Ianadmin

INDEX 2017 is in the air…

From 4 to 7 April, A.Celli Nonwovens will participate at INDEX 2017, the most important international trade show event of the year for the world of nonwovens, to be held in Geneva, Switzerland, at the Palexpo exhibition centre.

INDEX is a must for all those involved in nonwovens.

Technology, conferences, and an innovation award are the strongholds of this trade show that every three years gathers over 12,500 professional visitors coming from the world over. 586 exhibitors (with an increment of 10% over the previous edition) are taking part at the 2017 edition of INDEX, in a total exhibition area of 22,000 m2.

Four days to discover new sales opportunities, identify new markets and technological applications, and exchange experiences with the best professionals and suppliers of the nonwovens industry.

A.Celli Nonwovens would like to invite all visitors at stand no. 2527, where its staff will be pleased to illustrate the company's wide production range and dedicated technological solutions: winding and rewinding lines, packaging, reel palletising and handling for nonwovens, lamination, spooling and printing technologies for different kinds of substrates, including TNT, PP/PE film and tissue in a wide array of basis weights and much more.

A.Celli's wide-ranging offer is completed by a reliable 24/7 post-sales assistance service and the innovative MySp@res® service to identify, localize and request an on-line estimate for any spare parts need.

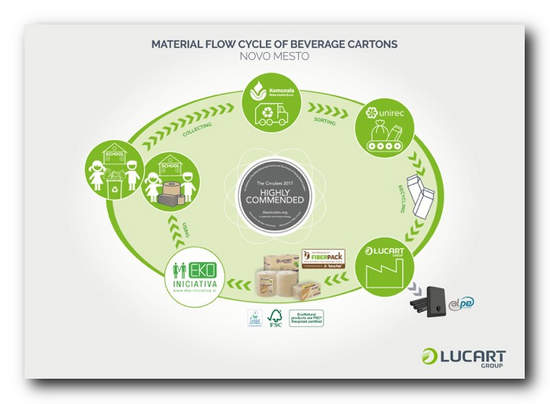

Lucart recycle used beverage cartons into sanitary paper: a successful practice of circular economy in Novo Mesto Slovenia

Komunala Novo mesto d.o.o. was the first municipal services company in Slovenia to take part in a pilot project to close the materials cycle for waste milk, juice and other beverage cartons (used beverage cartons or UBCs). Through a series of specially designed activities, they were encouraging schools and households to collect UBCs separately and to pass as many of them on for recycling as possible. This was part of Novo Mesto’s efforts to gradually establish its own closed materials loop for waste BCs, thereby securing enough raw materials to produce its own supply of sanitary paper over the long term.

Komunala Novo mesto provides municipal services for eight municipalities covering a total population of 65,000. This population disposes enough waste milk and juice UBCs per year in yellow containers or bags to provide just enough resource of cellulose for the production of annual quantity of sanitary paper used by local public institutions – municipal government offices, schools, nursery schools, health centers, libraries and the like. Around 45 hectares of woodland would have to be felled to make this quantity of sanitary paper; but if all UBCs in the area covered by Komunala Novo mesto were recycled into sanitary paper, this would meet the entirety of local needs and, moreover, save around 1,100 trees and provide total independency from primary resources. In a desire to lead the way in establishing this method of conserving the environment, Komunala Novo mesto has decided to take part in the pilot project.

The key partners in these efforts to close the materials cycle for UBCs in Novo mesto: Komunala Novo mesto, Slovenia; Dinos DROE Unirec waste packaging management company, Slovenia; LUCART, Italy; and EKO INICIATIVA - community of businesses and institutions that practice sustainable professional facility hygiene - set up and coordinated by VALTEX & Co., Slovenia.

How does the process of closing the materials cycle for UBCs in Novo Mesto actually work?

Once the end users have emptied, cleaned and folded the waste packaging, and placed it in the designated yellow container, Komunala Novo mesto takes it to the collection center. There it is received by Dinos DROE Unirec, a waste packaging management company, and sent for further processing to the specialist Lucart company. Lucart then separates the cellulose and uses it as a secondary raw material for the production of sanitary paper. Residents of Novo Mesto and the surrounding municipalities are then able to reuse these products in schools, shopping centers and other institutions that are part of the EKO INICIATIVA community. This closes the materials cycle.

