Ianadmin

Koehler Kehl trusts in Voith’s reliable and proven technology

The Koehler Kehl paper mill has awarded Voith the contract for the rebuild of the PM1. The aim of the rebuild is to improve the profile quality of the specialty papers produced and also increase the energy efficiency of the production line. The modifications will also allow production to be stepped up on the PM1 in the future.

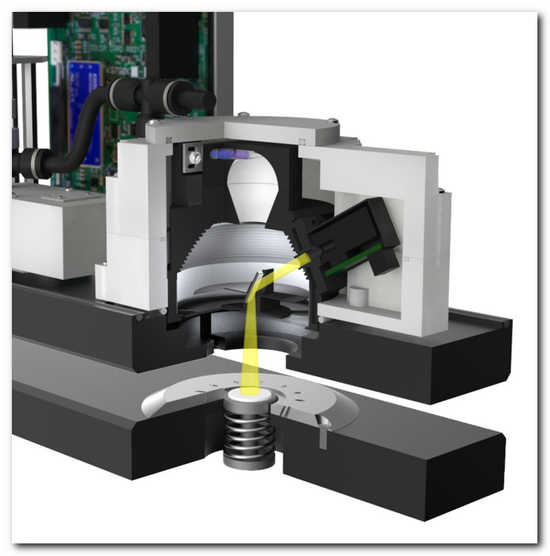

![]() The PM1 has been producing carbonless paper and thermal paper since 1988. The scope of the upgrade includes the installation of a MasterJet Pro F/B headbox and modification conversion of the approach flow system.

The PM1 has been producing carbonless paper and thermal paper since 1988. The scope of the upgrade includes the installation of a MasterJet Pro F/B headbox and modification conversion of the approach flow system.

The MasterJet Pro F/B will be fitted with ModuleJet dilution water technology to achieve optimum basis weight profiles. It is also equipped with lamella technology for optimum jet quality and an EdgeModule as an effective tool for fast optimization of fiber orientation in the event of grade changes or large differences in grammages.

The proven OnQ Profilmatic CD profile controller, which is already operating on the PM1’s DynaCoat coater, is used to achieve better basis weight profiles and minimal settling times in the case of grade changes.

On the MasterJet Pro F/B, energy is saved for example due to the absence of the return pipe on the cross-flow header of the HC line. This reduces the volume flow to the headbox, so that less pump energy is required.

The rebuild in the approach flow system comprises the supply of an IntegraGuard screen for both main and dilution water line. The IntegraGuard screen is setting benchmarks for minimal pressure pulsations with maximum screening efficiency. This is primarily the result of the proven combination of C-bar screen basket and Multifoil rotor. The conical, eccentric housing ensures that there are no deposits or strings.

Additional energy is saved thanks to the optimized flow concept in IntegraGuard with minimal pressure losses and the switch to a two-stage screening process in the modified approach flow system. Moreover, pulsation measurements in the approach flow system conducted by Voith have shown that in combination with the low-pulsation IntegraGuard screen, there is no need for a pulsation damper in front of the headbox.

The investment in the rebuild of the PM1 therefore helps ensure that the production facility in Kehl for carbonless paper and thermal paper continues to be one of the most modern and economic paper machines of its kind.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

New LED-based color sensor improves measurement accuracy during paper and board production

Discrete light emitting diodes (LEDs) provide continuous on-line color measurement for more accurate paper web analysis, at a lower cost of ownership

ABB High Performance Color Measurement is a completely new sensor design that incorporates LED technology for superior on-line measurements of color, brightness, florescence, opacity and whiteness.

Capable of taking up to 60 measurements per second from the moving web, the sensor offers greater accuracy with lower short-term variability. With more frequent and continuous measurement, paper manufacturers benefit from increased precision leading to more consistent color and improved final product quality. The sensor enables manufacturers to precisely control color while minimizing off-specification production and improving shade consistency as well as reducing the use of expensive fluorescent whitening agents, dye and pigments.

By replacing traditional Xenon and Halogen illumination sources, the LEDs modulate between UV-included and UV-excluded illumination at high speed and without the use of filters. This enables continuous UV-corrected color measurements, reducing color variation, and improving laboratory correlation. LEDs also provide a stable and repeatable illumination leading to better measurement stability.

