Ianadmin

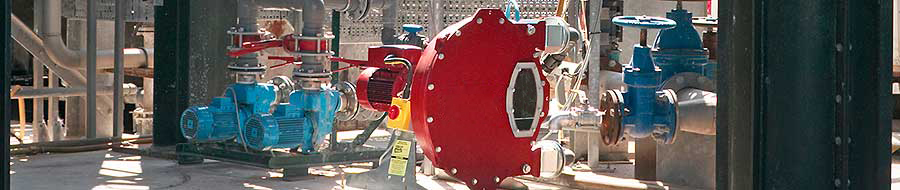

Bredel pumps save UK paper manufacturer £2700 per pump

Bredel pumps save UK paper manufacturer £2700 per pump / per year in electricity, compared with AODD pumps - Equating to an 80% reduction in energy consumption.

Today, all manufacturing and process plants see energy efficiency as a major priority on their agendas. Energy has become a board level commitment because it is driven by legislation in both the EU and the UK, and also because it’s an expensive overhead. Nearly all plants run pumps of some kind, and without the necessary energy management they can make for hefty electricity bills that can impact the bottom line and reduce competitiveness.

-

Energy efficiency and CO2 reduction is now a board level commitment

-

Correct pump selection is vital in the drive towards a greener future

-

A single Bredel pump is saving one manufacturer around £2700 a year in electricity costs compared with an AODD pump – reducing CO2 emissions by over 12,500 kg per year

Knowledge is power

According to the BPMA (British Pump Manufacturers’ Association), pumps account for around 10% of the world’s electricity consumption, while an alarming two-thirds of pumps use up to 60% more power than necessary.

Correct pump selection is therefore critical in controlling energy consumption, and not just the brand, but the correct pump technology, the size of pump and drive for the application. Only this will ensure the shortest payback times and allow plants to maximise the return of their investment. Quick ROI is also a great way to ensure board level buy-in.

Look beyond the price

When considering the acquisition of a new positive displacement pump, many engineers get seduced by a cheap purchase price. However, there are far more significant savings to be made over the lifetime of a pump if factors such as energy efficiency are more carefully considered. In fact, tests and calculations have shown that Bredel heavy duty hose pumps can save up to 80% in energy costs per pump in comparison with AODD pumps.

One recent example at a UK paper manufacturer highlights just how much can be saved by making more informed pump purchases. At a Midlands based paper and packaging company that was an established user of AODDs (air operated double diaphragm pumps), a prospective enquiry led to a very welcome boost to the bottom line by switching to Bredel hose pumps from Watson-Marlow Fluid Technology Group.

Like-for-like comparison

A direct comparison was drawn between their existing AODD pump and the Bredel 50 hose pump. At 29 rpm, the flow rate at 50 Hz is 5,000 l/hr. The AODD pump air consumption at this flow rate (at 6.9 bar pressure) is equal to 35.34 CFM.

Extrapolating the mathematics further, 35.34 CFM (based on 4 CFM per kW maximum generation) is equal to 8.83 kW. Hence, with electricity costing £0.10 per kW/hr, the cost of running the AODD pump per hour is £0.88. The duty cycle of the pumps for this client’s application is 16 hours running per day, 5 days per week, 48 weeks a year – which equates to annual running costs in electricity of £3379. In reality this figure is likely to be even higher because of the air system leakage suffered by most manufacturing sites.

Using the same parameters, the Bredel 50 draws just 1.75 kW, so the running cost per hour is £0.175. Based on identical hours of operation, the annual running cost in electricity is £672, delivering an impressive saving of £2707 per year, per pump. The company has installed three Bredel hose pumps, delivering an impressive saving of £8121 per year, thereby reducing their energy consumption by 80%.

Added to this, there is a reduction in CO2 emissions of over 12500kg per year, per pump based on the 2015 DEFRA conversion ratio of 0.46219kg of CO2 per kW hour of energy used.

Impressive savings

Factoring in the purchase price of the Bredel 50, the payback period is just 2.1 years, after which the pumps have a positive effect on the bottom line.

“For this client, the payback period was even shorter as the calculations shown do not include common issues associated with AODD pumps for this type of application - such as breakdown costs and lost production time,” says Andrew Edwards, a sector specialist at Watson-Marlow. The client also considered the reduced compressed air requirement, which resulted in less wear and tear on the compressor.