Niko Kumar, founder of EKO INICIATIVA says: ‘The municipal materials cycle established in eight Novo Mesto municipalities is the first in which residents, by carefully separating their waste, become actively responsible for the raw materials that go into making sanitary paper via a regular industrial process, for use in the municipal infrastructure of their home towns and villages and through existing and future members of EKO INICIATIVA. This is a practical example of a sustainable business and a sustainable way of life.’

Selected schools and the general public involved in the project

Komunala Novo mesto began by choosing four primary schools to take part in the project. As part of a class competition, pupils received special bags to use at home to collect and separate waste UBCs. At collection days, four per year, the packaging collected was brought to school, where Komunala staff examined it and awarded stickers. The class that collected the most stickers by the end of the year was the class that most diligently, consistently, and correctly separated its waste packaging. It was declared the winner and received a prize.

The general public has also had the chance to take part, taking bags containing UBCs to the Komunala Novo mesto collection center and receiving a small gift from the EKO INICIATIVA community in return: paper tissues made from recycled cellulose.

Both activities were used to communicate the project with general public.

Sanitary paper from processed cellulose fibre from used beverage cartons

The Fiberpack® logo (www.fiberpack.com) identifies the fibrous raw material obtained through Lucart exclusive treatment process of beverage cartons, which is used to produce Lucart Professional EcoNatural and Grazie Natural branded products.

The production process uses an innovative technology, which, by physical-mechanical action, separates the cellulose fibres found in beverage cartons from polyethylene and aluminium without using substances that are harmful to man or the environment.

The fibres are therefore used to obtain tissue products, whereas aluminium and polyethylene are recovered in other industries to produce items for a number of end uses.

Fiberpack® products feature a light Havana brown colour because the cellulose fibres are not bleached. The products feature excellent resistance, absorbency and softness and are 100% ecological, EU Ecolabel and FSC® Recycled certified.

Novo mesto project is a great example of the broader sustainability Company strategy which lead Lucart Group, considering tonnes of Fiberpack® products manufactured, to recover in 2013-2016 more than 2.8 billion beverage cartons, to save more than 1,200,000 trees and to avoid almost 73,500 tonnes of CO2.

Closing the materials cycle helps conserve natural resources and optimize waste management processes

Closing materials cycles, or what is known as the ‘circular economy’, is one of the mainstays of European Union policy currently and will be in the coming years, for this reason: our consumption is already at the level of twice the natural resources available. Establishing a circular economy means addressing the entire lifecycle of a product and its component materials, then defining the proportion of these materials that can be reused – and the form of reuse. This means that a new raw material is produced from waste and can go towards manufacturing a new product.

The foundations have now been laid with this project in Novo mesto which aims to close the materials cycle for UBCs. It all started mid 2016 when the first quantities of UBCs were designated for being recycled into sanitary paper. By early 2017 in the city of Novo mesto 35% of the demand for sanitary paper products are now covering citizens by themselves, with their own contribution of UBCs. This way they are actively participating in the day-to-day circular economy. We are hoping and expecting the Municipal Material Cycle of Novo mesto to achieve its full effect by 2018, covering as much as 80% of local demand for sanitary paper products.

Implementing the Municipal Material Flow Cycles globally

The Association of partners EKO INCIATIVA aims to roll this model of operation out in Slovenia as well as abroad. The potential of this project has already received a special global recognition, as a good example to practices of circular economy. Between number of applications of firms, institutions, cities, municipalities, and regions from all over the world, the project »Material flow cycle of BC – Novo mesto« was HIGHLY COMMENDED at THE CIRCULARS 2017 – in the category »Government, Cities & Regions« as an example of good practice in circular economy. The material flow cycle, which has been established in Novo mesto and eight surrounding Slovenian municipalities in 2015/2016, is the first such example of circular practice in the world. In the global competition for the prize have, so far, participated more than 36 countries. The expert committee, composed of 27 international experts recognized the potential of the project. The competition is organized each year by The World Economic Forum and The Forum of Young Global Leaders forum, to promote the best companies and implemented projects in the field of circular economy, this year it was held in January at the World Economic Summit, in Davos.