The sensor features a compact modular design and has no moving parts in the measurement module, thereby enhancing its reliability with lower maintenance and lifecycle costs. It can be applied the top or bottom of the web, or to both sides.

High-Performance Color Measurement is designed for a quick and easy upgrade path. The new measurement module can replace ABB Smart Color sensors in existing ABB QCS systems as part of ABB’s stepwise evolution options for ABB QCS systems.

ABB (http://www.abb.com) is a leading global technology company in power and automation that enables utility, industry, and transport & infrastructure customers to improve their performance while lowering environmental impact. The ABB Group of companies operates in roughly 100 countries and employs about 135,000 people.

For more information please contact:

Gunvor Latva

Communications, Pulp & Paper Solutions

ABB AB / Lorentzen & Wettre

Phone: +46 8 477 90 00

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

UPM sells its Schwedt mill to LEIPA Georg Leinfelder GmbH

UPM has signed an agreement to sell its Schwedt newsprint mill site and relevant assets to LEIPA Georg Leinfelder GmbH for the aim of a conversion into liner production. The entire personnel of Schwedt mill will transfer to LEIPA as old employees. The transaction price is EUR 70 million. The transaction is subject to customary third party approvals.

UPM has signed an agreement to sell its Schwedt newsprint mill site and relevant assets to LEIPA Georg Leinfelder GmbH for the aim of a conversion into liner production. The entire personnel of Schwedt mill will transfer to LEIPA as old employees. The transaction price is EUR 70 million. The transaction is subject to customary third party approvals.

As part of the transaction, the parties have agreed to enter into a contract manufacturing agreement for newsprint for a transition period which would end latest at the end of 2017. The mill's capacity is 280,000 tonnes of newsprint annually.

LEIPA will convert the mill into liner production. The planned production capacity would be approximately 450,000 tonnes of liner annually.

"With this transaction UPM and LEIPA will have an improved opportunity to develop their businesses to meet the market needs. LEIPA is a solid and successful player in the liner business," says Winfried Schaur, Executive Vice President, UPM Paper ENA.

"The negotiations with LEIPA have proceeded well and we believe that the transaction will bring benefits to the employees in the form of future employment at a converted site," says Schaur.

UPM continues newsprint production at its Chapelle, Kaipola, Hürth, Schongau, Shotton and Steyrermühl mills.

About UPM Schwedt

UPM Schwedt manufactures standard newsprint with the annual capacity of 280,000 tonnes. Located in the Eastern part of Germany the mill employs about 240 people.

About UPM Paper ENA

UPM Paper ENA (Europe & North America) is the world's leading producer of graphic papers, serving customers in Magazine Publishing & Advertising, Merchants, Home & Office, and Newspaper Publishing. A leader in sustainable and high performance papers, UPM Paper ENA's production is located in Finland, Germany, the United Kingdom, France, Austria, and the United States. With headquarters in Germany, UPM Paper ENA employs approximately 9,500 people. To learn more about UPM Paper ENA visit: www.upmpaper.com

About UPM

Through the renewing of the bio and forest industries, UPM is building a sustainable future across six business areas: UPM Biorefining, UPM Energy, UPM Raflatac, UPM Paper Asia, UPM Paper ENA and UPM Plywood. Our products are made of renewable raw materials and are recyclable. We serve our customers worldwide. The group employs around 19,600 people and its annual sales are approximately € 10 billion. UPM shares are listed on NASDAQ OMX Helsinki. UPM - The Biofore Company - www.upm.com

About LEIPA

LEIPA Georg Leinfelder GmbH is part of the LEIPA GROUP. Currently the LEIPA group of companies produces approximately 900,000 tons of graphic paper and packaging paper per year at its Schwedt and Schrobenhausen locations, based on sustainable and environmentally friendly production processes.

In 2014, the family-run medium-sized enterprise with 1,450 members of staff generated consolidated sales of approximately EUR 650 million. www.leipa.de

Xerium Announces New Rolls & Services Plant in Concepción, Chile

Xerium Technologies, Inc. (NYSE:XRM), a leading global provider of industrial consumable products and services, announced plans to establish a new roll cover and mechanical services facility located in Concepción, Chile. The Company is continuing to reposition assets from low-growth to high-growth markets. This new project is very capital efficient in that the Company already owns the majority of the equipment that will be installed in the new Concepción plant. The remaining spend will cross 2 calendar years and is already included in the capex guidance previously given by the Company.

