Super User

A culture of innovation: Mondi presents its latest product and business highlights in uncoated fine paper

Mondi, global leader in packaging and paper, unveils its latest uncoated fine paper highlights and innovations. As the main supplier of uncoated fine paper in Europe (including Russia), and a tradition of papermaking going back to 1793, Mondi has been keeping an eye on innovation, even in challenging times. Recent developments include new shades to enrich the premium brand PERGRAPHICA®; a creative cooperation with Adobe Stock; an innovative grass paper for premium packaging; and the expansion of Mondi’s successful B2B loyalty programme ‘Color Copy Club’.

- New, extended PERGRAPHICA® offering for premium graphic paper and luxury packaging market

- Partnership with Adobe Stock for premium brand PERGRAPHICA®

- Launch of grass paper for premium packaging under the new brand IQ GRASS+ PACKAGING

- New highlights on Color Copy: Expansion of loyalty programme “Color Copy Club” to Austria in cooperation with Europapier and EU-RO and ColorLok® certification

"Despite the difficult situation we are all facing this year, we have been keeping close to our customers and working intensively on our new uncoated fine paper products. We are pleased to present the impressive results to the market now," says Gunilla Saltin, CEO Mondi Uncoated Fine Paper. "Innovation, sustainability and partnerships have always been central pillars of our work at Mondi and will continue to be a foundation of our success in the future."

New PERGRAPHICA® shades for premium creative design, print and luxury packaging

Selecting the right paper is at the heart of every creative design, print and packaging project. Mondi has launched 31 new colours in its premium PERGRAPHICA® range to extend its offering. Alongside 10 rich and 10 pale shades, the new portfolio includes a variety of 10 dark and deep shades and the recently launched PERGRAPHICA® Infinite Black, which are ideally suited to luxury packaging for cosmetics, perfumes, wines, champagnes and spirits, as well as boutique bags. The new PERGRAPHICA® deep and dark shades are presented in a stunning ‘Wow Box’ enhanced with special finishing techniques to show how PERGRAPHICA® lends itself perfectly to diverse luxury packaging applications.

Partnership with Adobe Stock for PERGRAPHICA®

To mark the portfolio extension, Mondi is proud to introduce its campaign Catching Feels, developed in a unique digital to analogue partnership with Adobe Stock. The campaign starts on paper with a stunning new lookbook and continues on Mondi´s digital platform for paper lovers, mymondi.net, complemented by virtual events for customers and prospects and many other digital and analogue activities.

As we experience paper with all our senses, Catching Feels takes us on a sensory journey through six feelings with six photographers and illustrators, each chosen for their ability to bring feelings to life. The heart of the Catching Feels campaign is the new lookbook. Drawing on the full range of papers in the new PERGRAPHICA® portfolio, the emotive and technically challenging imagery in the Catching Feels lookbook features two surface finishes, four printing techniques, six paper weights, ten shades and 53 pages of special inks and finishes. The artists featured in the campaign contribute to the Adobe Stock Premium Collection, the premium stock image library, which enhances creative projects and empowers creatives.

There are a lot of shared values between Adobe Stock and PERGRAPHICA®. Adobe Stock´s motto of inspiring creatives to ‘make something amazing’ is very similar to PERGRAPHICA®’s ‘creatives inspiring creatives’. Mondi’s ‘digilogue’ or ‘digital to analogue’ strategy for uncoated fine paper – the transition from the screen to the page – gave Adobe Stock the opportunity to demonstrate just how well their imagery can leap off the page.

The new PERGRAPHICA® qualities and shades include additional laminated grades up to 400 g/m² and a widened HP Indigo offering. All PERGRAPHICA® papers provide excellent printability on a choice of textures, shades and weights and are perfectly suitable for post-print processing. The full range of PERGRAPHICA® qualities and shades is made in Austria and meets the strict international sustainability standards set by FSCTM as well as EU Ecolabel. They also belong to Green Range, Mondi´s umbrella trademark for sustainable paper solutions. The white shades as well as Infinite Black have a food safety certification.