About the partners:

The Lucart Group is one of the leading manufacturers of sanitary paper in Europe. Its seven factories (five in Italy, one in France, one in Hungary) have a joint production capacity of 319,000 tonnes a year. Lucart Group corporate mission is to provide trustable paper products, in accordance with market and environmental requirements, leveraging both the company indisputable technical know-how and the long-lasting relationship with innovating partners.

Komunala Novo mesto d.o.o. is a public company established by eight municipalities located in and around Novo Mesto. It operates compulsory and optional commercial public services, including municipal waste management services.

Dinos DROE Unirec is the second largest waste packaging management company in Slovenia, with a 25% market share. Over 800 companies are incorporated into the Unirec waste packaging management system. It realises its mission, as expressed in its slogan ‘Učinkovita formula recikliranja’ (An efficient recycling formula), by investing in development projects and by actively seeking circular economy solutions. It has partnered with the very first Slovenian projects that aim to close material flows: ‘Plastenka za plastenko’ (plastic bottles) and ‘KEMSO dosledno za naš higienski papir’ (sanitary paper from UBCs).

EKO INICIATIVA set up by VALTEX is a Slovenian community of companies and institutions engaged in the practical provision of sustainable professional hygiene. Members of the community use sanitary paper manufactured from UBCs in their own offices and buildings. The community realizes that everyone can play their part in helping to preserve the environment by using sustainable products for their professional hygiene needs.

VALTEX has been successful at assisting companies and institutions with their professional facility hygiene challenges since 1993. VALTEX is fulfilling the mission to find overall solutions for the maximum hygiene level, improve the standards of professional hygiene, implement hygiene strategies which are sustainable. It has evolved from a traditional distribution company to a solution provider setting up and maintaining sustainable facility.

KPA Unicon to deliver biomass-fired steam boiler plant to Cartulinas CMPC carton board mill in Valdivia, Chile

Cartulinas CMPC S.A. and KPA Unicon Oy have signed a contract for the delivery of Unicon Biograte 30 t/h steam boiler plant to Cartulinas Valdivia Mill in Valdivia, Chile. In addition to wood chips, bark and sawdust, the plant operates on bio sludge and it produces steam for the mills carton board production process. The plant will be started up for operation in December 2018.

The contract covers all process equipment, buildings, installation supervision, commissioning and training of operating personnel. The heart of the plant is Unicon Biograte combustion technology, which is specifically designed to utilize challenging biofuels for energy production with high efficiency and low emissions.

The contract covers all process equipment, buildings, installation supervision, commissioning and training of operating personnel. The heart of the plant is Unicon Biograte combustion technology, which is specifically designed to utilize challenging biofuels for energy production with high efficiency and low emissions.

The plant is also equipped with KPA Unicon’s PlantSys system for local and remote control. PlantSys collects data from the process equipment and makes operation of the plant easy and reliable. It also visualizes the data in easily understandable format. PlantSys also enables a secure remote access to the plant to optimize the parameters and predict the future service and maintenance needs.

KPA Unicon will also take care of the maintenance of the plant as the parties have agreed on a 5 years maintenance contract. In addition to spare parts and local maintenance activities, the contract includes remote support service from KPA Unicon control room.

“After a comprehensive project survey Cartulinas CMPC decided, that KPA Unicon is the right choice to supply the boiler plant. The most important technological factors are efficiency and low emissions. The plant can use various kinds of biomass even with high moisture contents. Our expectation is to achieve a plant with the best standards of the market, complemented with an efficient layout and a modern building. In summary, this must be a project of excellence. Therefore, I look forward to cooperating with KPA Unicon and getting the boiler plant started up in December 2018," says Jorge Aldana, Industrial Development and Projects Director of CMPC.

"This contract opens the Latin American market for us. We are extremely proud to take this important step together with a world class company such as CMPC. We are confident that this boiler plant will fulfill all the client’s requirements and exceeds them. This project is a good example of how challenging biofuel can be used to achieve high efficiency and low emission levels. These values are very important for CMPC and also work as guidelines for us during the project execution", says Pentti Savolainen, Project Development Director, KPA Unicon.

Cart ulinas CM P C S.A . is an affiliate of Empresas CMPC S.A. It manufactures and markets folding boxboard. Cartulinas CMPC’s longstanding experience in this line and its state-of-the-art technology together with the raw materials employed enables to deliver top quality products, competing with the most prestigious global suppliers.

