Ianadmin

Valmet to upgrade evaporator train at BillerudKorsnäs Gruvön pulp & paper mill in Sweden

Valmet will supply an upgrade of the evaporation plant at BillerudKorsnäs Gruvön pulp and paper mill in Sweden. The evaporation plant in a mill concentrates black liquor from the pulp cooking process. The installation of the new equipment is scheduled for spring 2018.

The order was included in Valmet's first quarter 2017 orders received. The value of the order will not be disclosed. A project of this type and scope is typically valued below EUR 15 million.

Evaporation plant at the BillerudKorsnäs Gruvön pulp and paper mill in Sweden

Evaporation plant at the BillerudKorsnäs Gruvön pulp and paper mill in Sweden

In this project, the existing evaporation train will be converted, from using medium-pressure steam as today's heating media, to become essentially low-pressure steam driven. This will optimize the overall steam balance at the Gruvön mill by making medium pressure steam available for the mill's new liquid board machine that will be installed at the mill.

"Valmet delivered the original evaporator train in 2001 and we are happy to cooperate with BillerudKorsnäs Gruvön also for this important plant modification. This upgrade will be beneficial in many ways for Gruvön mill. Besides ensuring medium pressure steam for the new board machine, we are adding washable heating surfaces in order to improve the availability and flexibility of the upgraded evaporation plant," says Thomas Norrgård, Product Sales Manager EVAPS at Valmet.

Details about the delivery

From the evaporation plant the evaporated water is brought back to the pulp process in order to minimize mill's water consumption. After evaporation the concentrated black liquor is fired in the recovery boiler for steam generation and recovery of cooking chemicals.

New equipment to be installed includes a TUBEL evaporator, two Tube Evaporators, two liquor preheaters, and Valmet's patented LP-steam boosting system. A substantial upgrade of the piping system will also be performed as part of the plant upgrade.

About BillerudKorsnäs

BillerudKorsnäs is a leading company within renewable packaging materials. Together with their partners, the company creates smart packaging solutions. It has about 4,200 employees and seven production units, one of which is the Gruvön mill. BillerudKorsnäs head office is located in Solna, Sweden.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet's Advanced Process Control application improves combustion at WestRock's Covington mill in Virginia, USA

Valmet's Advanced Process Control (APC) application, Valmet DNA FBB Combustion Manager, has improved combustion for the biomass boiler at WestRock's Covington mill in Virginia, USA.

By optimizing combustion, the mill has been able to maximize and increase the main steam output of the biomass boiler beyond the maximum continuous rating (MCR). Other benefits include more stable and controlled boiler steam output as well as improved operational uniformity across shifts, furnace symmetry and spray valve control. Valmet's APC application estimates the British thermal units (BTU) of the biomass fuel in real time and ensures a consistent optimum fuel power-to-air ratio.

The application has lowered the average O2 by about 0.3 percentage points, which improves boiler efficiency, reduces NOX emissions and subsequently minimizes NH3 consumption. Additionally, Valmet's advanced load controller now properly allocates the fuel demand between the feeders, taking into account any control and/or mechanical process limitations.

Valmet DNA FBB Combustion Manager protects the combustion process against variations in production, fuel amount, fuel quality and combustion circumstances.

Valmet DNA FBB Combustion Manager protects the combustion process against variations in production, fuel amount, fuel quality and combustion circumstances.

"This improvement has enabled us to run a higher, more stable load, resulting in a record-setting steaming average the following month," says Barry Hensley, Powerhouse Superintendent, WestRock.

The combustion control application is part of the boiler plant's Valmet DNA automation system.In 2012, Valmet was chosen as the automation supplier for the new biomass bubbling fluidized bed boiler at the Covington mill. The scope of the system included the boiler, Balance of the Plant, auxiliaries and a training simulator. Valmet's strong project execution team and close cooperation with Covington personnel made it possible to meet the challenging project deadlines.

