Ianadmin

PCMC’s XF800 wrapper offers a simpler operating system and increased flexibility for Sun Paper

The state-of-the-art wrapper meets the ever-changing needs of the tissue industry

Paper Converting Machine Company (PCMC), part of the Barry-Wehmiller family, has announced the sale of a new XF800 wrapper to Sun Paper in Duncan, South Carolina.

The XF800 is replacing a reciprocating wrapper that was a bottleneck on one of Sun Paper’s existing winder lines.

PCMC will install an XF800 wrapper at Sun Paper later this year

PCMC will install an XF800 wrapper at Sun Paper later this year

“PCMC’s continuous flow technology gives us increased throughput on a broad range of products from a single machine,” said Joe Salgado, Executive Vice President at Sun Paper. “We’re also excited about the improved change repeatability and the simpler operating system that the XF800 provides.”

As part of the family of packaging products from PCMC, the XF800 wrapper features a continuous motion design, flexible layout options and motorized adjustments for fast initial pack setup. With an optional fifth infeed lane and third level, it can adapt to a variety of packaging projects to meet the ever-changing needs facing the tissue industry today.

“This purchase is the result of creative thinking to solve a customer’s problem and steward the trust placed in us,” said Bob Schuh, Tissue Packaging Sales Director for PCMC. “Project team members from Sun Paper and PCMC took a holistic view of Sun Paper’s current production environment and future goals. In doing so, we actually codeveloped a solution outside of the original scope of the project that positions Sun Paper for even greater success through added efficiency and easier operations.”

The Sun Paper XF800 wrapper, the latest in an extraordinary boom in PCMC packaging equipment orders, is scheduled for installation in October 2017.

Sun Paper is a family-owned consumer products manufacturer in Duncan, South Carolina, with a primary focus on private label bath tissue, kitchen towels, napkins and facial tissue. Sun Paper’s products are found in major retailers across the country.

ABOUT PAPER CONVERTING MACHINE COMPANY (PCMC)

Paper Converting Machine Company (PCMC) specializes in the design and manufacture of high-performance converting machinery for the tissue, nonwovens, package-printing and envelope-manufacturing industries worldwide. Our comprehensive product offerings include rewinding, laminating, printing, embossing, perforating and packaging equipment for tissue and towels; folding and converting machines; and a complete range of flexographic printing presses, serving the flexible-packaging, prime-label and carton-converting industries. For more about PCMC, which is part of Barry-Wehmiller, go to pcmc.com.

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper-converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2.5 billion organization with more than 11,000 team members united by a common belief: to use the power of business to build a better world. CEO Bob Chapman shares the story of the company’s transformation in his new book, Everybody Matters: The Extraordinary Power of Caring for Your People Like Family. To learn more, go to barrywehmiller.com.

How RocktTenn (WestRock) Doubled their Speed, OEE and Reliability

All manufacturing leaders know what’s expected of them. They face financial statements, customers, stakeholders, etc. on an ongoing basis. There’s no denying the what. Truly world-class leaders continually search for the best how, and they ask, how are we going to do this? What is the best way to achieve our expectations? Even the best companies struggle with asking and implementing these questions, and they’ll struggle with it at the top of the organization. Once Leadership has consensus on the how, then it’s just a matter of maintaining that commitment and continually communicating that vision to the organization.

Beau Groover, Director of Performance Excellence with RockTenn (WestRock), says “RockTenn was not much different from most companies in how it previously established goals. We would look at where we are performing currently in a measure and then say, ‘How do we improve that by 5 percent, how do we improve that by 3 percent?’ And that would set about how they frame up their resources and their capital and their people.”

Beau Groover, Director of Performance Excellence with RockTenn (WestRock), says “RockTenn was not much different from most companies in how it previously established goals. We would look at where we are performing currently in a measure and then say, ‘How do we improve that by 5 percent, how do we improve that by 3 percent?’ And that would set about how they frame up their resources and their capital and their people.”

