Ianadmin

Kemira Capital Markets Day 2015: Financial targets for 2017 unchanged, updated strategic objectives for segments

Kemira held its 2015 Capital Markets Day (CMD) in its R&D center in Espoo, Finland. The company presents its current strategy and related financial targets.

Kemira held its 2015 Capital Markets Day (CMD) in its R&D center in Espoo, Finland. The company presents its current strategy and related financial targets.

The company's updated vision "The first choice in chemistry for water-intensive industries" communicates customer and innovation focus as well as sustainable, long-term shareholder value generation.

Company's mid-term financial targets remain unchanged, expecting revenue of EUR 2.7 billion in 2017, with an operative EBITDA margin of 15% and gearing level < 60%.

Kemira's mid-term targets are expected to be reached through organic and inorganic growth, as well as continuous efficiency and profitability improvements, including e.g.:

- Commercialization of new innovations, especially for packaging board industry

- Investments in long-term "chemical island" bleaching chemical contracts

- Scaling up operations in the APAC region

- Leveraging global polymer capacity by entering new application areas like Chemical Enhanced Oil Recovery (CEOR) and oil sands in Oil & Mining

- Organic growth and efficiency improvements in Municipal & Industrial

- Revenue and cost synergies from acquisitions.

Kemira has three core segments with well-defined strategic objectives. The company announces that the Paper segment has been renamed as Pulp & Paper segment. After the recent acquisition of AkzoNobel's paper chemicals business, Kemira is now the only bleaching, process and functional chemicals provider with a truly global reach, serving the pulp and paper industry. The company also updates the segment-specific strategic objectives as follows:

- Pulp & Paper segment: Targeting above-the-market growth with improved profitability (old strategic objective: targeting profitable above-the-market growth). The target is to reach at least two times the market growth. This may include selective bolt-on acquisitions. Pulp & Paper's profitability is expected to be in-line with the Kemira Group target.

- Oil & Mining segment: Targeting growth and expansion to new applications (old strategic objective: targeting profitable above-the-market growth). The segment is expected to return to organic growth in 2016, regardless of current oil price levels. Over-the-cycle growth target is to grow at double-digit rate. Over-the-cycle profitability is expected to be higher than the Group target.

- Municipal & Industrial segment: Steady growth and cash flow generation (old strategic objective: focus on profitability improvement and on maximizing cash flow generation). Municipal & Industrial's growth is expected to be between 2-4% (CAGR) and profitability slightly below the Group target.

Kemira's President and CEO, Jari Rosendal, will give an overview of the company's strategy in his CMD presentation. Other Kemira speakers include Petri Castrén, CFO; Heidi Fagerholm, CTO; Mats Rönnbäck, Interim President, Pulp & Paper; Billy Ford, SVP, Pulp & Paper Americas; Antti Salminen, President, Municipal & Industrial and Tarjei Johansen, President, Oil & Mining.

All Kemira CMD 2015 presentations are available at www.kemira.com at around 11.00 am (CET+1). The CMD can be followed via webcast at www.kemira.com/investors and in Twitter at #KemiraCMD.

For more information, please contact

Tero Huovinen, Senior Vice President, Communications & Corporate Responsibility

Tel. +358 10 862 1980

Kemira is a global chemicals company serving customers in water-intensive industries. We provide expertise, application know-how and chemicals that improve our customers' water, energy and raw material efficiency. Our focus is on pulp & paper, oil & gas, mining and water treatment. In 2014, Kemira had annual revenue of EUR 2.1 billion and around 4,250 employees. Kemira shares are listed on the NASDAQ OMX Helsinki Ltd.

www.kemira.com

Toscotec-supplied MODULO-PLUS tissue machine starts up at Liuzhou Liangmianzhen Paper Product mill in China

Liuzhou Liangmianzhen Paper Product Co., Ltd. has started up the first of two MODULO-PLUS ES tissue lines supplied by Toscotec at its mill in Liuzhou, Guangxi.

In the next couple of weeksthe start-up of the second tissue line and of the TT WIND-M high-speed slitter rewinder will follow suit.

This is the first imported tissue machine to come on stream at Liangmianzhen Paper Product mill, one of Liangmenzhen Group’s subsidiaries, and thanks to the strong partnership between Toscotec and the Chinese producer, start-up was successfully achieved according to schedule.