Xerium's facility will be the first major rolls and service facility established in Concepción, Chile, by any of the industry's major global suppliers. From this location, Xerium will be able to provide regional customers with dramatically quicker and more cost effective service. Importantly, these products and services will be delivered through a local workforce familiar and respectful of local customs.

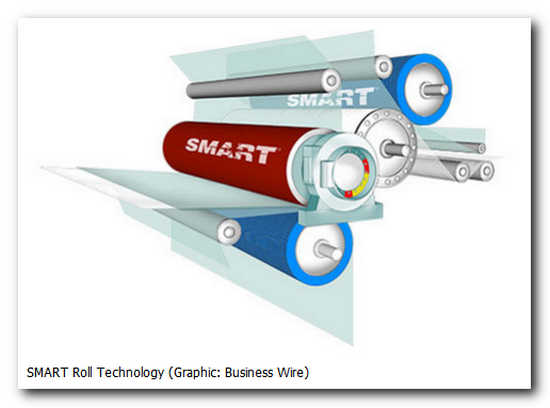

The facility will be state-of-the art and is expected to be fully in production Q2 2017. From this strategic geographic location, Xerium will provide its full suite of patented, performance-enhancing roll solutions to customers in the surrounding region. Xerium will perform roll grinding, roll recovering and mechanical services on site. Xerium is also increasing its field sales and service staff for the region for machine clothing, roll services, mechanical services and machine automation through its SMART® roll sensor solutions.

The facility will contain state-of-the-art rolls and service machines. Xerium will transfer all of its best practices and all of its global patented technology solutions to the region. The plant will also have state-of-the-art information systems and supply chain interfaces. This new facility will serve customers in Chile, Peru, Ecuador and Colombia.

This new operation will be under the regional direction of Mr. Eduardo Fracasso, President of Latin America. The Concepción, Chile greenfield implementation will be led by Luis Vitti; Project Manager. Luis has been with Xerium for 32+ years and brings significant leadership and customer focused expertise to this role.

Harold Bevis, President and CEO of Xerium Technologies, Inc., said, “For the first time ever, customers in the immediate Chilean region will receive locally provided & locally optimized state-of-the-art rubber extrusion technology. The Chile plant will be able to service large rolls from any industry or application.”

Mr. Bevis continued, “The commercial objective is to provide machine optimization solutions with world-class technology, short lead times, and a local cost structure. The customers in the region deserve this world-class approach and we are proud to provide it. Customers will immediately receive better lead times, better technology, better service and better costs. This new business start-up is part of Xerium’s investment strategy to realign its global business model and global factory locations to line up with growth markets in the world.”

ABOUT XERIUM

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 26 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,900 employees.

Xerium Technologies, Inc. (NYSE:XRM) is a leading global provider of industrial consumable products and services. Xerium, which operates around the world under a variety of brand names, utilizes a broad portfolio of patented and proprietary technologies to provide customers with tailored solutions and products integral to production, all designed to optimize performance and reduce operational costs. With 26 manufacturing facilities in 13 countries around the world, Xerium has approximately 2,900 employees.

Source: Xerium Technologies, Inc.

Kemira Oyj's Interim Report January-March 2016: Revenue and operative EBITDA growth continued

This is a summary of the January - March 2016 Interim report. The complete January - March 2016 Interim report with tables is attached to this release and available at www.kemira.com/investors.

This is a summary of the January - March 2016 Interim report. The complete January - March 2016 Interim report with tables is attached to this release and available at www.kemira.com/investors.

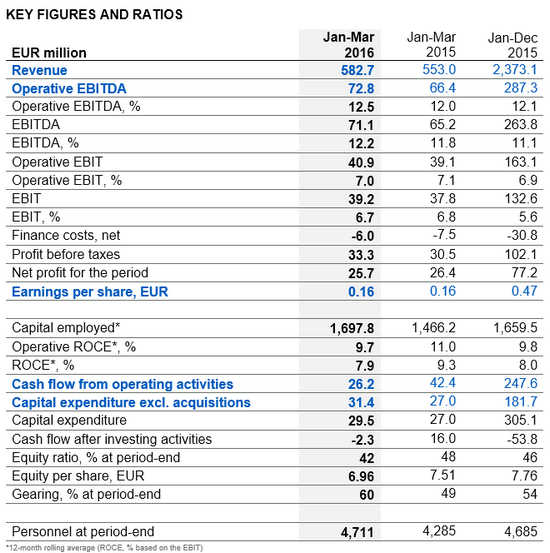

- Revenue increased 5% to EUR 582.7 million (553.0) mainly due to the acquisition of AkzoNobel's paper chemicals business. Revenue in local currencies, excluding acquisitions and divestments, decreased 2%.