"Valmet's commitment to a shared journey forward together with the Covington mill is how the APC project came about. The ROI for the project was less than six months. With our solution and biomass expertise, and working together with the mill's personnel, we were able to exceed all the project targets," says David Eapen, Solution Manager, Automation, Valmet.

Technical information about Valmet's Advanced Process Control

Valmet DNA FBB Combustion Manager is an advanced control application for the optimized combustion of both bubbling and circulating fluidized bed boilers. The purpose of the application is to protect the combustion process against variations in production, fuel amount, fuel quality and combustion circumstances.

As a result, Valmet DNA FBB Combustion Manager provides several environmental, operational and financial benefits, including a stabilized combustion process, increased boiler efficiency, a wider boiler operation range, minimized flue gas oxygen content, as well as minimized NOX and CO emissions.

Information about the customer WestRock

WestRock partners with its customers to provide differentiated paper and packaging solutions that help them win in the marketplace. WestRock's 39,000 team members support customers around the world from more than 250 operating and business locations spanning North America, South America, Europe and Asia.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Minerals Technologies Signs Agreement With PT Indah Kiat Pulp & Paper

Minerals Technologies Signs Agreement With PT Indah Kiat Pulp & Paper, a Subsidiary of Asia Pulp & Paper Group, to Construct a 125,000 Metric-Ton Per Year Satellite PCC Plant in Indonesia, and to Expand an Existing Satellite to 140,000 Metric Tons

Minerals Technologies Inc. (NYSE:MTX) has just announced that it has signed an agreement with PT Indah Kiat Pulp & Paper (IKPP), a subsidiary of Asia Pulp & Paper (APP) to build a 125,000 metric-ton per year satellite precipitated calcium carbonate (PCC) plant at its paper mill in Perawang, Indonesia. As part of the agreement, Minerals Technologies will also expand its present satellite PCC facility at the Perawang mill by 40,000 metric tons to 140,000 metric tons. The facility will be operated by PT Sinar Mas Specialty Minerals, an existing joint venture with APP in Indonesia.

“We are extremely pleased to expand our relationship with this long-term partner and world-class paper manufacturer through this agreement to build a new satellite and provide additional capacity at the satellite we have had at Perawang since 1997,” said Douglas T. Dietrich, chief executive officer. “This customer is integral to our Asia growth strategy for PCC.”

“We are extremely pleased to expand our relationship with this long-term partner and world-class paper manufacturer through this agreement to build a new satellite and provide additional capacity at the satellite we have had at Perawang since 1997,” said Douglas T. Dietrich, chief executive officer. “This customer is integral to our Asia growth strategy for PCC.”

These facilities are scheduled to begin operation in the second quarter of 2018. Rand Mendez, senior vice president and managing director of Paper PCC, commented further: “APP is an innovative paper company, and we are pleased that they have confirmed the value of our PCC technology in their fine paper grades. Our PCC will be used as a paper filler to improve brightness, opacity and bulk, and to reduce the cost to the papermaker of higher-cost fiber.”

PCC is a specialty pigment for filling and coating high-quality paper. By substituting Minerals Technologies' PCC for more expensive wood fiber, customers are able to produce brighter, higher quality paper at lower cost. In 1986, Minerals Technologies originated the satellite concept for making and delivering PCC on-site at paper mills, and the concept was a major factor in revolutionizing papermaking in North America. Today, the company has more than 60 satellite plants in operation or under construction around the world and continues to lead the industry with consistent quality and technical innovation.

New York-based Minerals Technologies Inc. is a resource- and technology-based growth company that develops, produces and markets worldwide a broad range of specialty mineral, mineral-based and synthetic mineral products and related systems and services. MTI serves the paper, foundry, steel, construction, environmental, energy, polymer and consumer products industries. The company reported sales of $1.638 billion in 2016.

