Ian Melin-Jones

VanHoutom News Flash - New shareholder assures continuity

Widespread recognition of our outstanding market position in the area of Corporate Social Responsibility, as evidenced by the prizes and certificates we have been awarded, has led to a new shareholder investing in Van Houtum. Private equity firm Friesland Bank Investments (FBI) has purchased a majority shareholding in Van Houtum, effective retroactively from 1 January 2011. The other shares remain in the hands of the management.

FBI is a wholly owned subsidiary of Friesland Bank N.V. and its mission is to invest in medium-sized Dutch businesses that are led by strong and ambitious management. Each investment is based on a clear strategy that is endorsed by both management and the shareholders. FBI is an active shareholder that supports management in implementing that strategy without getting actively involved in operations. FBI’s strategic plan perfectly matches the ideas and goals of Van Houtum’s management.

FBI’s investment will make it possible for Van Houtum to continue to grow in the future. A new paper machine will be purchased in the near future. This resolves a longstanding need for greater and high quality production capacity. Installation of the new paper machine will allow Van Houtum to significantly scale up the production of Satino Black in particular, the first and only Cradle to Cradle certified hygienic paper in the world. This step will substantially increase the share of the world’s first environmentally friendly toilet and hand towel paper in Van Houtum’s total production, thereby confirming once again Van Houtum’s position as a leading proponent of Corporate Social Responsibility.

This change in the shareholding structure not only creates a solid financial base for Van Houtum, it also ensures operational management continuity. Henk van Houtum will transfer his current responsibilities to Bas Gehlen during the coming two years. Afterwards Henk van Houtum will remain involved in the company.

M-real divests the Hallein Pulp mill in Austria to Schweighofer Group

M-real Oyj, part of Metsäliitto, has signed an agreement to divest the entire share capital in M-real Hallein GmbH to the Schweighofer Group. M-real Hallein GmbH assets consist of the Hallein pulp mill, bioenergy plant, paper mill closed in 2009 and the surrounding estate. The pulp mills annual capacity is approximately 160,000 tonnes of sulphite pulp and the amount of personnel is approximately 200. The debt-free value of the transaction is approximately EUR 34 million and the positive cash impact for M-real approximately EUR 24 million.

The divestment is expected to reduce M-real’s annual sales by approximately EUR 75 million and improve the operating result by approximately EUR 5 million based on Hallein mill’s actual performance in 2010.

“M-real is focusing on cartonboard business and this transaction is a good example of our work to divest the non-core assets. M-real does not use pulp from Hallein in its own board or paper operations and the profitability of the mill as a market pulp supplier has not met our targets. This is a good solution also for the mill as the new owner is in a better position to develop the operation further”, says Mikko Helander, CEO of M-real.

The transaction is subject to the approval of Austrian competition authorities and it is expected to be closed during 3Q 2011. M-real continues to sell Hallein pulp volumes to the market during 12-15 months following closing until the new owner has established their own sales organization and systems.

As a result of the transaction, M-real will classify Hallein according to IFRS 5 as Asset Held for Sale and recognizes it to its fair value. Market Pulp and Energy business area’s 2Q 2011 operating result is expected to include an approximately EUR 50 million negative non-recurring item.

The Schweighofer Group is a family owned, Austrian based holding company with companies in different branches and countries. The main focus of the group is forest industry.

Aikawa gathers forces to give papermakers a choice in stock preparation solutions

New organization under a single brand is driven by customer requests for alternatives to avoid being “boxed in” for key technologies

For many years, Aikawa Iron Works worked quietly to build its foundation as a premier supplier of stock preparation technologies in Japan. Its acquisitions of specialist companies such as AFT Screen Plates of Canada, Finebar of the USA, and POM Technology of Finland were conducted with little fanfare.

“Perhaps we have operated under-the-radar,” admits Masaki Aikawa, Chairman of the Aikawa Group. “But that has been our style. We put performance ahead of self-promotion.”

In pursuit of higher performance and recognition, the Aikawa Group is announcing a name change and a new, consolidated global organization. “This is in response to our customers’ requests,” Aikawa admits. “They want alternatives to the packaged offerings of the ‘Big Box’ major suppliers. They prefer the freedom to select the best single equipment, with the expertise to put systems together when required.”

The new organization is being consolidated outside of Japan under the umbrella of Aikawa Fiber Technologies (AFT), which is guided by Michael Stephens, President and a 35-year veteran of the pulp and paper industry.

