"In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity. Replacing outdated automation systems with modern cutting-edge solutions provides the means to stay in the race", points out Ilkka Saarinen, Director, Pulp & Paper Applications, EMEA, Automation, Metso

Pls feel free to ask for more information. We also appreciate your feedback in all automation related issues.

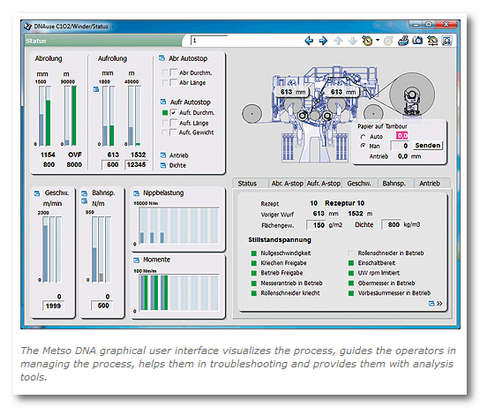

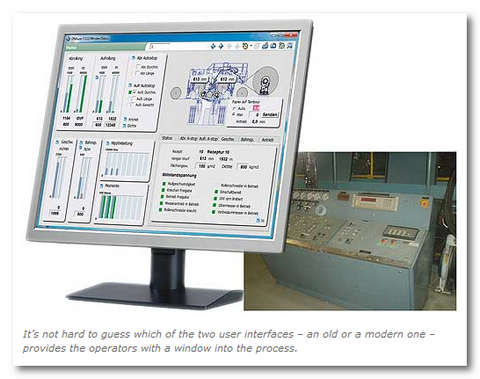

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds.

“Automation not only is a tool to manage the process and production, it provides a window into the process and the end product,” points out Ilkka Saarinen, Director, Pulp & Paper Applications, EMEA, Automation, Metso. “Today, the automation structure in many paper mills is largely a ‘historical patchwork quilt’, consisting of many isolated system islands. This does not provide a competitive platform for the efficiency race.”

Mind the technology gap

Having separate outdated systems for various tasks within a process often creates major challenges. Typical examples include limited functionality in the operator interface, reliability problems due to aging hardware, and complicated data links between the various systems. With the many different types of engineering tools, maintenance is a headache. It is difficult to find faults and identify interlocks, as well as add new loops in the old system. Plus, the people who can program are retiring, and spare parts and system support are no longer available.

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds. “In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity.”

The architecture of new-generation automation systems, such as Metso DNA, provides users with one single platform for all control functions in a paper mill, including process controls, machine controls, quality controls, drive controls, condition and runnability monitoring, as well as web break and web inspection analysis. As Saarinen puts it: “The system gives operators a feeling of control through high reliability, an effective user interface and advanced control algorithms.”

“There is a vast technology gap between the aging systems and modern solutions. For example, today’s graphical user interfaces visualize the process, guide operators in managing the process, help them troubleshoot, and provide them with analysis tools. Development steps in process controllers have been huge, too,” Saarinen adds. “In automation, new applications featuring the latest control technology enable papermakers to reach totally new levels with their processes when it comes to quality and productivity.”

The architecture of new-generation automation systems, such as Metso DNA, provides users with one single platform for all control functions in a paper mill, including process controls, machine controls, quality controls, drive controls, condition and runnability monitoring, as well as web break and web inspection analysis. As Saarinen puts it: “The system gives operators a feeling of control through high reliability, an effective user interface and advanced control algorithms.”

Minimizing area losses and idle time

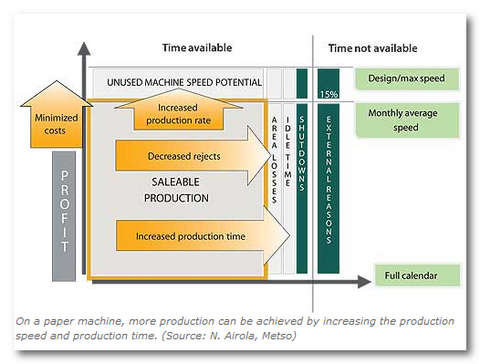

Operational efficiency is about identifying wasteful processes and resources that drain the organization’s profits and designing new work processes that improve quality and productivity. Modern automation makes this possible, as it enables mills to minimize area losses and idle time, and utilize the speed potential hidden in the production line.

