Ian Melin-Jones

Aikawa honored with Sasaki Award from Japan TAPPI

Prestigious award presented annually to most outstanding technology development

Aikawa Iron Works, headquartered in Japan, was awarded the prestigious Sasaki Award for its developments of FINEBAR® refiner plate technology. The Sasaki prize is given once a year to the company demonstrating the most outstanding technology development.

Shinichiro Kondo, Chairman of the Board of Japan TAPPI, presented the award to Takeshi Kanazawa, Director Vice President of Aikawa Iron Works, at a ceremony on May 26, 2011.

In presenting the award, Aikawa was cited for “developing a refiner plate that not only saves refiner energy, but also improves paper strength and refiner plate life. This has contributed to the development of the industry’s refining technology and has also made a great contribution to the Japanese pulp and paper industry.”

The FINEBAR® patented design is manufactured using precise techniques which achieve extremely thin bars and fine grooves. The result is the ability to refine fibers in low-consistency applications with ultra-low intensity – saving energy and enhancing paper qualities.

FINEBAR® plates are manufactured, marketed, and supported outside of Japan by Aikawa’s subsidiary, AFT.

Metso to rebuild M-real’s board machines at Kyro and Äänekoski mills in Finland

Metso will rebuild two board machines for M-real in Finland: the BM 1 cartonboard machine at the Kyro mill and the BM 1 cartonboard machine at the Äänekoski mill. The start-up of the rebuilt Kyro BM 1 machine is scheduled for the fourth quarter of 2011 and that of the rebuilt Äänekoski BM 1 machine for the second quarter of 2012. The combined value of the orders is over EUR 15 million.

Metso's delivery to the Kyro mill will include a rebuild of the press, dryer and coating sections. In a coating drying rebuild, new energy-efficient high-drying-capacity PowerDry Plus air dryers will be added both to increase drying capacity and to replace old gas infrared dryers. The Kyro BM 1 produces folding boxboard in the basis weight range of 200 to 370 g/m2. After the rebuild, the annual board capacity of the Kyro mill will increase to approximately 190,000 tonnes.

Metso’s delivery to the Äänekoski mill will include a rebuild of the headbox, the coating section and the reel including an automatic parent roll transfer system to the new winder. A new ValFlo headbox and a new WinDrum two-drum winder will aim at capacity increase. The Äänekoski BM 1 produces folding boxboard in the basis weight range of 185 to 360 g/m2. After the rebuild, the annual board capacity of the Äänekoski mill will increase to approximately 240,000 tonnes.

M-real is Europe’s leading primary fiber paperboard producer and a major paper supplier. The company’s customers include brand owners, carton printers, converters, publishers, printing houses, merchants and office product suppliers. In 2010, the company’s sales totaled EUR 2.6 billion, and it has approximately 4,500 employees. M-real is part of the Metsäliitto Group.

Significant energy savings and more production in Arjowiggins Dalum, PM7 after EV Drying section optimization project

Before ventilation rebuild, Dalum PM 7 suffered from several problems. Firstly, the hood humidity level was very high. Condensation in the hood caused corrosion in the drying section and hood constructions, and falling water drops led to paper defects.

Secondly, the pocket humidities were very high, which was causing uneven moisture profiles, poor evaporation and loss of drying capacity.

All these ventilation problems resulted in massive heating energy and production losses.

The ventilation project included modern heat recovery, hood exhaust units, condensate and steam coils, supply air fans, pocket ventilation technology and web stabilizing technology. Survey services for the PM 7 problems analysis and action plan as well as all different project phases were performed by EVG.

“Now 65% of the PM7 heating energy is recovered for district heating and hood supply air year round. Also the PM 7 speed has increased by about 20%. Our project was the biggest governmental energy saving project of Denmark in 2010.” (Mr. Claus Christiansen, Production Manager, Arjowiggins Dalum, PM7)

Metso to rebuild Hamburger-Rieger’s paper machine in Germany

Metso will supply Hamburger-Rieger GmbH & Co. KG with a rebuild of their PM 1 paper machine at their Spremberg mill in Germany. The start-up of the rebuilt machine is scheduled for the fourth quarter of 2011. The value of the order will not be disclosed.

Metso’s delivery will include a rebuild of the existing pond size press into a film size press and supply of a TurnFloat air turn as well as a PowerDry Plus air dryer for coating drying.

The new film size press with two new applicator beams will enable the mill to produce both surface sized and pigment coated papers. The applicator rolls will be provided with a CoteFalcon cover, suitable for both film coating and surface sizing. Contactless drying with the high-capacity PowerDry Plus air dryer provides the most efficient solution with respect to paper quality and energy consumption. The maximum trim width of PM 1 is 5,300 mm at a production speed of up to 1,200 m/min.