Stephens says that AFT is being structured into teams to serve the three major customer groups for Aikawa outside Japan: screen manufacturers (original equipment manufacturers) who contract with AFT for manufacturing of screen cylinders, plates, and rotors; mills who order these engineered wear parts directly from the company; and mills looking for technical solutions for fiber processing, stock preparation, and machine approach applications.

“Each of these customer groups has unique needs that often times are addressed separately,” Stephens says. “But there are also occasions where customers need solutions that cross over from capital equipment to engineered wear parts to process/systems knowledge. When this happens, we don’t want to confuse our customers with separate interfaces or separate companies with different ways of working.”

According to Stephens, in the contract manufacturing segment, AFT produces more screen cylinders than any manufacturer in the world. Stephens explains, “Most of the OEMs are customers of ours and we give them preferred pricing based on volume. The focus here is on high-precision, low-cost manufacturing that is private-labeled for OEMs.”

The fiber processing and stock preparation solutions are a combination of Aikawa technologies and the technologies of the former POM Technology Oy of Finland, which Aikawa acquired. POM has a patented compact wet end technology for paper machines. Timo Koivisto, formerly the head of POM Technology, is responsible for AFT’s Process/Equipment Solutions team.

The transition from separate companies to a unified AFT organization is currently underway and will be completed by year’s end, according to Stephens. Key management decisions will be announced in the near future.

M-real divests its Myllykoski Paper holding to UPM

M-real Corporation, a part of Metsäliitto Group, has entered into an agreement to divest to UPM-Kymmene Corporation its 35% holding in Myllykoski Paper and the capital loan M-real has granted to Myllykoski Paper. Consequently M-real books in its 2Q 2011 result before taxes a EUR 4 million impairment. M-real will classify the Myllykoski-holding according to IFRS5 as Assets Held for Sale and recognizes it to its fair value. The transaction has a EUR 10.5 million positive cash impact.

This transaction is subject to the closing of UPM’s acquisition of Myllykoski Group and Rhein Papier and requires competition law clearance. The transaction is expected to be closed during the 3Q 2011.

SCA acquires 50 percent of Turkish hygiene products company

SCA is acquiring 50 percent of the Turkish hygiene products company Komili from Yıldız Holding, which is the largest food group in Turkey. The purchase consideration corresponds to SEK 308m on a debt-free basis.

Komili is currently the fourth largest producer of baby diapers and feminine care products in Turkey, and the company also has operations in associated product areas such as wet wipes, soaps and shampoos. Komili will operate as a joint venture between SCA and Yıldız Holding.

The acquisition includes local production and access to a strong distribution network in the country. Komili’s annual sales are approximately SEK 530m.

“The acquisition will enable us to establish powerful hygiene products operations in Turkey in the fields of baby diapers and feminine care products. The business will also provide us with a platform for our incontinence care products in a key growth market with 70 million inhabitants and a fast-growing population,” says Jan Johansson, President and CEO of SCA.

The transaction is expected to be finalised during the third quarter of the current year, following approval from the authorities concerned.

Metso continues to strengthen its service network - New Metso Service Center at Gainneville, France

Metso has opened a new Metso Service Center in France, at Gainneville in the Normandy area. The new center, which covers 500 square meters of workshop, storage, training and office space, will further enhance  Metso’s service support for local valve customers.

Metso’s service support for local valve customers.

Besides traditional valve maintenance services, Metso Service Centers offer value-added services, such as Criticality Analysis, Valve HealthChecks and Valve Management Solutions. Customer-specific predictive and preventive maintenance programs are also part of the offering at the Gainneville service center.

As in all Metso Service Centers, all repair and overhaul work is carried out according to Metso-defined service procedures, and products leave with certification and a standard warranty.

The Metso Service Centers follow quality and environmental procedures according to ISO9001 and ISO14000- All service personnel at the French service center are ATEX certified. The Metso Service Center at Gainneville will be MASE certified during 2012.

31 service centers globally for valve maintenance

Metso’s strategy is to offer knowledge-based services close to customers’ premises, so its global service network is continuously growing. Today, Metso has 31 service centers globally to safeguard customers’ valve maintenance. Globally, Metso has signed more than 70 Valve Management Agreements with its customers.

Infrared dryers from Compact Engineering double laminator speed at James Cropper Converting Ltd.

James Cropper Converting Ltd, part of James Cropper Plc, the Cumbrian papermakers have invested in a new drying system from Compact Engineering to increase the speed of the laminator at their Burneside, Kendal mill.

