Sensor Products Inc. USA is hosting a seminar in Birmingham, Uk on the 25 - 26th January 2012, the seminar highlights the Principles of Winding & Slitting.

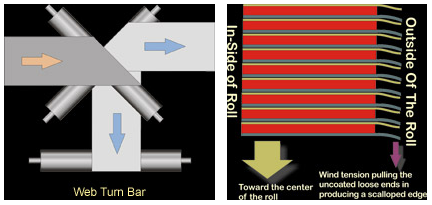

This seminar will help you understand your existing winding and slitting processes so you can optimize them and reduce the problems – both real and potential by immediately applying proven best practices. Major areas of focus include web handling principles, understanding the structure of a wound roll, equipment used in winding from simple to complex and the many type of winders on the market and where and how they are used, all the ways winding can go wrong and how to avoid them and solutions if you can’t, and the three conventional slitting methods (razor, crush, and shear) and slitter operations efficiency. These topics will be addresses at many levels, providing rules of thumb and the theory behind them.

Who Should Attend

Anyone working with supervising operators or managing operation of web machinery will benefit from this unique course. This includes product/process designers, process engineers, quality personnel, sales/service, maintenance and lead operators. Understanding winding and slitting is also vital to anyone working with webs and web processes, including material suppliers and equipment and component suppliers.

About the Instructor

Chris Watson, President of Watson consulting & Assoc., and former president of Kroenert Corp. a world leader in web handling, coating, and drying technology, began working with web handling issues and helping companies resolve them in 1971. With over 20 years consulting on hundreds of projects dealing with a myriad of issues and materials, Chris continues to help Fortune 500 companies and small startup companies.

Chris has lectured for over 30 years at conferences in the US and Europe on web handling technology, coating methods, drying technology, paper physics, and specific issues related to customers’ needs. Realizing that learning curves can be significantly shortened and costly mistakes avoided by consulting with experts who "have been there before", US and foreign companies involved in web coating and converting have attended in-house conference and national conferences to hear Chris Watson's involvement with web coating technologies goes back to the 1960's.

After graduating with a degree in chemistry from The King's College, he was made Project Leader for coated products at Riegel Paper. During this time, he also did graduate work in Polymer Science. Watson has been a successful independent consultant in a wide variety of web related issues including the field of silicone, pressure sensitive, and various web-coating and converting processes for over 25 years. He has advised such firms as Fasson, Coated Products, Mystic Tape, KDP in France, Sterling Coated Products in England, Renker in Germany, OpSec Banknote & High Security in Newcastle UK, Lohja in Finland, and major machine builders in the US.

• Understand what center and surface winding is and their best use

• Understand five benefits of gapped and nipped winding

• Understand the importance of how air enters a wound roll and problems with too little or much

• Understand rewind slip clutches and learn how to wind multiple rolls on one shaft and when differential winding is needed

• Understand what causes the most common wound roll defects and how to remedy them

• Understand how winding contributes to web bagginess and how to minimize it

• Understand what is the best setup and application of all slitting methods and why

• Center and surface winders

• Gap and nipped winders

• Differential winding

• Roll transfers

• Un-winders

• Specialty winding

Slitting

• Fracture Mechanics

• Razor Slitting

• Crush Slitting

• Rotary Slitting

• Shear Slitting

• Slitting in Registration (Stripe Slitting)

• Alternate Slitting Methods

• Slitting Operational Efficiency

The Process of Winding

• The goals of winding

• Winding and winder definitions

• Building a roll structure

• Center and surface winding

• Gap and nipped winding

• Roll dynamics

The Solutions of Winding

• Wrinkling during winding

• Too tight or too loose

• Scratching & debris

• Roll slippage

• Shifted layers

• Buckling within a roll

• Deformations

• Gauge variation defects

• Baggy webs

Below you can download the course brochure and syllabus