For further information about Minerals Technologies Inc. look on the internet at http://www.mineralstech.com/

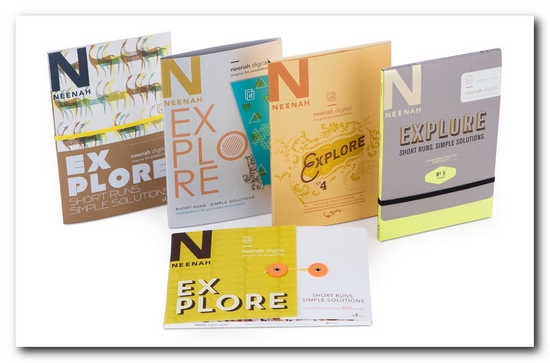

Neenah releases Explore 5: Creative ideas to optimize digital print projects for hospitality, plus free dielines

Neenah announces another edition to its popular Explore series. The new Explore 5 focuses on the hospitality industry, providing designers with practical, creative ideas to help differentiate their clients with digital print projects. To accompany the Explore 5 portfolio of samples, Neenah offers free downloadable dielines.

“Hospitality is in a state of vibrant growth. Hotels, restaurants and other businesses in this space will continue to look to designers to help create the personalized customer experience that today’s guests demand. With the ripple effect of social media, brands that create authentic customer experiences and memorable brand touchpoints will ultimately drive brand loyalty,” said Greg Maze, Sales & Marketing Manager, Digital & Wide Format, Neenah.

Explore 5 demonstrates that creativity and good design, combined with digital printing on colored, textured papers, can deliver unexpected benefits to businesses and their guests in practical ways. “Each of the samples in Explore 5 addresses one of the five E’s of hospitality: Entice, Enter, Engage, Exit or Extend,” said Maze. “For instance, what ideas help ‘extend’ the guest’s visit, long after they’ve left an establishment?”

The digital design solutions in Explore 5 are practical and strategic. “For example, a two-piece box for concept brand Limone Brothers demonstrates how an innkeeper might partner with a local, bespoke confectionery to create a special ‘exit’ gift for departing guests. This idea can ultimately benefit both businesses,” said Maze. “Our design brief was to create digitally printed samples that designers could use as a springboard for their own hospitality client assignments. We think of these samples as idea starters.”

Explore 5 features a range of premium Neenah papers, including new items from its CLASSIC® Papers line. Maze says that combining colored and textured papers with digital print can bring a new dimension to the simplest of designs. “When you introduce the idea of combining different papers into the mix, you start to see creativity come to life. Explore 5 celebrates the many strengths of digital printing on colored, textured papers with four-color, fluorescent inks, match colors, metallic’s and white ink technology. Designers will take these ideas and run with them,” he said.

Free, downloadable dielines

Neenah recognizes that designers are often expected to do great work with limited means. To help stretch the budget, dielines for all of the printed samples featured in Explore 5, and the entire Explore series, are available to download, free, at: www.neenahpaper.com/resources/dielines.

About Neenah Digital Papers

Explore 5 debuts with the just-announced expansion of the Neenah Digital Papers line. The addition of 70 new items creates a comprehensive digital portfolio with 22 brands, 19 unique textures, 60+ colors and multiple packaging and labeling options. And, with the recent refresh of its CLASSIC® Papers line, the Neenah Digital portfolio now includes 237 digital items from the CLASSIC® Brands alone, including the fast selling branded textures, Woodgrain and Techweave. “Neenah’s digital paper offering is simply unmatched,” said Maze.

About the Explore Series

Explore 5 is the fifth installment of Neenah’s popular, swatchbook-sized series, inspired by Neenah’s print partners. “The inherent value of the Explore series that it helps the creative community see fresh ways they can push the boundaries of possibility for all kinds of digital print and packaging projects,” said Maze. “And, they have tangible samples to show their clients, that yes, we can do this.”