RockTenn (WestRock) is a leading producer of corrugated and consumer packaging and recycling solutions; and is one of several companies that reached out to Performance Solutions by Milliken to helped adopt their own, unique version of the Milliken Performance System (MPS). An award-winning system geared to compliment, revamp, and accelerate current performance systems towards new levels of success.

At RockTenn, Groover serves as a conduit interacting with teams working in plants, managing the relationship with Performance Solutions, and bringing information to RockTenn’s steering committee. He says, “at the end of the day, there are thousands of books written on lean, six sigma, and TPS. If the leadership isn’t capable or willing to go through what it takes to build a high-performing team, it doesn’t matter how many tools and how many super-duper black belts you hire, you’ll never get there. And the Milliken system, in my opinion, focuses directly on the culture. And that’s what has enabled them to reach the performance levels they have.”

Groover notes that the Performance Solutions approach is heavily weighted on the front end to how an organization puts in the Performance System, and, on the back end, weighted to the actual performance it gets from the system. “We get so wrapped up in the results that we fail to look at the process.” He uses a baseball analogy of how well a team conducts batting and fielding practice will usually parallel with how well the team performs in a game. In manufacturing, it means focusing on the processes that yield an output target, such as OEE, rather than how to move the metric.

“Through the Milliken process, we’re trying to get our plants thinking about OEE as an output mechanism,” says Groover. “How well we run the equipment, how well we train our associates, how well we take care of our equipment, how well we prepare our inventory — all of that leads to the result. And the result is a high OEE number, which is what we want.” In approximately one year, the process work at RockTenn began to move the organization across never before seen thresholds of performance, adds Groover, yielding double-digit improvements in speed, OEE, and reliability. “We’ve uncovered/created the equivalent of 3 full sites worth of capacity that we didn’t even know was achievable. The financial impact of that goes far beyond the P/L and starts impacting decisions such as capital investment and footprint rationalizations.”

“It’s a different way of thinking about where your problems are and where your opportunities lie. We become very accepting of our reality that we see. We start just accepting things instead of challenging them to say, ‘Why does it work like that, or why do we have that failure, or why do we have that downtime?’ The Performance System takes all that emotion and acceptance out of it, and it makes it a data question. Here’s where you’re performing. Here’s where you’re losing dollars. What are you going to do about it?”

ABOUT PERFORMANCE SOLUTIONS BY MILLIKEN

Performance Solutions by Milliken brings a unique, Practitioner-based value proposition to its clients and has built an enviable record of helping companies achieve substantial and sustainable improvements in their operations and safety excellence efforts. This approach, built on the foundation of lessons learned while Milliken & Company created and implemented its own world-class performance system, helps client organizations engage and empower their associates by working side-by-side to establish a culture of continuous improvement and drive breakthrough operations impact. Performance Solutions currently serve companies in more than 100 operating locations in 28 countries across a wide range of industry sectors.

performancesolutionsbymilliken.com

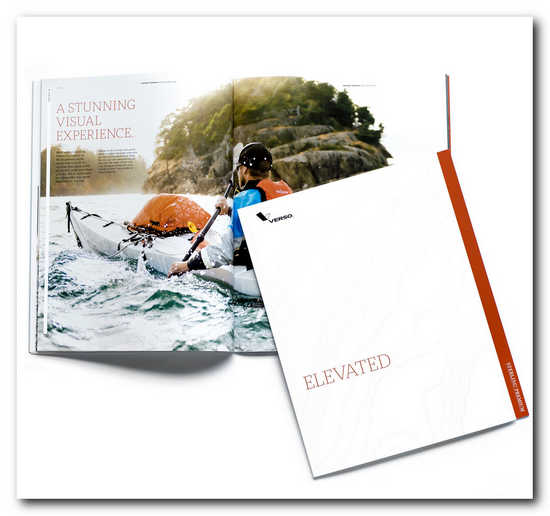

Verso Showcases Brighter, Whiter Sterling® Premium in New Printed Promotion: "Sterling® Premium. ELEVATED."

