYSTEM TO SAPPI BOARD MILL IN SOUTH AFRICA

Sappi has selected AFT to add new POM® Technology to their approach flow system at Ngodwana’s linerboard machine. The system will work with a kraft/recycle furnish mix on the mill’s nearly 700 tpd containerboard system.

The supply includes a headbox screen for the current approach system, POMp degassing and a POM cascade cleaning system in the machine’s wet-end loop for this multi-ply machine. Basic engineering and mill site services are included as part of the AFT offerings. The new system will work on all three-paper layers.

Sappi Ngodwana Mill

Sappi Ngodwana Mill

Compared to traditional systems, the POM paper machine wet end will deliver superior cleanliness in a compact degassing and cleaning package. This will enhance environmental performance with controlled air removal before the paper machine headbox – to help ensure proper operation and paper quality.

“AFT is proud to have been selected for this project and we are looking forward to a successful start-up in 2022”, local sales engineer John Pearson.

ABOUT AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the final product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT stock prep and approach flow equipment for JK Paper new multi-layer board machine

JK Paper Limited, one of the largest pulp and paper producers in India, selected AFT to supply a POM® approach flow and stock preparation system for their latest packaging board expansion project. PM5 is a 170 000 tpa multi-layer board machine at CPM, Fort Songadh in Gujarat, India. The new machine successfully ran its first paper reel in early September to begin commercial production this quarter.

The wet end system includes a full POM approach flow for multi-layer machine with stock processors and degasser arrangements. Basic engineering and mill site services were included as part of the AFT offerings.

Compared to traditional systems, the POM paper machine wet end with headbox screening delivers superior stock cleanliness in a compact and efficient package. Without the need for traditional storage tanks, POM runs smoothly with lower water and energy usage for an enhanced environmental performance.

“The installation allows for fast grade changes in a cleaner, short circulation system - with less air and biological build-up to yield fewer sheet defects and breaks, which is best for our multi-ply operation”, says, Mr. S K Jain, Head – Board Projects.

In addition, AFT supplied a complete stock preparation system. The refiner design increases production capacity for a single unit while offering easy access for maintenance and filling changes. Low intensity refining is achieved with Finebar® conical filling technology for optimum fiber development with low energy use.

Sourav Das, AFT Regional Sales & Marketing Manager - Asia Pacific, says “AFT is excited to be part of this JK Paper project. We are committed to delivering innovative technology that helps our customers produce high quality products in a sustainable way”.

About AFT:

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT ANNOUNCES START-UP OF NEW POM APPROACH FLOW SYSTEM AT STORA ENSO OULU

AFT is pleased to announce the successful start-up of a new POM® approach flow system at Stora Enso Oulu on the recently converted and commissioned board machine 7. The machine is now producing a high quality kraftliner called AvantForte™ by Stora Enso in both brown and white top. The kraftliner product has three layers of fiber to feature the strongest in the Stora Enso kraftliner portfolio, an essential element for e-commerce and food packaging.

The new wet end from AFT includes a complete POM approach flow system for all 3 layers including headbox screening, POMix stock processors to feed the paper machine, POMp degassers for air removal, a POMlock drop leg and a cleaning system. Basic engineering and mill site services were included as part of AFT’s offerings.

Compared to traditional systems with silos and tanks, the compact POM system runs efficiently with less water, energy and few web breaks. This is helping to enhance the environmental performance of board machine 7, while providing fast grade changes, process stability and sheet cleanliness.

Despite challenges from the pandemic, installation and start-up of the POM system were completed on time, helping the overall machine conversion and environmental projects to proceed ahead of plan.

“AFT is proud to have been selected for this project following similar successful installations at other Stora Enso mills”, says Timo Koivisto, Vice President - Process and Equipment Solutions. “We strive to deliver innovative technologies that help our customers produce high quality products in a sustainable way.”

ABOUT AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

AFT ANNOUNCES LATEST CONTAINERBOARD POM SYSTEM

AFT is pleased to announce three new advanced POM systems to be delivered for Klabin Puma II Project PM28, a multi-ply containerboard application in Brazil, South America. The POM system will help to provide superior cleanliness and fast response to grade changes on a new flex-board machine with multiple and frequent changes planned.

The new wet end includes a complete POM approach flow system for three plies with a capacity of 1,700 TPD, including POMix stock processors, POMp degassers, POMLock drop legs, basic engineering and mill site services.

The new wet end includes a complete POM approach flow system for three plies with a capacity of 1,700 TPD, including POMix stock processors, POMp degassers, POMLock drop legs, basic engineering and mill site services.

Compared to traditional systems with silos and tanks, the compact POM system runs efficiently with much lower water volume, less energy in a compact space. This enhances environmental performance by using less water and providing fast grade changes, process stability and sheet cleanliness.

“AFT is proud to have been selected to participate in this project” says Orlando Matteoni, Director of AFT do Brazil. “We are committed to delivering innovative technologies for the South American market that help our mills in reaching their sustainability goals.”

ABOUT AFT

AFT is a global supplier specialized in stock preparation, screening, refining and paper machine approach flow systems. With over 100 years of experience, we offer expert solutions that help mills produce more while using less energy, water and chemicals. Our solutions are tailored to the customer’s furnish, their application and the end-product being produced in order to optimize their return on investment. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

New AFT wet end system part of Stora Enso Oulu conversion to packaging board

As part of a major Euro 350 million conversion project, Stora Enso is converting its paper machine 7 at the Oulu mill into a high quality virgin fiber kraftliner machine. Production on the rebuilt machine is estimated to start late 2020.

AFT’s delivery follows successful similar projects at several other Stora Enso mills.

AFT’s delivery follows successful similar projects at several other Stora Enso mills.

The delivered system will include a full POM approach flow system for all 3 layers complete with POMp730 degasser, POMlock drop leg header and POMix stock mixer units, as well as screens and cleaners.

Compared to traditional systems, the POM system runs smoothly with lower water and energy usage. This will enhance the environmental performance along with providing faster grade changes, less entrained air and fewer sheet defects – all leading to greater production efficiency and improved product quality.

About AFT:

AFT is a global supplier specializing in stock preparation, screening, refining and paper machine approach flow systems. With over 110 years of experience in manufacturing and supplying tailored solutions, we respond to the needs of our customers and help improve performance with trademarked advancements such as Finebar ultra low intensity refining, Powerwave energy efficient screening, POM wet end systems, and more. For more information, please contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..