Ianadmin

Pulp and Paper Chemicals Markets in China: Historical Data (2004, 2009 and 2014) and Long-Term Forecasts Through 2019 and 2024

![]() Research and Markets has announced the addition of the "Pulp and Paper Chemicals Markets in China" report to their offering.

Research and Markets has announced the addition of the "Pulp and Paper Chemicals Markets in China" report to their offering.

“Pulp and Paper Chemicals Markets in China”

China's demand for Pulp and Paper Chemicals has grown at a fast pace in the past decade. In the next decade, both production and demand will continue to grow. The Chinese economy maintains a high speed growth which has been stimulated by the consecutive increases of industrial output, import & export, consumer consumption and capital investment for over two decades.

This new study examines China's economic trends, investment environment, industry development, supply and demand, industry capacity, industry structure, marketing channels and major industry participants. Historical data (2004, 2009 and 2014) and long-term forecasts through 2019 and 2024 are presented.

Major producers in China are profiled.

Key Topics Covered:

I. INTRODUCTION

II. BUSINESS ENVIRONMENT

III. PULP AND PAPER CHEMICALS INDUSTRY ASSESSMENTS

IV. PULP AND PAPER CHEMICALS PRODUCTION AND DEMAND

- Kaolin Clay

- Titanium Dioxide

- Starch

- Aluminum Sulfate

- Calcium Carbonate

- Talc

- Bleaching Chemicals

- Pulping & Deinking Chemicals

- Dyes & Pigments

- Sizing Agents

- Defoamers

- Other Pulp and Paper Chemicals

V. PULP AND PAPER CHEMICALS CONSUMPTION BY MARKET

VI. MARKET ENTRY CHANNELS

VII. PULP AND PAPER CHEMICALS PRODUCER DIRECTORY

Companies Mentioned

- Cenxi Titanium Dioxide Plant

- Changzhou Calcium Carbonate Company

For more information visit http://www.researchandmarkets.com/research/mc6pmh/pulp_and_paper

Sonoco Recognizes Facilities for Zero Waste to Landfill

1 Sonoco Location and 2 Partners Receive Gold Sonoco Sustainability Star Awards

Sonoco (NYSE:SON), one of the largest diversified packaging companies, has granted its gold-level Sonoco Sustainability Star Award to three plants across the United States for their successful efforts to achieve landfill-free status.

Sonoco (NYSE:SON), one of the largest diversified packaging companies, has granted its gold-level Sonoco Sustainability Star Award to three plants across the United States for their successful efforts to achieve landfill-free status.

The awards were granted to the following facilities:

- American Packaging Corporation, Flexographic Printing and Laminating Division, Story City, Iowa

- MillerCoors, Milwaukee, Wis.

- Sonoco Global Plastics, Chatham, N.Y.

All three facilities achieved 99% landfill diversion.

American Packaging worked to achieve and maintain ISO 14001 Environmental Management System certification, while also including employees across the organization in projects that increased efficiency, reduced waste, repurposed waste streams more effectively and lessened environmental impacts. The company has demonstrated a long commitment to sustainability, partnering with the Ames Resource Recovery Center for waste management since 1990.

MillerCoors eliminated 65 tons of waste that was previously sent to landfill each month from its Milwaukee brewery and corporate offices, logging its first landfill-free month at the brewery in December 2014. This marks the first MillerCoors campus to achieve complete landfill-free operations and the seventh of the company’s eight major breweries to reach this milestone. The Milwaukee Brewery reduced waste by 19 percent over the past year. Residual waste that cannot be reused or recycled is sent to a waste-to-energy facility.

Sonoco Plastics’ Chatham location supplemented a longstanding waste-to-energy partnership with Covanta, with a long-term dedication to encourage recycling and reuse of waste materials via improved recycling programs and waste-oil capture programs. Proximity to the waste-to-energy facility, as well as a shipment system based on volume rather than a calendar schedule, help minimize the program’s carbon footprint.