Promotion Features Innovative U.S. Manufacturer Oru Kayak®

Verso Corporation (NYSE: VRS) continues to celebrate innovative U.S. manufacturers that share its passion for being the best at what they do with the release of the second in its series of printed promotions titled Sterling® Premium. ELEVATED.

"Verso's Sterling® Premium challenged the paper quality/cost paradigm to create a first – premium paper at a budget friendly price," said Verso President of Graphic Papers Mike Weinhold. "We established a new status quo, and then challenged it again, improving shade and brightness to a whiter-white 96 – at the same great price."

"Sterling® Premium's new, brilliantly bright optics combined with premium surface quality, print performance, product breadth, sustainability and service have elevated the definition of what it means to be the best of the best," said Verso Brand Marketing Manager Tanya Pipo. "When we were looking for like-minded companies that share the same passion and courage for elevating their brands to the next level we were introduced to Oru Kayak® in San Francisco. Like Sterling® Premium, Oru Kayak is elevating the expectation of how to make quality kayaks with premium attributes at a reasonable price."

ADVENTURE, ELEVATED. Oru Kayak® co-founder and designer Anton Willis developed the concept of a foldable kayak designed with quality, aesthetics and portability in mind. "It was origami that got me thinking," he says. "What if you could actually make a kayak that folded up like a piece of paper?" Through great design, portability, lighter weight and lower price than a conventional craft with no sacrifice in performance, Oru Kayak® is changing the game, elevating adventure on the water by making it more accessible to more people.

PAPER, ELEVATED. This new printed brochure showcases the brighter, whiter shade and exceptional print quality of Sterling® Premium through detailed imagery of beautifully crafted kayaks. The print demonstrations on gloss, dull/silk and matte finishes highlight the paper's premium surface quality, and the print comparisons between Sterling® Premium sheetfed and Sterling® Premium Digital™ for HP Indigo show the flawless print quality from offset to digital. The promotion is enhanced with a short video featuring the founders of Oru Kayak® using Layar® technology, a leading augmented reality app. Verso Marketing Communications Manager Julie Davis explains, "When printed images are scanned using the Layar® app, the technology recognizes the image and relates it to a piece of registered content with Layar®. This is an exceptional way to show how print links to new technology for a deeper experience without ever leaving the printed page."

Sterling® Premium has the widest and deepest offering of any premium grade, with a full line of sizes, finishes and weights to meet any need. Sterling® Premium offers true premium selection, with the industry's broadest range of basis weights—70 lb. text through 130 lb. cover, including 7 pt. and 9 pt. caliper guaranteed products for direct mail. The product line also includes two matching digital companion products, Sterling® Premium Digital™ and Sterling® Premium Digital™ for HP Indigo, guaranteed on all digital offset, toner and HP Indigo print equipment. Sterling® Premium is available with post-consumer recycled fiber, complies with Lacey Act requirements and is chain-of-custody tri-certified to the Forest Stewardship Council® (FSC®) BV-COC-953662, Programme for the Endorsement of Forest Certification™ (PEFC™) BV-PEFCCOC-US09000012, and Sustainable Forestry Initiative® (SFI®), BV-SFICOC-US09000011 standards.

To learn more about Sterling® Premium, please visit our website versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. The FSC® trademark license code for Verso Corporation is FSC® C014984. For more information, visit us online at versoco.com.

About Oru Kayak®

Oru Kayak is a San Francisco-based company that manufactures and markets a line of unique high-performance folding kayaks. Inspired by the ancient Japanese art of origami (Oru means "fold" in Japanese), the company's patented technology, lightweight skin and ingenious design enable Oru Kayaks to be folded down, stowed in a trunk, checked on a plane and hiked into remote waters. This enables lovers of the outdoors to get out there, enjoy the water and explore like never before. Oru Kayak aims to change the way people connect with water, whether it's for an hour, afternoon or full weekend adventure. Through innovative products and services, the company and its people hope to make paddling more convenient, fun and freeing for everyone. Learn more about this extraordinary company at orukayak.com.