These effects were particularly common at the manufacturer in question because the product being pumped from bulk tanks to day containers is starch, which is quite abrasive and becomes even more abrasive when sheared.

Abrasives are known to wear AODD pump parts, such as expensive end caps and manifolds. Furthermore, the ball check valves of air operated double diaphragm pumps can be distorted by the wear, to the point they reach a size that they can extrude through the pump. If this occurs the result can be a contamination of the process or creating a blockage in the pipework system.

Less maintenance

Previously, the manufacturer had to maintain the AODD pumps every 2-3 weeks, and not just to replace normal wear parts like diaphragms, but high cost components. What’s more, the failures were unpredictable, causing line stoppages, process disruption and yet more costs.

In short, industrial manufacturers can become far more energy efficient and maximise process up time by switching to Bredel pumps.

Ultimately, the example described shows that switching to Bredel pump technology can improve energy efficiency and enable plants to increase profitability and remain competitive in today’s fierce marketplace. Benefits arrive not just in the shape of energy savings, reduced carbon emissions and legislative compliance, but in demonstrable greener credentials as part of a company’s corporate responsibility initiatives.

WWF Environmental Paper Awards 2016 open for submissions

WWF is now inviting pulp and paper producers, paper buyers, agents and merchants to participate in WWF´s Environmental Paper Awards 2016. Awards in the categories “Best Environmental Performance Paper Brands”, “Transparency”, “Striving for Continual Improvement” and “Advocacy for Continual Improvement” will be celebrated in November 2016. WWF created the WWF Environmental Paper Awards to give credit to company efforts in reducing the forest, water and climate footprint of paper production and consumption.

WWF is now inviting pulp and paper producers, paper buyers, agents and merchants to participate in WWF´s Environmental Paper Awards 2016. Awards in the categories “Best Environmental Performance Paper Brands”, “Transparency”, “Striving for Continual Improvement” and “Advocacy for Continual Improvement” will be celebrated in November 2016. WWF created the WWF Environmental Paper Awards to give credit to company efforts in reducing the forest, water and climate footprint of paper production and consumption.

In cooperation with scientists, paper buyers, producers and NGOs, WWF has developed a simple but scientifically robust method in evaluating a paper product’s footprint. The method is the basis for the online platform “checkyourpaper.panda.org” which allows producers and merchants to either do a non-public self-check on their paper brands, or to publish their brands publicly. Buyers and merchants can find brands with a low forest, climate and water footprint, but can also use the tool to work with their suppliers towards improvements.

In the last WWF Environmental Paper Awards in 2012, seven paper producers were recognized for transparency and 46 paper brands for environmental excellence. All paper products currently published on checkyourpaper.panda.org will automatically enter the Environmental Paper Awards 2016. Whereas the Awards primarily focus on brands, a company´s participation in the bi-annual Environmental Paper Company Index, which evaluates a company´s overall performance and targets, is part of the criteria in the category “Transparency”.

New Award categories in 2016 on “Striving for Continual Improvement” and “Advocacy for Continual Improvement” seek to recognise efforts by paper buyers and merchants in working collaboratively with their suppliers and customers in pursuit of improved environmental footprints. This requires proactive use of WWF´s Online Self-Check and/or the underlying method on checkyourpaper.panda.org.

“The WWF Environmental Paper Awards will recognize the efforts of producers and buyers/merchants that are transparent on their environmental footprint or act as advocates for continual improvement in the pulp and paper sector,” said Emmanuelle Neyroumande, Manager of WWFs global paper work.

In November 2016, WWF International will publicly recognize the Award winners on WWF´s website, via trade media outreach and communication to environmentally conscious paper buyers around the world. Details on how to enter the Awards can be found on wwf.panda.org/environmentalpaperaward2016. Deadline for submissions for all categories is 30 September, 2016. Contact This email address is being protected from spambots. You need JavaScript enabled to view it..

For further information: Helma Brandlmaier, WWF International ; +43676842728219 This email address is being protected from spambots. You need JavaScript enabled to view it.

Neenah Digital Papers’ Portfolio Continues to Grow; Showcased in New Swatchbook

Neenah announces the expansion of its comprehensive digital papers portfolio to include over 300 of Neenah’s most popular colors, textures, finishes and weights providing a wide range of versatile, high-performing paper choices for any digital print or packaging project.

With the expansion comes the release of the newly updated, comprehensive Neenah® Digital Papers swatchbook.