IQ GRASS+ PACKAGING: launch of a unique grass paper for premium packaging

Partnering with customers for innovation is one of Mondi’s four strategic value drivers. One of the latest innovations using alternative raw materials is IQ GRASS+ PACKAGING which uses fast-growing grass as a fibre source, and was developed in close collaboration with customers. The combination of 30 percent grass fibre and 70 percent fresh fibre from sustainable resources gives this new niche product a natural and unique look and feel making it suitable for premium shopping bags as well as liners for high-quality corrugated and solid board packaging. IQ GRASS+ PACKAGING has a high tear strength compared to typical uncoated fine paper products, is optimised for flexo printing, used for various types of packaging, and has a food safety certification for dry/non-fatty foods. The new material is available to order across Europe from September 2020 onwards. First projects have already been successfully implemented with customers.

Loyalty programme Color Copy Club opens in Austria

In 2019, Mondi successfully launched its loyalty programme ‘Color Copy Club’ in Germany. Now, the B2B platform is being extended to the Austrian market – in an exclusive cooperation with the paper merchant Europapier and EU-RO. The programme was developed to strengthen business relationships and to open new opportunities for cooperation. It addresses resellers, retailers, copy shops as well as commercial digital printers and provides them with bonuses and special promotions.

“It was particularly important to Mondi and Europapier that these bonuses offer real added value to our customers' business. We want to give our customers support for their operational business, personnel, marketing and sales. The club is an active community and a platform for exchange,” says Michael Hicker, Commercial Director Austria at Europapier.

‘Color Copy Club’ in Austria is open to Europapier and EU-RO customers buying Mondi’s digital colour printing paper brand Color Copy. After registering via colorcopyclub.com, customers automatically collect ‘bonus points’ whenever they are buying Color Copy paper through Europapier or EU-RO, which they can exchange for attractive bonuses. Members can also receive further information, promotions and marketing materials via the Color Copy Club online platform.

Mondi has been producing Color Copy for more than 30 years. It is the most well recognised uncoated fine paper brand in Europe1 and the perfect paper for digital printing in offices and professional print-rooms. Color Copy is CO2 neutral, FSCTM certified and available up to 400 g/m2.

Broadening the scope of Color Copy: adding improved inkjet printability with ColorLok® certification

Mondi is continuously advancing Color Copy, the signature collection for digital colour printing. Responding to the trend of an increase in small and home offices and a corresponding increase in inkjet printing, the latest Color Copy development is the ColorLok® certification for Color Copy original. ColorLok® Technology is used during paper production and consists of special additives that ensure high quality print results. The primary benefits of ColorLok® certified papers can be seen in inkjet printing when using pigment inks:

- Vivid colours: richer, brighter images and graphics

- Bolder blacks: crisp, sharp text with bolder blacks

- Faster drying: documents printed with ColorLok® papers dry faster, resulting in less smearing

The ColorLok® certified Color Copy original papers will be available internationally in cut-size from Q4 2020 onwards.

About Mondi Uncoated Fine Paper

Uncoated Fine Paper is a business unit of Mondi Group. In six operating sites in Austria, Slovakia, Russia, and South Africa, Mondi Uncoated Fine Paper produces pulp and environmentally sound office and professional printing papers tailored to the latest professional digital and offset print technologies. The company complies with the strictest international certification standards to support sustainable production processes through the responsible management of forest, water and air resources. All Mondi uncoated fine papers belong to the Green Range of papers that are FSCTM or PEFCTM certified, 100% recycled or bleached entirely without chlorine. Its renowned brands such as Color Copy, PERGRAPHICA®, NAUTILUS®, NEUJET®, IQ, MAESTRO®, BIO TOP 3®, DNS®, Snegurochka or ROTATRIM are used in office environments on laser or inkjet printers and by professional printers on digital or offset presses to create brochures, transactional material, folders, invitations, business cards, letterheads or other high-impact communication. Converters appreciate the excellent printability and smooth handling of Mondi’s professional printing papers.