A Bright, Beautiful SBS Paperboard/Caliper Cover That Fits

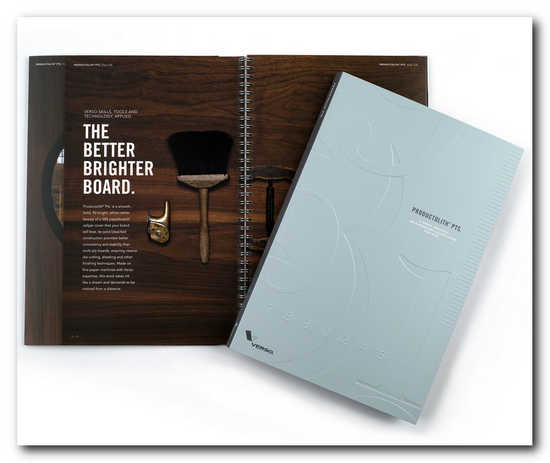

Verso Introduces New Productolith® Pts. Promotion

Verso Corporation (NYSE: VRS) has just released "A Bright, Beautiful SBS Paperboard/Caliper Cover That Fits," a new printed promotion showcasing its Productolith® Pts. product line. Productolith® Pts. is the ultimate combination of a solid bleached sulfate (SBS) construction produced with a bright, beautiful fine-paper surface. Its SBS construction provides better consistency and stability than multi-ply boards, ensuring cleaner die cutting, sheeting and other finishing techniques.

"Productolith® Pts. is a proven performer with the right optics, printability and price to do the job it's needed to do," said Verso President of Graphic Papers Mike Weinhold. "It offers all the attributes you want from a graphical paperboard or coated cover—and a new 16 pt. C1S and C2S in both a folio and digital product offering to better serve the needs of our customers."

"This promotion is a demonstration piece that showcases the breadth of applications that are beautifully created using Productolith® Pts.," said Verso Brand Manager Tanya Pipo. "Using a variety of print techniques and post press applications, this promotion illustrates the smooth, bold, enhanced 92-bright, whiter-white offering of Productolith® Pts. and Productolith Pts. Digital®."

Pipo adds, "Productolith® Pts. SBS construction and fine-paper surface support a quality image in a wide range of applications. Postcards to posters. Packaging to point-of-purchase displays. Tags to tickets. Calendars to greeting cards. Book covers to laminated corrugated board. Productolith® Pts. is perfect for printing and post press applications, including converting, scoring, folding, die cutting, film laminating, foil stamping, or embossing to create something that will get your brand noticed."

Productolith® Pts. is made in America on fine-paper machines with Verso expertise. It is available in a wide selection of stocking items as well as custom sizes through Verso's three-day PressDate® Service program, saving customers time and money. Productolith® Pts. matching sheets, digital and web products are all backed by Verso's guarantee of full customer and technical support from start to finish.

To learn more about Productolith® Pts., please visit our website versoco.com.

About Verso

Verso Corporation is the turn-to company for those looking to successfully navigate the complexities of paper sourcing and performance. The leading North American producer of printing and specialty papers and pulp, Verso provides insightful solutions that help drive improved customer efficiency, productivity, brand awareness and business results. Verso's long-standing reputation for quality and reliability is directly tied to our vision to be a company with passion that is respected and trusted by all. Verso's passion is rooted in ethical business practices that demand safe workplaces for our employees and sustainable wood sourcing for our products. This passion, combined with our flexible manufacturing capabilities and an unmatched commitment to product performance, delivery and service, make Verso a preferred choice among commercial printers, paper merchants and brokers, converters, publishers and other end users. For more information, visit us online at versoco.com.