Compact have a great deal of expertise and experience in drying heavyweight sheets and understand exactly how to get the water out of the sheet without over drying it or scorching the surface. Based on this  experience, James Cropper Converting Ltd had little hesitation in placing an order for the supply of one of Compact’s special laminator dryers to double the existing machine speed.

experience, James Cropper Converting Ltd had little hesitation in placing an order for the supply of one of Compact’s special laminator dryers to double the existing machine speed.

The customers of James Cropper Converting Ltd are particular about the appearance and quality of the final sheet. This is because some of the laminated sheets are used for point of sale displays and mounting boards and as such are subject to the scrutiny of many a passing eye and the quality of the board conveys an unspoken message about the quality of the products being promoted.

The system delivered by Compact Engineering had to meet certain criteria in addition to the efficiency of the drying operation. The infrared dryers had to be installed so that they had the minimum impression on the existing machine footprint while still catering for the fact that the machine is fed by hand, ruling out the possibility of extending the sheet run vertically above the factory floor.

When the dryers were commissioned at the end of April, the infrared was turned on to its lowest setting to start and the laminator was run at its normal operating speed and a check of the sheet moisture made. The sheet was too dry, so the laminator speed had to be increased. Both the laminator speed and the power from the infrared were increased until the drive limit on the laminator was reached, about twice the normal operating speed.

The infrared has additional capacity available should the machine drive be upgraded at some time in the future.

James Cropper Converting Ltd laminate a very wide range of basis weights and colours, both of which have an influence on the drying rate when using infrared as a heat source. The flexibility and unique wavelength of the infrared dryers from Compact Engineering means that they are able to cope with the extremes of colour and weight presented to them, while delivering the desired dryness at the dry end of the process.

Compact Engineering makes a wide range of dryers for papermakers and converters from edge dryers to high-intensity Corona dryers for full width CD moisture profile control and Titan dryers for energy efficient coating drying. All of Compact’s dryers are engineered to fit seamlessly into the existing process.

Canfor Pulp invests $10M in Innovation

Joe Nemeth, President and CEO of Canfor Pulp Products Inc. which owns 49.8% of Canfor Pulp Limited Partnership, has announced three major new investments in innovation for the company in a ceremony opening the new Canfor Pulp Innovation Centre in Burnaby, BC.

Noting that CPLP is the largest producer of market kraft pulp in British Columbia, and the third largest in the world, Mr. Nemeth stated that “Innovation is the cornerstone of globally successful companies. This major investment of more than $10 million is aimed at securing our future as a global leader in pulp.”

The Canfor Pulp Innovation Centre will have an annual operating budget of $2 million and a laboratory of 6,400 square feet. Its staff of nine technical professionals will perform research on a host of challenges and opportunities important to CPLP. Key equipment items in the Centre are a pilot refiner for simulating paper mill treatment of pulps, and extensive, advanced technical instruments for testing pulp and paper.

Complementing CPLP’s in-house research, Mr. Nemeth also announced the company’s commitment to a new research grant program: a collaboration between CPLP and the University of British Columbia and the University of Northern British Columbia. The program will provide a total of $225 thousand over the next three years to university faculty for novel research projects in areas relevant to CPLP’s mandate. “We want to encourage the wealth of academic talent at UBC and UNBC to dedicate renewed efforts and enthusiasm toward the manufacture and development of products from our forest resource, and thereby contribute to the future of one of the largest and most consistent contributors to provincial GDP”, said Mr. Nemeth.

The third initiative is a set of partnerships with government in collaboration with equipment suppliers to implement advanced sensing technology in all three of CPLP’s Prince George mills. CPLP’s investment of $8 million in these technologies will include the Metso Quality Vision System, the Eurocon PulpEye and two sensors developed by FPInnovations in Vancouver. The FPInnovations sensors consist of a patented fibre wall thickness measurement sensor and a specialized wood chip sensor. This comprehensive initiative in sensing technology is supported by matching funding of $2.4 million from Natural Resources Canada and $2.1 million from the BC Ministry of Forests, Mines and Lands. It will provide CPLP with unique capabilities for monitoring the quality of its fibres on-line and thereby provide information to adjust operations and maximize pulp value recovery from the sawmill-produced wood chips it uses.