The Spremberg mill of Hamburger-Rieger has been producing white top testliner grades from 100 % waste paper since 2005.

source: Metso Pulp and Paper

EVG optimized runnability and drying section performance in Stora Enso Anjala PM2, Finland.

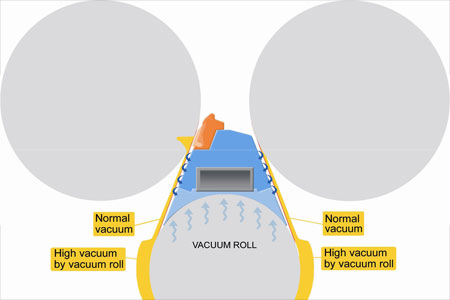

Poor runnability at Stora Enso Anjala PM2 (bookpaper) drying section created problems in higher machine speeds. In the double felted section sheet fluttering caused wrinkles. In single felted section it was impossible to increase the speed, because the web did not release nicely from contact and followed the upper cylinder surface.

The PM2 drying section runnability was optimized in two steps. In 2009, runnability problems of the double felted section were eliminated with machine geometry modification and stabilizing technology tailored for the area. In the second step, in 2010, runnability of the single felted section was optimized with the EV EasyOne technology / high vacuum stabilizing technology.

”The problems because of poor runnability are eliminated after the web stabilizing projects in single and double felted sections. We have now more stable sheet run, and the drying section runnability enables also higher speed.” (Mr. Antti Outinen, Production Manager, Stora Enso Anjala PM2)

Competence in Paper: Kelheim Fibres expands in-house Technical Centre

Kelheim Fibres, the world’s leading manufacturer of viscose specialities, has extended its in-house technical centre for paper making.

Research and development are key points for the producer of functional and tailor-made speciality fibres. The development work focuses not only on the development of new fibres but also on the potential end products made out of them.

A range of in-house pilot plants and technical equipment allow Kelheim Fibres to simulate their customers’ processes and to duplicate the properties of the end product. In this way they have been able to develop a broad understanding for the customer’s needs.

For the development of viscose fibres for speciality papers and wet laid products, Kelheim Fibres makes intensive use of its own in-house technical centre for paper production.

To meet the growing demand in this area, the technical centre has now been extended.

The new pilot plant has inclined wire technology and it is possible to process all types of fibre, pulp and – if required – to include different additives in papers with weights from 20–200g/m². The new inline dryer also enables the production of larger samples.

Using this new technical centre Kelheim Fibres is able to rapidly verify the results of the fundamental research carried out in cooperation with the Institute for Paper, Pulp and Fibre Technology at the Graz University of Technology and transform the theories developed into innovative paper products. The new Paper Competence Centre is also available for Kelheim Fibres customers′ own trial work.

Test runs on big production plants are expensive and disrupt regular production campaigns. With the new pilot plant customers can take the first steps in developing innovative papers – and engineer these new products in close cooperation with Kelheim’s R&D fibre experts.

Walki invests in Russia

Walki Group, the leading producer of technical laminates and protective packaging materials, will establish a plant in Svetogorsk, Russia, with production set to start during autumn 2011.

The investment in a new plant in western Russia, close to the Finnish border, is part of the Groups strategic plan to expand in emerging markets. The initiative will offer enhanced support to existing key customers in the Russian paper industry, as well as creating a platform for growth in other business areas.

The first phase of development will see investment to install both extrusion and printing capability in the new plant.

"This is an exciting development for Walki Group and provides an ideal platform for us to build our business in a growth region. Furthermore, we are delighted to be able to announce the creation of the new plant and to think of all the opportunities that this development will facilitate with both existing and new customers ", says Leif Frilund, President and CEO of Walki Group.

New cluster leader at The Paper Province

Maria Hollander succeeds Mats Williams as CEO of The Paper Province. Maria, who has held management positions within Tieto

and own businesses, will assume the position on August 15.

“I’m excited to lead an organization that means so much to the pulp and paper industry. I hope to contribute to The Paper Province

“I’m excited to lead an organization that means so much to the pulp and paper industry. I hope to contribute to The Paper Province

continuing being a positive force for development and growth amongst our member companies," says Maria Hollander.

Between 1995 and 2010 Maria worked at Ericsson and Tieto, including ten years as Head of Department. She has also run a couple of own businesses.

“Maria is a talented leader with high social ability and strong regional commitment. Her personal experience running small business is an advantage as

there is great potential among our small and medium-sized member companies. Therefore, we are very pleased to welcome Maria to the Paper Province”

says Per Bjurbom, president of The Paper Province.

World-class cluster

The Paper Province was initiated in 1999 and is a cluster organisation for the pulp and paper industry in the Swedish region of Värmland and surrounding areas.