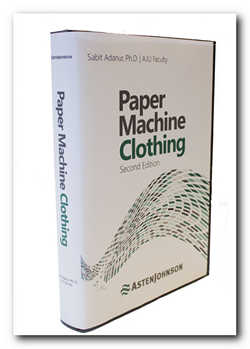

Second edition of Paper Machine Clothing book available for pre-order on web or during PaperCon

AstenJohnson, the people who “wrote the book” on paper machine clothing, have done it again.

The Second Edition of Paper Machine Clothing is being finalized for print and will be available in September. Interested papermakers, managers, engineers, professionals, and students can pre-order a copy in advance at a discounted price during PaperCon 2017 (April 23-26) in Minneapolis or by visiting AstenJohnson’s website.

The Second Edition of Paper Machine Clothing is being finalized for print and will be available in September. Interested papermakers, managers, engineers, professionals, and students can pre-order a copy in advance at a discounted price during PaperCon 2017 (April 23-26) in Minneapolis or by visiting AstenJohnson’s website.

Paper Machine Clothing, which builds on the excellent work in the first edition authored by a former AstenJohnson associate, Dr. Sabit Adanur in 1997, is a hardback 200+ page reference resource providing information about key papermaking topics as well as some of the latest technology available in paper machine clothing. Practical guides for troubleshooting and properly applying machine fabrics are included throughout the book.

In brief, the book gives an introduction to pulp and papermaking technology and then covers the main processes of Forming, Pressing, and Drying in detail. Design, manufacturing, testing, application, and service of paper machine fabrics for each machine section are explained in detail.

New features in the Second Edition include:

- Includes international units

- Chapter devoted to Lean Manufacturing and Six Sigma

- Papermaking tips for forming, pressing, and drying

- Chapter on paper machine auditing

- Expanded troubleshooting section.

To see examples of Paper Machine Clothing, or to pre-order copies at a discount, visit AstenJohnson at PaperCon (booth 315) or browse to: www.astenjohnson.com/papermachineclothing.

Valmet and Children and Youth Foundation launch a unique social responsibility program to enhance employment possibilities for young people in Finland

To celebrate its 220 years of industrial history and the centenary of Finland's independence, Valmet is offering 100 young people an opportunity to develop their working life skills. The company will hire young people aged 16-29, who might for example have challenges in finding their paths in life or in working life skills, to complete practical work training and gain work experience in its Finnish units during the spring and autumn.

"Valmet has strong roots in Finland, and the company has played a significant role in the development of the country throughout its long history. In this year of celebration, we want to remember the young people in Finland. We are offering an opportunity to practice working life skills especially to those young people who are still searching for their strengths and paths in life, and need support," says Pasi Laine, President and CEO of Valmet.

Valmet's program was planned and will be executed in cooperation with Children and Youth Foundation, Academic Work and Work Pilots. The Children and Youth Foundation is responsible for finding the right young people for the program and for coaching their Valmet mentors. Academic Work provides the participants with coaching in job searches and study-related issues as part of the program. Work Pilots is handling some of the worker compensations.

Valmet's program was planned and will be executed in cooperation with Children and Youth Foundation, Academic Work and Work Pilots. The Children and Youth Foundation is responsible for finding the right young people for the program and for coaching their Valmet mentors. Academic Work provides the participants with coaching in job searches and study-related issues as part of the program. Work Pilots is handling some of the worker compensations.

Ninety young people applied for the spring program, and the 46 who were chosen started today, April 18, in the following Valmet units: Tampere, Pori, Ulvila, Järvenpää, Kajaani, and Espoo. Another group of young people will start practical work training at Valmet's Jyväskylä, Tampere, Raisio, and Järvenpää units in the autumn.

