Displaying items by tag: voith paper

Voith expands Papermaking 4.0 portfolio with three new apps for higher process stability and efficiency in paper production

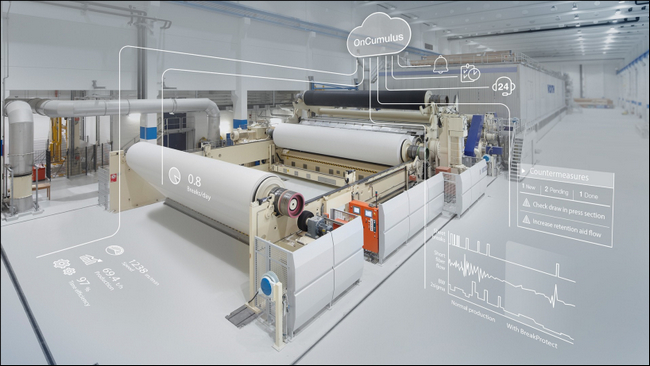

Customers worldwide rely on Voith's modular Papermaking 4.0 portfolio to individually optimize their production with the leading digital industrial applications. Based on extensive expertise, Voith is introducing OnEfficiency.BreakProtect, OnView.VirtualSensorBuilder and OnView.MassBalance, three new apps on the IIoT platform OnCumulus. The new digitalization solutions feature the highest safety standards, are quick to install and easy to use. The technologies are already successfully implemented in several plants worldwide. Due to the process optimizations and lower resource consumption, the applications often pay off in less than a year and pave the way to the digital paper mill.

- OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

- OnView.VirtualSensorBuilder: Quickly and easily calculate and visualize relevant quality parameters in real time

- OnView.MassBalance: Visualize raw material losses in stock preparation and increase yields

OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

The IIoT platform OnCumulus has already established itself as a central hub for data from multiple sources for numerous paper manufacturers. OnEfficiency.BreakProtect uses artificial intelligence to analyze the process data bundled in OnCumulus. Thereby, the innovative solution automatically detects various critical process conditions that can lead to breaks. This allows the development of specific countermeasures and the reliable prevention of tear-offs.

"I am always fascinated by the correlations that artificial intelligence can recognize," says Jürgen Käser, Director Process Applications at Voith. "Among other things, we were able to use OnEfficiency.BreakProtect to identify increased dirt and starch agglomerate loads – for which there is no measurement data at all – at the SpeedSizer pulper. In the past, these had repeatedly led to break-off series. A small mechanical rebuild, which prevents starch from entering the pulper in larger quantities, has permanently solved the previously undetected problem."

OnView.VirtualSensorBuilder: Calculate and visualize quality parameters quickly and easily using virtual sensors

Virtual sensors, also called soft sensors, have proven themselves in the process industry for many years. With the help of data models, the sensors calculate various quality parameters and thus reliably supplement laboratory tests. Until now, the use of virtual sensors required considerable time and, above all, data analysis skills. With OnView.VirtualSensorBuilder, Voith introduces a user-friendly app that allows paper manufacturers to quickly and easily create the virtual sensors themselves with just a few mouse clicks.

"With OnView.VirtualSensorBuilder, it only takes a few hours for a new soft sensor to be ready for use," says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. "Previously, this required a time-consuming and costly process of several weeks."

Once installed, operators can use OnView.VirtualSensorBuilder to continuously calculate, visualize and control relevant quality values, such as strength values, in real time. Combined with OnCumulus.Suite, the digital application identifies critical values and provides preventive warnings, allowing personnel to make immediate improvement adjustments. The solution thus increases process stability, enables compliance with desired quality standards, reduces raw material costs and minimizes waste.

OnView.MassBalance: Visualize and reduce fiber losses in stock preparation

OnView.MassBalance maps the current stock flows in an intuitive Sankey diagram and provides information on deviations that are no longer within the standard range. If a defined warning threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable action to avoid fiber losses. OnView.MassBalance thus leads to targeted process optimization in stock preparation and also enables centralized knowledge management.

With the help of OnView.DigitalEye, the accuracy of OnView.MassBalance can be increased even further. The innovation makes it possible for the first time to analyze recovered paper quality even before stock preparation with the help of artificial intelligence. The award-winning AI application OnView.DigitalEye is currently undergoing final testing as part of pilot installations at national and international customer sites and is expected to be available starting next year. Another application that will be launched in 2022 is OnView.Energy from Voith. The app visualizes and analyzes energy consumption and CO2 emissions in production. This enables significant savings potential to be identified, leading to lower energy costs, improved sustainability and competitiveness.

