Super User

Metsä Board joins forces with the new European Paper Packaging Alliance

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, is one of the founding members of the recently established European Paper Packaging Alliance (EPPA). EPPA is a food and food service packaging association whose aim is to promote food safety, circular solutions, and lower carbon emissions as well as call for evidence-based policy making. The members represent leading raw material manufacturers and food & food service packaging producers.

"I believe that EPPA has a really good and important message to tell. Fibre-based food service packaging has a significant role in terms of food hygiene, public health and consumer safety. It is made of a renewable raw material – wood fibre. It is recyclable and also recycles well; in Europe paper and board packaging recycling rates are over 80%. That is circular economy at its best,” says Risto Auero, Sales Director, Metsä Board Food Service Boards.

ANDRITZ to supply largest pressurized refining system to China

International technology Group ANDRITZ has received an order from Guangxi Guoxu Group Co., Ltd. to supply a pressurized refining system for their MDF production line in Wuzhou City, Guangxi Province. This will be the largest system ever installed in China, with a capacity of 45 bdmt/h and including an S2064M refiner. Start-up of the equipment is scheduled for the end of 2020.

The proven ANDRITZ equipment will process 60% eucalyptus and 40% pine and hardwood as raw materials. Its state-of-the-art design ensures best fiber quality at very low energy demand. The ANDRITZ refiner supplied is characterized by its long-lasting and proven bearing design, with many successful references around the globe.

Group photo (from left to right): Hao Zhifeng, Senior Sales Manager, ANDRITZ; Li Yongqiang, Vice General Manager, Guoxu Group; Li Xiaobo, General Manager, Guoxu Group; Michael Rupp, Vice President Panelboard, ANDRITZ; Liang Jiepei, Vice General Manager, Guoxu Group; Chen Zhuo, Sales Manager, ANDRITZ Photo: ANDRITZ

Group photo (from left to right): Hao Zhifeng, Senior Sales Manager, ANDRITZ; Li Yongqiang, Vice General Manager, Guoxu Group; Li Xiaobo, General Manager, Guoxu Group; Michael Rupp, Vice President Panelboard, ANDRITZ; Liang Jiepei, Vice General Manager, Guoxu Group; Chen Zhuo, Sales Manager, ANDRITZ Photo: ANDRITZ

The exceptional technological solutions proposed by ANDRITZ as well as the well-established service availability of ANDRITZ in China, with a service and spare part hub located in Foshan, were key in awarding the order to ANDRITZ.

“This project aims at the high-end fiberboard market, which requires excellent fiber quality. ANDRITZ has a globally leading position in fiber preparation and a strong market share. In this project, ANDRITZ introduced the advanced concept of pulping and papermaking into fiber preparation, and we believe that it will take the industry to a higher level in fiber quality and energy savings. We hope to work closely with ANDRITZ to become the benchmark in the industry and provide society with high-end fiberboard products,” says Li Xiaobo, General Manager of the Gouxu Group. “ANDRITZ refiners have a high market share in the world’s wood-based panel industry. We trust in their technology, products and services,” adds Vice General Manager Li Yongqiang.

This order once more demonstrates ANDRITZ’s strong position in the Chinese panelboard industry, with more than 170 references.

The Guoxu Group, headquartered in Nanning, is one of the largest wood-based panel industry groups in China, integrating R&D, production and sales of wood-based panels, and operates seven production sites in China.

ANDRITZ to supply OCC line including detailed engineering to UPPC, Philippines

International technology Group ANDRITZ will install an OCC line with a design capacity of 870 admt/d at United Pulp and Paper Co., Inc. (UPPC), Calumpit mill, Bulacan, Philippines. Start-up is scheduled for the fourth quarter of 2020.

The new line will process OCC (Old Corrugated Cardboard) as raw material to produce corrugated medium. The pulping system comprises an ANDRITZ FibreSolve FSR pulper with FibreGuard detrashing system. The innovative layout of the detrashing system features an elevated FibreGuard detrasher above the drum screen, type ANDRITZ FibreWashDrum, to ensure easy and efficient reject removal. Fractionators and fine screens will be equipped with newly developed PrimeRotors to remove stickies efficiently and at lower energy consumption compared to conventional rotor types.