Cartulinas CMPC S.A. operates two mills, one located close to the city of Valdivia in Southern Chile, and a second one located in the Maule region, with an annual aggregate production capacity of 450,000 tons. Valdivia mill, built in 1951, pioneered in Latin America the carton board manufacturing for cases and displays. Its current annual output amounts to 70.000 tons thanks to the full renovation of its paper machine. Currently Cartulinas CMPC S.A. supplies the national market, and ships nearly 85% of its production to customers in more than 45 countries in the 5 continents.

K P A Unicon provides responsible energy solutions for efficient energy production. The company specializes in boiler and power plant projects. The solutions utilize biomass fuels as well as fossil fuels sustainably. KPA Unicon also provides operation and maintenance services, and offers support during the whole life cycle of plants. KPA Unicon’s headquarters are located in Pieksämäki, Finland. The company employs 250 energy industry professionals.

Sappi Biotech partners with CellMark to increase global sales reach of Sappi’s Hansa lignin products

Sappi Limited is pleased to announce that its Biotech division has entered into an agreement with CellMark appointing CellMark as the non-exclusive sales agent for Sappi Biotech’s Hansa lignin products, produced in liquid and powder formats in South Africa at Sappi Tugela Mill.

Sappi Limited is pleased to announce that its Biotech division has entered into an agreement with CellMark appointing CellMark as the non-exclusive sales agent for Sappi Biotech’s Hansa lignin products, produced in liquid and powder formats in South Africa at Sappi Tugela Mill.

Sappi is the world’s largest producer of Lignosulphonates from operations in South Africa and Europe. The material is both used internally for bio-energy generation or beneficiated and processed to technical lignins for sale to global lignin markets.

CellMark operates a global sales, marketing, financing and logistics business aimed at consistently surpassing customer expectations.

Louis Kruyshaar who leads the Sappi Biotech business commented, “We are really pleased to partner with CellMark which brings an excellent fit to our Biotech business at a stage when accelerated market penetration is key to attain our growth targets.”

He continued, “The partnership, which is built on common core values, will include a joint social investment initiative to benefit rural communities in South Africa.”

“We are delighted to represent the Sappi Biotech Hansa quality lignin and offer enhanced lignin solutions to customers ’’ indicates Jean-Luc Carrière, Vice President and General Manager Lignin for CellMark Basic Chemicals. He adds, ‘’This partnership will enable both companies to advance towards their common goal to expand markets and applications for this versatile biopolymer.’’

Lignins are commonly used as surfactants, binders, dispersers and emulsifying agents leading to the use of this renewable material produced from trees used in a large number of applications globally.

About Sappi Limited

A global leader in paper, paper pulp and dissolving wood pulp solutions, Sappi Limited (listed and in the Top 40 on the JSE), is headquartered in Johannesburg, South Africa; has over 12,000 employees; manufacturing operations on three continents, in seven countries (seven mills in Europe, three mills in America and four mills in South Africa) and customers in over 150 countries worldwide

Sappi works closely with customers to provide relevant and sustainable paper, paper pulp, dissolving wood pulp and biomaterial products and related services and innovations. Our market-leading range of paper products includes: coated fine papers used by printers, publishers and corporate end-users; casting release papers used by suppliers to the fashion, textiles, automobile and household industries; and in our Southern African region newsprint, uncoated graphic and business papers, premium quality packaging papers and paper grade pulp. Our dissolving wood pulp products are used worldwide by converters to produce viscose fibre, pharmaceutical products as well as a wide range of household and consumer products.

In FY2016 we produced approximately: 5.4 million tons per year of graphic and printing paper and packaging and speciality paper; 2.3 million tons per year of market paper pulp, and 1.3 million tons per year of dissolving wood pulp.

We continue to grow into a profitable and cash-generative diversified business with an exciting future in woodfibre, a renewable resource.

For further information visit www.sappi.com or www.sappi.com/biomaterials

About CellMark

CellMark serves as a global meeting place for entrepreneurial companies seeking business opportunities and relationships for collaborative innovation. Together with our business partners we deliver products, services and solutions to the world market. With a network of 70 offices in 30 countries we specialize in a variety of supply-chain services including sales & marketing, logistics and financial services.