This release is part of the current "PAPER IS ON" campaign, in which Voith highlights the focus topics of the digital Papermaking 4.0 portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more at voith.com/PaperIsOn. For more information on the solutions from the OnCumulus, OnView and OnEfficiency family as part of Voith's Papermaking 4.0 portfolio, please visit https://voith.com/corp-en/products-services/automation-digital-solutions/onefficiency.html. In addition, read more about OnView.DigitalEye receiving the AI Champions Award: https://voith.com/corp-en/news-room/press-releases/voith-wins-ai-champions-award-2021.html.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Leading paper manufacturers rely on Voith expertise for resource-efficient rebuilds and optimization projects to boost competitiveness

With its full-line supplier approach, Voith Paper strengthens position as partner of choice for extensive rebuilds and customized optimization projects. Shifting consumer demands, tougher environmental regulations and ongoing supply chain issues with raw materials have combined to create a perfect storm in the paper industry. To remain competitive in unprecedented conditions, leading papermakers around the globe are relying on Voith to modernize their existing paper production lines, undertake comprehensive grade conversions or upgrade their current assets in the market. As a full-line supplier, Voith realizes every type of rebuild to give paper machines a second life. In the process, Voith expertise, innovative components and advanced digital tools ensure customers achieve their efficiency and productivity targets with a lower capital investment.

Extensive grade conversion in Indonesia

In September 2021, Voith kicked off the grade conversion of Mojokerto MSE-PM2 for PT Mega Surya Eratama. The extensive rebuild will transform the former newsprint paper machine, which is currently out of service, to a state-of-the-art packaging production line at the company’s Mojokerto paper mill in East Java, Indonesia.

As is the case with every rebuild, Voith is placing a special focus on high machine availability, technological efficiency, process stability and sustainability with the lowest possible energy balance for the plant. After conversion, the PM 2 will produce high-quality containerboard grades between 70 g/m² and 180 g/m², with a design speed of 1,400 m/min and 6,660 mm paper width at reel. After start-up, the XcelLine paper machine will have an annual production capacity of 450,000 tons, and, as a result, the PM 2 will be one of the most powerful paper machines of this grade in Indonesia. The Voith scope of supply includes a forming section rebuild into a DuoFormer CBh with shoe-blade technology, a new DuoCentri NipcoFlex Press and SpeedSizer AT film sizer for starch application. The order also includes a complete BlueLine stock preparation and approach flow line. The start-up after conversion is scheduled for the end of 2023.

As is the case with every rebuild, Voith is placing a special focus on high machine availability, technological efficiency, process stability and sustainability with the lowest possible energy balance for the plant. After conversion, the PM 2 will produce high-quality containerboard grades between 70 g/m² and 180 g/m², with a design speed of 1,400 m/min and 6,660 mm paper width at reel. After start-up, the XcelLine paper machine will have an annual production capacity of 450,000 tons, and, as a result, the PM 2 will be one of the most powerful paper machines of this grade in Indonesia. The Voith scope of supply includes a forming section rebuild into a DuoFormer CBh with shoe-blade technology, a new DuoCentri NipcoFlex Press and SpeedSizer AT film sizer for starch application. The order also includes a complete BlueLine stock preparation and approach flow line. The start-up after conversion is scheduled for the end of 2023.

“We were convinced by Voith’s capability as a full-line supplier to meet our highest benchmark and sustainability requirements for this strategic grade conversion,” says Eric Saputra, General Manager at PT Mega Surya Eratama. “Given their extensive experience and innovative equipment, Voith is ideally positioned to bring out the full potential of the PM 2 production line. We rely on Voith to support us in producing the highest paper quality on a machine with the best operational reliability.”

Record-breaking 30th shoe press rebuild

This year, Voith marked the 30th successful rapid shoe press rebuild in a row in China, with five more underway. The most recent was completed for the Sun Paper Group. As it took a mere seven days from shutdown to paper on reel, the project set a record for the fastest shoe press rebuild in the region, saving the customer valuable production time as a result. The centerpiece is a new NipcoFlex shoe press for the existing press section. In addition, the scope of delivery included a PLC control system for NFP, erection and start-up service as well as spare part and wear part packages. Previously, in December 2020, Voith successfully completed the rebuild and smooth start-up of the NipcoFlex shoe press on PM 9 for JiangXi WuXing, a leading paper manufacturer based in Jiujiang City.