“We’ve expanded our digital offering in direct response to the needs of today’s market. With digital equipment manufacturers focusing on innovating their digital equipment, we’re seeing increased customer demand for larger sheet sizes, heavier paper weights, more textures, and an increased desire for more paper colors ranging from bright whites and vibrant colors to unexpected dark blues and blacks,” said Greg Maze, Senior Brand Manager, Neenah.

Newly Expanded Neenah Digital Papers Portfolio:

More Sheet Sizes

Because most digital printers can accept larger sheet sizes today, Neenah has added expanded sizes 13 x 19 and 19 x 13 sheets throughout the line, and 20.75 x 29.5 and 29.5 x 20.75 for the growing HP Indigo® 10000 user base.

Heavier Weights

With digital presses accepting heavier stocks today, Neenah has added heavier weights across the line ranging from 24 Writing up to 130 Double Thick Cover.

Packaging: Neenah® Folding Board

Neenah® Folding Board Digital is a stylish, premium and versatile choice for specialty, short-run folding carton packaging, now available in 18pt and 24 pt. Perfect for cosmetic and fragrance boxes, gift cards, hang tags, electronics and confectionary packaging.

Cross Platform: Neenah® Digital Color Copy

Neenah® Digital Color Copy is now fully optimized for both liquid and dry toner digital print applications, making it a true cross platform digital sheet. Customers can now expect exceptional performance from Neenah Digital on a wide variety of equipment from desktop printers and copiers to commercial digital printing presses. It comes with Neenah’s Digital Guarantee.

More colors, more textures and finishes

Neenah Digital now provides printers and designers with the widest range of high-performing digital paper choices for any customized or short-run print collateral or packaging application.

· 17 unique finishes from Smooth to LETTRA®, Pearlized and Raw®

· 22 pearlized, brights and colors from Crystal to Pulsar Pink™ and Epic Black

· 27 whites, naturals and fibers from Avalanche White to Antique Gray

· 3 packaging papers from Bright White to Deep Black

· 3 ESTATE LABEL® pressure sensitive papers from Bright White to Cream

“Digital printing is no longer just about low cost production. Improvements in productivity and reliability continue to make digital printing more cost effective, and for specialty applications too. So it’s about finding creative solutions for smaller, more exclusive projects,” said Maze. “The new digital portfolio now includes 20 Neenah brands featuring the newly re-engineered Neenah Digital Color Copy and Neenah Folding Board. Our portfolio is unmatched.”

Get a free copy of the Neenah Digital swatchbook (a $10.99 value) through your Neenah rep or your local merchant. Find a Neenah distributor here: http://www.neenahpaper.com/resources/findadistributor

About Neenah

For more than 100 years, Neenah Paper (NYSE: NP) has been an innovative leader in the creation and manufacturing of papers for premium writing, text, cover, digital, packaging and specialty needs. The Neenah signature portfolio includes market leading brands such as CLASSIC®, ENVIRONMENT®, and ROYAL SUNDANCE® Papers. The company also offers envelopes in thousands of unique colors, finishes and styles. Neenah is committed to developing relevant mobile and online technologies including Neenah Cabinet™ for iPad, iPhone and Android. With multiple manufacturing facilities in Wisconsin, prime importance is also placed on recycled and alternative fiber products through the Neenah Green initiative. For more information on Neenah call (800) 558-5061. Follow Neenah on Twitter: @neenahpaper; subscribe to the Neenah Facebook page; or visit Against the Grain, Neenah’s blog for designers, printers and paper-lovers.

Domtar Provides Business Update

Domtar Corporation (NYSE: UFS) (TSX: UFS) has just provided an update on its financial performance for the first quarter of 2016. Domtar's management expects sales to be $1,287 million and estimates the operating profit to be between $16 and $19 million. EBITDA before items1 will be between $128 and $131 million.

Estimated operating profit in the first quarter of 2016 includes an impairment of property, plant and equipment of $21 million, closure and restructuring costs of $2 million and depreciation and amortization of $89 million. Adjusting estimated operating profit for these three amounts yields EBITDA before items1.

Estimated operating profit in the first quarter of 2016 includes an impairment of property, plant and equipment of $21 million, closure and restructuring costs of $2 million and depreciation and amortization of $89 million. Adjusting estimated operating profit for these three amounts yields EBITDA before items1.

"We had extensive planned maintenance outages across our mill network in the first quarter. Within the shutdowns, we came across a number of unexpected issues that resulted in longer than anticipated outages, leading to higher planned maintenance and related costs," said John D. Williams, President and Chief Executive Officer. "Nonetheless, the issues were mostly related to specific incidents and they are now behind us."