- Operative EBITDA increased 10% to EUR 72.8 million (66.4) with a margin of 12.5% (12.0%).

- Earnings per share were EUR 0.16 (0.16).

- Outlook (unchanged): Kemira continues to focus on profitable growth. Kemira expects its revenue and operative EBITDA to increase in 2016 compared to 2015.

Kemira's President and CEO Jari Rosendal:

"The year started according to our expectations. The Pulp & Paper segment had a strong first quarter with revenue growth and improvement in profitability. The Municipal & Industrial segment maintained its volume growth, and the Oil & Mining segment took actions to mitigate the challenging market environment while maintaining focus on the long-term opportunities. In January-March the Group's revenue increased 5% and operative EBITDA 10%, and resulted an improved EBITDA margin of 12.5%.

In the Pulp & Paper segment, revenue in local currencies, excluding acquisitions and divestments, increased 3%. We had a very good growth in APAC and South America. The operative EBITDA margin of the segment improved for the fourth consecutive quarter to 13%. Strong demand for pulp continues and therefore the timing is excellent for the new sodium chlorate plant in Brazil, which successfully started up in March 2016. In addition, we announced in March the investment in the additional sodium chlorate capacity in Finland, which is expected to be operational during the fourth quarter of 2017.

The Oil & Mining segment continued to face a challenging market in the U.S. shale operations. However, the segment was able to improve its operative EBITDA margin from 5% to 9% compared to the fourth quarter of 2015, which is a good achievement in this market. We have taken actions to protect our existing business and have maintained discipline in cost management. We continue to invest in new applications and promising growth areas, such as Chemical Enhanced Oil Recovery.

In the Municipal & Industrial segment, the volume growth continued at 3%, while sales prices declined leading to a 1% revenue growth in local currencies, excluding acquisitions and divestments. We are overcoming the temporary cost increase in North America, which was due to the disruption caused by a closure of a supplier's site in the fourth quarter of 2015. The operative EBITDA margin improved sequentially and was almost 13%.

We continue to grow and focus on improved profitability through operational improvements, leveraging growth, and capturing synergies. After the first quarter, Kemira is on track to increase its revenue and operative EBITDA in 2016."

KEY FIGURES AND RATIOS

Definitions of key figures are available at www.kemira.com > Investors > Financial information. Comparative 2015 figures are provided in parentheses for some financial results, where appropriate. Operative EBITDA, operative EBIT and operative ROCE do not include non-recurring items.

FINANCIAL TARGETS 2017 AND OUTLOOK for 2016 (unchanged)

Kemira will continue to focus on improving its profitability and cash flow. The company will also continue to invest in order to secure future growth to serve selected water-intensive industries.

The company's financial targets for 2017 are:

- Revenue EUR 2.7 billion

- Operative EBITDA-% of revenue 15%

- Gearing level <60%.

The basis for growth is the expanding market for chemicals and Kemira's expertise that helps customers in water-intensive industries to increase their water, energy and raw material efficiency. The need to increase operational efficiency in our customer industries creates opportunities for Kemira to develop new products and services for both current and new customers. Research and Development is a critical enabler of growth for Kemira, providing differentiation capabilities in its relevant markets.

Outlook for 2016

Kemira continues to focus on profitable growth. Kemira expects its revenue and operative EBITDA to increase in 2016 compared to 2015.

Kemira expects its capital expenditure, excluding acquisitions, to be around EUR 200 million in 2016.

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Kemira Q1 2016 Interim Report Town of Jay and Verso Reach Agreement in Property Tax Dispute

The Town of Jay, Maine, and Verso Corporation (OTCPink: VRSZQ) have reached an agreement to resolve their dispute concerning property tax assessments for Verso's Androscoggin Mill.