Large-scale Voith rebuilds spread across the globe

Voith successfully provides full-line supplier support for large-scale rebuilds around the world, all of which have ambitious efficiency targets and productivity goals. In Spain, for instance, PAPRESA, the leading southern European manufacturer of newsprint, commissioned Voith for the resource-efficient grade conversion of PM 5 from newsprint paper to testliner and corrugating medium at the company’s Rentería mill. Papermaking 4.0 tools supports the company’s ambitious efficiency and sustainability goals. Other notable projects in Europe include the PM 2 rebuild for Schumacher Packaging, a corrugated board producer and full-range supplier of paper-based packaging solutions. The rebuild at the company’s Myszków site in Poland involves a forming section upgrade to DuoFormer D, a new headbox MasterJet Pro and DuoShake DG 800, which will ensure the necessary dewatering capacity and final paper quality. While in North America, Domtar, a leading U.S. paper manufacturer, has entrusted Voith to support the company’s entry into the containerboard market and set higher industry standards. At the company’s Kingsport mill in Tennessee, Voith is to install a BlueLine stock preparation line and perform the grade conversion of its production line.

“Drawing on our full-line supplier expertise, we provide the know-how and technology for rebuilds of every kind. Whatever the ultimate business and sustainability goals of an optimization project, our comprehensive approach ensures we are in a leading position to fully exploit the potential of existing paper production lines,” states Martin Jauch, Senior Vice President Global Rebuilds at Voith.

To discover more insights and updates on Voith solutions for rebuilds and optimizations projects, visit our website: https://voith.com/corp-en/industry-solutions/papermaking/rebuilds-and-optimization.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

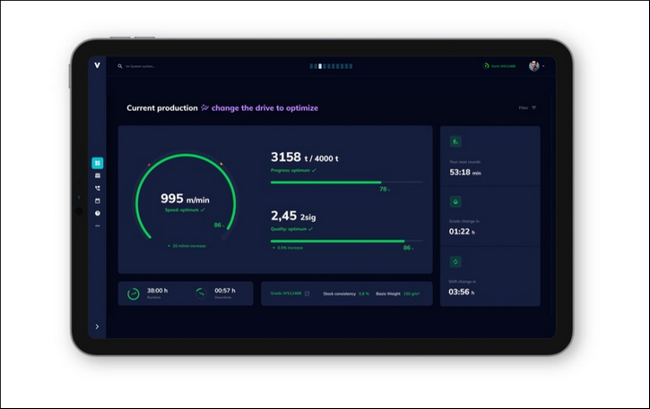

Optimized efficiency and user-friendliness: Voith presents its vision for future user interface

The technology leader Voith presents its vision for future user interfaces with paper machines. Developed for the paper production of tomorrow, the innovative user interface significantly increases plant productivity, ensures paper quality and reduces operating costs. Based on artificial intelligence and the latest digital technologies, Voith’s interface design significantly simplifies plant operation and maintenance and increases the degree of networking. As a full-line supplier, Voith will introduce the user interface across the entire papermaking process from stock preparation to reeling. The individual conditions on site will be flexibly taken into account. In addition, the new user interface convinces with an appealing design.

- Voith confirms its technology leadership with a new visionary design for future user guidance.

- The vision convinces with an appealing design, more intuitive operation and multiple functions to optimize the system.

- The user interface will significantly increase the future production and resource efficiency, reaction speed and operability of paper production.

"Voith's vision consistently pursues the goal of an innovative user interface with maximized operating efficiency and minimized complexity," explains Jürgen Abraham, President Products and Services and Digital Business Officer at Voith. "The new user interface provides a comprehensive overview of all relevant parameters with integrated dialogue and optimization functions. This means that machine downtimes can be efficiently avoided thanks to faster response times and more targeted interventions. In addition, resources and operating costs are significantly saved, while production capacity is increased at the same time. The positive results are clearly visible from the first application."

Many new smart capabilities and digital solutions are integrated into the future interface, providing an excellent user experience. With the new design, users can see at a glance all the information and key performance indicators (KPIs) relevant to their work. This allows the operator to use artificial intelligence to intuitively optimize production settings, assign tasks individually and track them. Guided operating steps prevent information overload and incorrect operation. At the same time, smart functions optimize communication and ensure a smooth process. After shift handover, all data is archived so that a complete handover and documentation can take place. Voith developed the new concept together with the digitalization agency Ray Sono.