Our platform supports and helps entrepreneurs exchange products and services more efficiently, improves business, mitigates risk and the impact on natural resources. We connect entrepreneurs in the areas of Chemicals, Metals, Pulp, Paper, Packaging, Recycling, Energy and Medical around the world. The company is employee-owned, has an annual sales of USD 3 Billion with a trade volume of 6 million tons.

For further information visit www.cellmark.com

Valmet to supply a fine paper line for Ittihad International Investment in United Arab Emirates

Valmet will supply a fine paper line for Ittihad International Investment L.L.C. in Abu Dhabi, United Arab Emirates. The new greenfield production line (PM 1) with a wide automation package will be producing high-quality printing and writing paper grades for the growing domestic markets and the Middle East and North Africa region. The start-up of the machine is scheduled for the end of year 2018.

The order is included in Valmet's first quarter of 2017 orders received. The value of the order will not be disclosed. The value of an order of this type is typically around EUR 45-70 million.

The order was placed by China Light Industry International Engineering Co., Ltd, an EPC (engineering, procurement and construction work) company, which will be responsible for the complete turnkey delivery of the mill site.

OptiConcept M fine paper machine

OptiConcept M fine paper machine

"Ittihad enters the papermaking business for the first time with this new OptiConcept M machine. By guiding and supporting from the very beginning of the sales process, Valmet wanted to ease Ittihad in the complex investment puzzle. We were also able to display well our papermaking concept with good references. The OptiConcept M line enables high productivity and resource efficiency, excellent quality and low operating cost," says Antero Kunnari, Sales Director, Valmet.

Technical details about the delivery

Valmet's delivery includes a complete fine papermaking line from a stock preparation line and headbox to a reel followed by a parent roll cart and two winders. The delivery includes also a wide scope of automation. The selected technology and automation improve runnability, quality, and the cost, material and energy efficiency. It is possible to lower basis weight still maintaining stiffness and opacity, which results in raw material savings.

The 7,100 mm wide (wire) paper machine will produce uncoated woodfree paper (WFU) grades. The design speed of the machine will be 1,700 m/min with daily capacity of 1,200 tonnes.

About the customer Ittihad International Investment and EPC contractor CLIEC

Established in 2008, Ittihad International Investment group governs several companies in the Middle East. Ittihad Paper Mill (IPM) is the first printing and writing paper production facility in the area of the Gulf Cooperation Council. IPM is located on a 230,000 square meter plot in the Industrial City of Abu Dhabi (ICAD) and is the largest producer of printing & writing paper in the MENA (Middle East and North Africa) region covering around 10% of the MENA market.

China Light Industry International Engineering Co., Ltd. (CLIEC) was founded in January 1953. CLIEC has provided engineering design, consulting and project general contracting services for more than 5,000 medium and large scale projects in China and more than 60 medium, and large scaled projects abroad in more than 20 countries.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Resolute Announces Start-up of New Tissue Machine at Calhoun

Resolute Forest Products Inc. is pleased to announce the successful start-up of its new tissue machine in Calhoun (Tennessee). The first tissue parent roll was produced on February 28, 2017.

The machine will continue its scheduled ramp-up through 2017 and is expected to be producing at maximum capacity toward mid-2018. With its fully operational converting facility, converted tissue products sold from Calhoun are now manufactured entirely from parent rolls produced on-site.

The Calhoun tissue operation, built at Resolute's pulp and paper mill, has the capacity to manufacture 66,000 short tons (60,000 metric tons) annually of premium private-label tissue, including bath and towel, aimed at the at-home market.

With its state-of-the-art machine, three converting lines and integration of pulp from the existing Calhoun pulp mill, this will be one of the most efficient and cost-competitive tissue operations in North America once full production is achieved, positioning Resolute as a key player in this growing market segment.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including market pulp, tissue, wood products, newsprint and specialty papers, which are marketed in over 70 countries. The company owns or operates some 40 manufacturing facilities, as well as power generation assets, in the United States and Canada. Resolute has third-party certified 100% of its managed woodlands to internationally recognized sustainable forest management standards. The shares of Resolute Forest Products trade under the stock symbol RFP on both the New York Stock Exchange and the Toronto Stock Exchange.

Resolute has received regional, North American and global recognition for its leadership in corporate social responsibility and sustainable development, as well as for its business practices. Visit www.resolutefp.com for more information.