Administered by Sonoco Recycling, the Company’s recycling business, the Sonoco Sustainability Star Awards program is comprised of three tiers:

- Gold recognizes facilities that have achieved 99% landfill diversion;

- Silver is awarded to facilities achieving 95% landfill diversion; and

- Bronze recognizes facilities that have made significant waste reduction achievements, such as drastically reducing their waste streams or implementing a new composting system.

A recycling leader with locations and expertise worldwide, Sonoco Recycling annually collects more than 3 million tons of old corrugated containers, various grades of paper, metals and plastics. In addition, the Company has experts who provide secure, reliable and innovative recycling solutions to residential and commercial customers. Currently, Sonoco Recycling operates five material recovery facilities (MRFs) serving more than 125 communities in which curbside-collected residential and commercial materials are processed. The Company also operates recycling programs, which identify waste reduction opportunities that reduce operating expenses for many of the largest consumer product companies in the United States.

About Sonoco:

Founded in 1899, Sonoco is a global provider of a variety of consumer packaging, industrial products, protective packaging, and displays and packaging supply chain services. With annualized net sales of approximately $5 billion, the Company has 20,800 employees working in more than 330 operations in 34 countries, serving some of the world's best known brands in some 85 nations. Sonoco is a proud member of the 2014/2015 Dow Jones Sustainability World Index. For more information on Sonoco, visit www.sonoco.com.

SPI: The Plastics Industry Trade Association and GIE Media Join Forces

The two industry-leading groups will help program and co-promote SPI’s Re|focus Recycling Summit and Expo and GIE Media’s Paper & Plastic Recycling Conference (PPRC).

SPI: The Plastics Industry Trade Association and GIE Media, publisher of Recycling Today, announced Tuesday that they would form a partnership to co-promote SPI’s Re|focus Recycling Summit & Expo, which will take place April 25-27, 2016 in Orlando, Fla., and GIE’s Paper & Plastics Recycling Conference (PPRC), which will take place October 14-16, 2015 in Chicago.

“SPI has made it its mission to move the needle on plastics recycling and pursue the goal of zero waste for the plastics industry and our products,” said SPI President and CEO William R. Carteaux. “The only way to do this in a way that has long-lasting, real-world results is by engaging the entire plastics supply chain, and that’s exactly why GIE Media makes for a great partner. By partnering with GIE, SPI will be able to reach recycling and manufacturing professionals through five different GIE media brands, including Recycling Today, expanding the reach of SPI’s message to even more manufacturers, processors, brand owners and sustainability-minded professionals. This expanded reach simply augments the community SPI has built through its own properties, such as NPE, and will help to bring the entire supply chain together for Re|focus.”

“SPI has made it its mission to move the needle on plastics recycling and pursue the goal of zero waste for the plastics industry and our products,” said SPI President and CEO William R. Carteaux. “The only way to do this in a way that has long-lasting, real-world results is by engaging the entire plastics supply chain, and that’s exactly why GIE Media makes for a great partner. By partnering with GIE, SPI will be able to reach recycling and manufacturing professionals through five different GIE media brands, including Recycling Today, expanding the reach of SPI’s message to even more manufacturers, processors, brand owners and sustainability-minded professionals. This expanded reach simply augments the community SPI has built through its own properties, such as NPE, and will help to bring the entire supply chain together for Re|focus.”

“As conferences, Paper & Plastics Recycling Conference and Re|focus share many of the same goals. Both events aim to empower professionals in the recycling industry with the market insight and professional connections they need to solve the most pressing problems facing today’s recycling industry,” said James R. Keefe, executive vice president and group publisher, GIE Media. “This partnership will enable GIE to leverage SPI’s properties in order to attract more plastics professionals interested in post-consumer and post-industrial recovery and processing to the Paper & Plastics Recycling Conference, enhancing the value that our event provides to its attendees and ultimately the value they bring back to their companies.”

The two-year partnership between SPI and GIE Media means both groups will provide programming for the other, while also assisting with speaking recruitment. Both SPI and GIE will sponsor and exhibit at the other’s event as well.

For SPI, this makes GIE Media its latest promotion partner for Re|focus. SPE’s Plastics Environment Division has also been announced as a programming partner, providing technical content on recycling and the manufacturing of plastic products with recycled content.