Latest digitization solutions from the Papermaking 4.0 portfolio

The new user interface with a modern style guide is part of Voith's design study for the paper production line of the future, in which digital innovations are used to significantly increase the competitiveness, efficiency and speed of paper production. As a leading provider of 4.0 applications, Voith already offers forward-looking and modular digitalization solutions for optimizing paper production. Intelligent technologies combine efficiency increases with ambitious sustainability goals by saving water, energy and fiber. In the process, intelligent hardware and software solutions are continuously being further developed. One of the latest developments, for example, is the OnEfficiency.BreakProtect system. With the help of artificial intelligence, this system on the OnCumulus IIoT platform will predict breaks in good time. The revolutionary digitalization technology thus makes it possible to minimize cost-intensive downtimes.

Under the following link you can find more information about the future user interface: https://voith.com/corp-en/industry-solutions/papermaking/papermaking-vision.html#144435.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith announces necessary price adjustments for paper machine clothing, shoe press sleeves, roll covers, mechanical roll service and doctoring solutions

The global pandemic has caused major unpredictable challenges in both public and private areas. One of these effects is enormous cost increases in many industrial sectors, for example raw materials, packaging and transport.

- Due to continuing significant cost increases in many industrial sectors, Voith has to make price adjustments in the paper industry

- The adjustments pertain to paper machine clothing, shoe press sleeves, roll covers, mechanical roll service and doctoring solutions

- The increases will apply to new orders placed starting this autumn and range between 2.8% and 4.8%

Over a period of time, Voith was able to offset this development through various measures, thus avoiding significant price increases for its customers. Due to the ongoing development, it is now unfortunately no longer possible to compensate all increased costs. In line with the current tense market situation, Voith is therefore forced to make price adjustments for some products and services in the paper industry.

Over a period of time, Voith was able to offset this development through various measures, thus avoiding significant price increases for its customers. Due to the ongoing development, it is now unfortunately no longer possible to compensate all increased costs. In line with the current tense market situation, Voith is therefore forced to make price adjustments for some products and services in the paper industry.

In the product areas of paper machine clothing, shoe press sleeves, roll covers, mechanical roll service and doctoring solutions, prices will increase between 2.8% and 4.2%. Further details will be announced in autumn and will then apply to newly placed orders.

The target of Voith remains unchanged: to support its customers and business partners with leading expertise, outstanding service and innovative products and solutions – in an increasingly complex and challenging business world.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Full-line supplier Voith receives order from Shandong Huatai Paper to rebuild PM 11 for production of woodfree uncoated paper

In response to changing market demand, Shandong Huatai Paper decided to rebuild and modernize PM 11 in order to progressively convert newsprint production to high-quality graphic paper. The paper producer selected the full-line supplier Voith as a suitable partner. After the rebuild, the production line will have a significantly increased annual capacity of 520,000 tons at a design speed of 1,800 m/min. The rebuilt production plant, located in the eastern Chinese province of Shandong, will start up in 2023.

- Shandong Huatai Paper, one of the world's largest newsprint producers, commissions the full-line supplier Voith with the rebuild of PM 11

- After the rebuild, the state-of-the-art machine produces wood-free uncoated paper with significantly increased productivity

- Voith already supplied the customer with various paper machines for the efficient production of newsprint in the past years and successfully rebuilt PM 10 to graphic paper

"We are very pleased that Shandong Huatai Paper has chosen us again," says Hanson Zhao, Vice President Sales and Application Asia at Voith. "Our leading technologies, long-standing partnership and very good results were decisive in winning the order. After the paper machine rebuild, the system will be one of the most powerful of its kind in the world. With Voith's state-of-the-art solutions and outstanding service competence, Shandong Huatai Paper benefits from optimized plant production and paper quality."

"With the rebuild of PM 11, we are aiming for a stronger positioning in the segment of high-quality graphic paper," says Wei Lijun, Vice General Manager at Shandong Huatai Paper. "We are glad to have found a strong and reliable partner in Voith by our side. The order is another milestone in our successful business relationship."

Voith Huatai PM11

Voith Huatai PM11

With the help of leading Voith technologies, the annual capacity of PM 11 will be significantly increased. The tailor-made package enables state-of-the-art paper production, focusing on the efficiency, stability and reliability of the plant. In addition, the solutions ensure more sustainable production by minimizing the carbon footprint and reducing water and fiber consumption. Among other things, a new MasterJet Pro G headbox is used, which improves paper quality while enabling significant savings in energy costs. In addition, Voith experts are upgrading the forming section similar to the DuoFormer concept to achieve optimum formation and higher throughput. New ProRelease+ HighEnd boxes in the pre-dryer section guarantee improved web stability at high speeds. Futhermore, a SpeedSizer AT with its smooth film application will ensure even and high-quality paper profiles. In the after-dryer section, the efficient CombiDuoRun drying concept will be installed. The scope of supply also includes new automation solutions to efficiently upgrade the existing control systems.