ANDRITZ FibreSolve FSR pulper with detrashing system (shown here with conventional layout). Photo: ANDRITZ

ANDRITZ FibreSolve FSR pulper with detrashing system (shown here with conventional layout). Photo: ANDRITZ

With this turnkey project, UPPC’s parent company, Siam Kraft Industry Co., Ltd., which is part of the well-known SCG Group, once again affirms the long-term cooperation between Siam Kraft Industry and ANDRITZ (China) Ltd., which has already supplied two complete new lines and rebuilt several OCC systems for Siam Kraft Industry. ANDRITZ (China) Ltd. will also supply the complete detailed engineering as well as reject equipment.

ANDRITZ’s innovative technologies and the excellent performance of the OCC lines previously supplied were the decisive criteria for the repeat order.

SCG Packaging is a leading manufacturer of high-quality packaging paper in Thailand, the largest manufacturer in Southeast Asia and operates mills in Thailand, Vietnam, Indonesia and the Philippines.

ANDRITZ receives major order for paper machine rebuild from MOPAK Kağıt Karton, Turkey

International technology Group ANDRITZ has received an order from MOPAK Kağıt Karton, Turkey, to rebuild paper machine PM3 at its mill in Dalaman, Turkey. With this rebuild, which is the first part of a multi-stage project, the capacity of the mill will be increased to 500,000 t/a. Start-up is scheduled for the first quarter of 2021.

Production will be converted from coated board grades to lightweight coated and uncoated White Top Testliner with high strength and gloss values, as well as coated board and gray board, using 100% wastepaper or partially wastepaper. In addition, PM3 will be able to produce virgin pulp-based light/heavy coated and uncoated board as well as offset printing papers. The machine has a working width of 4.34 m and a design speed of 600 m/min.

After the rebuild, production at the Dalaman mill will reach up to 500,000 t/a of different board grades. Photo: ANDRITZ

After the rebuild, production at the Dalaman mill will reach up to 500,000 t/a of different board grades. Photo: ANDRITZ

Mr. Ruhi Molay, Managing Director of MOPAK Kağıt Karton, says: “The upgraded PM3 offers us a new dimension. The rebuild will not only increase our capacity, but also our flexibility as we will be able to offer board grades for a broad range of applications.”

The Mopak Group, which began paper production 94 years ago, is one of the largest paper and cardboard manufacturers in the Middle East and the Balkans today and a leading supplier to the Turkish paper and cardboard sector.

Process and product optimization with the right instruments

emtec Electronic represented at key European paper symposium

In line with this year's theme "Advances in paper and board production," emtec Electronic is presenting the ACA Ash Content Analyzer, TSA Tissue Softness Analyzer, EST 12 as well as the CAS touch! and the FPA touch! at the 29th International Munich Paper Symposium from 18th to the 20th of March.

The ACA, Ash Content Analyzer from emtec Electronic, measures minerals and fillers in paper and board. With this innovative technology, non-destructive measurements within 30 seconds are possible for the first time. The innovative laboratory device replaces the traditional combustion method with the latest X-ray technology and thus enables measurements of the total mineral filler content as well as the percentage of individual filler components in paper and board. The disadvantages of combustion, such as time-consuming test procedures and dependence on the moisture of the sample, are no longer an issue with the ACA Ash Content Analyzer.

In addition, emtec Electronic will present its specialized portfolio of testing devices designed for a relaible and fast quality assurance as well as the optimization of production and converting processes and by this the quality of the finished product, such as the TSA - Tissue Softness Analyzer, the CAS touch! - Charge Analyzing System, the FPA touch! - Fiber Potential Analyzer or the EST 12 - emtec Surface and Sizing Tester. Participants and visitors are invited to bring their own samples and test them live on site.