Each of the participants gets a personal mentor from Valmet, responsible for creating a safe and inspiring environment for the trainees and providing meaningful assignments that help them practice their working life skills and build self-confidence.

"The transition to working life is a sensitive time of change in a young person's life. It may very well be an exciting - and even scary - moment for many. Therefore, positive working life experiences are extremely important at this stage, as they strengthen young people's self-esteem and relieve any fears they may have about working life. Now, Valmet's practical training program offers young people a unique opportunity to strengthen their working life skills in a safe environment in cooperation with their mentors," says Tuula Colliander from the Children and Youth Foundation.

"Youth employment is close to our heart and the basis of all operations at Academic Work. When Valmet approached us with this great idea, it was obvious that we would join them in this project. We want to support young people in finding their best path in life, whether that involves a job, training, or a hint of inspiration and energy to proceed in a new direction," says Laura Korpilauri from Academic Work.

Read more about Valmet's 220 years of industrial history www.valmet.com/220years

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

The Children and Youth Foundation

No society can afford to lose its young people. This is why the Children and Youth Foundation uses creative and active means to help young people who are in difficult situations in life. With these methods, young people can strengthen their life skills and find their place in the society. The Foundation operates in Finland, as well as in developing countries in cooperation with local experts. Read more: www.nuori.fi #nuori, #elämäntaidot

Academic Work is the leading staffing and recruitment agency focused on young professionals in the Nordics. During 2016 we employed an impressive 1500 young professionals to our valued clients throughout Finland. The pillars of our recent success are our people, our contagious and energetic culture and our continuous desire to improve all areas of our business. Our website academicwork.fi and our social media channels are a great spot to see all our open positions as well as expert tips for job search and career progression.

IT’s Tissue scoops Most Sustainable Exhibitor Award at Tissue World

The Tissue Italy Network behind the iT’s Tissue event 2018 has received the Most Sustainable Exhibitor Award from the organisers of Tissue World Milan 2017 which took place this week.

The cooperation which has led 12 independent tissue technology companies to create an extraordinary technology experience in Lucca, also resulted in an award-winning approach at Tissue World Milan, where the iT’s Tissue area provided a unique visitor experience.

The cooperation which has led 12 independent tissue technology companies to create an extraordinary technology experience in Lucca, also resulted in an award-winning approach at Tissue World Milan, where the iT’s Tissue area provided a unique visitor experience.

Tissue Italy earned the award in the face of strong competition, thanks to the sharing of services including tranportation, low energy and rechargable electrics, re-usable stand materials, the use of sustainable, seasonal food and a number of other environmentally-considered initiatives.

it’s Tissue Project Manager Maddalena Marconi, who accepted the award on behalf of iT’s Tissue, said: “The collaborative spirit which is set to provide a third exceptional Italian Technology Experience in 2018 has also enabled us to stand out from the crowd in Milan this year. We are delighted to receive the award as it acknowledges the serious attitude to sustainability taken by all network members. We also thank Tissue World for their recognition which is greatly appreciated.”

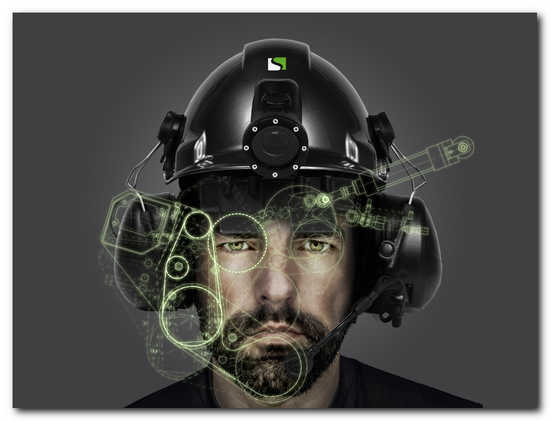

Weareable: Comprehensive Remote Support

Fabio Perini concretely interprets the extraordinary challenge proposed by the Industry 4.0 macro trend by presenting the device that bridges distances: Weareable.