Shandong Huatai Paper is one of the world's largest newsprint producers, with an annual production of 1.5 million tons. As a long-standing partner, the customer has already commissioned Voith with various orders for new plants. For the rebuild project of PM 10 to graphic paper, Shandong Huatai Paper also decided to work with Voith. The full-line supplier Voith successfully completed this project in 2016.

About Shandong Huatai Paper

Shandong Huatai Paper is part of the Huatai Group. As a major global player, the company mainly produces and sells paper products, including newsprint, graphic paper and pulp products. The group is the world's largest producer of newsprint and the largest producer in the chlor-alkali industry in China. The company sells its products domestically and overseas.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Koehler Paper relies on Voith for the second expansion stage of paper machine 5 in Oberkirch, Germany

After a successful first rebuild stage of PM 5 in Oberkirch – with the installation of the Voith SpeedSizer film press and contactless qDryPro Compact high-performance drying system – specialty paper manufacturer Koehler Paper has confirmed its confidence in Voith. Koehler has selected the full-line supplier to deliver the second modernization stage, focusing on the much-proven NipcoFlex shoe press.

- Koehler confirms very good and successful cooperation with Voith

- After the second rebuild phase, a new NipcoFlex shoe press in the existing press section ensures more sustainable production

- The technologically leading solution from Voith also increases production capacity

"We have a long-standing, successful business relationship with Koehler," says Thorsten Heidt, Senior Sales Manager at Voith. "Just recently, Koehler was able to achieve a world speed record with the new PM 8 line at the Kehl location thanks to our successful cooperation and continuous optimization. We are very pleased that Koehler has again opted for our leading technologies and that our solution convinced in all points."

"For the second rebuild stage, we are again relying on Voith to achieve an optimum production result," says Hartmut Felsch, plant manager at Koehler’s Oberkirch site. "In Voith, we have found a strong and reliable partner with the highest quality standards for all areas of paper production."

With the installation of the NipcoFlex shoe press in the existing press section, the dry content after the press is significantly increased. As a result, large amounts of steam can be saved in the dryer section for drying the paper web. The rebuild thus helps save energy and reduce CO2 emissions in the plant. In addition, the higher dry content increases line speed and production capacity. At the same time, work safety and operability are improved when changing the felt with the aid of the cantilever framing for the pick-up felt.

The rebuild is a tailor-made solution and addresses the limited space available, especially on the drive side of the machine. As part of the rebuild, the transfer process from the press to the dryer section is optimized and a draw reduction is achieved to significantly increase efficiency. The press roll uses a TerraSpeed Trend Supreme ceramic coating, which is also utilized on other Koehler Paper machines. This guarantees optimized sheet release with long running times and a high level of cleanliness. The order is complemented by the proven QualiFlex shoe press sleeves and a start-up set for all press felts.

About the Koehler Group

The Koehler Group was founded in 1807 and has been family-run to this day. The Group’s core area of business is the development and production of high-quality, specialty paper, including thermal paper, playing card board, drink coasters, fine paper, carbonless paper, recycled paper, decor paper, wood pulp board, sublimation paper, and, since 2019, innovative specialty paper for the packaging industry, too. In Germany, the Koehler Group, with its more than 2,000 employees, has five production sites, as well as three more in the USA. The Group operates on an international level, with an export ratio of 70% in 2020 and annual revenue of €770 million.

As an energy-intensive enterprise, Koehler invests in renewable energy projects such as wind energy, hydroelectric power, photovoltaics and biomass. The Koehler Group has committed itself to producing more power from renewable sources than is needed for paper production by 2030. More information is available here: https://www.koehler.com.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

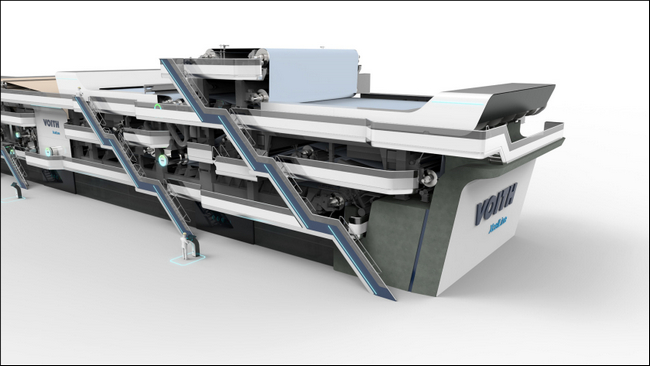

Papermaking Vision: Voith creates visionary design study for the paper production line of the future

With a visionary design study, technology group Voith is creating the paper production line of the future. The design particularly focuses on improved efficiency and ease of maintenance. As a full-line supplier, the company has considered all aspects of the paper production process for an integrated concept. Maintenance and operation of the facility are simplified, a higher degree of interconnectedness reduces interfaces, and an appealing design ensures a consistent overall look, while at the same time improving efficiency, safety and sustainability.