Atlas Tissue Launches New Green Heritage Tissue Line

Atlas Tissue is pleased to introduce the Green Heritage® line of recycled tissue products to the at-home market. Atlas Tissue, a business of Resolute Forest Products (NYSE: RFP) (TSX: RFP), is changing the way consumers view recycled products with its Green Heritage premium 100% recycled tissue line that is Soft on you. Easy on the planet.TM

The Green Heritage brand is designed to offer today’s environmentally conscious consumers a first-in-class product that is additive-free, septic-safe and so much more. Green Heritage is manufactured with recycled pulp from Resolute’s Fairmont (West Virginia) mill. This allows for precise control of the entire production process, ensuring cost-competitiveness and consistent quality, while offering the flexibility and customization customers demand.

The Green Heritage brand is designed to offer today’s environmentally conscious consumers a first-in-class product that is additive-free, septic-safe and so much more. Green Heritage is manufactured with recycled pulp from Resolute’s Fairmont (West Virginia) mill. This allows for precise control of the entire production process, ensuring cost-competitiveness and consistent quality, while offering the flexibility and customization customers demand.

“When comparing Green Heritage products to those of our competitors, third-party testing confirmed that our bath tissue is brighter, thicker and stronger than the leading recycled bath tissues on the market,” stated André Piché, senior vice president, Tissue Business Group, for Resolute Forest Products. “We are confident consumers will appreciate the quality and comfort of our new recycled product line.”

About Atlas Tissue

Atlas Tissue has a manufacturing capacity of 62,000 short tons of tissue across three paper machines and 11 converting lines located in Hialeah (Miami) and Sanford (Orlando), in Florida. It also operates a paper recycling center in Tampa. Atlas Tissue produces branded and private-label products for at-home and away-from-home channels, and offers both virgin and recycled products, covering a wide range of grades. Branded products are marketed under Windsor Place®, Green Heritage®, Bunny Soft®, Harmony® and Eversoft®. Atlas Tissue is the proud recipient of the 2016 Tissue World Mill Award in the Most Energy-Aware Mill category. Visit www.atlastissue.com for more information and learn more about Green Heritage at www.greenheritagetissue.com.

Atlas Tissue is part of Resolute Forest Products Inc., a publicly traded company listed on both the New York Stock Exchange and the Toronto Stock Exchange under the stock symbol RFP.

About Resolute Forest Products

Resolute Forest Products is a global leader in the forest products industry with a diverse range of products, including market pulp, tissue, wood products, newsprint and specialty papers, which are marketed in over 70 countries. The company owns or operates some 40 manufacturing facilities, as well as power generation assets, in the United States and Canada. Resolute has third-party certified 100% of its managed woodlands to internationally recognized sustainable forest management standards. To learn more about Resolute Forest Products, visit www.resolutefp.com.

SOURCE Atlas Tissue

Xerium Ships First Forming Fabric from Its Kunshan, China, Plant

Xerium Technologies, Inc. (NYSE: XRM), a leading global provider of industrial consumable products and services, today announced that it recently shipped its first forming fabric from the Company’s Kunshan, China, machine clothing plant.

“We are extremely excited to now be producing world-class forming fabrics for our customers here in China and the greater Asia-Pacific market,” said Bob Burke, President of Xerium Asia. “We are very proud of the entire team in Kunshan. Their dedication and hard work helped pave the way for Xerium to now be a local producer of forming fabrics in addition to press felts for the Asia-Pacific region from the new Kunshan plant. The technology transfer process from our Xerium Germany team has been extremely successful and we look forward to producing our newly launched high-performance TransFormTM portfolio in the near future.”

Xerium’s Kunshan plant is located in the heart of the Yangtze River papermaking region of China at the very center of the largest and fastest growing papermaking region in the world. Xerium has significantly increased its competitive position with this plant, first with press felt production, and is now closely partnered with customers in China and the rest of Asia.

Xerium's Kunshan Team Celebrates Shipment of First Forming Fabric (Photo: Business Wire)

Xerium's Kunshan Team Celebrates Shipment of First Forming Fabric (Photo: Business Wire)

The forming fabric on a papermaking-type machine is a continuous belt, or multiple belts on some machines, made of specially engineered synthetic mesh upon which various grades of fibrous products are formed. Forming fabrics essentially act as a high-tech filter media separating the fiber from water. Highly engineered weave patterns and multiple layering of modern forming fabrics are specially designed to meet stringent requirements for mechanical stability while running on the machine: resistance to abrasion, controlled water drainage rates, fiber retention, and overall quality of the paperboard, tissue, or paper being produced. Small differences in forming fabrics can be the difference between a machine running effectively, or having downtime due to inferior performance.