Domtar Corporation (NYSE: UFS) (TSX: UFS) will release its first quarter 2016 financial results before markets open on Thursday, April 28, 2016. A conference call will be held to discuss the results at 10:00 a.m. (ET). Financial analysts are invited to participate in the call by dialing 1-800-499-4035 (North America) or 1-416-204-9269 (International). Media and other interested individuals are invited to listen to the live webcast at www.domtar.com.

About Domtar

Domtar is a leading provider of a wide variety of fiber-based products including communication, specialty and packaging papers, market pulp and absorbent hygiene products. With approximately 9,850 employees serving more than 50 countries around the world, Domtar is driven by a commitment to turn sustainable wood fiber into useful products that people rely on every day. Domtar's annual sales are approximately $5.3 billion and its common stock is traded on the New York and Toronto Stock Exchanges. Domtar's principal executive office is in Fort Mill, South Carolina. To learn more, visit www.domtar.com.

1 Non-GAAP financial measure. EBITDA before items is presented as a complement to enhance the understanding of operating results but not in substitution for GAAP results.

(All financial information is in U.S. dollars, unless otherwise noted.)

Rottneros Board raises the proposed dividend for 2015

The Board of Rottneros AB (publ) has decided to increase the dividend proposal and propose to the Annual General Meeting a dividend of 0,30 SEK per share and an extra dividend of 0,20 SEK per share, i.e. a total dividend of 0,50 SEK per share.

The Board has previously proposed an ordinary dividend of 0,30 SEK per share, announced in the year-end report for 2015, published February 12, 2016, and in the profit allocation proposal in the Annual Report for 2015, published March 21, 2016.

The Board has previously proposed an ordinary dividend of 0,30 SEK per share, announced in the year-end report for 2015, published February 12, 2016, and in the profit allocation proposal in the Annual Report for 2015, published March 21, 2016.

The background of the increased proposal is the positive development of the Group during the past two years, resulting in a very strong balance sheet with a high equity ratio. At the end of 2015, the company was debt-free with a large liquidity reserve and the equity ratio was 77 percent. The proposed extra dividend improves Rottneros’ current and future financing and capital structure and the rate of return on capital employed will increase. The Board's long-term objective is to transform the company's financial structure through increased borrowing.

The Board believes that the Group's very strong financial position enables continued investments and expansion of the operations and that the increased dividend therefore is defensible.

Decision regarding dividend will be made at the Annual General Meeting May 20, 2016.

For further information, please contact:

Rune Ingvarsson, Chairman of the Board of Rottneros AB (publ), +46 70 288 79 76 Per Lundeen, President and CEO of Rottneros AB (publ), +46 70 518 33 47

Verso Introduces Sterling® Premium Digital™ Tough Tear

A Coated Paper Alternative to Synthetic Paper and Other Durable Media Products

Verso Corporation (OTCPink: VRSZQ), a leading producer of digital coated papers, today introduced Sterling® Premium Digital™ Tough Tear, a premium digital coated paper enhanced with poly for greater print performance, durability and tear resistance.

Sterling® Premium Digital™ Tough Tear was created as an alternative to synthetic paper and other durable media products using a patented manufacturing process. Sterling® Premium Digital™ is a three-ply, 108 lb. (10 pt.) laminate designed with a heavyweight tear-resistant poly between two layers of Sterling® Premium Digital™.

Sterling® Premium Digital™ Tough Tear was created as an alternative to synthetic paper and other durable media products using a patented manufacturing process. Sterling® Premium Digital™ is a three-ply, 108 lb. (10 pt.) laminate designed with a heavyweight tear-resistant poly between two layers of Sterling® Premium Digital™.

"This new substrate is designed for applications requiring more strength than a traditional paper product," said Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold. "It provides digital printers with significant advantages in strength, durability and tear resistance for optimal printing and finishing performance. It also prints and converts like paper with no need for additional processes, resulting in superior toner adhesion for better image reproduction."

Sterling® Premium Digital™ Tough Tear is versatile, with optimal performance on dry toner printers, color and black-and-white laser printers, HP Indigo and digital offset technologies. It is guaranteed for both digital offset and production laser equipment, and is tri-certified to the Forest Stewardship Council® (FSC®) (License FSC - C014984), Programme for the Endorsement of Forest Certification™ (PEFC™) and Sustainable Forestry Initiative® (SFI®) standards.