- As a full-line supplier, Voith presents a holistic concept for all areas of paper production

- The long-term design study is to significantly increase efficiency and maintainability

- The focus is on the implementation of a "Clean Design" as well as the latest digitalization and automation solutions in combination with artificial intelligence

“The goal of our long-term design study is to significantly improve efficiency and ease of maintenance across the entire production line,” says Dr. Michael Trefz, President Division Projects at Voith Paper. “We are considering a wide variety of aspects, such as the degree of automation of the machine, the interconnectivity of various sections, better accessibility and greater safety as well as optimized availability. However, the materiality and an appealing design also play an important role in the concept.”

‘Clean design’ for greater efficiency and a smooth production process

Special attention was paid to the implementation of ‘clean design’ principles, for example by increasing cleanliness in the wet end. Less contamination reduces the risk of unscheduled downtimes due to web breaks. Consequently, operational reliability and machine efficiency are improved and the production process runs smoothly. Also, scheduled shutdowns are completed more efficiently thanks to more accessible work areas and simpler maintenance procedures. The design concept is a long-term project and will be implemented step by step over the coming months and years.

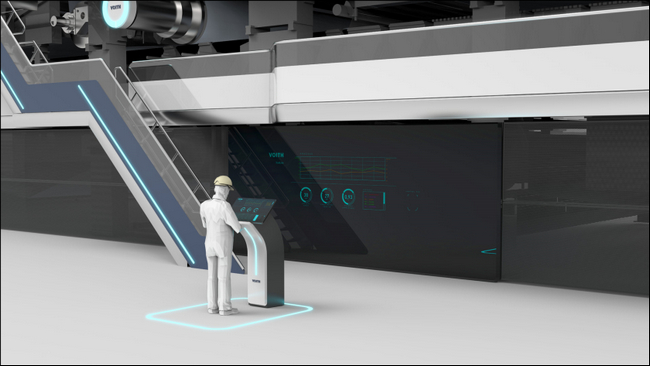

Optimized human-machine interface improves ease of maintenance

“The smartphone has shown how simple and intuitive communication between humans and machines makes many areas of everyday life more efficient. In the industrial environment too, the information and all relevant functions a user needs will in future be presented in one platform,” says Oliver Kunerth, Digital Product Manager at Voith Paper. As part of the vision for the future, a standardized and intuitive user interface will therefore be introduced from stock preparation through to the reeling. In this context, the human-machine interface uses a role-based operating concept to adapt to the individual task of users, which at the same time improves ease of maintenance. In the future, more efficiency will also be ensured by distinctive SmartLights on individual components of the system. They show the machine status at a glance, and if necessary, whether operator intervention is required.

Automatic data analysis replaces pure monitoring

Papermaking 4.0 solutions, sensors, field devices, scanners and actuators already monitor the condition of machines and the quality of production in real time. In the coming years, automatic data analysis will become even more important and replace pure monitoring. Intelligent algorithms will then ensure that in a very short time, the system autonomously creates the optimal conditions for resource-saving production. In the near future, new apps on the Voith OnCumulus IIoT platform will create complete transparency about all conditions in a paper mill and give paper producers far-reaching optimization potential. “For example, one of these apps, the AI-based OnEfficiency.BreakProtect system, can already provide users with recommendations about how to avoid web breaks,” says Oliver Kunerth. Time-consuming and cost-intensive downtimes can thus be minimized, while maintenance and servicing are optimized in a forward-looking manner.

In the future, the OnCumulus cloud platform will also provide a networked interface to all service functions, such as for ordering spare parts via the web store or to the remote service center OnPerformance.Lab, enabling more efficient and sustainable production.

Appealing design for a calm overall appearance

In future, Voith’s expertise as a full-line supplier is also set to be reflected in the design of a plant. In this context, clear structures, high-quality surface finishes and modern materials underline the special quality of a Voith BlueLine stock preparation and XcelLine paper machine.

