Displaying items by tag: voith paper

Higher bulk with lower raw material usage: Voith’s EcoCal Plus reduces production costs in board manufacturing

With the new EcoCal Plus calender, Voith is ensuring that papermakers can produce high-grade board products with high stability and lower basis weight. The special thermal smoothing of the EcoCal Plus allows raw material savings of up to 3.5 percent. In addition, the process results in an improved surface structure of the paper.

The demand for board grades with maximum possible bulk has been growing steadily over the last few years. With lightweight and stable board products, significant cost savings can be achieved for example in the mail-order business. At the same time, board packaging products are increasingly important for advertising of consumer goods by focusing attention on the package contents which indirectly support its sales. Good printability and surface quality are just as important as stability and low weight. Both properties are positively influenced by the EcoCal Plus calender.

For the production of these board grades, the manufacturers usually use high fresh fiber content. Secondary fibers are only added in some cases. Lower basis weights and maintaining or improving board properties are therefore crucial for lowering resource consumption and production costs on the manufacturer side.

The new Voith EcoCal Plus calender is ensuring that papermakers can produce high-grade board products with high stability but with low raw material use. It can be integrated into existing plants as part of an upgrade.

The new Voith EcoCal Plus calender is ensuring that papermakers can produce high-grade board products with high stability but with low raw material use. It can be integrated into existing plants as part of an upgrade.

Thermal smoothing key to paper quality

The hard nip calender plays a decisive role in the manufacturing of high-quality, stable board with low basis weight. It smoothes the paper surface and gives the board a uniform surface. This is where Voith’s EcoCal Plus comes in. The machine calender used for pre-calendering makes use of the fact that surfaces can be smoothed more easily when moisturized and warm. Voith thus equipped the EcoCal Plus with an external induction-heated system that additionally heats the thermo roll to a temperature of up to 260°C. This is considerably higher than the temperatures of conventional systems with 200°C. The EcoCal Plus also has an additional nozzle moisturizer for intensifying the bulk-preserving smoothing effect by regulating the paper web temperature.

More bulk and better surface structure

With thermal smoothing, less mechanical force must be applied to the paper web. As a result, the bulk loss is much lower than with conventional calendering. Paper smoothed with the EcoCal Plus thus has a higher specific volume. The process has another advantage: through the optimum interplay between temperature, moisture, and line load, the board surface structure is optimized. This is especially important for the packaging of high-grade foodstuffs, cosmetics, electronics, and medical products. The uniform surface and the higher stiffness greatly ease the tasks of board finishing and printing.

Cost savings through lower fiber consumption

The moisture and temperature gradients used in calendering with the EcoCal Plus require only a negligible amount of additional energy. However, this is more than balanced by the economic advantages offered by the EcoCal Plus. The EcoCal Plus technology allows papermakers to reduce their fiber consumption. This saving greatly improves the cost efficiency of the plant: an annual production of 500,000 tonnes with a one-percent saving in raw materials use translates into savings of around 250,000 euros per month for the manufacturer. In practice, the savings potential is much higher: EcoCal Plus calenders have been in operation since 2011 and have achieved bulk savings of up to 3.5% due to the uniqueness of the technology. Thus, the break-even point for investment in the technology can be reached after half a year, depending on the machine size. Alternatively, with the EcoCal Plus, lower-cost raw materials can be used to achieve the same board quality, which also drastically lowers production costs.

The EcoCal Plus calender can be integrated into existing plants as an upgrade. Especially practical is the ability of the calender to be installed in a short period of time during a planned shutdown. In new plants the technology provides great efficiency right from the start.