"I am looking forward to the exchange with our existing customers and new interested parties. Being close to our customers and understanding their daily challenges is the key to the further development of our products," says Stefan Rübesam, Area Manager at emtec Electronic, who will be attending the symposium on site.

The International Munich Paper Symposium is targeted at the paper and board manufacturing and converting industry and their suppliers.

More information about the International Munich Paper Symposium can be found on their website: https://paper-online.de/de/imps-2020

Toscotec completes two drying section rebuilds for Lucart.

From July 2019 to February 2020, Toscotec successfully completed two customized rebuilds at Lucart Diecimo tissue mill. The two rebuilding solutions included the replacement of PM5 and PM6’s existing Yankees with Toscotec’s second-generation Steel Yankee Dryers, complete steam and condensate systems, as well as the installation of a TT SuctionPressRoll.

This is yet again another major achievement in the strong and long-lasting cooperation between Lucart and Toscotec. Over the last ten years, Toscotec supplied to Lucart Group one complete tissue line, two slitter rewinders TT WIND, and various tailor-made rebuilding solutions on six different tissue machines in Italy and France.

The Lucart Group are pioneers in sustainability and they continuously uphold the highest standards of energy efficiency and specific energy consumption in their production processes to promote fair and sustainable development in our shared environment.

Lucart has tapped Toscotec for its efficient drying solutions, in particular TT SYD and its energy recovery-oriented system design. The extraordinary energy saving advantages that TT SYD delivers, on a potentially infinite number of cycles over the course of its life, save a significant amount of energy and operating costs. Toscotec’s energy recovery equipment, chiefly heat exchangers, are a key part of TT SYD’s steam and condensate system in that they contribute to achieving the highest possible level of thermal energy efficiency.

“Based on the high quality of the work done on PM5 and PM6, Toscotec confirmed its leadership in the construction and installation of steel Yankee dryers. We are very satisfied with the achieved performances, as well as the time schedule and project management of these rebuilds. The work team and the constructive collaboration have been an important key to the success of the projects.” said Eng. Franco Pasquini, Lucart’s Chief Technology Officer.

Valerio Volpi, Toscotec’s Project Manager of Lucart’s PM5 and PM6 rebuilds, says: “Our highly qualified Italian technicians worked with Lucart’s experts as one team. We were right on schedule according to the agreed timetable and the two TT SYDs performed well from the first hours of operation. This is a shared achievement for the Lucart-Toscotec team.”

About Lucart

Lucart, a leading company in Europe in the production of tissue products for daily use (toilet, kitchen, napkins, tablecloths, handkerchiefs etc.), airlaid products, and MG paper was founded in 1953 by the Pasquini Family.

The company's production activities are distributed over 3 Business Units (Business to Business,

Away from Home and Consumer) operating in the development and sales of products with brands such as Tenderly, Tutto, Grazie Natural and Smile (Consumer area), Lucart Professional, Tenderly Professional, Fato and Velo (Away from Home area).

Lucart’s production capacity is 395,000 tonnes/year of paper on 12 continuous machines. Its

consolidated turnover will amount to more than €500 million, with more than 1,500 employees in 9 production plants (five in Italy, one in France, one in Hungary and two in Spain) and a Logistics Centre in Italy. Since 2018, Lucart has been part of the CE100 network, the pre- competitive innovation program designed by the Ellen MacArthur Foundation to give organizations the opportunity to develop new opportunities and achieve their circular economy goals as quickly as possible.

Sappi celebrates technical innovation and sustainable innovative solutions

The Sappi Technical Innovation Awards take place annually across Sappi’s global businesses. Started in 2000, the awards programme is aimed at recognising and celebrating the best technical innovation within Sappi. The awards also help drive the creation of sustainable solutions within Sappi, paving the way for the next generation of people, sustainable products and processes.

The award allows Sappi’s mills to demonstrate technical innovation in action across a range of projects. Nominations for the awards need to demonstrate technical innovation, economic impact, market leadership value, product/process impact and customer satisfaction.