In exchange for the Town's agreement to reduce Verso's property tax liability to more accurately reflect the assessed value of the mill property, Verso has agreed to withdraw its pending property tax appeals, and not to seek further abatements of taxes absent material changes to the mill property or operations.

In exchange for the Town's agreement to reduce Verso's property tax liability to more accurately reflect the assessed value of the mill property, Verso has agreed to withdraw its pending property tax appeals, and not to seek further abatements of taxes absent material changes to the mill property or operations.

This agreement is intended to allow both parties to achieve sustainable operations over the coming years based on changing circumstances concerning the mill's taxable value.

The reduction in the mill's property tax liability will be paid over time by the Town as credits against Verso's future tax bills.

This agreement is subject to approval by the Town's select board and the bankruptcy court overseeing the Verso bankruptcy cases.

The Town and Verso are pleased to have reached this agreement as part of a mutual effort to support the long-term viability of the Androscoggin Mill, which is an important goal of both parties.

SOURCE Verso Corporation

Asia Pulp & Paper welcomes landmark moment in EU / Indonesia trade and illegal logging controls

Asia Pulp & Paper Group (APP) welcomes the announcement by President Joko Widodo of Indonesia, European Commission President Jean-Claude Juncker and President Donald Tusk of the European Council that the European Union and Indonesia are ready to move towards the start of the first ever Forest Law Enforcement, Governance and Trade (FLEGT) licensing scheme.

The announcement is based on the joint assessment that Indonesia is fully ready to implement the Voluntary Partnership Agreement (VPA), a form of bilateral trade agreement agreed through the EU Forest Law Enforcement, Governance and Trade (FLEGT) action plan. The VPA with Indonesia aims to guarantee that any wood products exported from Indonesia to the EU comes from legal sources. Under the VPA, Indonesia developed the SVLK system to verify that its export of timber-based products are legal, and the EU agreed to accept only licensed imports from Indonesia.

The announcement is based on the joint assessment that Indonesia is fully ready to implement the Voluntary Partnership Agreement (VPA), a form of bilateral trade agreement agreed through the EU Forest Law Enforcement, Governance and Trade (FLEGT) action plan. The VPA with Indonesia aims to guarantee that any wood products exported from Indonesia to the EU comes from legal sources. Under the VPA, Indonesia developed the SVLK system to verify that its export of timber-based products are legal, and the EU agreed to accept only licensed imports from Indonesia.

A related regulation, the European Union Timber Regulation (EUTR) aims to reduce illegal logging by ensuring that no illegal timber or timber products can be sold in the EU by placing responsibility for control through due diligence on to EU businesses. The VPA once fully implemented, will enable Indonesia’s SVLK system to begin issuing V- legal licenses, enabling EU businesses to automatically demonstrate compliance with the EUTR.

The start of the FLEGT scheme represents a landmark development in the global campaign against illegal logging, an illegal trade that was recently estimated to have cost Indonesia alone close to $9 billion between 2003 and 2014. Legal Indonesian exporters will be at a significant competitive advantage over other tropical timber producing countries due to automatic compliance with the EUTR. The start of the FLEGT scheme demonstrates how global trade can be focused to both support legality and deprive illegal logging of an export market.

Commenting on this landmark development, Aida Greenbury, Managing Director Sustainability and Stakeholder Engagement said:

“APP warmly welcomes the new partnership between Indonesia and the European Union to work together on trade and sustainability, a partnership that could redefine how countries collaborate on sustainability and forest protection. For the first time, timber consumers, suppliers, civil society and NGOs and governments across the world have come together to forge a trade deal that will conserve forests that are crucial to avoiding catastrophic climate change.

The start of the FLEGT scheme is a huge opportunity and a tribute to the work of industry, policymakers and NGOs in Indonesia and in Europe. APP will continue to support the EU and Indonesian government and its sustainable economic development and trade, and will look to drive sustainable forestry practices to the highest standards.”

APP became the first Indonesian mill group to achieve full SVLK certification status in November 2012.

About Asia Pulp & Paper

Asia Pulp & Paper Group (APP) is a trade name for a group of pulp and paper manufacturing companies in Indonesia and China. APP is responsible for delivering quality products to meet the growing global demand for tissue, packaging and paper. On any given day, our products find their way into the hands of consumers in various branded forms from all over the world.