Voith Paper is a group division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

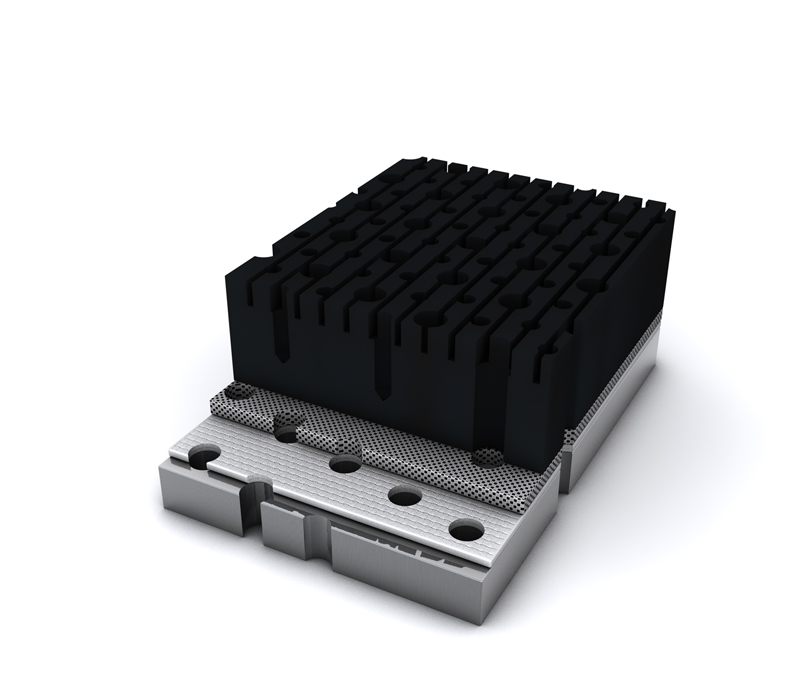

More Efficiency in stock preparation: InfiltraDiscfilter with new HiCon 2.0 technology from Voith

In the BlueLine stock preparation product portfolio, the InfiltraDiscfilter with new HiCon 2.0 technology from Voith satisfies two of the key customer requirements for modern paper manufacturing, enabling efficient and resource-conserving production, an increase in fiber yield and water consumption may be reduced. The improved efficiency in the stock preparation offers a potential capacity increase of up to 20 percent at the disc filter and savings in pump energy of maximum 50 percent.

- Prevents vat thickening

- Minimizes maintenance and operating costs

- Up to 20 percent capacity increase and 50 percent less pump energy

Conventional disc filters not only necessitate a high level of monitoring and maintenance; especially in the event of process fluctuations they can cause malfunctions that result in costly machine downtimes. These kinds of problems are triggered above all by uncontrolled highs in stock consistency in the disc filter. If such highs go undetected this often results in a thickening in the vat, especially in high freeness ranges. In these circumstances the disc filter clothing is exposed to high mechanical stresses and can readily become damaged. In the worst-case scenario the entire filter is damaged. To prevent such difficulties, the stock flow is diluted upstream of the disc filter, which is associated with a considerable increase in pump energy and loss of drainage capacity.

The InfiltraDiscfilter with new HiCon 2.0 technology from Voith is used in the BlueLine stock preparation unit at Schoellershammer PM 6.

The InfiltraDiscfilter with new HiCon 2.0 technology from Voith is used in the BlueLine stock preparation unit at Schoellershammer PM 6.

For its HiCon 2.0 technology Voith is also relying on the proven bagless system but has added two new decisive innovations: Firstly, the HiCon disc filters are fitted with a solid system which safely guides the discs. As a result the new disc filters are much more robust and have even longer service lives. In addition, the flow pattern in the vat is reversed, by feeding each individual disc with the flow of stock separately from the others. The patented innovative technology from Voith's BlueLine range prevents the occurrence of critical areas in which the pulp thickens. This allows production to be run with a stock consistency that is up to two percent. Disc filters with HiCon technology can optionally be integrated into existing machines during an upgrade.

With the launch of its BaglessPlus technology in 2012, Voith had already eliminated a large number of vulnerabilities in conventional filters and had thus set a new benchmark for disc filters. On the one hand because the bagless filters reduced maintenance and operating costs, and on the other because they can better withstand critical situations and therefore reduce the number of costly shutdowns.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