For more information on Re|focus, to include exhibit and sponsorship opportunities, click here. For more information on the Paper & Plastics Recycling Conference, click here.

Founded in 1937, SPI: The Plastics Industry Trade Association promotes growth in the $373 billion U.S. plastics industry. Representing nearly 900,000 American workers in the third largest U.S. manufacturing industry, SPI delivers legislative and regulatory advocacy, market research, industry promotion and the fostering of business relationships and zero waste strategies. SPI also owns and produces the international NPE trade show. All profits from NPE are reinvested into SPI’s industry services. Find SPI online at http://www.plasticsindustry.org and http://www.inthehopper.org.

"From resin suppliers and equipment makers to processors and brand owners, SPI is proud to represent all facets of the U.S. plastics industry," said William R. Carteaux, president and CEO, SPI. Our most recent economic reports show that the plastics industry as a whole is resilient, and has come through the recession significantly better than other U.S. manufacturing sectors."

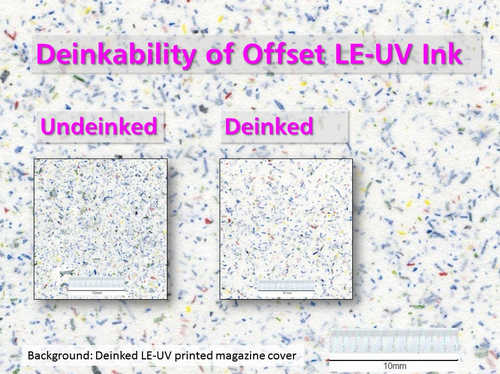

Pay Attention to Recycling: Low-energy UV Printing is not necessarily environmentally friendly

Cross-linked inks are difficult to remove in the deinking process — coloured dots within the paper fibres

Coloured specks on the recycled paper: Just because the curing radiation can now be generated by energy-saving LEDs, instead of high-power mercury bulbs, some try to market UV printing processes to be environmentally friendly. However, the shiny appearances are deceptive: Prints with radiation-cured inks can considerably impair paper recycling because they can hardly be deinked.*

UV-curable printing inks to date hardly fulfil criteria for good recyclability. All inks tested so far contaminate the processed paper for recycling with far too many ink particles that can not or not sufficiently be removed during the paper recycling process. This is also the case for UV-curable inks used in some inkjet printers.

As small amounts of papers printed with UV-cured inks can impair the deinkability of a load of paper for recycling, UV-prints have to be kept separately where they accumulate, e. g. printer waste, and must not be mixed with other graphic papers for deinking. Once they have left the print shop, it is almost impossible to identify and separate them during collection and recycling processes. Newly developed inks might be a way out, if they are designed to be removable in the paper recycling process: They should detach from the fibres under the alkaline pulping conditions, disintegrate into small particles, and leave the process clinging to the soap bubbles in a flotation cell.

Water is not better than oil: Check your ink’s properties

Different printing inks pose different challenges to the deinking process. Water based inks cause problems as they dissolve in the process water; cross-linked particles due to their size, flexibility or surface properties can neither be separated mechanically (screens) nor by flotation. This is why — also without UV-curing — most current commercially used inkjet inks are rated undeinkable. Already in small amounts they can lead to severe brightness problems in the paper mill.

Another cross-linked challenge is polyethylene liquid toner (HP Indigo), currently used for most of the photobooks. This is a thin plastic film rather than a conventional printing ink. During the recycling process, this film breaks into snippets, which cannot be removed sufficiently. These snippets have already led to significant damage in a paper mill, since then photobook printer waste must not be mixed with graphic paper for recycling and at best be used for corrugated board.

More ink, more variety, less fibres

At the same time, with decreasing grammage of newspapers and more coloured illustrations, paper mills have to remove more and more ink from less and less fibres.

Together with ink manufacturers, the respective associations, and publishers paper mills continuously check the deinkability of current printed products. For this purpose together with the European Recovered Paper Council (ERPC) a scoring system has been developed.** Together the industries look for ways to replace poor deinkable printing inks by more recycling-friendly solutions.