Representatives from the beneficiaries of CPLP’s research grant program praised these initiatives. Professor Gail Fondhal, Vice President, Research of UNBC in Prince George lauded the grants program saying, “We welcome this contribution as it supports our growing research programs and builds closer links with CPLP whose mills are within view of our campus.” Similarly, Professor Tyseer Aboulnasr, Dean of Applied Science at UBC commended CPLP’s commitment to innovation and in particular, “This valuable University program will enhance and continue UBC’s longstanding link with the industry through our Pulp and Paper Centre.” The program complements existing CPLP initiatives and others currently under development with various universities across Canada.

In closing, Mr. Nemeth noted that CPLP employs 1,200 people in BC and annually produces pulp and paper products worth $1 billion. “Our pulps and papers are recognized around the world as premium products. To remain competitive in a changing marketplace, we must be at the forefront of technologies that affect the production and optimal end-use of our pulps. These innovation initiatives are important steps to accomplish this.”

Excellent Runnabilty at Bollore Leman PM4 after the press and slalom section optimization by EV Group

EV Group has delivered stabilizing technology to Bolloré Thin Papers Léman mill, PM 4 in France.

EV Group has delivered stabilizing technology to Bolloré Thin Papers Léman mill, PM 4 in France.

The delivery included EVp Web Stabilizer for the press section and 2 pcs of EVsf2 Web Stabilizers for the first single felted group.

PM 4 produces cigarette paper and fine paper, light grades 14 - 60 g/m2 at speed of 650 m/min and the width of the PM is 3,2 m.

Mr. Stéphane Barbereau, Industry Director of Bolloré Thin Papers:

“I am very satisfied with the installation of the EV Web Stabilizers. After their installation we never had any sheet fluttering problems even though we produce ultra thin papers as low as 14 g/m2. EV Web Stabilizers do not need particular attention and they are very easy to use.

I appreciate the professional work of EVG personnel as well as the quality and solidity of their equipment.”

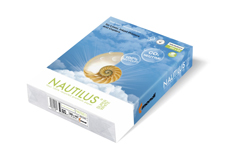

Mondi receives HP Indigo SPP certification for NAUTILUS® SuperWhite and NAUTILUS® Universal

Mondi’s NAUTILUS® SuperWhite and NAUTILUS® Universal can add perfect runnability and excellent blanket compatibility to their current list of accreditations since obtaining HP Indigo’s SPP certification.  NAUTILUS®’s exceptional environmental profile, which cumulatively includes the EU Ecolabel, Blue Angel certification and a CO2 Neutral option, assures printers that these papers cause less harm to the environment – and their machines – as excellent runnability considerably decreases printer wear and premature maintenance.

NAUTILUS®’s exceptional environmental profile, which cumulatively includes the EU Ecolabel, Blue Angel certification and a CO2 Neutral option, assures printers that these papers cause less harm to the environment – and their machines – as excellent runnability considerably decreases printer wear and premature maintenance.

The HP Indigo SPP certification applies to uncoated products which have no primer surface treatment. The criteria for SPP certification is based heavily on the runnability and blanket compatibility of paper. In these areas, both NAUTILUS® SuperWhite and NAUTILUS® Universal received the best possible rating — three stars. HP Indigo SPP certification is a significant benchmark for light colour and monochrome printing, key factors to consider in industries like publishing and such applications as transactional invoicing. Moreover, there is a cost advantage for customers who want the reassurance of a quality guarantee from a reputable OEM (original equipment manufacturer) for an unprimed paper.

NAUTILUS® SuperWhite and NAUTILUS® Universal are ideal for book- and magazine-printing and for transactional material, like standard invoices and statement. Offering a wide range of certified grammages, NAUTILUS® SuperWhite received a 3-star rating for blanket compatibility and runnablitiy on grammages between 70-250 gsm. NAUTILUS® Universal is 3-star certified on grammages between 80-250 gsm. Both products are available in the typical HP Indigo formats, 32 x 46 cm and 46 x 32 cm.

NAUTILUS® SuperWhite and NAUTILUS® Universal are ideal for book- and magazine-printing and for transactional material, like standard invoices and statement. Offering a wide range of certified grammages, NAUTILUS® SuperWhite received a 3-star rating for blanket compatibility and runnablitiy on grammages between 70-250 gsm. NAUTILUS® Universal is 3-star certified on grammages between 80-250 gsm. Both products are available in the typical HP Indigo formats, 32 x 46 cm and 46 x 32 cm.

In 2010, NAUTILUS® SuperWhite became available with a CO2 neutral option. It is also produced with FSC® recycled fibre and is EU Ecolabel certified. In addition to having the EU Ecolabel, NAUTILUS® Universal is Blue Angel certified.