Displaying items by tag: ANDRITZ Oy

ANDRITZ plant will prepare date palm waste for fiberboard production

International technology group ANDRITZ will supply a complete fiber preparation line for a greenfield plant in the Toshka area in the south of Egypt. The pioneering and eco-friendly plant will produce high-density and medium-density fiberboard (HDF/MDF) from date palm fronds, a material normally considered farm waste.

ANDRITZ will execute this order in cooperation with the engineering, procurement and construction (EPC) specialist WESER Industrie- und Anlagentechnik GmbH and DIEFFENBACHER GmbH Maschinen- und Anlagenbau, a leading manufacturer of press systems and complete plants for the wood-based panel industry. On behalf of Egypt’s National Service Projects Organization (NSPO), the German company WESER is acting as the general contractor for this turnkey project.

Michael Frint, Director Technology Panelboard Systems at ANDRITZ says: “Alternative raw materials, in particular from waste streams, are becoming increasingly important in the panel industry. Participating in this innovative and sustainable NSPO project is an important milestone for us.”

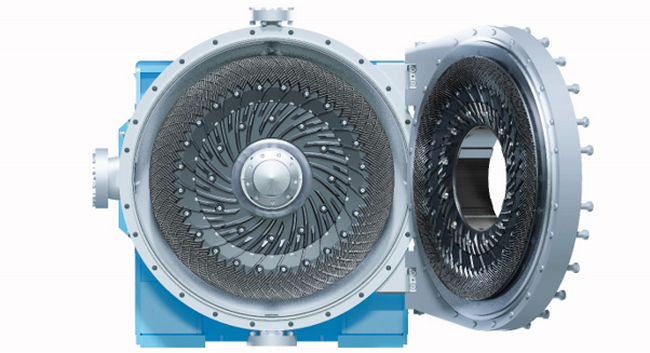

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

The ANDRITZ line, with a capacity of up to 14 bdmt/h, will process date palm fronds from a nearby 40,000-acre date farm. It includes a system to wash and condition the chips from the palm frond stems, and a pressurized refining system with a well-proven refiner to process the washed and conditioned chips into high quality fibers at very low energy consumption. The fibers will be used to produce high quality fiberboards, mainly for the flooring and furniture industries. The plant is scheduled to commence production in the autumn of 2025.

About Andritz

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply resource efficient debarking line to Smurfit Kappa in Colombia

International technology group ANDRITZ has received an order from Smurfit Kappa to deliver a new energy-efficient debarking line for its paper mill in Yumbo, Colombia. Start-up is scheduled for the fourth quarter of 2024.

- ANDRITZ sustainable technologies support Smurfit Kappa to achieve its net zero emissions goals

- ANDRITZ debarking line provides exceptional high wood-usage-rate to fuel Smurfit Kappa’s new energy supply system effectively

The order is part of Smurfit Kappa´s project to replace the fossil fuels currently used with different types of organic waste to generate cleaner energy at its paper mill in Yumbo. The installation is another step towards Smurfit Kappa’s ambitious goals of achieving net zero CO2 emissions by 2050. The organic waste, processed in the ANDRITZ debarking line, will be comprised of pine and eucalyptus bark from the company’s own forestry plantations and waste from its wood treatment plant, among other materials.

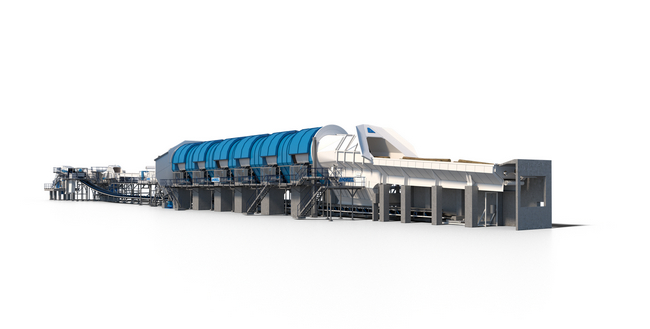

ANDRITZ rubber tire supported debarking drum provides excellent debarking results. “Photo: ANDRITZ”.