INGEDE is an association of leading European paper manufacturers founded in 1989. INGEDE aims at promoting utilisation of graphic paper for recycling (newsprint, magazines and office paper) and improving the conditions for an extended use of paper for recycling for the production of graphic and hygiene papers.

* Deinking is the removal of printing ink during the paper recycling process.

** ERPC is the European Recovered Paper Council. The “Deinkability Score” system is available from the ERPC website www.paperrecovery.org.

It’s Tissue scores another great success

Tissue Italy network confirms the next edition for 2018

The second edition of It’s Tissue has proved inspirational for the sector with more than 1,000 visitors from around the world visiting Lucca between June 21 and 28. This is an increase of more than 42 percent on the debut event.

The second edition of It’s Tissue has proved inspirational for the sector with more than 1,000 visitors from around the world visiting Lucca between June 21 and 28. This is an increase of more than 42 percent on the debut event.

The Tissue Italy network of 12 companies behind iT’s Tissue have confirmed that, thanks to the very enthusiastic international response, the third edition will take place in 2018. The 12 companies forming the Tissue Italy network are: A Celli, Elettric 80, Fabio Perini, Futura, Gambini, MTC, Omet, PCMC, Pulsar, Recard, TMC and Toscotec. Some of the companies are competitors, others offer complementary solutions. All share the passion for tissue technology synonymous with Lucca, Reggio Emilia and Lecco.

Tissue technology is one of many industries to be limited by the traditional exhibition format because of the sheer size of the equipment involved. This is where It’s Tissue, a week’s worth of open houses and other events, really plays its part. The participants can see, hear and touch technology, working with real products.

Network President Matteo Gentili said: “iT’s Tissue has proved again to be a great success. It is a wonderful celebration and exploration of tissue technology and a strong signal of the health of the Italian sector. To see so many people from five continents make the journey to Lucca to witness our solutions in action is a source of great pride and an affirmation of the event itself. They have seen the best the market can offer.”

Voith: Rebuild of Gruvön PM 6 successfully completed

Voith has successfully completed the modernization of the paper machine PM 6 at BillerudKorsnäs AB in Gruvön, Sweden. As part of the rebuild project, the press section and parts of the dryer section have been modernized. BillerudKorsnäs manufactures on the PM 6 fluting for packaging paper from virgin fibers.

Voith has successfully completed the modernization of the paper machine PM 6 at BillerudKorsnäs AB in Gruvön, Sweden. As part of the rebuild project, the press section and parts of the dryer section have been modernized. BillerudKorsnäs manufactures on the PM 6 fluting for packaging paper from virgin fibers.

In the press section the existing roll press was taken out of the second position and installed in the first press position. Now a new NipcoFlex shoe press is being used as the second press. The NipcoFlex package delivered to BillerudKorsnäs is the first one which can achieve lineloads of up to 1,700 kN/m. This is only possible through an optimal combination of roll, shoe, press sleeve and press felt, which were all developed by Voith. Through the extremely high press pulse maximum dewatering is achieved with the highest paper quality. The closed web run through the press reduces sheet breaks and increases the runnability of the paper machine. Dryness and speed of the paper machine are increased simultaneously. In addition, the cantilevering structure in the shoe press position of the new press allows the use of endless felts.

For the conditioning of the press felt a ProLub cleaning system has been installed for the first time in a paper machine for packaging papers. ProLub cleans continuously the felt across the entire working width. The dryer section has been reduced by two dryers, resulting in further energy savings.

Also part of the scope of supply were MultiFlex machine clothings in the press and dryer section and an OnQ ModuleSteam steam box that ensures a uniform CD moisture profile and a higher dryness.

BillerudKorsnäs AB, headquartered in Solna, Sweden, emerged in 2012 from the merger of Billerud and Korsnäs and is one of the leading manufacturers of packaging paper made from virgin fibers.

Further information is available on the Voith website at www.voith.com/paper. Voith Paper is also on Twitter and YouTube.