From left to right: Steve Binnie (Sappi Group CEO), Rainer Lex, Daniel Müller, Paul Post, Lukas Rebernig, Jürgen Lind and Berry Wiersum (Sappi Europe CEO)

From left to right: Steve Binnie (Sappi Group CEO), Rainer Lex, Daniel Müller, Paul Post, Lukas Rebernig, Jürgen Lind and Berry Wiersum (Sappi Europe CEO)

The awards which are run globally include regional finals in Europe, North America and South Africa, culminating in a global final.

Sappi Europe announced the winner of its European Technical Innovation Award (TIA) in Vienna on the 2 March 2020. Sappi’s Ehingen Mill in Germany was the winning team with innovative solutions created by a team spanning sales, technical marketing, technology and production who created a range of innovative solutions.

Sappi Southern Africa will host its awards on 11 March 2020 and Sappi North America on 4 March 2020. The Global final this year will be held on 4 May 2020 in Belgium.

ANDRITZ to supply complete recovery island to Tamil Nadu Newsprint and Papers Limited in India

International technology group ANDRITZ has received an order from Tamil Nadu Newsprint and Papers Limited (TNPL) to supply a complete recovery island for its mill in Mondipatti Village, Tamil Nadu, India. Start-up is scheduled for early 2021.

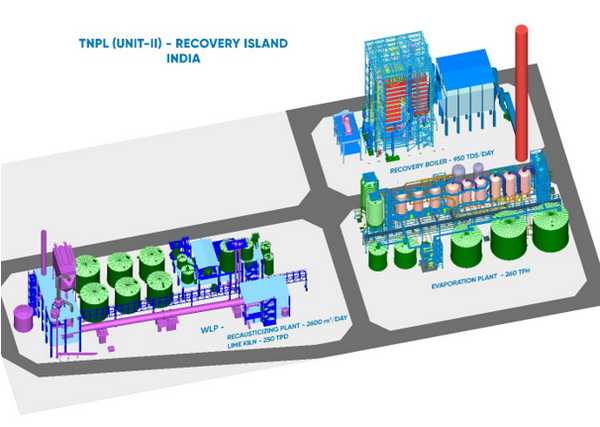

ANDRITZ recovery island with evaporation plant, recovery boiler and white liquor plant “Photo: ANDRITZ”.

ANDRITZ recovery island with evaporation plant, recovery boiler and white liquor plant “Photo: ANDRITZ”.

The ANDRITZ scope of supply includes:

- A HERB recovery boiler with a capacity of 950 tds/d on EPC basis, with a provision for upgrade to 1,100 tds/d in the future

- An evaporation plant with a capacity of 260 t/h on EPC basis, which will concentrate black liquor to a final dry solids content of 75%

- A white liquor plant containing

- A recausticizing plant (2,600 m3/day white liquor production) on EPS basis

- A lime kiln (250 t/d) on EPC basis.

This investment is part of TNPL’s mill expansion plans to further strengthen its position in the printing and writing paper segment. TNPL is a leading producer of paper and board based on bagasse – a sugar cane residue. The mill’s “Unit II” produces multi-layer coated board for use in pharmaceutical, health care, food, cosmetics and consumer packaging applications.

The recovery island to be supplied by ANDRITZ incorporates state-of-the-art technologies, thus ensuring highest energy efficiency and optimum environmental protection. ANDRITZ HERB recovery boilers maximize the use of thermal energy while efficiently recovering cooking chemicals. The latest ANDRITZ technology for evaporation plants ensures optimum reuse of condensates with minimum energy consumption, while the white liquor plant will recycle and reuse the mill’s process streams in order to minimize waste.

Tissue World Miami Conference to Feature Industry Leaders and Experts to Explore Solutions to the Challenges Facing the Tissue Industry in the 2020s

Four-day conference complements the three-day exhibition showcasing the products and services of over 150 suppliers and manufacturers

In less than a week, Tissue World Miami 2020 will open with conference sessions from March 10-13 and an extensive trade show running March 11-13 at the Miami Beach Convention Center. Tissue World Miami is North America’s largest and exclusively dedicated tissue manufacturing gathering.