For more information and details on the paper production of the future please go to: Papermaking Vision | Voith.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith wins AI Champions Award 2021 for its OnView.DigitalEye innovation in the ‘large enterprise’ category

Voith wins this year’s AI Champions Award in the ‘large enterprise’ category for its newly developed AI application OnView.DigitalEye. For the first time, this innovation allows the quality of recovered paper to be analyzed at the stock preparation stage, one process step before paper production. Every year, the Ministry for Economic Affairs, Employment and Tourism of the state of Baden-Württemberg awards the accolade to outstanding innovations that contribute to a successful AI ecosystem with the help of artificial intelligence. Voith’s digital solution impressed the committee with its sustainability, innovative strength, area of application, and added value for the customer.

- With its AI Champions Award, the Ministry for Economic Affairs, Employment and Tourism of the state of Baden-Württemberg recognizes outstanding solutions from the field of artificial intelligence (AI) that contribute to a successful AI eco-system.

- With the help of the digital analysis tool OnView.DigitalEye, it is possible for the first time to determine the precise quality of recovered paper even before the stock preparation process.

- The key criteria applied by the jury included sustainability, degree of innovation, areas of application, and the added value of the Voith innovation for the customer.

“With the award-winning modular system OnView.DigitalEye it is possible for the first time in the paper industry to assess the quality of the recovered paper immediately before the first step in paper manufacturing,” says Dr. Linus Friedrich, Senior Manager R&D Technology & Digitalization at Voith Paper. “We can use the newly generated signals for example to increase the yield from recovered paper preparation and improve operational reliability. The innovation is thus another important element of Papermaking 4.0 and autonomous paper production.”

More than 70 percent of the paper produced in Europe is recovered from recycled paper. Nowadays, assessing the quality of the recovered paper is generally limited to an incoming goods inspection that either takes the form of a visual inspection or a random sampling process involving costly or labor-intensive solutions. However, the quality of the recovered paper is not known immediately before it is pulped for paper manufacture, which can result in a high degree of uncertainty for the process. Voith has now developed a solution to deal with this. OnView.DigitalEye is based on artificial intelligence, although it uses images from conventional color cameras, which keeps the investment costs comparatively low. The centerpiece of OnView.DigitalEyes is an artificial neural network that leverages expert knowledge to learn how to assign recovered paper with a high degree of accuracy to its respective commercial grade. In combination with conventional image analysis, additional valuable signals are generated for recovered paper properties that can be used for efficient process control. The AI application OnView.DigitalEye is currently undergoing final trials in pilot installations at customers in Germany and abroad, and will probably be available from the middle of next year.

KI champions awards

KI champions awards

The expertise and digital infrastructure established for OnView.DigitalEye are planned to also be used in future for other cross-industry applications relating to AI-supported visual inspection at the Voith Group. “By using Voith’s own robust IIoT & AI services, we can realize customer solutions for groundbreaking application requirements simply and agilely,” says Thomas Greil, Vice President IIoT & Advanced Applications at Voith Group Innovation & Technology. “In the process, the underlying technology services will be further expanded successively and sustainably, while at the same time creating a harmonious application eco-system for our customers. The added value for the customer, with a pragmatic approach to the latest technologies, is always the focus of our digital ambitions.”

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Koehler Paper sets new production speed record with Voith paper machine

Designed as one of the most efficient specialty paper machines in the world, Koehler Paper commissioned Voith's production line 8 at its Kehl mill at the end of October 2019 - after a previous project time of only around two and a half years.

- Fastest MG paper machine in the world with consistent speed of more than 1,400 m/min

- Flexible production of packaging paper covering a wide range of grades from 22 gsm to 95 gsm

- Trailblazing paper products developed to market readiness

Thanks to ongoing optimization, the company recently achieved a groundbreaking level of performance for the production of around 40 gsm base paper at a continuous speed of more than 1,400 m/min. Thanks to intensive cooperation, permanent project support and continuous optimization from Koehler and Voith, the line achieved an average speed of 1,410 m/min over a period of 24 hours as well as a maximum value of 1,432 m/min - a world record for the MG paper machine.

On the occasion of this event, Voith presented Koehler Paper with an engraved glass plate that records this historic speed record. At the award ceremony at the Kehl mill last week, Dr. Michael Trefz, President Projects at Voith, was pleased to present the recognition: "An outstanding value, which was made possible by the cooperation between Koehler and Voith, the combination of extensive technical knowledge and a long-standing and trusting partnership. Koehler and Voith are thus once again demonstrating their pioneering spirit in paper production." Dr. Stefan Karrer, COO at Koehler, and Joachim Uhl, Mill Director in Kehl, also appreciate the cooperation and are proud of the team's performance on production line 8: "The optimizations have enabled us to raise our machine to a new level."