This first new line alone will increase the company’s tissue production by 21k t/y.

Toscotec’s scope of supply included a MODULO-PLUS ES machine, designed for aspeed of 1500 m/min, featuring TT SYD-15FT (4572mm) and double press configuration, Milltech’s steam-heated hood, stock preparation equipment, electrical and control systems, spare parts for the entire plant and a full service package.

The significant advantage of Toscotec’s technology has been proved to be its cutting-edge Energy Saving drying package: Toscotec’s TT DOES (Drying Optimization for Energy Saving) ensures the lowest energy consumption,

with the highest machine performances. Its reliance on steam, as the sole drying energy source, perfectly meets the twofold objective of Chinese producers to profit from the most accessible and cost-effective energy source and achieve maximum production of high-quality tissue.

About Toscotec S.p.A.

Toscotec is a turnkey technology supplier to the global paper industry, offering a complete suite of solutions for tissue, paper and board manufacture, as well as maintenance services for rolls and cylinders. Based in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec’s tradition of innovation, energy saving and partnership with customers dates back to its foundation in 1948. Since 2013 Toscotec has been the market leader in tissue machines sales.

Interview: Pulp and Paper industry is a forerunner for maintenance outsourcing

According to a survey made by Bain & Co, the pulp and paper (P&P) industry has been a forerunner in maintenance outsourcing. Pulp-PaperWorld.com sat down with Pertti Weissenfelt, Pulp and Paper Industry Segment Manager for Quant to get an insight into why this industry has outsourced more maintenance than any other industry.

According to a survey made by Bain & Co, the pulp and paper (P&P) industry has been a forerunner in maintenance outsourcing. Pulp-PaperWorld.com sat down with Pertti Weissenfelt, Pulp and Paper Industry Segment Manager for Quant to get an insight into why this industry has outsourced more maintenance than any other industry.

Has the P&P industry been under harder cost pressure than other industries?

They are today, especially printing paper production where the demand is declining all the time because of the digitalization that has had huge defect on printing paper consumption. Paper producers are looking for all possible ways to cut costs and ensure their own competitiveness in the market where prices have been declining for years.

Board and pulp producers are in a lot better market situation and basically they can sell what they are able to produce. For them, the most important thing than pure cost cutting is the reliability of the machinery to ensure the highest possible production efficiency – without forgetting the maintenance costs.

So one main driver for maintenance outsourcing in the P&P Industry has certainly been due to cost cutting. This is especially in Europe and US, while in some other regions the main driver has been the need to keep and improve maintenance capabilities and expertise.

Are P&P industry maintenance organizations more traditional when needing a culture change?

This is the main reason in many cases for maintenance outsourcing in every industry. Outsourced maintenance is driven as a business, which makes it vital for everyone to always consider the most efficient way of their own work. Furthermore, continuously develop it to be able to guarantee the most cost efficient solution to the customer and stay competitive in the market.

Does outsourcing maintenance give more flexibility than having it in-house?

This has always been important in the P&P industry. This is because the need for maintenance resources varies a lot for a longer period of time. For example, a pulp mill shut (normally between every 12-18 months) requires a lot more resources compared to the production phase. Secondly, due to a weak market (like now), when paper machines need to be occasionally stopped temporarily for days or even weeks due to lack of orders, the machines don’t need any maintenance. Both these situations are easier for the customers to outsource this maintenance cost, which guarantees better flexibility for resource allocations.

Do P&P mills contain more complex technology than other industries?

Today the P&P mills are highly automated and that has caused quite a big reduction of people working at mills. For example, the European P&P Industry had 420 000 employees in 1992. However in 2014, the amount was 180 000. Production at the same time has increased from 65Mt to 90Mt.

This result creates a higher automation rate, making machinery and maintaining them more complex, which requires an in-depth knowledge and skill base from the maintenance team. P&P mills don’t have many employees anymore. All of them have their own expertise, therefore they support the increasing development of maintenance outsourcing to companies who have a wide enough customer base to keep all needed resources. Pulp and paper production processes are already by themselves, complex enough to be managed. By outsourcing maintenance, the production organization can concentrate 100% on their own core, pulp and paper production.