About Mondi

Mondi is a global leader in packaging and paper, contributing to a better world by making innovative packaging and paper solutions that are sustainable by design. Our business is fully integrated across the value chain – from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is at the centre of our strategy and intrinsic in the way we do business. We lead the industry with our customer- centric approach, EcoSolutions, where we ask the right questions to find the most sustainable solution. In 2019, Mondi had revenues of €7.27 billion and underlying EBITDA of €1.66 billion.

Mondi has a premium listing on the London Stock Exchange (MNDI), and a secondary listing on the JSE Limited (MNP). Mondi is a FTSE 100 constituent, and has been included in the FTSE4Good Index Series since 2008 and the FTSE/JSE Responsible Investment Index Series since 2007.

ANDRITZ to supply innovative logyard cranes to Metsä Fibre

International technology group ANDRITZ and Metsä Fibre, part of the Metsä Group, have signed a preliminary agreement under which ANDRITZ will supply two fully autonomous logyard cranes to the planned Metsä Fibre bioproduct mill in Kemi, Finland. Metsä Fibre will make the EUR 1.5 billion investment decision for the new mill in autumn 2020 at the earliest, and the new mill will take approximately two and a half years to build.

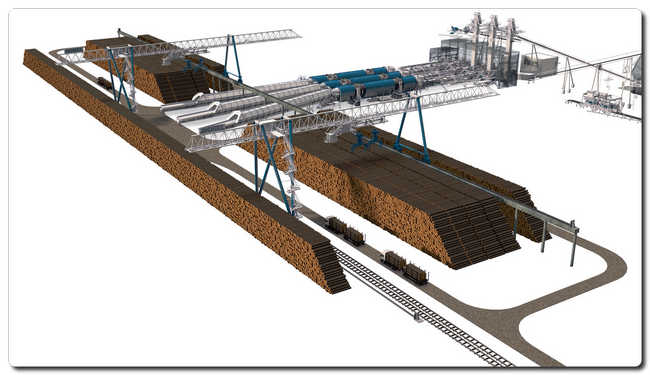

Included in the EPC delivery are two 2 x 25-ton cranes on a 540 m long runway with storage capacity of approximately 120,000 m3. The cranes will handle approximately 7,600,000 m3 wood/year shipped on trucks and trains as well as handling log storage and feeding the wood to the pulping process.

Illustrative drawing of the ANDRITZ autonomous crane solution

Illustrative drawing of the ANDRITZ autonomous crane solution

These ANDRITZ cranes will be the first autonomously operated logyard cranes worldwide.They feature the latest in artificial intelligence, thus optimizing log handling, minimizing wood losses and securing environmentally friendly and cost-effective operation compared with traditional log-handling solutions. This agreement is a significant breakthrough for logyard cranes in Europe. ANDRITZ has over 50 successful references for crane installations in North America.

“We valued the low noise – considering the planned mill location – the energy efficiency and all-electric drives with no fossil fuels consumed, and also the advantages created by applying advanced robotics and artificial intelligence to achieve autonomous operation,” says Ismo Nousiainen, CEO of Metsä Fibre Ltd.

This order once again confirms the excellent business relationship between ANDRITZ and Metsä Fibre, the latest reference being the innovative technologies and process equipment delivery to Metsä Fibre’s Äänekoski bioproduct mill, which was started up successfully in 2017.

Metsä Fibre is a leading producer of biochemicals, bioenergy and other bioproducts. Planning of the new bioproduct mill is based on a high level of environmental efficiency as well as efficiency in terms of energy and materials used. The mill will not use any fossil fuels at all, and its electricity self-sufficiency rate will be 250%. If built, the Kemi bioproduct mill will produce 1.5 million tons of softwood and hardwood pulp a year as well as many other bioproducts.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

OnCall.Video: Voith adds new tool for remote video support to its digital service portfolio

Voith has added a new tool for remote video support to its service portfolio, offering customers access to expert support at any time and from any location. OnCall.Video enables fast problem-solving and cuts downtimes, resulting in improved machine availability and productivity. With this tool, Voith is playing an important role in making processes even more efficient and sustainable through the use of digital solutions.