Started in 1972 with Tjiwi Kimia producing caustic soda, now we run operations across Indonesia and China with an annual combined pulp, paper, packaging product and converting capacity of over 19 million tons per annum. Today, APP markets its products in more than 120 countries across six continents.

Over the years, we have expanded our operations significantly through the acquisition and expansion of several of our pulp and paper mills. It’s our commitment to customer satisfaction that enables us to grow our share in paper sales worldwide and broaden our presence through offices in many countries. We believe ‘tradition and modernity go hand in hand’ which means we value long term relationships as part of our Eastern traditions, while we also are eager to embrace the modern values of innovation and efficiency.

Maintaining the integrity of our supply chain is also crucial to APP’s operations as well as our commitment to our Sustainability Roadmap Vision 2020. Learn more about APP’s path to operational excellence by reading our Sustainability Reports and Forest Conservation Policy. Mondi to showcase paper portfolio for professional printing at Drupa 2016

Mondi, the international packaging and paper Group, will exhibit its wide range of professional paper solutions at the Drupa fair in Düsseldorf, Germany, from 31 May to 10 June. As a one-stop paper manufacturer, Mondi offers sustainable paper solutions for all printing technologies and needs. Print industry customers will find more than they expect at the Mondi booth C21 located near the centre of hall 4.

Johannes Klumpp, marketing & sales director Mondi Uncoated Fine Paper, explains, “We can offer the right solution for any printing technology – whether digital, hybrid, offset, HP indigo or high-speed inkjet. What’s more, customers have peace of mind knowing that all Mondi papers are environmentally certified, so they have the best paper solutions combined with proven, environmentally sound production. We look forward to exhibiting at Drupa and showcasing our wide-ranging innovative paper solutions developed to meet the exacting needs of professional printers and the latest printing technologies.”

Johannes Klumpp, marketing & sales director Mondi Uncoated Fine Paper, explains, “We can offer the right solution for any printing technology – whether digital, hybrid, offset, HP indigo or high-speed inkjet. What’s more, customers have peace of mind knowing that all Mondi papers are environmentally certified, so they have the best paper solutions combined with proven, environmentally sound production. We look forward to exhibiting at Drupa and showcasing our wide-ranging innovative paper solutions developed to meet the exacting needs of professional printers and the latest printing technologies.”

Sustainable. Every day.

Sustainability is one of the key drivers of Mondi’s business and will be a key topic for Drupa. All Mondi uncoated fine paper branded products are part of Mondi’s Green Range, meaning that they are FSC® or PEFC™ certified, 100% recycled or totally chlorine free bleached (TCF). Mondi continually invests in making its mills and production plants as energy efficient and sustainable as possible. For Mondi, sustainability makes good business sense - every day.

Mondi house at Drupa – innovations in touch with the emotions of paper

Mondi’s booth will show visitors both the technical and the emotional sides of the paper world. On the one hand, Mondi demonstrates its commitment to innovative paper solutions for the latest professional printing technologies with the Océ ColorStream 3000 Z high-speed digital inkjet printing press provided by Canon and the Mcor ARKe 3D printer. On the other hand, paper also conveys an emotional element through its shades and how it feels to the touch. One of the highlights of the booth is the Mondi ‘paper house’ reflecting Mondi’s one-stop paper manufacturer approach. In this house, visitors can feel at home, be well taken care of, discover the creative environment of an art gallery and personally experience a variety of paper haptics.

Innovative. Every day

“We are strongly committed to continuously developing our portfolio serving our customers’ needs. At the same time, we adapt our papers to the technology developments in the professional printing industry,” explains Johannes Klumpp. “Mondi and the Neusiedler mill are well known for innovative, high-quality papers produced in a sustainable way. Our clear dedication to quality leadership is demonstrated in one of our latest innovations in our premium hybrid segment.”

Under the slogan ‘one quality – one mill – one look’, Mondi Neusiedler sets a new quality reference guaranteeing hybrid offset, preprint and laser printing. Professional printers, creative agencies and end users will benefit from consistent print quality and one shade from 50 – 400 g/m² with DNS® premium, MAESTRO® extra and IQ premium.