Voith Paper is a division of the Voith Group and the leading partner to and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-saving products to reduce the use of energy, water, and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 39,000 employees, sales of €5.3 billion and locations in more than 50 countries, making it one of the largest family-owned companies in Europe.

European paper and beverage carton industries welcome European Parliament’s views on renewable and recyclable materials

On Thursday 9 July, the European Parliament gave a clear message to the European Commission to address crucial issues in an ambitious circular economy package. These include ending the landfill and incineration of recyclable waste, applying mandatory separate collection schemes and making the bio-economy an integral part of the circular economy.

The European paper and beverage carton industries have called upon the European Commission for a long time to support the industry’s efforts in further improving recycling, but also to extend the scope of the circular economy package from reducing waste to including measures that foster responsible sourcing of raw materials and particularly promote the use of responsibly sourced renewable materials.

Marco Mensink, CEPI Director General says: “The European Parliament has now given a clear mandate for making the bio-economy an integral part of the circular economy. Renewability is nature’s way of circularity, clearly recognized by MEPs in their vote.”

Bertil Heerink, ACE Director General adds: “A well-functioning circular economy will benefit from an increased use of renewable resources. We therefore welcome Thursday’s vote that underlines the importance of shifting from finite to renewable resources. We are looking forward to a constructive dialogue with the European Parliament on all topics related to the circular economy.”

CEPI aisbl - The Confederation of European Paper Industries

CEPI is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 515 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 940 paper mills. Together they represent 23% of world production. For more information please visit: http://www.cepi.org/

ACE aisbl - The Alliance for Beverage Cartons and the Environment

ACE provides a European platform for beverage carton manufacturers Tetra Pak, SIG Combibloc and Elopak and their paperboard suppliers in Europe Stora Enso and BillerudKorsnäs to benchmark and profile cartons as renewable, recyclable and low carbon packaging solutions. Engaging with stakeholders and partners seeking high environmental stewardship, it contributes expertise to EU policy, legislation and standard‐setting. For more information please visit: http://www.beveragecarton.eu

For further information please contact:

CEPI: ULRICH LEBERLE, RAW MATERIALS DIRECTOR

TEL +32 (0)2 627 49 23 • This email address is being protected from spambots. You need JavaScript enabled to view it.This email address is being protected from spambots. You need JavaScript enabled to view it.

ACE: MAJA DRČA, POLICY AND COMMUNICATIONS ASSISTANT

TEL +32 (0)2 504 07 12 • This email address is being protected from spambots. You need JavaScript enabled to view it.

ETS falls short of expectations

The Juncker Commission has launched the largest industrial policy decision it will take in its entire mandate, with the new proposal for the EU Emission Trading System. The proposal has a number of good elements but falls short in its protection of energy intensive industries. Member states hold the key to the solution.

The Juncker Commission has launched the largest industrial policy decision it will take in its entire mandate, with the new proposal for the EU Emission Trading System. The proposal has a number of good elements but falls short in its protection of energy intensive industries. Member states hold the key to the solution.

In October 2014 the European Council recognised that measures to protect energy intensive industry from carbon leakage should be maintained when revising the EU ETS. The Council concluded the most efficient installations in sectors such as the pulp and paper industry should not face undue carbon costs that would impact their global competitiveness.

Member states however added expectations on the revenues they want from the EU ETS. Today’s proposal therefore fixes the share of auctioning vs. the share of free allocation. “The proposal shows the member states cannot have their cake and eat it. If policy makers in Brussels and the member states are serious on growths and jobs, the fixed share of free allocation should be changed to really protect industry as agreed by the Heads of State”, said Marco Mensink, CEPI Director General.

CEPI does appreciate the focus on low carbon investments and support for technology and innovation in the new proposal. The use of more accurate production data is good, even though the proposal could be more ambitious. CEPI also believes the linear reduction of the benchmarks used for free allocation is reasonable and improves predictability.

The proposal does however not solve the lack of free allocation for Combined Heat and Power Plants in Europe, which has been an additional factor in closing down very carbon efficient gas-fired energy plants in Europe. The pulp and paper industry is a leading CHP sector, producing over 50% of its electricity consumption by itself.