Video-assisted communication tool for access to expertise at any time and from any location

Thanks to the audio-visual communication system OnCall.Video, customers worldwide can draw on Voith expertise via an internet-based video collaboration platform at any time and from any location. Using OnCall.Video, the Voith specialist can see in real time exactly what the customer or operator is seeing at the production facility. In addition to recommending action and documentation, important information can be quickly conveyed to staff on site to provide an optimum level of support.

The digital solution is device-independent, so any device can be used for communication purposes. To perform servicing work with the machine still running, the technician can also wear industrial-grade smart data glasses that allow optimum communication with the Voith expert thanks to integrated voice control and active noise cancellation. Moreover, the smart glasses allow operators to keep their hands free, are splash-proof and dust-tight, and are compatible with the necessary PPE.

Wide-ranging applications for improved machine availability and productivity

“With the help of OnCall.Video, we can quickly analyze mechanical or technological problems and then recommend specific courses of action,” says Patrick Dengel, Manager Remote Solutions at Voith. “In addition to problem analyses, inspections and general service support, the system can also be used to assist with factory acceptance tests and commissioning.”

“Following an emergency in the wet end of our PM 1, the local Voith service team was able to carry out the necessary repairs quickly and professionally with expert support via OnCall.Video,” says Franz Gstettenhofer, Authorized Signatory and Member of the Management Board at Lenzing Papier GmbH in Austria. “This reduced the machine downtime and we were able to restart production shortly afterwards.”

Knowledge transfer across locations

Apart from providing a way to connect quickly with Voith experts, OnCall.Video can also improve knowledge transfer within a company. “This is an option both for our customers, who can then optimally connect their various sites with each other, and for Voith,” says Stefan Endras, Product Manager OnCall.Video at Voith. “Using OnCall.Video, collaboration between specialists across all distances can be accomplished quickly and easily. We have already been able to use the solution successfully for service assignments without the expert in charge having to travel to the relevant site.”

Even when travel options are limited, OnCall.Video provides fast and reliable support to ensure on-time delivery and commissioning.

For more information on OnCall.Video please visit: www.voith.com/OnCallVideo

ABB L&W Tearing Tester adds full automation and digital connectivity for safer, faster strength measurement

Newest paper lab testing instrument offers more streamlined and user-friendly operation across grades with accurate, repeatable results

ABB has just launched its market-leading L&W Tearing Tester with enhancements to ease operator use and safe handling, expand on tearing resistance testing capabilities and improve digital connectivity.

Paper mills already recognize the instrument for safely and accurately measuring tearing resistance on all paper grades and its unique automation, digitalization and safety features. Tearing resistance is a crucial determinant of product toughness and machine runnability and can help mills characterize pulp to determine if refining and reinforcement fibers are optimized.

ABB’s L&W Tearing Tester, which uses a pendulum to further tear a pre-cut sample, helps mills achieve tearing strength results faster with automatic clamping and notch cutting of the sample piece as well as automatic pendulum release, catch and retraction. Plus, testing for different grades is now faster than ever with interchangeable weights for the instrument’s one pendulum.

Lab technicians will benefit from a user-friendly touchscreen and more ergonomic-friendly operation. They will also be better protected with the two-hand operation requirement, avoiding contact with moving parts and the blade, and a unique pendulum safety guard that minimizes the risk of injury without interrupting the pendulum swing or slowing the test.

Th e instrument interfaces with ABB’s L&W Lab Management System, a web-based automated data acquisition and lab reporting solution that helps halve lab procedure times. With its capability to connect to ABB Ability™ Manufacturing Execution System for pulp and paper, manufacturers gain visibility of data across the mill and the entire enterprise to ensure consistent product quality.

“All mills aim for the best possible product toughness and machine runnability, and yet many struggle with measurement challenges – such as reliability or repeatability – associated with ageing equipment that could affect improvement opportunities,” said Per Sandstrom, Head of Lab and Process Testing Measurements for ABB Pulp & Paper.