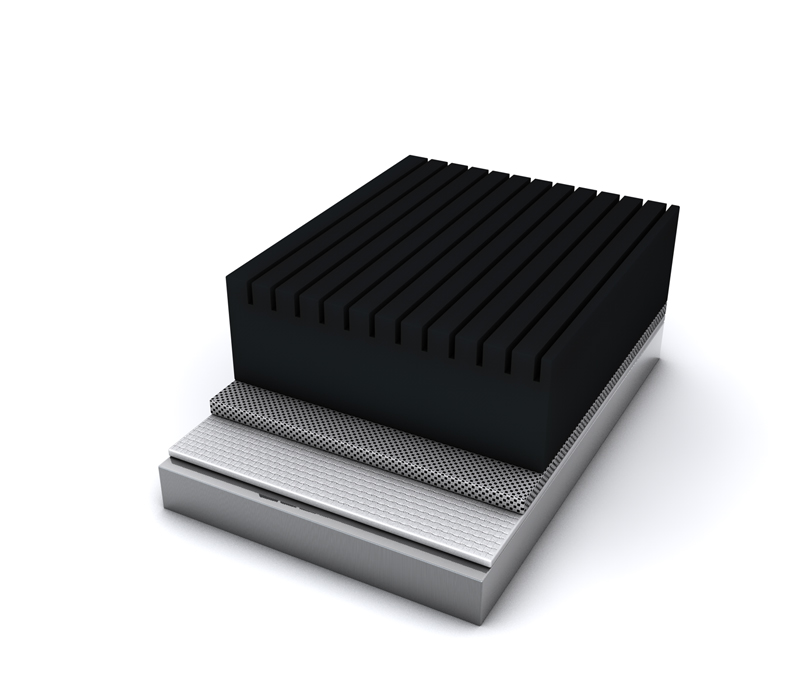

MiniGrinder: Voith's compact grinder for restoring the Yankee cylinder's ideal crown profile

Deformations on Yankee cylinders frequently result in production and quality deficiencies in tissue manufacturing. The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of these kinds of irregularities restoring the Yankee cylinder's ideal crown profile.

The MiniGrinder also readily removes old coatings and chatter marks. What is special about the MiniGrinder is its size. It is so compact that it can be used on any tissue machine without the need to remove and re-install key machine parts, as is normally the case with conventional grinding machines. This reduces time and labor for the maintenance crew allowing production to restart much sooner.

The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of deformations on Yankee cylinders.

The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of deformations on Yankee cylinders.

One Voith customer was able to reduce the downtime for his machine by 14 hours, because there was no need to dismantle machine parts. The exhaust air system used with the MiniGrinder removes the airborne dust that inevitably occurs during the grinding process. On the one hand this reduces the cleaning effort before restarting the machine, and on the other hand it protects the health of personnel working on and around the Yankee cylinder.

The design and shape of the MiniGrinder has been optimized so that the grinding bed has optimum rigidity. Although the grinding bed is smaller than conventional grinding machines the rigidity is significantly higher. The grinding force of the head is equivalent to that of conventional tangential grinding heads, ensuring maximum precision for all types of applications. The MiniGrinder is suitable for all kinds of metal surfaces.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

SkySoft Creping Blade with Ceramic Coating helps to increase Tissue Productivity

SkySoft is a new creping blade from Voith that ensures constant tissue quality. The specially developed ceramic tip of the SkySoft creping blade is highly wear-resistant for a longer lifetime and less machine downtime. SkySoft was also designed to reduce friction on the Yankee cylinder, avoiding damage to its surface.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life.

Thanks to its special coating and high precision SkySoft ensures constant tissue quality through a longer service life. Furthermore, SkySoft has no limits on operation bevels, ensuring state-of-the-art technology for tissue production.

The SkySoft creping blades are produced at the Voith manufacturing site in Theresienfeld, Austria, where significant investments have been made into advanced grinding techniques. The fully automated production process guarantees constant characteristics and quality and allows creping blades to be supplied with a full range of angles to suit all applications. The new blades are compatible with all blade holders, and Voith OnSite Yankee specialists ensure that they fit perfectly with the customer’s machine setup at their production site.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Voith wins two new PM 36 and PM 37 XcelLine papermaking machine orders from Sun Paper

A signing ceremony was held on the morning of January 25, 2017 to mark Sun Paper’s order of two new XcelLine papermaking production lines from Voith. The orders are for the PM 36 production line with an annual production of 400,000 metric tons of low-grammage high-grade Testliner and the PM 37 production line with an annual production of 300,000 metric tons of high-quality corrugating medium paper.