ANDRITZ rubber tire supported debarking drum provides excellent debarking results. “Photo: ANDRITZ”.

The scope of supply, on an EPS (Engineering, Procurement, Supervision) basis, includes a new debarking line with rubber tire supported debarking drum which provides excellent debarking results with very low wood losses. The capacities of the new line are 333 m3 hardwood and 370 m3 softwood solid-over-bark per hour. The scope also includes chip screening equipment and a bark handling system with ANDRITZ BioCrusher BSX.

Smurfit Kappa is one of the leading providers of paper-based packaging in the world, with operations in 23 European countries and 13 countries in the Americas.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ Oy and LUT University open new fiber research laboratory in Lahti, Finland

ANDRITZ Oy, part of international technology group ANDRITZ, and LUT University (Lappeenranta-Lahti University of Technology LUT) launched an extensive collaboration in the field of fiber technology a year ago. As a result, a new state-of-the-art research laboratory for the joint development of sustainable fiber technologies will open at the LUT campus in Lahti on November 3, 2022. The unique corporate collaboration model is a substantial step towards a new way of sharing infrastructures and intensifying research work with external partners.

The new research laboratory and LUT's academic expertise bring added value to ANDRITZ’s own research and innovation. Collaboration with LUT strongly supports ANDRITZ’s development of highly efficient, sustainable products and technologies. In addition, ANDRITZ aims to strengthen its position as a pioneer in innovative technologies whilst supporting its position as one of the most attractive employers in the Finish fiber industry.

Kari Tuominen, President and CEO of ANDRITZ Oy, says: “Locating the research laboratory in Lahti will enable close collaboration between ANDRITZ and LUT researchers. Our cooperation has always been fruitful and effortless for both parties. We’re glad that LUT managed to build the laboratory nearly on schedule despite the logistical challenges related to the global situation.”

“The brand-new laboratory enables us to study, test and analyse on biomass-based fibres and fibre products even better than before. The new facilities will meet the needs of LUT research groups, ANDRITZ and regional industry,” adds Mari Kallioinen-Mänttäri, LUT University Dean.

As a result of the collaboration, a modern research laboratory meeting the highest industry standards will be opened on the LUT campus in Lahti, Finland. Photo: Andritz

As a result of the collaboration, a modern research laboratory meeting the highest industry standards will be opened on the LUT campus in Lahti, Finland. Photo: Andritz

The aim is to strengthen the bioeconomy cluster in the Lahti area and support the start-up and growth of new businesses. Biorefinery research currently employs four professors and ten researchers on the Lahti campus. LUT aims to increase the overall number to 40 in the near future.

Mari Kallioinen-Mänttäri points out that such a large-scale investment would not have been possible without considerable financial support by the university’s partners.

“Collaboration with ANDRITZ constitutes one of the largest business commissions in LUT’s history. In addition to current joint research, we are exploring possibilities to expand our collaboration beyond fiber research. For students, it will mean more thesis and job opportunities,” says Mari Kallioinen-Mänttäri.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ OY

ANDRITZ Oy is a leading global supplier of systems, equipment and services for the pulp and paper industry including wood processing, fiber processing, chemical recovery, and stock preparation. In addition, ANDRITZ Oy offers biomass boilers and gasification plants for energy production. ANDRITZ Hydro Oy, located in Tampere, delivers systems, equipment, and services for hydraulic power generation. The number of employees of ANDRITZ companies in Finland is approximately 1 600. The Center of Excellence are Kerava, Kotka, Lahti, Lappeenranta, Savonlinna, Tampere, Vantaa, and Varkaus. The Headquarters are located in Helsinki, Finland. President and CEO is Kari Tuominen. The company is owned by ANDRITZ AG of Austria.

LUT UNIVERSITY

Clean energy, water and air are life-giving resources for which we at LUT University seek new solutions with our expertise in technology, business and social sciences. We help society and businesses in their sustainable renewal. Our international community consists of 7 500 members. Our campuses are in Lappeenranta and Lahti, Finland. We are the world’s ninth best university for climate action. lut.fi/en