“The new ABB L&W Tearing Tester is the only instrument on the market that combines the best modern automation, digitalization and safety advancements to deliver accurate and repeatable tearing strength results to help expedite quality and machine optimization.”

As the worldwide market leader for paper testing technical support, with local service organizations in all markets, ABB provides a comprehensive support network for the L&W Tearing Tester using L&W-specific calibration devices that are regularly certified with traceable calibration from global certification institutes.

For further information on ABB L&W Tearing Tester, please visit: https://new.abb.com/pulp-paper/abb-in-pulp-and-paper/products/lorentzen-wettre-products/laboratory-paper-testing/paper-strength-testing/l-w-tearing-tester

Valmet takes its services to the next level for the best customer experience

Valmet streamlines its services to customers globally by introducing ‘Valmet’s way to serve’ concept. The aim is to provide the best customer experience in all the touch points of the customer journey. Valmet’s services are based on comprehensive services offering, lifecycle collaboration and core commitments.

“Over the years we have been constantly developing our services to improve the reliability and performance of our customers’ production processes. Valmet’s unique combination of process technology, services and automation and over 200 years of industrial experience form a strong basis to help our customers to reach the wanted maintenance and operational results of their production process,” says Aki Niemi, Business Line President, Services business line, Valmet.

Right combination of services for every stage in the lifecycle

Valmet’s services offering is designed to match customer’s specific need, whether it’s reduced energy and raw material costs, reduced process variability, optimized quality and production or enhanced environmental performance.

Valmet streamlines the way it serves customers globally by introducing ‘Valmet’s way to serve’.

Valmet streamlines the way it serves customers globally by introducing ‘Valmet’s way to serve’.

The services offering ranges from spare and process parts, workshop and roll services, and fabrics all the way to field services, maintenance development and outsourcing as well as process upgrades. The services are complemented with Industrial Internet solutions on-site and remotely. Depending on the need, the service solution can be provided as a one-time delivery or as a longer-term partnership through service agreements.

The key driver in Valmet’s way to serve is the lifecycle collaboration between the customer and Valmet.

“When planning the investment, together with the customer we can set the foundation for optimized operational results for the production process to come. Services can help to accelerate the start-up curve when ramping up the production. By working together in maintenance and operations, we can ensure maximized reliability and optimized performance of the production process,” Niemi says.

Safety comes first in all operations

Valmet’s four core commitments to customers are: ‘Safety comes first,’ ‘Close to you,’ ‘Solutions to your needs’ and ‘People you can trust’.

“Safety is put before anything else in our daily operations. We support customers in reaching their safety targets. Our professionals work close to customers, through a network of over 100 service centers. Our experts are also available remotely with the help of Industrial Internet and remote technologies. We work closely with our customers to find exactly the right solution to their needs. We know that trust has to be earned, and we work hard to reach that goal every day”, concludes Niemi.

The Last Straw: Paper U-bend straw for juice drinks cartons unveiled by Transcend Packaging and Ribena

Ribena rolls out Transcend’s sustainable paper straws with Tesco in national trial.

Inspired by a desire to help create more sustainability in the packaging options we use every day, award-winning British manufacturer Transcend Packaging has unveiled a fully-recyclable and biodegradable U-bend paper straw. Ribena will be the first UK juice drinks brand to introduce the sustainable straws to its drinks cartons, with the new packs now available in Tesco as part of a trial of the new paper straw design.

With single-use plastic straws thought to account for 4% of all plastic waste globally and 2,000 tonnes of plastic straws believed to end up in the world’s oceans every year[1], the new paper straws can make a meaningful contribution toward reducing plastic waste.

Available to be adopted immediately by drinks companies and bottlers, Transcend’s ground-breaking paper U-bend straw is a major step in replacing some of the millions of plastic straws being used in the UK daily.