The event brings industry professionals from across the tissue supply chain together for four days of insightful conference sessions and a three-day tradeshow with over 150 fantastic exhibitors from across the globe.

Get your free visitor ticket to guarantee access to:

- Free-to-attend tech talks (March 12) on the show floor, discussing the latest innovations and solutions to new and familiar challenges in our industry.

- An opportunity to network at happy hour sessions on the show floor on March 11 and 12.

- The Tissue World matchmaking app that provides a platform to organize those all-important meetings and facilitate catching up with familiar faces in the industry.

- Source and evaluate new products and services from world-class exhibitors.

Industry Leaders Headline Conference Lineup

Conference keynote speaker is none other than Kimberly-Clark’s Group President Kim Underhill. Kimberly-Clark personal-care products are used by a quarter of the world’s population every day in 175 countries around the world.

Joining Kim Underhill for a casual yet wide-ranging “Fireside Chat" will be founder of Blue Earth Network, Udaiyan Jatar. Blue Earth Network trains, develops and supports leaders in discovering, inventing and scaling innovation and brands that transform business and society.

Pulp is the single most costly element of tissue, and Marina Negrisoli of Suzano Papel e Celulose anticipates the cycles to come that can make the difference between healthy profit and life-limiting losses. Headquartered in Brazil, Suzano is the largest pulp and paper company in Latin America, with presence in over 80 countries.

Walmart’s Sam’s Club — who wouldn’t want to know what that massive consumer tissue product developer has in mind? Ivo Kool, senior products development manager, is on the program to discuss the latest trends in consumer paper products from both the demand and supply sides.

Recruiting and retaining the talent to run 21st century tissue mills can be an all-consuming challenge. Heidi Brock, President and CEO of American Forest & Paper Association brings paper and other industry expertise to this vital subject.

And no Tissue World Miami conference would be complete without the man who knows the tissue universe better than any other: Esko Uutela, Principal, Tissue, at RISI. He’ll be looking at shifts in quality and trade barriers driving change in North America.

There is limited availability of conference tickets, so make sure to get yours soon to avoid disappointment.

For more information about Tissue World Miami 2020, visit:

Registration: https://registration.n200.com/survey/12ejeykp4edbp?actioncode=PRS2

Exhibitor List: https://exhibitors.informamarkets-info.com/tissue-world-miami-2020/

Conference Sessions: https://www.tissueworld.com/miami/en-us/conferencesessions

Conference Brochure: https://www.tissueworld.com/miami/en-us/Conference/Conference-Brochure

Solenis to Acquire the Paper Business of ChemSystems

Effective February 28, 2020, Solenis signed an agreement to acquire the paper business of ChemSystems, a division of AECI Ltd. The transaction is expected to close in the second quarter of 2020.

Headquartered in Johannesburg, South Africa, ChemSystems produces and supplies specialized chemical solutions for water intensive industries, including the pulp, paper and tissue manufacturing industries in South Africa and Sub-Saharan Africa. Until this acquisition, the business was Solenis’ pulp and paper specialty chemical distributor in Africa.

Headquartered in Johannesburg, South Africa, ChemSystems produces and supplies specialized chemical solutions for water intensive industries, including the pulp, paper and tissue manufacturing industries in South Africa and Sub-Saharan Africa. Until this acquisition, the business was Solenis’ pulp and paper specialty chemical distributor in Africa.

“This is an excellent opportunity to continue to consolidate our channel to market after the recent successful merger of BASF’s Paper and Water Chemicals business with Solenis.” said John Panichella, president and CEO, Solenis. “We have had an exceptional working relationship with ChemSystems for many years and this acquisition will allow Solenis to directly provide value to pulp, paper and tissue markets in South Africa.”

Mark Dytor, Chief Executive, AECI added, “Through ChemSystems, we have partnered with South Africa’s pulp and paper customers for many years. Excellent relationships have been developed and I am certain that these will be enhanced further by Solenis.”