Like all Verso digital coated papers, this product is precision cut to prevent paper edge bonding jams and duplex registration issues. Strict quality control yields ultra-clean paper, reducing paper dust contamination and increasing print productivity and equipment life.

To learn more about Verso's entire product portfolio, including digital, sheetfed, web and specialty papers, visit us at Booth No. 249 from April 14 to16 at DSCOOP 11, San Antonio, Texas or at versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

CMPC Riograndense chooses Voith for Pulp Dryer Rebuild

Voith has been chosen by CMPC Riograndense to carry out a rebuild of its PDM1 pulp dryer in Guaíba, a city located in the Brazilian state of Rio Grande do Sul.

Voith has been chosen by CMPC Riograndense to carry out a rebuild of its PDM1 pulp dryer in Guaíba, a city located in the Brazilian state of Rio Grande do Sul.

The rebuild project aims to improve the machine's stability and performance, as well as to make it easier to carry out maintenance services on the machine's drive systems. Upon scheduled completion in the second half of 2016, the PDM1 will increase its capacity to produce up to 1,320 metric tons per day at a speed of 165 meters per minute.

The project will be carried out under the PLP (Process Line Package) concept, whereby Voith takes full responsibility for procuring and managing the supply of all the necessary equipment and services to operate the machine. This includes new controls for the machine's individual drive systems, a steam box with automatic profile control, a threading system, the lubrication and steam and condensate systems, electrical drives, basic and detail engineering and electromechanical assembly, along with all the necessary training and commissioning services.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

Voith sets standards in the energy, oil & gas, paper, raw materials and transport & automotive markets. Founded in 1867, Voith today has more than 20,000 employees and earns €4.3 billion in sales. It has locations in over 60 countries and is one of the large family-owned companies in Europe.*

* Excluding the discontinued Group Division Voith industrial Services.

FITNIR Awarded Ten New Projects

FITNIR ANALYZERS CONTINUES TO BUILD MOMENTUM IN 2016

Ten New Projects Awarded with Pulp Mills in North America and Asia

On the heels of a successful 2015, FITNIR Analyzers continues to build on the momentum in 2016. With seven projects awarded in 2015 and already three in Q1 of 2016, it’s expected the activity won’t slow down anytime soon. “We are excited to announce five new projects in Canada, four in the U.S., and a tenth in Asia,” said Tom Sands, President of FITNIR Analyzers. “It’s gratifying to see our products contributing to the success of mills throughout North America and now expanding internationally.”

Paper Excellence’s Mackenzie Pulp Mill Corporation was one of the three mills in North America that selected FITNIR’s fully automated, online FT-NIR analyzer. FITNIR Online provides more reliable, accurate and true measurements versus inferred measurements of traditional solutions. Integrating FITNIR Online into these mills will enable real-time monitoring of various unit operations for process optimization and control.

Paper Excellence’s Mackenzie Pulp Mill Corporation was one of the three mills in North America that selected FITNIR’s fully automated, online FT-NIR analyzer. FITNIR Online provides more reliable, accurate and true measurements versus inferred measurements of traditional solutions. Integrating FITNIR Online into these mills will enable real-time monitoring of various unit operations for process optimization and control.

Skookumchuck Pulp, another Paper Excellence mill, is expanding its FITNIR Online system to now include the digester and chlorine dioxide generator. “We decided to go with FITNIR again after the success we had with our recaust analyzer installation for smelt dissolving tank TTA control, CGL trim control, and slaker and CE control,” said Roger Puar, Technical Manager at Skookumchuck Pulp. “Not only does the technology meet our needs, but we also received excellent service from the FITNIR team.”

Another repeat customer in eastern Canada selected FITNIR Benchtop in 2014 for liquor measurement, and then in 2015 chose FITNIR Kappa to measure the kappa number of wet kraft pulp to help control its digester operations. Also in 2015, a western Canadian mill was the first to implement FITNIR Kappa for dry pulp sheet applications. Their confidence in the unit led to the selection of FITNIR again in 2016, this time to analyze brownstock kappa. And just recently, two other mills in the US opted for FITNIR Kappa to provide quick, consistent and accurate kappa number measurements via Near Infrared (NIR) spectroscopy.