Lorenzo Angelucci, CEO at Transcend Packaging said: “Anyone who has ever had a carton drink will instantly recognise the bendable plastic straws on the side of juice boxes found in supermarkets, cafes and packed lunch boxes across the country. The problem is these straws are used just once but then the plastic remains, as the straws are not often recycled.

Because these straws need to be bendable and sharp enough to pierce the seal on the drink, it has traditionally been thought to be very difficult to create them from paper. Our new U-bend straw represents a significant design advancement and we are deploying it into the market at scale to provide drinks brands with a more sustainable option for their products.”

Jo Padwick, Business Transformation Manager at Suntory Beverage & Food GB&I, comments: “Further improving the recyclability of our cartons is an important step in achieving our 100% sustainable packaging by 2030 ambition, but for full circularity, local authorities need to work with brands to ensure cartons and straws are recycled. Currently only 65%[2] of local authorities collect cartons from household waste which is why we’re welcoming national governments’ moves to introduce consistency in household recycling collections.

“Developing a bendable, durable paper straw, hasn’t been easy but recycling it should be. We’ve conducted hours of consumer testing to make sure our new paper straws can puncture the carton, that they don’t become soggy, and that Ribena lovers enjoy the feel of sipping from them. Now that they’re out in market we can gather even more feedback before rolling the straws out more widely.”

Reducing the Environmental Impact

Transcend’s work with Ribena to bring the U-bend paper straw to market will help this leading brand move forward on their ambitious sustainability goals, preventing up to 16 tonnes of plastic waste, per year[3].

Angelucci concluded: “Whichever way you look at it, finding a viable alternative to plastic straws is important because they often go unrecycled. Additionally, by sourcing paper straws from within the UK, brands can reduce their carbon footprint compared to shipping products over long distances and eliminating the quality control challenges of relying on imports from outside of Europe.

The British sustainable packaging industry is right at the forefront of innovation, so it is important for leading brands to have sourcing options from within their own shores for their supplies.”

A Paper-Bending Breakthrough

Mark Mitchell, Sales Director for Transcend’s U-bend straw, spoke of the complexities of the operation: “Engineering a bendable paper straw that could pierce through the foil film on a drinks carton whilst retaining its own form was a real challenge, but we are delighted to say that the new straw satisfies both of these requirements.”

Made from sustainably sourced paper, the straws can be recycled in their entirety alongside any other paper product.

[1] The University of Georgia as quoted in PHYS.org, 2018: https://phys.org/news/2018-04-science-amount-straws-plastic-pollution.html#:~:text=Straws%20make%20up%20about%204,that%20yearly%20hits%20the%20waters.

[2] https://tetrapak.com/uk/sustainability/carton-recycling-in-the-uk

[3] Annually SBF GB&I consume 40,000,000 straws equalling 16 tonnes by weight

About Transcend Packaging

Transcend was established in 2017 to provide sustainable packaging solutions to customers in the food service, food and beverage and health and beauty industries.

Transcend has a manufacturing facility in South Wales that began production in 2018 and was the first major producer of paper straws in the UK.

Transcend Packaging aspires to be a different kind of packaging company. With a leadership team boasting extensive experience in the international packaging industry, the company’s objective is to deliver on the promise of what is possible in packaging, for clients, employees, and the environment. Transcend works everyday with major international brands to enhance the sustainability of their packaging products and is the European leader in paper straw production.

In 2019, Transcend was named Economic Disruptor of the Year for the Northwest and Wales by The Spectator and Julius Baer. It also collected the National Runner Up award for the UK.

About Ribena:

Ribena has been leading the way towards sustainable packaging for over a decade, becoming the first UK drinks brand to make bottles from 100% recycled plastic all the way back in 2007.

About Suntory Beverage & Food Great Britain and Ireland

Suntory Beverage & Food Great Britain and Ireland (SBF GB&I) is one of the leading soft drinks businesses in the UK and Ireland. SBF GB&I was formed in 2014 as Lucozade Ribena Suntory and is part of Suntory Beverage & Food Europe. Our much-loved soft drinks brands include Lucozade Energy, Lucozade Sport, Lucozade Revive, Ribena, Orangina and MayTea.