The event was attended by the Deputy General Manager and Chief Engineer of Sun Paper, Mr. Ying Guangdong; the Director of the Packaging Paper Division, Mr. Fu Guoling; the President of Voith Paper Asia, Mr. Thomas Holzer; and Dr. Michael Trefz, the Senior Vice President Project Sales. The design speed of the two paper machines is 1200 m/min, with a working width of 6,660 mm at the reel. The two production lines will be built as part of the second phase of the Zoucheng Papermaking Industry Park, with foundation work planned to begin in May 2017 and startup scheduled for July and September 2018. The machines are based on the PM 31 and PM 32 paper machines of 2016. The resulting paper offers low basis weight, high ring crush strength, high strength and good folding resistance. It also saves resources, and reduces packing costs and carbon emissions. These products are already widely used in domestic and overseas medium-quality and premium product packaging markets.

Voith is now deepening the implementation of its new "Papermaking. Next Level" concept of product transformation, in order to improve efficiency, increase production, ensure quality and create more intelligent, cost-effective and sustainable industrial processes throughout the entire papermaking chain.

Front row f.l.t.r.: The signing ceremony, with Dr. Michael Trefz, Senior Vice President Project Sales Voith Paper; Mr. Thomas Holzer, President of Voith Paper Asia; Mr. Ying Guangdong, Deputy General Manager and Chief Engineer; and Mr. Fu Guoling, Director of Packaging Paper Division at Sun Paper

Voith Paper ensures that customers can save costs and achieve sustainable development through new resource-saving technologies. They can therefore achieve their best performance at lower prices through every papermaking step and paper grade, to better meet the challenges of "Industry 4.0". The concept of "Papermaking. Next Level" has opened up a new journey towards intelligent production for manufacturers using Voith technology. When the two production lines ordered by Sun Paper are put into operation, they will enrich its product mix and variety, enhance its core competitiveness and further promote Sun Paper’s strategic transformation.

Sun Paper was established in 1982 and is now a multinational papermaking group operating worldwide, specializing in forestry-pulp-paper integration and playing a leading role in the Chinese paper industry. With total assets of 29.2 billion yuan and more than 10,000 employees, the annual pulp and paper production capacity of Sun Paper is 5.7 million tons. Sun Paper ranks 312th in China's top 500 enterprises and ranks 48th in the world's top 100 paper-making enterprises.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Voith Receives Further Order from Lee & Man for Two Tissue Machines

Voith signed a contract in June 2016 with Lee & Man Paper Manufacturing Limited to provide it with two tissue machines in Dongguan. The move is not only a continuation of the previous successful cooperation between Lee & Man and Voith, but also a consolidation of Voith's strong position in the global tissue machine market.

![]() The location for the TM11 and TM12 is in Dongguan, China. The start-up of these two tissue machines is expected to take place respectively in September and July of 2017. Lee & Man ordered its TM3, TM9 and TM10 machines from Voith, and the start-up of TM9 and TM10 will take place respectively in March and May of 2017. From March through to September in 2017, four tissue machines from Voith will start up in a row in Lee & Man’s mill, at the pace of one machine every other two months. This exciting scenario is built upon great customer trust, which Voith has earned over many years of high quality performance.

The location for the TM11 and TM12 is in Dongguan, China. The start-up of these two tissue machines is expected to take place respectively in September and July of 2017. Lee & Man ordered its TM3, TM9 and TM10 machines from Voith, and the start-up of TM9 and TM10 will take place respectively in March and May of 2017. From March through to September in 2017, four tissue machines from Voith will start up in a row in Lee & Man’s mill, at the pace of one machine every other two months. This exciting scenario is built upon great customer trust, which Voith has earned over many years of high quality performance.

The TM11 and TM12 machines have a working width of 5,600 mm, a design speed of 2,200 m/min and a maximum operating speed of 2,000 m/min. Each of these two tissue machines will produce 60,000 tons of household paper from virgin fiber annually. The scope of supply includes stock preparation, approach, broke handling, a white water system and the tissue machine. It features the perfect combination of a NipcoFlex T shoe press to offer remarkable energy savings, a 5.5 meter steel Yankee dryer which can enhance drying efficiency by optimizing the heat transfer and a high-performance steam hood to guarantee paper quality with a lower energy consumption. Moreover, the technically mature Voith automation package including DCS, MCS and QCS forms an integral part of the order.