Most noteworthy for 2015 is FITNIR’s break into the Asian market with a landmark project boasting FITNIR’s largest contract to date. Geared to commence installation this spring, the pulp and paper mill located in Southern Sumatra, Indonesia will use FITNIR Online to optimize its recaust and recovery processes via two analyzers and six field sampling stations.

About FITNIR Analyzers Inc.

FITNIR’s automated online, benchtop and kappa analyzers reliably measure complete pulp liquor compositions. Fast, frequent and accurate measurements drive control strategies that decrease process variability and environmental impact for improved efficiencies and profitability. Proven applications for the digester, recausticizer, recovery boiler, ClO2 generator, brownstock washer, and now kappa measurements for wet and dry pulp, FITNIR is the next generation of process analyzers. Visit www.fitnir.com.

For further information contact:

Thanh Trung, Vice-President of Technology

001 (604) 221 2230

This email address is being protected from spambots. You need JavaScript enabled to view it.

Kemira increases prices of coagulants in selected European countries

Kemira, a global chemicals company serving customers in water intensive industries, announces price increase for its inorganic coagulant product lines for water treatment applications and specific pulp and paper manufacturing applications in selected European countries. The adjustment will be immediately implemented or as the existing contracts allow.

Kemira, a global chemicals company serving customers in water intensive industries, announces price increase for its inorganic coagulant product lines for water treatment applications and specific pulp and paper manufacturing applications in selected European countries. The adjustment will be immediately implemented or as the existing contracts allow.

In addition to the operational efficiency improvements implemented in recent years, price adjustments for the iron and aluminum salts are necessary due to increased cost within the coagulant value chain, partially driven by local scarcity of certain raw materials and the overall increased regulatory and sustainability requirements.

The increase will range from 5-8% but can be significantly higher for specific product types in selected locations which are more acutely impacted by the above mentioned cost drivers.

For more information:

Wido Waelput

Senior Vice President, Kemira M&I EMEA

Tel. +49 172 884 349 6

This email address is being protected from spambots. You need JavaScript enabled to view it.

Harri Eronen

VP, Sales & Technical Service, Paper EMEA

Tel. +49 171 802 8790

This email address is being protected from spambots. You need JavaScript enabled to view it.

About Kemira

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2015, Kemira had annual revenue of EUR 2.4 billion and around 4,700 employees. Kemira shares are listed on the Nasdaq Helsinki Ltd.

www.kemira.com

Verso Expands Blazer Digital® Coated Paper Line

Verso Aligns Product Offering to Meet Needs of Digital Press Owners

Verso Corporation, a leading producer of digital coated papers, has just announced the expansion of its Blazer Digital® economy digital coated paper line to include 65 lb. gloss and satin covers available in 19" x 13" and 18" x 12" stocking sizes. These new sizes are in stock and readily available.

"Blazer Digital® is an economical, coated digital paper with weight and finish choices similar to conventional folio formats," said Verso Senior Vice President of Sales, Marketing and Product Development Mike Weinhold. "Offered in text and cover weights with gloss or satin finishes, it provides excellent performance on dry or liquid toner, production color laser printers and digital offset technologies."

Verso has been a leader in manufacturing digital papers since digital printing technology first emerged, offering specialized expertise, dedicated production capacity and one of the broadest offerings of digital-specific products in the industry.

Verso has been a leader in manufacturing digital papers since digital printing technology first emerged, offering specialized expertise, dedicated production capacity and one of the broadest offerings of digital-specific products in the industry.

"Verso continues to focus on the digital print market and align its grade offering to better meet the needs of digital press owners," Weinhold said. "These additional cover weights provide our customers with more choices and flexibility when specifying the appropriate cover weight for various applications such as variable imaging, direct mail, postcards, brochures, flyers, sell sheets, short run catalogs and magazines."

Along with the Blazer Digital® economy product, Verso offers a variety of premium digital products including Futura®, Sterling® Premium Digital™ and Sterling® Premium Digital™ for HP Indigo, each with premium optics, exceptional surface quality and budget-friendly pricing, as well as Productolith Pts. Digital® for heavy-weight packaging and applications requiring a caliper guarantee. Verso also produces Sterling® Ultra TrueJet®, a specialized line of digital coated papers for production inkjet presses which optimizes quality and is designed to deliver significant savings in ink cost.

To learn more about Verso's entire product portfolio, including digital, sheetfed, web and specialty papers, visit us at Booth No. 249 from April 14 to 16 at DSCOOP 11, San Antonio, Texas or at versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.