Our business is driven by our “Yatte Minahare” spirit and our role is to have a positive impact on the lives of our consumers by providing them with a responsible choice of great-tasting drinks that people can feel good about while enabling them to lead active lifestyles.

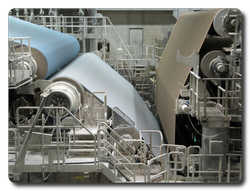

How to prevent breaks in the press section of your paper machine?

Pick-up troubleshooting tips for the press section.

Besides removing the most water of all press felts, the pick-up felt has another important task: it has to pick up the delicate sheet from the forming fabric and guide it into the press section. Problems in the pick-up area, often leading to breaks in the press section, are certainly not uncommon.

Five easy solutions that each papermaker can try immediately to optimize the press section:

- Increase the water content of the felt before the pick-up point

The water will smoothen the felt’s paper side, improving the stickiness of the felt. The additional water increases the hydraulic pressure in the first nip. This can give better dewatering, but taken to the extreme it may also cause crushing – on which I will write another time. - Check tensions of the forming fabric and the pick-up felt

First of all the tension of both fabrics must be equal over the width of the machine. So take the Feltest TensioMaster and measure tension on both the tender side and the drive side. Make sure the guiding lines are running as straight as possible.

Next, if possible increase the forming fabric tension a little. After that, you can also play a little with pick-up felt tension. A little slacker or a little tighter, it might both work. - Push the pick-up roll a little deeper into the forming fabric

This increases the load on the still vulnerable sheet, so use this option with care. Take a look at the pick-up point from the back (machine) side of the fabric with a powerful lamp or PowerStrobe to see if the pick-up roll is evenly pushed into the fabric over the full width of the machine. If not, you might have some alignment work ahead of you. - Check for unexpected speed differences

Some mills run the press felt a little faster, others have the same speed setting for both fabrics. The fact of the matter is that speed differences are very delicate in the pick-up zone. Small deviations due to slip (a fabric runs slower than the DCS expects) or incorrect roll diameter settings (resulting in differences between the actual and the calculated DCS speed). The actual speeds of drive rolls, forming fabrics and pick-up felt can easily be measured and compared with the Feltest TrueSpeed. - Reduce the initial dewatering in the forming section

When there is hard initial dewatering at the forming table of the machine, fibers are dragged into the dewatering holes of the forming fabric. The fabric slowly loses drainage capacity and sometimes this is compensated by increased vacuum in the forming section. All this leads to fibers being vertically stuck into the forming fabric, resulting in a more difficult release at the pick-up point.

Moving the touchpoint of the jet further onto the forming table, reducing the angle of the first dewatering foils, and eventually reduce the vacuum on the first vacufoil boxes will improve the release of the sheet at the pick-up.

“33% break reduction after re-adjusting the speed difference to practically zero” — René K (Netherlands)

“33% break reduction after re-adjusting the speed difference to practically zero” — René K (Netherlands)

These above troubleshooting tips are only 5 of many more machine-related solutions for pick up problems. Also, the felt design must be right for your machine and circumstances, contact your suppliers to learn what a modified felt design can do.

Troubleshooting usually means identifying the differences between the current situation and when the machine was running well. Only when you know that you can start working on the solution. Therefore I am a big fan of collecting Paper machine Clothing data when the machine is running well, as it will give you this important baseline for troubleshooting.

So remember DDPP - Daily Data Powers Profit.

Keep on innovating!

TietoEVRY and Yazzoom partnership promotes the use of Artificial Intelligence in the pulp, paper and fibre industry

Data analysis in mills has a long history, but new technologies are making the next level possible through AI and machine learning.

TietoEVRY will enhance data science capabilities with specialist third-party cooperation. Yazzoom, a digital services and software company, has in-depth expertise in applying Artificial Intelligence (AI), machine learning and advanced analytics to machine data and production processes, with positive references from the pulp and paper industry. Together, by combining the expertise, our customers’ operational excellence can be improved.

