Displaying items by tag: BMG

BMG Announces the Mantis™ Robotic Trim Press Handler from NAS Nalle Automation Systems

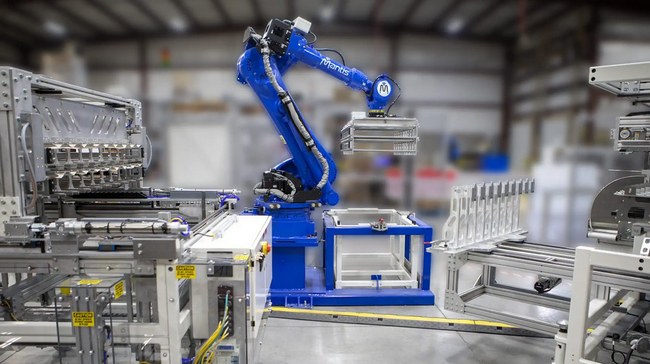

BMG announces the Mantis Robotic Trim Press Handler from NAS Nalle Automation Systems, the industry’s first robotic automated system that reliably handles the flow of parts ejected from any trim press. This compact, intuitive, and configurable system enables full automation of the entire thermoforming process — from resin to palletized product — for medium to high-volume production lines using either non-servo continuous flow or servo-driven long eject trim presses.

Previously, parts ejected from non-servo trim presses needed to be manually separated and counted, a labour-intensive, error-prone, and inconsistent process that limits the automation of downstream packaging functions. NAS solved this problem with the patent-pending Trim Press Receiver (TPR) which uses a unique separating mechanism to count and contain stacks of product, followed by a raking mechanism to take the product into the receiver for transfer by the robot.

“Consistent and reliable separation of product on a continuously flowing, non-servo eject trim press was the key to the development of Mantis”, according to Kurt Huelsman, President of NAS. “The design of the receiver coupled with NAS’s robotic automation capabilities brings a safe, productive and cost-effective solution to a historically very manual process.”

The TPR presents the parts to a six-axis robot equipped with product matching End of Arm Tooling that in turn automatically transfers the product to a Shuttle Station, which integrates with downstream packaging functions that may include wrapping, boxing, case packing, sealing, and palletizing. Incorporating the robot allows the Mantis system to be very compact and configurable, making installation possible where the available floor space is limited or obstructed.

The Mantis Robotic Trim Press Handler is compatible with all trim presses, including BMG brands Brown and Lyle. The fully automated system can reduce labor requirements by up to 75% and the modular robotic design allows for tool changeovers in under an hour.

Visit www.bmg-solutions.com/machine/nas-mantis-robotic-trim-press-handler/ for more information.

About BMG

BMG in Beaverton, MI, is a global leader in thermoforming, tooling and automation solutions with best-in-class quality and innovative product lines. It designs and manufactures a complete line of continuous thermoforming equipment, tooling, material handling and packaging automation, robotics, and related services including system upgrades, prototyping, process optimization, and technical support. Its equipment has been “Made in North America” for nearly 70 years, with systems operating in over 80 countries serving customers worldwide. Visit www.BMG-Solutions.com for more information.

BMG Announces State-of-the-Art QuadProTM Paper Former from Brown Machine

World’s first continuous large-bed paper former outperforms competition

BMG, the world’s leading provider of forming, tooling and automation solutions announces the QuadProTM paper former, which provides the highest production output and lowest scrap rate in the industry by using a patent-pending, continuous forming process. This innovative system is the product of cooperation among three BMG companies, Brown Machine, Freeman Tooling and NAS Nalle Automation Systems. These companies brought together state-of-the-art technologies and processes to create an innovative turnkey paper forming, tooling and automation solution that meets industry demand.

The QuadProTM consistently outperforms the market leader in paper forming. When compared to its competition, QuadProTM achieves up to 3.5 times as much product output, over 95% product yield, and under 5% product scrap. Moreover, it produces higher quality products with improved rigidity.

One significant feature of the QuadProTM is its ability to provide material scoring without cutting blanks while running printed or unprinted paper with automatic continuous decurling and splice detection, enabling easier operation. This means that no operator adjustments are needed, machine jams are drastically reduced, product quality is significantly improved, and machine operation is easier overall.

The system’s automatic splice detection capability also allows it to bypass score and form stations, achieving a faster changeover and less scrap. Further, its servo-controlled score depth adjustment allows for easy on-screen adjustments stored in a recipe for recall, as well as on-the-fly adjustments that reduce downtime. This helps achieve consistent, ultraprecise score depth in increments of .0005 inches.

Other benefits of the QuadProTM include its ability to, to cut and form in place, and its automated product extractions, stacking, counting and conveyance. In addition to running printed and unprinted paper, the system can also form plates, bowls, and trays, allowing for a diverse set of products to be produced.

Visit www.BMG-Solutions.com for more information.

About BMG

BMG in Beaverton, MI, is a global leader in thermoforming, tooling and automation with best-in-class quality and innovative product lines. It designs and manufactures a complete line of continuous thermoforming equipment, tooling, material handling and packaging automation, robotics, and related services including system upgrades, prototyping, process optimization, and technical support. Its equipment has been “Made in North America” for nearly 70 years, with systems operating in over 70 countries serving customers worldwide. Visit www.BMG-Solutions.com for more information.

Brown Machine Group is now BMG

New name reflects growth and integration into complete turn-key solution provider in the plastic and paper industry

Brown Machine Group, the world’s leading provider of forming, tooling and automation solutions for the global packaging industry, announces that it is changing its name to BMG to reflect its growth and market position as a leading global turn-key solutions provider for the plastic and paper packaging industry.

Brown Machine Group was originally created with the purpose of unifying a collection of industrial brands into one family. The company has grown steadily, including by recently acquiring GN Thermoforming. The company’s new branding as BMG brings together the companies already owned by Brown Machine Group under one consistent name.

Brown Machine Group was originally created with the purpose of unifying a collection of industrial brands into one family. The company has grown steadily, including by recently acquiring GN Thermoforming. The company’s new branding as BMG brings together the companies already owned by Brown Machine Group under one consistent name.

“BMG is Brown, Lyle, GN, Freeman, NAS and aXatronics. Brown Machine Group was already being shortened to BMG both externally and internally, and we believe the change is more inclusive to our family of brands and is easy for our customers to identify and remember,” explains Greg Wolf, BMG’s President and CEO. “BMG is our umbrella, and each brand can talk about solutions across the portfolio to fit customer needs. Together, BMG represents experience, innovation, and superior customer service, with a reputation for delivering solutions to improve consistency, productivity, and profitability. We look forward to building on BMG’s solid foundation in future growth through acquisition.”

In conjunction with the name change, BMG has aligned its businesses into three core areas to serve its customers:

- BMG FORMING SOLUTIONS, which offers a wide variety of sizes and capabilities for thermoforming machines through the Brown, Lyle, and GN product offerings;

- BMG TOOLING SOLUTIONS, which offers forming, trim, form-fill seal and contact heat tooling by Freeman and GN;

- BMG AUTOMATION SOLUTIONS, which offers robotic material handling and packaging automation by integrating NAS and Axatronics products.

Visit www.BMG-Solutions.com for more information.

About BMG

BMG in Beaverton, MI, is a global leader in thermoforming, tooling and automation with best-in-class quality and innovative product lines. It designs and manufactures a complete line of continuous thermoforming equipment, tooling, material handling and packaging automation, robotics, and related services including system upgrades, prototyping, process optimization, and technical support. Its equipment has been “Made in North America” for nearly 70 years, with systems operating in over 70 countries serving customers worldwide. Visit www.BMG-Solutions.com for more information.