Pertti Weissenfelt, Pulp and Paper Industry Segment Manager

From Finland, Pertti has 30 years of experience in industrial maintenance most of that being from Pulp and Paper industry in Finland, Belgium and Australia. He has been working as Maintenance Manager, Project Manager in Greenfields and Rebuilds, P&P Industry Specialist in Asia Pacific, MPC Manager for P&P, VP Engineering & Projects, VP Business Development, Global P&P Industry Sales Director and latest as Cluster Manager for Finland and Baltics.

“Pulp and Paper industry has always been a strong segment in our maintenance outsourcing business and we have a great track record and references in it. I’m exited being back in the global team and looking forward to work together with our regional teams to get us growing in P&P Industry.”

Do P&P Industry customers get more benefit out of outsourcing than other industries?

It is maybe easier in the P&P industry to define the full potential that exists in maintenance than in some other industry. This is because paper machines are quite similar for each different paper and board grades. Regardless of the original equipment manufacturer (OEM) who has made the machine, the machines have been like that for decades. This similarity makes them easier to compare.

Usually P&P companies are comparing their own machines to identify the ones that perform and the ones that don’t. Quite often, company targets are set based on their top sites. That still doesn’t demonstrate to the company if they are among the best compared to their competitors. Quant has been benchmarking the P&P industry for over 10 years and has a wide global database of paper and board machines’ efficiencies and maintenance costs, divided by production grades and geographical regions. Benchmarking with the best in the P&P industry is a strong tool when defining the full potential of maintenance.

Having such a similar machinery makes it more important to have the capability to find, share and implement best practices. There is basically no new equipment failures in the P&P industry. If you get a machine failure or problem that you haven’t seen before, it most certainly has happened somewhere else earlier and there is maybe a solution for it already.

Quant being a global industrial maintenance company with experience in the P&P industry over 25 years has wide network in the industry as well as other industries. This guarantees the access to best practices and specialists.

In your opinion, did the Pulp and Paper industry just happen to be the first industry where outsourcing started?

In some cases this may be true. Many of Quant’s (ABB at that time) first outsourcing agreements were done in the P&P industry and we became very good references that encouraged others in the same industry to outsource as well.

I would like to contact someone about outsourcing in this industry, click This email address is being protected from spambots. You need JavaScript enabled to view it.

About Quant

Quant ( www.quantservice.com ) is a global leader in industrial maintenance. For over 25 years, we have been realizing the full potential of maintenance for our customers.

Quant ( www.quantservice.com ) is a global leader in industrial maintenance. For over 25 years, we have been realizing the full potential of maintenance for our customers.

From embedding superior safety practices and building a true maintenance culture, to optimising maintenance cost and improving plant performance, our people make the difference.

We are passionate about maintenance and proud of ensuring we achieve our customers’ goals in the most professional way.

For more information about Quant, visit www.quantservice.com

To subscribe to our magazine Quant plus, please click here

Global Forest Products Industry Sponsors Awards Recognizing Student Architects

WASHINGTON - The International Council of Forest and Paper Associations (ICFPA) sponsored prizes to the student winners of the TREEHOUSING International Wood Design Competition, who were recognized at the United Nations Food and Agriculture Organization’s XIV World Forestry Congress in Durban, South Africa.

The winning designs can be viewed at www.treehousing-competition.com.

In the Affordable Wood Housing category, Monica Wozniak of Poland won the student prize for her design Natural Wood Skin. The student prize in the Tall Wood Buildings category went to Tatiana Chaatziioannou of France and Soufiane Chibani of Germany for their design The Social Net Wood.

“Congratulations to Ms. Wozniak, Ms. Chaatziioannou and Ms. Chibani for their prestigious accomplishments in wood design,” said ICFPA President and Brazilian Tree Industry (Ibà) President Elizabeth de Carvalhaes. “Our industry provides sustainable, affordable building materials, and we are thrilled to see young architects and designers invested in the efficient use of these valuable natural resources.”

“Wood in building design is seeing a resurgence around the world as architects and designers learn to work with it in more innovative and sustainable ways,” said renowned architect Michael Green, who judged the competition entries. “New wood technologies are linking our rural forest economies with our growing urban environments with increasingly larger and now taller wood buildings.”

The ICFPA will continue its support of students and young professionals through its soon-to-be launched Blue Sky Young Researchers Innovation Award initiative, which aims to demonstrate the global forest products sector as a vibrant and dynamic workplace for the future.