“We are delighted to celebrate yet another important milestone with the expansion of the Kunshan plant that is now producing our industry-leading forming fabric technology. We have a strong Lean Six Sigma certified team leading the plant utilizing the latest product designs, best materials, and most modern manufacturing processes in the world,” said Mr. Harold Bevis, President and Chief Executive Officer of Xerium. “Customers have really welcomed Kunshan as the new local source of high-value press felts when we opened it in 2015. Now we can deliver the most modern forming fabric technology from this same facility, Xerium is locally positioned to deliver the most modern machine clothing products to the largest machines in the world,” adds Bevis.

ABOUT XERIUM TECHNOLOGIES

Xerium Technologies, Inc. (XRM) is a leading global manufacturer and supplier of consumable products used primarily in the production of containerboard, tissue, consumer packaging, pulp and paper. In addition, the Company also services nonwoven fabric manufacturers, building products producers, and other specialty industrial sectors. The Company’s products, machine clothing and roll covers, are installed on machines and perform critical roles in the manufacturing process by which raw materials are converted into finished products. The Company employs a broad portfolio of patented and proprietary product and manufacturing technologies, as well as extensive industry experience, to provide customers with tailored solutions designed to optimize the performance of their equipment and reduce the costs of their operations. XRM is a global enterprise selling to customers in 63 countries, with 28 manufacturing facilities in 13 countries and approximately 2,950 employees.

BioBase4SME Natural Fibertastic Workshop aims to encourage SMEs to apply for fully funded Bio-Innovation Coupons for fibre application testing

The BioBase4SME project (co-financed by Interreg NWE), offering bio-innovation support for SMEs, herewith proudly announces its Natural Fibertastic Workshop hosted at the Natural Fiber Application Center (NAC, The Netherlands) on April 5th, 2017.

The theme of the day is natural fiber application development focusing on thermoplastic composites. Delegates will benefit from an update on application advances, inspiration for new developments and gain experience from knowledge exchange between entrepreneurs through networking in a first-class atmosphere. The workshop will be a good opportunity to learn about the services NAC offers and how they can be accessed by SMEs via fully funded BioBase4SME Innovation Coupons worth 4000 €.

In 2014, the Natural Fibre Application Centre was founded to develop new business chains on a pilot scale (100 kg) in the areas of the development of paper and board recipes and thermoplastic composites. NAC is equipped for biomass treatment* and paper/board experiments on lab scale*. Likewise, NAC offers technologies for paper making* and for physical and mechanical testing*. Finally, NAC owns a pilot paper machine, unique in the Benelux, that can produce small paper rolls of 30 cm width and 25 kg. Besides processing wet biomass, investments were made to obtain dry fibres applications for the bio composite market with e.g. a pilot scale compounder (20-70 kg/h).

During the workshop at NAC, SMEs can visit the center, learn about other SMEs active in the natural fibers sector and get the opportunity to promote their technology at the technology market. Furthermore, the workshop will provide information on the BioBase4SME innovation coupon scheme and other support mechanisms the project offers to SMEs innovating in the biobased economy.

Stapper Duurzaam Advies (SDA), a Dutch company developing indoor biobased construction material for fairs and exhibitions was recently granted a BioBase4SME Innovation Coupon for performing application testing at NAC. Esther Stapper, director of SDA testifies on how the coupon brought her innovation closer to the market: “During the cooperation with the Natural Fiber Application Center I entered an environment with a high innovating DNA in which all employees thought along and surprised me with their creative solutions. The collaboration enabled us to enter into the next phase of our biobased development.”

The BioBase4SME network, representing leading bio-based economy experts, support SMEs and start-ups across North-West Europe on how to develop new ideas into marketable products. The BioBase4SME expert network organises workshops on specific topics, diverse training events and an innovation bio-camp. Furthermore, SMEs and start-ups can apply for bio-innovation coupons with a value up to €100.000 when looking for technical (process development, scale-up…) and non-technical support (LCA, application testing, market research, business plan coaching, social acceptance…). For more information on the project: www.nweurope.eu/BioBase4SME

For more information on the workshop and registration: http://www.nweurope.eu/projects/project-search/bio-innovation-support-for-entrepreneurs-throughout-nwe-regions/events/ or contact Roel Koevoets, tel: +31 (0)6 226 639 34, This email address is being protected from spambots. You need JavaScript enabled to view it..