Voith has always been committed to meet the requirements of the paper industry for lower energy and water consumption, less fiber usage and higher system availability. The signing of this contract has once again highlighted the strong regard for Voith’s innovative technology in the tissue paper industry.

Established in 1994, Lee & Man Paper Manufacturing Limited is one of the world’s leading paper manufacturers, mainly producing packaging paper and tissue paper with different grades and specifications. The company’s annual sales volume in 2015 was up to 525 million tons. The company currently has five factories in China, with a total of 6,500 employees.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Little Rapids Corporation Awards Voith to Supply New Tissue Machine for its Plant in Wisconsin (USA)

American specialty paper manufacturer Little Rapids Corporation has signed a contract with Voith Brazil to purchase a new tissue paper machine. This new machine will replace the existing PM3, located in Shawano, Wisconsin (USA).

![]() Besides significant improvement of paper quality, the new machine will produce 119 metric tons per day at a speed of 1,830 m/min. Except for the existing Yankee dryer, which will be reused, all other machine components will be new and based on Voith's machine model VTM3.

Besides significant improvement of paper quality, the new machine will produce 119 metric tons per day at a speed of 1,830 m/min. Except for the existing Yankee dryer, which will be reused, all other machine components will be new and based on Voith's machine model VTM3.

In addition to the new tissue machine and auxiliaries, Voith's scope of supply includes: stock preparation, approach flow system, steam box, dust and mist removal systems, DCS systems and field services.

The project is scheduled to start in the third quarter of this year and the start-up is expected for the end of 2017.

About Little Rapids Corporation

Little Rapids Corporation was founded by Charles Egan in 1947 and re-mains a family-owned business. The company’s core product lines serve the medical and beauty market segments, flexographic printing for a variety of packaging markets, and tissue, MG paper, and wet crepe paper for the specialty paper market. With headquarters and manufacturing facilities in Green Bay, the company, which employs 435, also has a paper manufacturing facility in Shawano, Wisconsin. In addition, the company donates to the region via the Little Rapids Corporation - Egan Family Foundation, a private foundation established by the Egan family in 1986 with the mission to fund charities in communities where Little Rapids Corporation has facilities.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Voith Breakthrough with the Successful Startup of Sun Paper’s New Testliner Project

Sun Paper, one of the leading paper makers in China, recently successfully started up its new testliner paper machines with an annual capacity of 800,000 metric tons at its location in Zoucheng. The main paper machine, the right-hand machine PM31 and the left-hand machine PM32 are both provided by Voith. The PM31 has successfully started up, marking a milestone in China’s papermaking sector, as it is the first time that two different packaging paper machines have ever been installed in a common production hall.

With support from Voith, the project enables Sun Paper to achieve high production efficiency, significant cost savings and efficient fiber utilization along the manufacturing process.

With a production width of 6,660 mm and an operating speed of 1,200 m/min, the PM31 produces testliner in the basis weight range of 110 to 250 g/m2. It adopts the cutting edge technology of the three layer MasterJet headbox, the Tandem NipcoFlex shoe press and the SpeedSizer as well as the hard nip calender. The installation of the PM31 started in October 2015 and it became operational on July 10, 2016, an impressive achievement in the domestic papermaking industry.

With a relentless effort and close cooperation of the special taskforces from Voith and Sun Paper, the PM31 achieved paper on reel earlier than Sun Paper had anticipated. In addition, it took only 12 hours from stock on wire to paper on reel. And it only took one day to produce saleable paper. Moreover, the PM31 is running quite smoothly and stable after startup.

The PM32 is expected to start up in August 2016. The PM32 adopts the advanced technology of “one headbox, two layers” with tandem NipcoFlex, surface sizing and hard nip calendar. It produces corrugating medium and testliner in the basis weight range of 90 to 140 g/m2.