The ICFPA represents more than 30 national and regional forest and paper associations around the world. Together, ICFPA members represent over 90 percent of global paper production and more than half of global wood production.

For more information about the global forest and paper industry, visit icfpa.org.

Catalyst Announces Powell River Land Sale

Catalyst has announced the sale of approximately 250 hectares of surplus land in Powell River, British Columbia, for $4.5 million.

Catalyst has announced the sale of approximately 250 hectares of surplus land in Powell River, British Columbia, for $4.5 million.

The forested land is adjacent to the Powell River mill site. While the land was previously harvested by predecessor companies, it has never been the site of manufacturing activity. Catalyst had no plans to use this parcel of land.

About Catalyst Paper Corporation

Catalyst Paper manufactures diverse printing papers such as coated freesheet, C1S, coated and uncoated groundwood, newsprint, directory, as well as market pulp. Customers include retailers, publishers and commercial printers in North America, Latin America, the Pacific Rim and Europe. With five mills across North America, Catalyst has annual production capacity of 2.3 million tonnes. Catalyst is headquartered in Richmond, British Columbia, Canada, and is ranked by Corporate Knights magazine as one of the 50 Best Corporate Citizens in Canada.

SOURCE Catalyst Paper Corporation

For further information:

Investor Contact: Frank De Costanzo, Senior Vice President and Chief Financial Officer, 604-247-4014, This email address is being protected from spambots. You need JavaScript enabled to view it.; Media Contact: Fred Chinn, Vice President & General Manager, Powell River Mill, 604-483-2715, This email address is being protected from spambots. You need JavaScript enabled to view it.; Eduarda Hodgins, Director, Organization Development & Communications, 604-247-4369, This email address is being protected from spambots. You need JavaScript enabled to view it.

MoveRoll sucessfully completes its winder deck startup in USA paper mill

MoveRoll Oy has successfully completed a new winder deck startup in a Southern USA paper mill.This installation was made by our North America´s assembly partner Advanced Dynamics.

The full system consists of 20 MoveRoll horizontal conveyor modules with a total width of 7,5 meters and conveying length of 10 meters. In addition a MoveRoll Zero Energy receiver with same width as the conveyors was installed to ensure a gentle stopping of paper rolls into the next conveying device. This project has been MoveRoll´s first large scale winder deck application with three roll buffering places.

MoveRoll system was installed in the course of paper mill´s modernization the roll handling system. From a concrete floor with traditional roll stops, the paper mill has now an automated safe roll handling system. By completing the installation of MoveRoll horizontal conveyor, the paper mill not only has increased significantly the safety of its employees but it also improved the efficiency in roll handling process. Moreover, the system offers the possibility to store more rolls onto the winder deck and eliminates the need of an operator on that specific area. This lead to lower operational cost and fulfillment of new safety standards for the paper mill.

If you are interested to see the winder deck completed system receiving and conveying the paper rolls please watch the video below

For more information please contact us:

MoveRoll Oy

Pienteollisuustie 3 B

06450 Porvoo

Finland

Phone: +358 400 610764

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Pöyry awarded EPCM services assignment for state-of-the-art pulp mill, Fibria, Brazil

Fibria, the largest eucalyptus pulp producer in the world, has awarded Pöyry with the assignment for the Engineering, Procurement and Construction Management (EPCM) services for the Balance of Plant (BOP) of the Horizonte 2 project in Brazil. The services cover the required interconnection between all process areas, turbo generators and steam distribution system, water intake and effluent outfall systems, cooling towers, air compressors, chilled water system, central air conditioning for the mill and other complementary systems.

Fibria, the largest eucalyptus pulp producer in the world, has awarded Pöyry with the assignment for the Engineering, Procurement and Construction Management (EPCM) services for the Balance of Plant (BOP) of the Horizonte 2 project in Brazil. The services cover the required interconnection between all process areas, turbo generators and steam distribution system, water intake and effluent outfall systems, cooling towers, air compressors, chilled water system, central air conditioning for the mill and other complementary systems.

The annual target capacity for the mill is 1.75 million tonnes of eucalyptus-baled bleached pulp and the start-up is planned for the fourth quarter of 2017. The new pulp mill will be located in Três Lagoas, Mato Grosso do Sul State, where Fibria already has the Horizonte 1 pulp mill producing 1.3 MADtB/a since 2009. For Horizonte 1, Pöyry was responsible for the concept development and environmental studies, as well as for the BOP and EPCM services and overall project management.