* grinding, wet refining, fractionation and compacting • pulp and fiber testing: zeta potential, cationic demand, Schopper Riegler, consistency, microscopic fiber analysis and fiber distribution by Clarck method • technologies for paper making: hand sheets, Rapid Köthen lab scale, size press sheets and rolls • physical and mechanical testing: tensile strength, roughness, grammage, thickness, porosity, Cobb and printability.

The project:

The European Commission has launched through its INTERREG NWE Programme a three-year project “BioBase4SME” to further support the development of the biobased economy in North West Europe (NWE). The €5.83 million project will help start-ups and Small and Medium Enterprises (SMEs) to overcome technological and non-technological barriers on their path to turn biobased research into commercial innovation. BioBase4SME offers training, innovation biocamps, workshops and innovation coupons worth up to €100.000. The BioBase4SME partnership includes eight organisations from six different countries http://www.nweurope.eu/BioBase4SME

The BioBase4SME partners are:

- Bio Base Europe Pilot Plant (BBEPP), Ghent, Belgium, http://www.bbeu.org/pilotplant/

- Flanders Biobased Valley, Ghent, Belgium,http://www.fbbv.be

- Materia Nova, Mons, Belgium, http://www.materianova.be/

- Association of the Chambers of Agriculture of the Atlantic Arc (AC3A), Nantes, France, http://www.ac3a.fr/AC3A_en.php

- CLIB2021 Cluster Industrielle Biotechnologie, Düsseldorf, Germany, http://www.clib2021.de/en

- tcbb RESOURCE, Galway, Ireland, http://www.tcbbresource.ie/

- REWIN Projecten, Breda, The Netherlands, http://www.rewin.nl/

- The National Non-Food Crop Centre, York, UK, http://www.nnfcc.co.uk/

- The University of York, York, UK, https://www.york.ac.uk/

3. INTERREG North-West Europe Programme

BioBase4SME is 60% funded by the INTERREG NWE Programme. The Interreg North-West Europe Programme fosters transnational cooperation to make the North Western Europe a key economic player and an attractive place to work and live, with high levels of innovation, sustainability and cohesion. http://www.nweurope.eu/

BioBase4SME is co-financed by:

BioBase4SME Project Office:

The BioBase4SME project is coordinated by Bio Base Europe Pilot Plant (Ghent, Belgium). For more information, comment or interview requests about BioBase4SME, please contact:

Dr Lieve Hoflack, Project Manager, tel: +32 (0)9 335 70 01, This email address is being protected from spambots. You need JavaScript enabled to view it.

A.Celli Packaging Spunlace: the evolution in packaging systems!

A.Celli Nonwovens develops and launches the new automatic system for rolls handling and packaging dedicated to the carded products market.

A.Celli technology breakthroughs never stop.

Having attained top performance standards and acknowledgements in the realm of downstream-line management, the challenge – already won – was to automate the handling of Spunlace reels, gearing the plant on the packaging specifications and production capacity typical of carded products (Spunlace, ATB, ADL, etc.).

And so A.Celli Packaging Spunlace is born: the evolution in Packaging systems.

Fully automatic, highly flexible and completely modular, A.CELLI PACKAGING SPUNLACE is a handling and packaging system that allows producers to package any reels combination and dimension, based on the standards and specifications typical of the Carded products.

Below are some features of the system:

- Automatic Roll Sorting.

- Automatic handling of reels with different product qualities and waste reels.

- Automatic application of top and bottom foil.

- Automatic application of top and bottom headers.

- Automatic application of bundle edge protection.

- Automatic labelling (individual reel and bundle).

- Automatic wrapping of the pack with application of the stretchable film cutting-protection-band.

- Automatic weighing (individual reel and bundle).

- Automatic Pallet applicator.

- Integration with any production management software.

- 24/7 technical support Hotline.

Contact This email address is being protected from spambots. You need JavaScript enabled to view it. for consultancy or for a dedicated case study.