“We followed our vision: the customer at the center. We were looking for a solution that would allow us to be in immediate contact with our customers’ needs”, explains Francesco Maltagliati, Chief Customer Service Officer at Fabio Perini. “With Weareable, we acquire the ability to see, listen and react in a few minutes around the world, using our experience transversally, on every type of request, whether electronic or mechanical, and across our product range, limiting the presence of our hyper-specialized technicians to where and when the customer unquestionably needs them, yielding speed and efficiency. A wearable technology to share in real time videos, audio, diagrams and precise graphic indications between the operator on-board the machine and the pool of online Fabio Perini experts at our operational centers disseminated in the four continents where we are present with production sites”.

The device is comprised of bi-directional audio-video instrumentation. Thanks to the incorporated visor, the two Full HD support video cameras – one located directly on the helmet and one pivoting – to the integrated audio system and to the data connection, the technician at the operational center can precisely understand what the operator with the Weareable helmet on is showing simply by directly facing the “problem”. And all this allows the technician to provide indications on how to proceed to promptly solve the issue.

Activating the Fabio Perini technicians and receiving 50 years of experience and knowledge at one’s facilities is simply a matter of connecting to the Internet. Just a simple click of a button away!

A few minutes, and Weareable - whether in New Caledonia or in Canada, passing through Nigeria or the Virgin Islands - becomes operational.

The final experimentation phase on the field began in November 2016: Weareable was successfully used by our customers in the Middle East and then in Europe and the United States. “We are answering the concrete needs of our market”, continues Francesco Maltagliati, “through our propensity - consolidated in the course of the years - for technological innovation at the service of the true needs of all our customers”.

And Weareable is not the only innovation that Fabio Perini S.p.A. is proud of: Web applications, upgrade programs, high quality original spare parts are our spearheads. For this market, for the market of the future.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

Digital Tissue(™): Fabio Perini’s value proposition for industry 4.0

In the era of Industry 4.0, managing the entire production process becomes the true added value for the tissue industry as a whole. Being able to define and map out a complete line to manufacture the finished product means fully understanding customers’ production needs.

Fabio Perini is the only company in the world capable of producing complete lines integrating converting and packaging, hence creating the product and the process together with the customer in order to optimize efficiency, reduce costs and maximize the quality of the finished product. An extraordinary value for customers, who find in Fabio Perini their one-stop interlocutor and all-in-one provider of production solutions for their business.

Fabio Perini is the only company in the world capable of producing complete lines integrating converting and packaging, hence creating the product and the process together with the customer in order to optimize efficiency, reduce costs and maximize the quality of the finished product. An extraordinary value for customers, who find in Fabio Perini their one-stop interlocutor and all-in-one provider of production solutions for their business.

“A holistic vision of the business is what the market demands”, comments Stefano Di Santo, CEO at Fabio Perini, “and it is in this direction that the technological and service development is projected at our company. We have used a very specific term to call this new way of considering our customers’ 4.0 facility by speaking of Digital Tissue™. It is not just a question of adding sensors to our technology or into the solutions we propose, but rather to create predictive and self-learning systems that allow maximizing the production efficiency of the individual machines and even more, the efficiency of the complete line.”

The concept of Digital Tissue™ has been our guiding light also in the recent innovations that Fabio Perini S.p.A. has brought about, such as All-In-One and Weareable: products that are already available as concrete answers to converting, packaging and service demands.

More evolution will follow, with the aim to always put our customers at the center and to deliver visible innovation to the eyes of the consumer.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

The Constellation(™) Effect

Constellation™ introduces a new era in tissue converting. Launched in June 2015, Constellation™ has quickly become a success on a truly global scale: in just 18 months, over 50 lines have been sold throughout the 5 continents. A result fruit of considerable investments in means and people: 3 Constellation™ lines in Italy, Brazil and the USA are dedicated to customers to perform tests and to confirm in an industrial production setting Constellation™’s exceptional performance in terms of product and production technology. All these benefits are certified by the new Pivot service. Pivot is much more than a laboratory for the characterization of the toilet roll or kitchen towel: it is the missing link between technology, the industrial process and the market. A holistic vision of business that allows generating true value in a commodities market such as tissue.