Joint development of trailblazing packaging paper products

Another outcome of the collaboration between Koehler and Voith is the development of cutting-edge products. As part of the development partnership for new paper grades, Voith carried out several test series on the R&D pilot coater at the Voith Paper Technology Center in Heidenheim. The technological requirements of the new paper grades were investigated in depth and then implemented in the new production line. This has resulted in the innovative products of the NexFlex® product line, Koehler's flexible packaging paper.

State-of-the-art technologies for effective production

With a volume of 300 million euros, the entire production line 8 is one of the largest investments in Koehler's history. As well as the XcelLine paper machine and a offline coating machine, the project includes a BlueLine stock preparation system including wet end process and a VariPlus winder. The facility is designed to produce around 100,000 tons per year of various paper grades. An offline coating machine enables variable coating orders and combinations, resulting in an enormous range of grades. This extensive range of different paper grades and basis weights from 22 gsm to 95 gsm is another unique selling point of the production line. PM 8 paper machine thus supplies already finished paper and raw paper for the further finishing process.

A special technical highlight is the MG cylinder, which has a diameter of 7,315 mm, the largest of its kind worldwide at the time of installation. The cylinder gives the paper its unique smoothness, which is essential for optimum downstream processing. Thanks to the MCB air dryers, the coated paper is dried extremely gently and without contact, while at the same time maintaining high thermal efficiency. A special calender design ensures final calendering of the specialty papers.

About the Koehler Group

The Koehler Group was founded in 1807 and has been family-run to this day. The Group’s core area of business is the development and production of high-quality, specialty paper, including thermal paper, playing card board, drink coasters, fine paper, carbonless paper, recycled paper, decor paper, wood pulp board, sublimation paper, and, since 2019, innovative specialty paper for the packaging industry, too. In Germany, the Koehler Group, with its more than 2,000 employees, has five production sites, as well as three more in the USA. The Group operates on an international level, with an export ratio of 70% in 2020 and annual revenue of €770 million.

As an energy-intensive enterprise, Koehler invests in renewable energy projects such as wind energy, hydroelectric power, photovoltaics and biomass. The Koehler Group has committed itself to producing more power from renewable sources than is needed for paper production by 2030. More information is available here: https://www.koehler.com

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 20,000 employees, sales of € 4.2 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith receives order from Nine Dragons Paper to deliver three XcelLine paper machines to China

Nine Dragons Paper, the biggest manufacturer of packaging paper in China, has commissioned Voith to build and deliver three XcelLine paper machines for the production of high performance testliner and white top testliner. The three lines will further strengthen the paper manufacturer’s leading position in the packaging paper segment.

- Voith’s technological performance as decisive factor in winning the order.

- Significant capacity expansion reinforces Nine Dragons’ leading position in China’s packaging paper industry.

“We are delighted to have received the orders from China’s largest packaging paper manufacturer Nine Dragons and we look forward to our renewed collaboration on a partnership basis,” says Hanson Zhao, Vice President Sales & Application Asia at Voith Paper.

“We are delighted to have received the orders from China’s largest packaging paper manufacturer Nine Dragons and we look forward to our renewed collaboration on a partnership basis,” says Hanson Zhao, Vice President Sales & Application Asia at Voith Paper.

The planned daily production volume of the three identical paper machines is especially high: approximately 2,400 metric tons each, at production speeds of 1,400 m/min. In order to meet these requirements, the components must be extremely high-performing and robust. The elaborate former design of the machines, which are equipped with a DuoFormer DII E, allows for the required speed with high basis weights at the same time. The press sections each feature a Triple NipcoFlex press, which ensures excellent surface smoothness of white top liner. Due to the double unwind configuration and a fully automated full reel change, the high-performance TwinDrive winder enables fast and efficient winding and thereby ensures a winder capacity that is up to 20 percent higher than conventional unwinding systems.

The commissioning of the machines is planned for 2022 and 2023.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of plants, products, services, and digital applications, Voith sets standards in the markets for energy, oil & gas, paper, raw materials, and transport & automotive. Founded in 1867, Voith today has more than 20,000 employees, sales of €4.2 billion and locations in over 60 countries worldwide, and is thus one of Europe’s larger family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.