Professional printing paper campaign ‘We have the perfect pape® for you’

At Drupa, Mondi will showcase its complete range of professional printing paper and board. The new Pro Paper campaign ‘We have the perfect pape® for you’ reflects Mondi’s approach to act as one-stop paper manufacturer for the professional printing industry. The Pro Paper portfolio encompasses all of Mondi’s paper optimised for the needs of professional printers with different printing technologies. Some of the most recent additions to Mondi’s portfolio for professional printers include:

- NEUJET®, Mondi’s newest high-speed inkjet paper. The full NEUJET® portfolio will be presented at Drupa. It represents Mondi’s next generation of high-speed inkjet papers optimised for medium to heavy colour, direct mail, graphic arts and book printing applications. The portfolio is offered in two quality levels, standard and premium, and two surface finishes, matte and silk, closing the gap to coated offset printing.

- PERGRAPHICA® design papers. PERGRAPHICA® is called ‘Paper for Perfectionists’ because it fulfils the most demanding requirements for sophisticated and elegant printed documents. Graphic designers, advertising agencies and fine book publishers are just a few of the creative industries that will appreciate PERGRAPHICA®’s variety of options: two textures (Rough and Smooth), three shades (High White, Classic and Natural) and six grammages between 90 and 300 g/m2. It is produced in Austria and FSC®and EU Ecolabel certified. PERGRAPHICA® is sold exclusively through Mondi’s long-term distribution partners Europapier (Austria and CEE), Papierunion/Inapa Group (Germany), Burgo Distribuzione (Italy), and Double V (Russia).

Live print demonstrations on Mondi paper

Visitors to Drupa can see Mondi paper in action on various printing equipment – both at the Mondi booth and at the booths of printing equipment manufacturers with which Mondi works closely. Mondi’s own booth will feature demonstrations on an Océ ColorStream 3000 Z high-speed digital inkjet printing press provided by Canon and featuring Hunkeler finishing equipment. Visitors can take with them print-outs on a variety of Mondi uncoated fine papers specifically tailored for high-speed inkjet printing. For example, NEUJET® as well as high-speed inkjet optimised DNS® and recycled paper NAUTILUS® will be demonstrated on the Canon printing press at the Mondi booth.

Throughout the Drupa fair grounds, several partner companies will be using Mondi papers in their live printing demonstrations: Canon (hall 8a booth B50), Domino (hall 5, booth A23), FujiFilm (hall 1, booth B19 and hall 8b, booth A25), Hewlett Packard (hall 17), Komori (hall 15, booth D4), Konica Minolta (hall 8b, booth A65), RISO (hall 5, booth C20), Screen (hall 8a, booth C11), Xanté (hall 5, booth D03), Xeikon (hall 8a, booth B20), and Xerox (hall 8b, booth A62).

X-Rite Pantone colour management master classes

In collaboration with X-Rite Pantone, Mondi will offer seminars on colour management before and during the Drupa fair. On 10 May, customers can take part in a Mondi webinar called ‘Colour Management in Practice’.

During the Drupa fair, Mondi and X-Rite Pantone, global leader in colour science and technology, will co-host several colour management master classes at the Mondi booth. X-Rite Pantone will present the theoretical part of the master class, which was developed in collaboration with Mondi and is based on ICC (International Colour Consortium) profiles customised to the company’s papers. Mondi colour experts will be on site for the live demonstrations – showing in particular the specific complexity when printing full colour with high-speed inkjet technology.

Mondi now also provides ICC profiles for different printing technologies and specifically for the Mondi paper portfolio. This is to ensure consistent colour performance on any Mondi paper and with any printing technology, making it even easier for professional printers to attain perfect print results quickly and efficiently.

Industry partnership in 3D printing completes Mondi’s offer

In addition, Mondi has partnered with Mcor, an innovative manufacturer of the world’s most affordable, full-colour, safe and eco-friendly 3D printers, on the development of paper optimised for Mcor 3D printers. Mcor recently launched the Mcor ARKe, the world’s first, full-colour, desktop 3D printer and at Drupa Mondi will feature the Mcor ARKe printing full colour paper 3D models. Mcor ARKe uniquely employs the global-standard ICC colour map to provide the industry’s most accurate, photorealistic colour 3D printing and was named Best of Innovation Awards Honoree in the 3D Printing Product category at the Consumer Electronics Show in January 2016.