Data analysis in mills has a long history, but new technologies are making the next level possible through AI and machine learning. Yazzoom provides a rich set of tools and algorithms, from simple single sensor anomaly detection all the way to real-time predictive modelling and optimisation. TietoEVRY will embed these capabilities in its TIPS industry solutions and services.

TietoEVRY has more than 1,000 pulp and paper industry experts worldwide, and we offer our customers a Manufacturing Execution System (MES) and other industry-specific solutions and services. TietoEVRY and Yazzoom can also provide our customers with related support and maintenance services and training.

“We’re pleased to expand the use of our AI-based data analytics software and services in the pulp and paper industry, thus helping the industry create value from their process and MES data. We welcome this cooperation with TietoEVRY, whose extensive experience in this industry and software solutions will allow us together to create an integrated solution covering all aspects, from accessing the data and applying machine learning to reporting the impact on relevant Key Performance Indicators,” says Jan Verhasselt, PhD, Managing Director of Yazzoom.

“Data plays an increasing role in the industrial sector, and it helps companies to improve in areas like efficiency, preventive maintenance, and problem solving. We’re constantly seeking new ways to improve our customers’ efficiency and operational excellence. The partnership with Yazzoom is a great step for our ecosystem and will expand our capacity to create more value from data,” says Jarmo Ropponen of TietoEVRY.

MIAC 2020 is postponed to April 2021 and it is called MIAC RESTART

We wish to inform you that EDIPAP S.R.L., the MIAC Organizer, has decided, after recent consultations with companies in the paper industry sector, to postpone the October 2020 edition of the MIAC Exhibition to April 2021 on 21.22.23 April 2021. The April 2021 edition takes the official name of MIAC RESTART.

"It was a difficult decision, especially because MIAC still had 160 direct Exhibitors ready to exhibit at the exhibition in October 2020. Furthermore, during the last months we have worked to offer both Exhibitors and Visitors a safe environment and fully in line with governmental, regional and local directives in terms of personal safety and health," says Gianmaria Pfeiffer, director of MIAC.

"We have studied very specific protocols to allow people to visit the MIAC Exhibition in a responsible way and in total safety and we have waited for the month of September to make a final decision by evaluating the Covid-19 situation: organizing the exhibition this October, however, would not have guaranteed the Exhibitors and Visitors to 'experience' the MIAC that we all know due to travel restrictions on an international level," continues Pfeiffer," and so we decided to move the exhibition to April 2021 waiting for better times."

MIAC 2020 then becomes MIAC RESTART and is organized on 21.22.23 April 2021 at the Exhibition Centre of Lucca in Italy.

MIAC 2021, on the other hand, remains scheduled in the usual month of October and is organized on 13.14.15 October 2021.

Artificial intelligence integration further improves quality consistency at Metsä Board Kemi mill

Metsä Board, a leading European producer of premium fresh fibre paperboards and part of Metsä Group, is putting the latest artificial intelligence to good use at its Kemi mill in order to improve the runnability of its white kraftliner on a customer’s corrugating line. Metsä Board will be collaborating with DS Smith, a leading provider of corrugated packaging solutions operating across 37 countries. The analytical solutions and technology are supplied by Valmet, the leading global developer and supplier of process technologies, automation and services to the pulp, paper and energy industries.

“We strive at continuously developing the high performance of our paperboards. In paperboard production there are several quality parameters that we need to balance. With the data coming directly from the customer’s converting lines we can find the optimal combination. In addition, we can follow the effect of the supply chain on the quality parameters, for example, the moisture content of the board during transport,” says Ari Kiviranta, SVP Development at Metsä Board.

Metsä Board’s Kyro mill began using artificial intelligence for quality management on its folding boxboard machine last year. Metsä Board is also continuing to investigate different possibilities to implement artificial intelligence on other production lines.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards and forerunner in sustainability. We produce premium lightweight folding boxboards, food service boards and white kraftliners for consumer goods packaging as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests. We aim for completely fossil free mills and raw materials by 2030.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2019, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

{module 132}