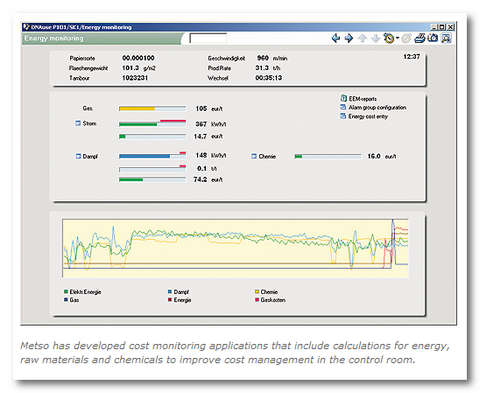

Carrying out automation migration also contributes to better efficiency by preventing unplanned shutdowns and allowing better cost management with new tools. Saarinen continues: “Traditionally, cost awareness in the production line control room has not been very evident when operators take care of process stability. This has led to a situation of having safety margins in several places, as stability can be easily improved by adding more chemicals, more raw materials, and more drying. Metso, for example, has developed cost monitoring applications that include calculations for energy, raw materials and chemicals.”

Operational efficiency is about identifying wasteful processes and resources that drain the organization’s profits and designing new work processes that improve quality and productivity. Modern automation makes this possible, as it enables mills to minimize area losses and idle time, and utilize the speed potential hidden in the production line.

Carrying out automation migration also contributes to better efficiency by preventing unplanned shutdowns and allowing better cost management with new tools. Saarinen continues: “Traditionally, cost awareness in the production line control room has not been very evident when operators take care of process stability. This has led to a situation of having safety margins in several places, as stability can be easily improved by adding more chemicals, more raw materials, and more drying. Metso, for example, has developed cost monitoring applications that include calculations for energy, raw materials and chemicals.”

Something old, something new

Saarinen names two main alternatives for automation migration. The first one is the so-called Bulldozer method, where only field equipment and parts of the field wiring remain. “This alternative is the most costly in terms of new equipment and shutdown time,” he says.

The second one preserves the mill’s existing I/O connections and field wiring, but the I/Os are replaced. Profibus I/O cards or some other I/O cards with Profibus converters can be reused. “Metso has successfully used this second alternative with numerous paper mills. This concept uses the old automation system as much as possible, and a new control strategy is built on top of it,” Saarinen points out. “In this way, there is no need to increase the amount of expensive field instrumentation.”

An automation migration project is usually scheduled to be carried out in small steps over 1 to 3 years. Only in the case of a complete paper grade changeover in a production line is a machine shutdown is long enough to carry out the replacement in one stage.

Fast payback to be expected

Replacing a control system (DCS, QCS) or machine controls (MCS) is major investment. However, it soon pays back with increased operational efficiency. The payback is visible through increased time efficiency, as there are fewer unplanned shutdowns thanks to better process reliability. The process recovers faster from shutdowns and breaks, and has less break time thanks to faster troubleshooting. Grade changes are faster, too, thanks to new control applications.

Cost savings are gained by using less raw material and energy per produced ton paper. With only one single integrated system, fewer spare parts are needed and less maintenance effort is required as the same people with the same tools can maintain all applications. According to Saarinen, the average target is to have a 16-month payback for an automation migration investment.

“When planning an automation replacement project, it is vital to understand that like-to-like replacement doesn’t generate payback,” he emphasizes. “The components generating the payback offer reliability through new technology, faster troubleshooting through increased information from the process, as well as overall visibility and increased information from the system components and field equipment. Included are also new control applications and cost savings through higher efficiency, fewer spare parts and less maintenance.”

Well planned and executed equals success

In migration projects, professional project flow and management are key to success. Each project should start with an audit that provides an overview of the mill’s installed base and expectations for the outcome. An audit is also necessary when a paper machine is moved to another location or a production shift occurs from one grade to another during a machine rebuild.

In the following pre-study phase, a detailed plan needs to be made about how the system will be replaced and defines which field devices (transmitters and valves) have to be replaced or repaired. This work produces a detailed replacement plan, which sets the framework for basic engineering. During the basic engineering, a new process and machine control strategy based on the existing field devices will be defined.

Pls feel free to ask for more information. We also appreciate your feedback in all automation related issues.