Visit the Mondi booth at Drupa from 31 May to 10 June in hall 4, booth C21. Mondi’s team of paper experts looks forward to welcoming you and showing how Mondi offers more than you expect for professional printing. Every day.

Read more about Mondi at Drupa here: www.mondigroup.com/drupa

Magma and MagmaHigh: New Dryer Fabrics from Voith for the High-temperature Range

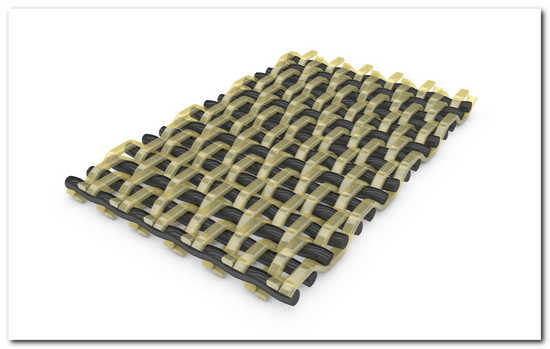

Voith has enhanced its CleanWeave product range with the new Magma and MagmaHigh dryer fabrics. Magma dryer fabrics are made from hydrolysis-resistant PPS which ensures performance in the hottest dryer positions.

- Heat-resistant material for high-temperature ranges

- Clean machine run due to proven weave pattern

- Predictable servicing schedule for cost-efficient operation

Extreme temperatures in some paper machines put dryer fabrics under severe stress and call for special material properties. Hydrolysis-resistant PPS reduces the stress on the fabric, allows service intervals to be properly planned and thus prevents unscheduled machine downtimes. Moreover, both Magma and MagmaHigh use the weave pattern that has already proven effective in the CleanWeave product range. The weave structure features industry low internal void volume, which significantly reduces dirt within the fabric. Due to its relatively low number of yarn crossover points, this compact weave pattern makes surface cleaning easier and ensures constant air permeability. This guarantees that the fabric maintains its air permeability for optimum drying and web running properties over its entire service life.

The superior reliability of Magma and MagmaHigh dryer fabrics makes planning easier and ultimately leads to more efficient and economic paper machine operation. As well as the dryer fabrics, Voith offers excellent service support and associated consultancy services.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith Industrial Services.

New Product Press Release from the Electromatic Equipment Company

MODELS QB-LEDAND QBS-LED HAND-HELD STROBOSCOPES DELIVERS CLASS-LEADING LIGHT OUTPUT

- Two new, hand-held, battery powered stroboscopes from CHECK•LINE® deliver

- best-in-class-brightness and performance.Model QB-LED employs 40 high-powered

- LEDs to deliver a peak brightness of 5,000 Lux, while Model QBS-LED, with 118 high-powered LEDs, yields a peak brightness of 10,000 LUX.

Both models have an adjustable flash range—from 30 to 300,000 FPM (0.5-5000Hz)—that is displayed in user-selectable units (FPM, Hz, or 1/MIN.) on a bright, backlit LCD display.Adjustable flash duration ensures optimal brightness and image sharpness for every application.

Both models employ a simple menu structure that makes accessing common and special functions easy.Operator controls are conveniently located on the back.A built-in Lithium-Ion battery provides up to seven hours of continuous operation on a single charge.A universal battery charger can provide continuous power for fixed- mount use.

Special Operating Modes

The Slow Motion Mode (QB-LED and QBS-LED) allows users to offset the flash rate and put the frozen image into apparent slow-motion.The PRO Mode (QB-LED and QBS-LED) adds functions including Multiplier, Delay and Memory (5 user-set val- ues).Both models also provide Phase Shift and External/InternalTrigger functions as standard.The QBS-LED model adds anAuto Sync Mode, which instantly freezes the rotating target without adjustment and a Non-ContactTachometer Mode.

Designed for machine observation, visual inspection and motion analysis, the QB- LED and QBS-LED’s robust design and rugged aluminum housing suit demanding industrial environments.Both models are ideal for textile, paper making, sheet metal production automotive and printing applications.

For additional information contact:

Andrew Kaner

Product Manager

ELECTROMATIC Equipment Co., Inc. CHECK-LINE® Division

1-800-645-4330

FAX:1-516-295-4399 www.checkline.com