This state-of-the-art mill is based on the use of best available technologies and best environmental practices. With this expansion, Fibria's total production capacity will increase from 5.3 million to more than 7 million tons of pulp per year. The existing mill is already self-sufficient in energy production and the Horizonte 2 Project will produce a surplus of 120 MWH.

Pöyry has been involved in the project since January 2011 when it was awarded an assignment by Fibria for the environmental and conceptual studies for the project.

"This assignment strengthens Pöyry's position as the world's leading pulp and paper engineering consultancy, and is the result of bringing together expertise from across a number of complementary disciplines within Pöyry" says Marcelo Cordaro, President of Pöyry's Regional Operations Latin America.

The value of the order is not disclosed. The order will be recognised in the Regional Operations, Latin America Business Line order stock in Q3/2015.

For further information, contact:

Marcelo H. Cordaro

President, Regional Operations Latin America

Tel. +55 11 34727398

Pöyry is an international consulting and engineering company. We serve clients globally across the energy and industrial sectors and provide local services in our core markets. We deliver management consulting and engineering services, underpinned by strong project implementation capability and expertise. Our focus sectors are power generation, transmission & distribution, forest industry, chemicals & biorefining, mining & metals, transportation and water. Pöyry has an extensive local office network employing about 6,000 experts. Pöyry's net sales in 2014 were EUR 571 million and the company's shares are quoted on NASDAQ OMX Helsinki (Pöyry PLC: POY1V).

Södra Cell Mörrum meets new environmental standards

Södra has just inaugurated the upgraded biological treatment facility for process water at Södra Cell Mörrum. The investment ensures that the mill will comply with the new environmental standards set by the Industrial Emissions Directive (IED), and is part of Södra’s major expansion project now being implemented across all three of its pulp mills.

Södra officially inaugurated a new water treatment plant to meet the latest environmental standards for sustainable industry, in compliance with the Industrial Emissions Directive (IED).

Pulp production is a water-intensive business, so treating and recycling process water to the highest standard is vital for a sustainable business, and thus an area of high priority for Södra.

This upgrade includes the addition of a new disc filter, which is used in the final stage of the treatment process. In addition, the system has been expanded to handle higher volumes of the process water in preparation for future pulp capacity increases.

The environmental impact of Södra’s pulp mills is at such a low level that all of the company’s pulp can be used for paper products that carry the Swan or EU ecolabels. The biological treatment facility has mainly been designed to reduce emissions of nitrogen, phosphorus and TOC (Total Organic Carbon) to the Baltic Sea. Södra aims to be more environmentally conscious than mandated by law, and to exceed the expectations placed on a modern industry.

Further information:

Thomas Mörnhed, Project Manager

Tel: +46 (0)454-596 09

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Arjowiggins Graphic Scoops Award for recycled-papers.co.uk

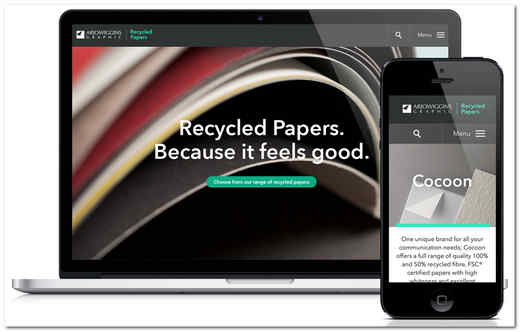

Arjowiggins Graphic, the leading environmental paper manufacturer, is pleased to announce that it’s re-launched UK website, www.recycled-paper.co.uk, has won Best Environmental Website at the 2015 WebAwards. In addition, the website has been shortlisted for Best Website at the B2B Marketing Awards.

Since launching in February, www.recycled-paper.co.uk has seen record results, which includes the highest ever recorded web traffic, sample orders enquiries and environmental benefit statement requests.

In the months of February and March 2015 alone, the business saw more website visits than the previous 12 months of 2014, with a 750% year on year increase in website traffic in the first three months. Sample requests increased 350% with interaction on social media channels boosted by 130%.

Will Green, Digital Marketing Manager, Arjowiggins Graphic UK says: "The development of the new recycled-papers website has been an astounding success. Not only does Arjowiggins Graphic have one of the leading websites in our field, we also have delivered outstanding brand and business results."