With Fourdrinier and DuoFormer D II, the PM32 can guarantee product quality at a high operating speed. In addition, the PM32 is the first paper machine to adopt the most advanced double layer headbox MasterJet Pro F/B2, which offers high efficiency, good formation, even basis weight, high paper strength and stable quality for production of top-quality testliner of low basis weight.

Sun Paper, headquartered in Shandong Province, is a major paper manufacturer in China and one of the TOP 500 enterprises in the country, with total assets worth 28.8 billion yuan and an annual pulp and paper manufacturing capacity of 4.5 million metric tons.

About Voith Paper

Voith Paper is a Group Division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the markets for energy, oil & gas, paper, raw materials, transport & automotive. Founded in 1867, Voith employs more than 20,000 people, generates €4.3 billion in sales, operates in over 60 countries around the world and is one of the biggest family owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

New MatchPress and MatchFlow Roll Covers from Voith

Two new roll covers, MatchPress for press rolls and MatchFlow for suction press rolls, are additions to Voith‘s product portfolio. MatchPress and MatchFlow are designed for graphic and packaging paper machines with a wire width of up to 6,000 mm and speeds up to 800 m/min. The new covers are specifically designed to meet the demands of these machines and enable the operator to lift production to a new level and thus gain a competitive advantage.

- Tailored to the requirements of small and medium-sized paper machines

- High dewatering performance through customized surface design

- Improved material characteristics for reduced wear

MatchPress and MatchFlow offer markedly improved material characteristics. These enable surface designs that increase dewatering capacity in the press section. Furthermore the material characteristics are key for the high wear resistance of the covers. Constant high grinding intervals can thus be achieved for the operator.

Unique groove dimensions and blind-drilled design in the covers guarantee high dewatering of the paper web. This effect is reinforced thanks to high open area of the new roll covers MatchPress and MatchFlow. This leads to higher production volumes or lower energy consumption. Initial runs in actual operating scenarios demonstrate these characteristics impressively: For example, a Voith customer was able to increase its annual production with MatchPress by 10,000 metric tons, or by nearly 4%.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

Koehler Kehl trusts in Voith’s reliable and proven technology

The Koehler Kehl paper mill has awarded Voith the contract for the rebuild of the PM1. The aim of the rebuild is to improve the profile quality of the specialty papers produced and also increase the energy efficiency of the production line. The modifications will also allow production to be stepped up on the PM1 in the future.

![]() The PM1 has been producing carbonless paper and thermal paper since 1988. The scope of the upgrade includes the installation of a MasterJet Pro F/B headbox and modification conversion of the approach flow system.

The PM1 has been producing carbonless paper and thermal paper since 1988. The scope of the upgrade includes the installation of a MasterJet Pro F/B headbox and modification conversion of the approach flow system.

The MasterJet Pro F/B will be fitted with ModuleJet dilution water technology to achieve optimum basis weight profiles. It is also equipped with lamella technology for optimum jet quality and an EdgeModule as an effective tool for fast optimization of fiber orientation in the event of grade changes or large differences in grammages.

The proven OnQ Profilmatic CD profile controller, which is already operating on the PM1’s DynaCoat coater, is used to achieve better basis weight profiles and minimal settling times in the case of grade changes.

On the MasterJet Pro F/B, energy is saved for example due to the absence of the return pipe on the cross-flow header of the HC line. This reduces the volume flow to the headbox, so that less pump energy is required.

The rebuild in the approach flow system comprises the supply of an IntegraGuard screen for both main and dilution water line. The IntegraGuard screen is setting benchmarks for minimal pressure pulsations with maximum screening efficiency. This is primarily the result of the proven combination of C-bar screen basket and Multifoil rotor. The conical, eccentric housing ensures that there are no deposits or strings.

Additional energy is saved thanks to the optimized flow concept in IntegraGuard with minimal pressure losses and the switch to a two-stage screening process in the modified approach flow system. Moreover, pulsation measurements in the approach flow system conducted by Voith have shown that in combination with the low-pulsation IntegraGuard screen, there is no need for a pulsation damper in front of the headbox.

The investment in the rebuild of the PM1 therefore helps ensure that the production facility in Kehl for carbonless paper and thermal paper continues to be one of the most modern and economic paper machines of its kind.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.