The cluster organisation is owned and managed by some 90 member companies active in more than 100 countries. The Paper Province supports the development of innovative forms of collaboration that improve competitive strength and increase growth within the pulp and paper industry.

The Paper Province is home to major machinery and process system suppliers such as Metso, Andritz, GL&V, Voith and BTG, as well as technology and IT consultants such as ÅF, Pöyry, Citec, Sogeti and Tieto. There are also paper mills and packaging production units operated by Stora Enso, Billerud, Rottneros, Nordic Paper, Tetra Pak and Mondi, alongside an extensive network of suppliers and contractors.

Recently the European Cluster Observatory, monitoring European cluster on behalf of the European Commission, identified The Paper Province as a world-class cluster.

International Paper's Board of Directors Elects Joan E. Spero to Its Board

International Paper Company announced the election of Joan E. Spero, Ph.D., to its board of directors effective today.

"Joan's experience as a business and foundation executive, a corporate board member and in government service lends a unique perspective to our board of directors," said John Faraci, Chairman and CEO. "We are very pleased to welcome her today."

Ms. Spero served in the U.S. Department of State as Undersecretary for Economic, Business and Agricultural Affairs and as Ambassador to the United Nations for Economic and Social Affairs. She has held leadership positions in Corporate Strategy and Corporate Affairs over a span of 12 years at American Express, and from 1997 to 2008, she served as President of the Doris Duke Charitable Foundation. Ms. Spero is currently a Senior Research Scholar at Columbia University's School of International and Public Affairs.

Previously, Ms. Spero served on the board of directors of ING Groep N.V., Delta Air Lines Inc., and First Data Corporation. She is a member of IBM's board of directors, a Trustee of both the Council on Foreign Relations and the Wisconsin Alumni Research Foundation, and a Trustee Emeritus of Columbia University and Amherst College. Ms. Spero earned a masters degree and a doctorate from Columbia University.

SOURCE International Paper Company

Metso to deliver world’s largest biomass gasification plant to Vaskiluodon Voima in Vaasa

Metso will supply Vaskiluodon Voima Oy in Vaasa, Finland, with a 140-megawatt bio-gasification plant. Vaskiluodon Voima’s total investment is about 40 million euros, over half of which is attributable to Metso’s delivery. The bio-gasification plant is scheduled for commissioning in December 2012. Metso’s full-scope solution includes fuel handling, a drying plant and a circulating fluidized bed gasifier, modification work on the existing coal boiler, and automation and IT systems.

The bio-gasification plant will be constructed as part of the existing coal-fired power plant. The plant will be fueled primarily with wood-based biomasses, particularly forest residue, and the produced gas will be combusted along with coal in the coal boiler. The delivery includes the drying plant where biomass will be dried to the proper level for gasification. As a result of the new solution, close to 25-40 percent of the coal can be replaced with renewable energy, which will reduce carbon dioxide emissions by about 230,000 tons per year. This is the first time in the world that biomass gasification is being adopted on such a large scale.

”Metso has a great opportunity to offer a solution that includes biomass drying technology and gasification. This provides the possibility for a diverse range of biofuels and a significant share of biomass in the combustion process. At the same time, our cost- and eco-efficient solution provides an opportunity to significantly increase the use of biofuel. The size class of the delivery makes this delivery interesting to large coal-fired power plants around the world,” explains Juhani Isaksson, Metso’s Manager responsible for gasifiers and pyrolysis systems.

”The fact that Metso is a full-scope supplier of bio-gasification plants and is capable of combining the power plant process, biomass drying, modification of the existing coal boiler, and the automation into a functional and competitive package supported the decision to start collaboration with Metso. A significant advantage of Metso’s gasification solution is the diversity of the fuel selection; it gives us flexibility in acquiring biomass,” says Mauri Blomberg, Managing Director, Vaskiluodon Voima.

Vaskiluodon Voima Oy is a power and heat production company equally owned by EPV Energia Oy and Pohjolan Voima Oy. EPV Energia Oy is a Finnish company specializing in power and heat production and procurements, and its domicile is Vaasa, Finland. Pohjolan Voima Oy is a national energy company; its main products are power and heat.

Technical information

Metso’s delivery to Vaskiluodon Voima is a full-scope solution that includes biomass reception, pre-handling, a large-scale KUVO dryer and a circulating fluidized bed gasifier, the modification work for the existing coal boiler plant, and the electrification and automation for the entire delivery. The order is included in Metso’s Energy and Environmental Technology’s Q2/2011 orders received. The automation delivery includes the automation and IT systems for the gasifier and the fuel handling integrated with the existing Metso DNA system, and adjustments to the existing coal boiler. Vaskiluodon Voima’s current coal boiler was also supplied by Metso.