Finally, the proposal strengthens the focus of member states on compensation for higher electricity costs to industry, but does not lead to a harmonised EU approach, which is what the internal market requires. Member States have to align their compensation schemes, so industry is treated equal across Europe.

The European Pulp and Paper Industry is a globally competing sector, with over 700 installations covered by the EU ETS. Total sector fossil CO2 emissions were 31 Million tonnes in 2014, already reduced from 43 Million tonnes of CO2 in 2005. The sector has a clear focus on breakthrough technology programmes through its 2050 Low Carbon Roadmap for the Forest Fibre Sector. “Sufficient carbon leakage protection is essential, especially for sectors that want to invest in low carbon technologies in Europe. In order to reduce emissions, we need to be attractive for investments”, concluded Marco Mensink. CEPI calls upon the policy makers to rethink their approach.

CEPI aisbl - The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus Norway) CEPI represents some 505 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 920 paper mills. Together they represent 23% of world production.

Website: http://www.cepi.org/

Ingevity Announced as Name of MWV Specialty Chemicals Division

Ingevity will be the new name of MWV Specialty Chemicals division of WestRock Company (NYSE:WRK). It will begin transacting business as Ingevity on September 1. As previously announced, the business is slated to be spun off as an independent, publicly-traded company around the end of the year.

Ingevity will be the new name of MWV Specialty Chemicals division of WestRock Company (NYSE:WRK). It will begin transacting business as Ingevity on September 1. As previously announced, the business is slated to be spun off as an independent, publicly-traded company around the end of the year.

"Ingevity is a unique expression of our purpose - to turn our customers' complex challenges into powerful possibilities," said Ed Rose, president, MWV Specialty Chemicals. "The name speaks to our longstanding record of success and commitment to serving our customers through innovative products, processes and services. Our announcement is the first step in a comprehensive plan to launch our brand, and define our future as a separate and independent company that will be better positioned to profitably grow in our targeted markets."

The Specialty Chemicals division develops and delivers high performance chemicals and materials that make a real difference in the real world - enabling oil to flow better, colors to shine brighter, roads to last longer and air to breathe cleaner. With a history of innovation spanning over 100 years, the division generates industry leading returns by exceeding the performance expectations of its customers across the mega-trend aligned markets of energy, infrastructure and transportation.

The separation is expected to be executed by means of a tax-free spinoff of the Specialty Chemicals business to shareholders of WestRock Company, resulting in two independent, publicly traded companies.The spinoff is expected to be completed around the end of the calendar year, subject to customary conditions. There can be no assurance regarding the ultimate timing of the spinoff or that it will be completed.

About WestRock

WestRock Company (NYSE:WRK) aspires to be the premier partner and unrivaled provider of paper and packaging solutions in consumer and corrugated markets. WestRock's 42,000 team members support customers around the world from approximately 275 operating and business locations spanning North America, South America, Europe and Asia. Learn more at westrock.com.

Andromeda redraws the boundaries at iT’s Tissue

Futura launched a complete new converting solution at iT’s Tissue which redraws the boundaries for tissue roll products converting for the benefit of customers.

Revealed at FuturaLab during the Andromeda Showcase, It’s Tissue, June 22-26 in Lucca, this extraordinary concept has been two years in development. Tissue professionals from around the world came to witness Andromeda for themselves.

They were very impressed: In all the key areas of process continuity, overall equipment effectiveness, safety, productivity, layout, manpower reduction and finished product quality, Andromeda sets a new benchmark.

Head of Technology and Futura Lab Director Giovacchino Giurlani said: “The Andromeda Concept is the result of a tremendous team effort at FuturaLab. We are convinced that it represents a better way to make roll products in all respects. Now that people have seen the concepts in action, they can see their positive impact in a commercial context. For Futura, the Andromeda Showcase represents a revelation for the future of converting.”

CEO Fabio Boschi added: “We are delighted that so many people from around the world came to witness this landmark event in converting. The Andromeda Concept was only made possible because of our faith in the vision of dedicated engineers and designers. The status quo is easier, but that is not the Futura way.”