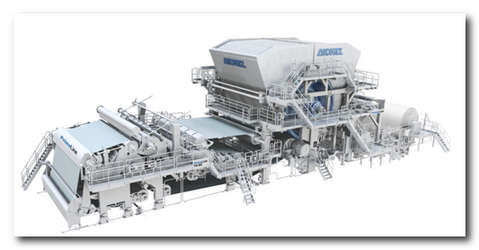

ANDRITZ successfully starts up twelfth tissue machine for Hengan Group

International technology Group ANDRITZ has successfully started up the tissue machine supplied to the Hengan Group, China, at its Chongqing mill.

The PrimeLineTM W8 tissue machine is the twelfth tissue machine supplied by ANDRITZ to the Hengan Group. It has a design speed of 2,000 m/min and a width of 5.6 m. The machine is equipped with an 18-foot steel Yankee for energy-efficient drying and safe operation. The scope of supply also included the complete stock preparation plant with ShortFlow concept, which minimizes both the investment costs and energy consumption as well as ensures high flexibility for grade changes. The entire automation system was also supplied by ANDRITZ

ANDRITZ has started up its twelfth tissue machine for the Hengan Group, China. “Photo: ANDRITZ”.

ANDRITZ has started up its twelfth tissue machine for the Hengan Group, China. “Photo: ANDRITZ”.

The Hengan Group was established in 1985 and, with around 30,000 employees, is one of the leading Chinese manufacturers of hygiene and sanitary products.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Valmet to supply new bleaching plant to CENIBRA's pulp mill in Brazil

Valmet has been selected as supplier for a new bleaching plant to be installed at CENIBRA's pulp mill in Belo Oriente in Brazil. The new plant will have the capacity to produce 500,000 tonnes of pulp per year. Start-up is scheduled to be in April, 2018.

The order was included in Valmet's fourth quarter 2016 orders received. A typical value for this scope of supply is around EUR 30-50 million.

The new bleaching plant, equipped with Valmet's modern TwinRoll press technology, will replace the original plant, dated from 1977, that is based on vacuum filter technology. The bleach plant renewal utilizing the most advanced existing washer technology, is part of CENIBRA's project for fiberline modernization.

"Along the years, CENIBRA has searched the balance between the production activities and environmental performance, always looking for the process improvement of pulp production through implementation of environmentally sustainable projects and technological innovations, as this new bleaching plant," mentioned the Industrial Director and Technician, Róbinson Félix from CENIBRA.

CENIBRA's pulp mill in Belo Oriente in Brazil.

CENIBRA's pulp mill in Belo Oriente in Brazil.

"By upgrading individual key process parts in chemical pulping to latest technology, it is possible to reach significant reductions in environmental impacts, and at the same time, increase the performance of the production process. We are very pleased that CENIBRA appreciates our bleach plant technology and that we got their confidence to deliver this important project," says Stefan Mattson, Vice President, Fiber Processing, Valmet.

About the customer CENIBRA

Celulose Nipo-Brasileira S.A. - CENIBRA is one of the biggest world producers of bleached eucalyptus pulp (hardwood). Their annual production is approximately 1,200,000 tons, which more than 90% is exported for external market. CENIBRA operates in 54 municipalities of Minas Gerais state. Since July 2002, CENIBRA produces only ECF (Elemental Chlorine Free) pulp. As recognizing of the work with highest international standards of excellency CENIBRA is certificated in standards ISO 9001 / ISO 14001 / ISO IEC 17.025 and has the Forest Stewardiship Council - FSC certificates and the National Program of Forestall Certificate (CERFLOR). The pulp traceability can be done from the forest to customer or from the customer to forest.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

North Charleston Mill Incident

KapStone Paper and Packaging Corporation (NYSE: KS) – At approximately 8:45 p.m. EDT, Sunday, April 30, 2017, an incident occurred at our North Charleston, SC paper mill involving employees performing maintenance work in an operating area that was offline for repairs. The incident resulted in the fatality of one employee and injuries to a second employee. The second employee was transported to a local hospital and released.

Our primary concern is for the privacy and welfare of the families involved and for the safety and well-being of employees working on our site.