Constellation™ is the technology patented by Fabio Perini S.p.A., a solution that offers unprecedented winding quality. An innovative geometry consisting of mobile rolls with independent drives accompany the log from first to last sheet with consistency and uniformity. Complete log control during its formation allows attaining production efficiencies unobtainable until today.

Log growth during winding is managed by an innovative algorithm that characterizes Constellation™ technology, eliminating variability in the quality of the finished product and ensuring a repeatability never experienced before, yielding clear advantages throughout the converting process.

Additionally, the new Easy HMI operator panel makes managing the machine easier and more immediate, since it focusses on the parameters that characterize the finished product, such as internal core diameter, external roll diameter, meters of paper, perforation length. This means that thanks to the Easy HMI software, Constellation™ autonomously adapts to produce the perfect roll, exactly as it has been set on the operator panel. This simplicity of use is further underscored in product changes because all the operator needs to do is recall the recipe saved and the system begins producing immediately with no waste. This benefit translates into greater efficiency and unprecedented cost reduction. Easy HMI becomes a true assistant capable of supporting both less-experienced operators and department supervisors in guaranteeing consistent, qualitatively superior output.

“Constellation™ is a milestone for the tissue industry” comments Matteo Benedusi, CSO at Fabio Perini S.p.A. “because it represents perfect winding, something never attained with traditional technology until today. And also because it is oriented towards Industry 4.0. thanks to the on-board software and hardware that allow interacting and retroacting with the machines upstream and downstream of the rewinder. This means optimizing the production process and hence maximizing the competitive advantage for all our customers”.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

Mercer International Inc. Announces Acquisition of Sawmill and Bio-Mass Power Plant

Mercer International Inc., or "Mercer", (Nasdaq:MERC) (TSX:MERC.U) today announced that it has completed, through its wholly owned subsidiary Mercer Timber Products GmbH ("MTP"), its previously announced agreement to acquire substantially all of the assets of one of Germany's largest sawmills and a bio-mass power plant, near Friesau, Germany (the "Friesau Facility"), for approximately $55.1 million plus defined working capital of approximately $6.5 million (the "Acquisition").

In connection with the Acquisition, Mercer announced that it has also successfully replaced the existing €25 million revolving working capital facility of its subsidiary, Zellstoff-und Papierfabrik Rosenthal GmbH ("ZPR"), with a new €70 million joint revolving credit facility (the "New Facility") for ZPR and MTP. The New Facility is available to both ZPR and MTP, with MTP's borrowings not to exceed €45 million thereunder, has a five-year term, is secured by a first ranking security interest on the inventories, receivables and accounts of the borrowers and accrues interest at a rate of Euribor plus 2.95% per annum.

In connection with the Acquisition, Mercer announced that it has also successfully replaced the existing €25 million revolving working capital facility of its subsidiary, Zellstoff-und Papierfabrik Rosenthal GmbH ("ZPR"), with a new €70 million joint revolving credit facility (the "New Facility") for ZPR and MTP. The New Facility is available to both ZPR and MTP, with MTP's borrowings not to exceed €45 million thereunder, has a five-year term, is secured by a first ranking security interest on the inventories, receivables and accounts of the borrowers and accrues interest at a rate of Euribor plus 2.95% per annum.

Mr. David Gandossi, Mercer's Chief Executive Officer, stated: "We are excited with the acquisition of the Friesau Facility and welcome its employees to the Mercer Group and look forward to working together to enhance value for all of our stakeholders."

Mercer International Inc. is a global pulp manufacturing company. To obtain further information on the company, please visit its web site at http://www.mercerint.com.