In awarding the prestigious WebAwards Best Environment Website award, an evaluation of the Arjowiggins Graphic UK website was conducted by independent expert judges that included representatives from Google, Yahoo! and Disney.

The website features ground breaking imagery and design, with a dynamic interface that is fully compatible with mobile devices. This means that printers, designers and end users can easily order samples and calculate Environmental Benefit Statements on the go. A new innovative ‘paper finder’ feature, selects the perfect paper fit, providing users detailed information on the environmental efficiency and technical specification of each paper manufactured by Arjowiggins Graphic.

The website features ground breaking imagery and design, with a dynamic interface that is fully compatible with mobile devices. This means that printers, designers and end users can easily order samples and calculate Environmental Benefit Statements on the go. A new innovative ‘paper finder’ feature, selects the perfect paper fit, providing users detailed information on the environmental efficiency and technical specification of each paper manufactured by Arjowiggins Graphic.

Featuring original photography of all of Arjowiggins Graphic papers throughout the site - including Cocoon, Cyclus and Eural - as well as examples of end products in a dedicated paper showcase, the website offers visitors the opportunity to explore the range in an increasingly visual and dynamic format. The Green Matters section of the website includes new videos and animations depicting the lifecycle of recycled paper and behind the scenes footage of the Arjowiggins Graphic manufacturing mills, emphasising the benefits of recycled paper and engaging customers in environmental concerns.

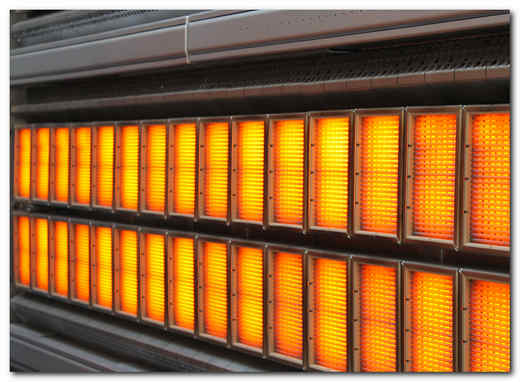

Bekaert Solaronics will install a UniDryer® V3 at Technocell Günzach, Germany.

Bekaert Solaronics is partnering with Bellmer for the installation of a UniDryer® V3 system in PM14 at Technocell Günzach’s paper mill in Germany. The extensive revamp of the paper machine is scheduled to take place in the 4th quarter 2015.

This installation is part of the Technocell Günzach’s project to expand the production of pre-impregnated papers, a key growth segment. After the rebuild, the paper machine PM14 will produce both pre-impregnated PRIP® as well as nonwoven papers coated on both sides for wallpapers.

The objective of the installation in the Günzach mill is the non-contact drying of a new specialty paper. The UniDryer® V3 offers a rapid heating, high energy efficiency, high compactness and ultimately a better paper quality. The system will be equipped with Gem12E, the latest generation of Bekaert Solaronics emitters that allow an increased drying efficiency by approximately 10 % compared to the regular Gem12 emitters.

About Gebr. Bellmer GmbH Maschinenfabrik

Located in Nierfen, Bellmer is a specialist starting from the planning up to the turnkey implementation of machines and plants for the manufacturing of paper and board. The company supplies from individual parts to complete machines for the paper industry. Bellmer has been working for the pulp and paper industry all over the world since 1842.

About Felix Schoeller Group

Founded in 1895, the Felix Schoeller Group is a family business with worldwide operations producing specialty papers for photographic applications, digital printing systems, self-adhesive applications and for the furniture, wood-based products and wallpaper industry.

About Bekaert and Bekaert Solaronics

Bekaert www.bekaert.com is a world market and technology leader in steel wire transformation and coating technologies. We pursue to be the preferred supplier for our steel wire products and solutions by continuously delivering superior value to our customers worldwide. Bekaert (Euronext Brussels: BEKB) is a global company with 30 000 employees worldwide, headquarters in Belgium and € 4 billion in annual revenue. Founded in 1967, Bekaert Solaronics supplies customized drying and heating systems based on gas and electrical infrared technology to a wide range of industries. Today, more than 1 000 systems have been installed worldwide. The company also provides maintenance services and is available to assist on upgrades or improved energy efficiency of existing systems.