The incident was reported to South Carolina OSHA and is currently under investigation.

Further information will be provided, as appropriate, when it becomes available.

About KapStone

Headquartered in Northbrook, IL, KapStone Paper and Packaging Corporation is the fifth largest producer of containerboard and corrugated packaging products and is the largest kraft paper producer in the United States. The Company has four paper mills, 21 converting plants and 65 distribution centers. The business has approximately 6,300 employees.

MiniGrinder: Voith's compact grinder for restoring the Yankee cylinder's ideal crown profile

Deformations on Yankee cylinders frequently result in production and quality deficiencies in tissue manufacturing. The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of these kinds of irregularities restoring the Yankee cylinder's ideal crown profile.

The MiniGrinder also readily removes old coatings and chatter marks. What is special about the MiniGrinder is its size. It is so compact that it can be used on any tissue machine without the need to remove and re-install key machine parts, as is normally the case with conventional grinding machines. This reduces time and labor for the maintenance crew allowing production to restart much sooner.

The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of deformations on Yankee cylinders.

The MiniGrinder developed by Voith's OnSite Yankee Service enables easy, accurate removal of deformations on Yankee cylinders.

One Voith customer was able to reduce the downtime for his machine by 14 hours, because there was no need to dismantle machine parts. The exhaust air system used with the MiniGrinder removes the airborne dust that inevitably occurs during the grinding process. On the one hand this reduces the cleaning effort before restarting the machine, and on the other hand it protects the health of personnel working on and around the Yankee cylinder.

The design and shape of the MiniGrinder has been optimized so that the grinding bed has optimum rigidity. Although the grinding bed is smaller than conventional grinding machines the rigidity is significantly higher. The grinding force of the head is equivalent to that of conventional tangential grinding heads, ensuring maximum precision for all types of applications. The MiniGrinder is suitable for all kinds of metal surfaces.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.

Voith AdvancedPRODUCTS improve the paper production process – in the former, press and dryer sections

With FormMax, PressMax and DryMax, Voith achieves a higher level of performance for the paper machine by using the optimum combination of products in the paper production process. In the former, press and dryer sections, the Voith products combine perfectly with one another as AdvancedPRODUCTS to lower operating costs, increase productivity, improve quality and provide a safer workplace for operators.

DuoCleaner Excell is an efficient cleaning system for consistent and uni-form cleaning of the surface and structure of forming and press fabrics.

DuoCleaner Excell is an efficient cleaning system for consistent and uni-form cleaning of the surface and structure of forming and press fabrics.

- Optimized machine performance

- Lower operating costs

- Successful installation at Green Bay Packaging

The Green Bay Packaging mill team in Wisconsin, USA has found that the FormMax approach has realized all of these goals in their forming section. The drainage is more uniform, dry line on the wire is more level, sheet breaks have been halved, chemical cleaning and hazards are significantly reduced, and the paper strength target is achieved using a lower basis weight.

This FormMax solution includes the DuoShake to optimize fiber orientation through high-frequency shaking of the breast roll and to achieve good formation and a low tensile strength ratio. In addition the DuoCleaner Excell traversing cleaning system on both wires is significantly more effective than high-pressure showers. It gives more uniform cleaning of the surface and structure of forming fabrics. The Voith I-Series forming fabric will be installed later this year as part of the continuing optimization program.

The DuoShake optimizes fiber orientation through high-frequency shaking of the breast roll. The result is good formation with all paper grades and a low tensile strength ratio.

The DuoShake optimizes fiber orientation through high-frequency shaking of the breast roll. The result is good formation with all paper grades and a low tensile strength ratio.

About Voith Paper

Voith Paper is a corporate division of Voith and is one of the leading partners and pioneers in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About the company

For 150 years, Voith’s technologies have been inspiring customers, business partners and employees around the world. Founded in 1867, Voith today has around 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the largest family-owned companies in Europe. Being a technology leader, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive.