Ianadmin

Get exposure to over 6,000 pigment and TiO2 decision makers by sponsoring or exhibiting at Pigments and TiO2 2017

Sponsoring or exhibiting at the co-located Pigment and Colour Science Forum and TiO2 World Summit 2017 is the perfect opportunity to raise your profile, put yourself ahead of the competition and get unprecedented access to key decision makers.

By sponsoring or exhibiting at these globally renowned events, you'll be able to reach an audience of 6,000 plus through inclusion in pre-conference marketing messages AND meet face-to-face with over 300 pigment and TiO2 decision makers at the conferences themselves.

Both conferences are dedicated to bringing together key members of the pigments and colourants sector and the titanium dioxide supply chain to discuss the latest global projects, applications, technologies, processes, investment perspectives and much more.

Companies including BASF and Schlenk have already confirmed their sponsorship packages so there's no time to lose!

Download the sponsorship and exhibition guide to find out more, or contact Cherrie Keene today on +44 (0) 1372 802255 or This email address is being protected from spambots. You need JavaScript enabled to view it. to discuss your bespoke package.

ANDRITZ to supply TAD tissue machine to First Quality Tissue, USA

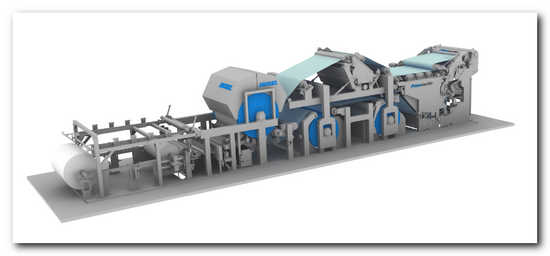

International technology Group ANDRITZ has received an order from First Quality Tissue to supply a PrimeLineTAD tissue machine with complete stock preparation for its mill in Lock Haven, USA. Start-up is scheduled for 2019.

The TAD (Through-Air-Drying) tissue machine has a capacity of approximately 70,000 tons per year. The improved softness, absorbency, and bulk generated by the TAD technology give these products superiority over products made using conventional processes. ANDRITZ has supplied two TAD machines previously to First Quality Tissue’s Lock Haven mill.

3D sketch of an ANDRITZ PrimeLineTAD tissue machine. “Photo: ANDRITZ”.

3D sketch of an ANDRITZ PrimeLineTAD tissue machine. “Photo: ANDRITZ”.

First Quality Tissue, which markets its products under the brand name “PlentyTM”, is one of the leading private label producers worldwide of TAD premium quality tissue and towel products. It currently operates five tissue machines in the USA (two at Lock Haven, Pennsylvania and three at Anderson, South Carolina).

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Stora Enso and Aalto University to build special stage for public debate forum SuomiAreena

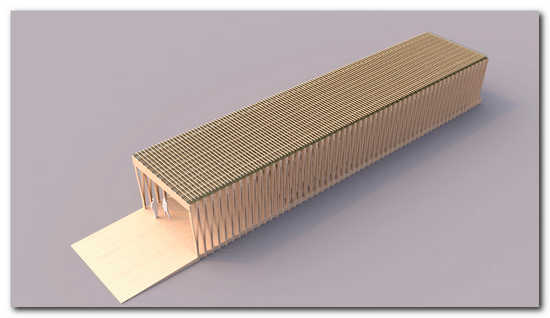

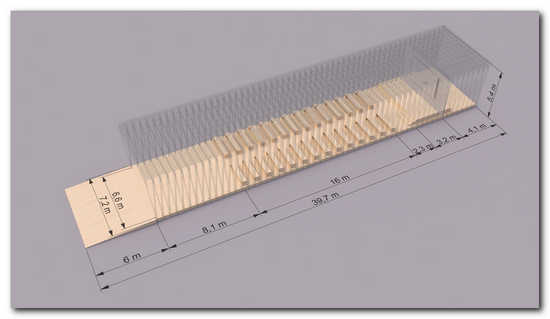

Aalto University and Stora Enso have joined hands in building Finland. The outcome of the co-operation is the Aika (Time) stage for the public debate forum SuomiAreena, in Finland, in honour of Finland’s centenary year of independence. The base of the stage is made up of 50 laminated veneer lumber frames with 100 legs symbolising Finland’s era of independence.

Students at Aalto University’s Department of Architecture were given the challenge of designing a stage using Stora Enso’s LVL material in just 100 hours. The design had to be of high architectural quality and innovative, and meet the technical requirements of SuomiAreena. Antti Hannula and Antti Rantamäki, students of landscape architecture were selected winners of the competition.

“Stora Enso wants to promote the use of renewable materials and show what a tree can do. We have been involved in planning and organising several events that celebrate Finland 100 years. Through our participation in SuomiAreena, we can communicate the opportunities of building with wood as well as our other renewable solutions. The Aika stage will be implemented in the spirit of the centenary together with Aalto University, using high-quality Finnish wood material and design and processing expertise,” says Seppo Parvi, Stora Enso’s CFO and Country Manager Finland.

“At Aalto University, we are educating game changers who are able to see and combine science, arts and business in a new way. Aalto was recently ranked as one of world’s 55 technology challenger universities, and it maintains close contact with business and society at large. The Aika stage to be built for SuomiAreena is an outstanding piece of work, reflecting our values and ways of operating,” says Eero Eloranta, Aalto University’s Vice President of Education.

“The Aika stage will be one of the highlights of the week-long SuomiAreena event. Visitors can see anything but traditional panel debates on the stage. During the week, there will be cooking, innovations, business pitches, hackathons and a cavalcade of the most interesting projects of the Finland 100 programme,” says Mari Haavisto, Executive Producer of SuomiAreena.

The surface area of the Aika stage is 285 square metres, and the spectator area contains 150 seats. The stage will be built of Stora Enso’s structurally strong LVL, which is manufactured in Varkaus, Finland. The stage is covered with translucent Vitrea profiled glass.

The Aika stage will be built in front of the Sokos Hotel Vaakuna, at Gallen-Kallelankatu 7, Pori, for the duration of the SuomiAreena forum (10‒14 July 2017). Once the event is over, the stage will be moved to Aalto University’s campus in Otaniemi, Espoo, to enrich the lives of students and the public.

Stora Enso is a leading provider of renewable solutions in packaging, biomaterials, wooden constructions and paper on global markets. Our aim is to replace fossil-based materials by innovating and developing new products and services based on wood and other renewable materials. We employ some 25 000 people in more than 35 countries, and our sales in 2016 were EUR 9.8 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Aalto University: Shaping the future. Aalto University is a community of bold thinkers where science and art are together with technology and business. We are committed to identifying and solving grand societal challenges and building an innovative future. Aalto University has 11 000 students and more than 400 professors. Our campuses are located in Espoo and Helsinki, Finland.

disclamer: The illustrations are based on sketches and do not necessarily conform to the final appearance and structure

BillerudKorsnäs fluting production in Gruvön up and running

As communicated earlier BillerudKorsnäs experienced a major breakdown in the digester in the semi-chemical pulp production line in Gruvön. The problem has now been resolved. The pulp line and the fluting machine PM6 is back in production.

As communicated earlier BillerudKorsnäs experienced a major breakdown in the digester in the semi-chemical pulp production line in Gruvön. The problem has now been resolved. The pulp line and the fluting machine PM6 is back in production.

The impact on EBITDA for the breakdown is estimated to approximately SEK 25 million after compensation from insurance.

“The impact of the breakdown could be limited thanks to a very efficient work in the mill, and we could start up production relatively quickly. Now we have to limit the indirect damage in the form of missing deliveries and customer relations,” says Per Lindberg, CEO of BillerudKorsnäs.

Related article : BillerudKorsnäs production of semi-chemical pulp supplying PM6 in Gruvön experience breakdown

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Mitsubishi HiTec Paper presents B.A.U.M. environmental prize 2017, "science" category

Mitsubishi HiTec Paper, the Bielefeld producer of coated speciality papers, has presented the Environmental award, science category, to Prof. Dr. Alexander Bassen at the annual meeting of B.A.U.M. on 17th& 18th May in Frankfurt a.M. / Germany.

The German Working Group for Environmentally Conscious Management (B.A.U.M. eV ) has honoured company representatives, scientists and journalists who have made outstanding contributions to the environment and sustainability every year since 1993. In 2017, the focus was on sustainable investment.

Prof. Dr. Alexander Bassen with the award certificate l to r: Dieter Brübach (B.A.U.M.), Dr. Thomas Holzmann (German Federal Environmental Agency), Prof. Dr. Alexander Bassen (University of Hamburg), Prof. Dr. Maximilian Gege (B.A.U.M.), Martin Odeland (B.A.U.M.), Dr. Bernd Gerecht (Mitsubishi HiTec Paper Europe GmbH)

Prof. Dr. Alexander Bassen with the award certificate l to r: Dieter Brübach (B.A.U.M.), Dr. Thomas Holzmann (German Federal Environmental Agency), Prof. Dr. Alexander Bassen (University of Hamburg), Prof. Dr. Maximilian Gege (B.A.U.M.), Martin Odeland (B.A.U.M.), Dr. Bernd Gerecht (Mitsubishi HiTec Paper Europe GmbH)

"It is time to recognize the fact that we have the power to promote sustainable economic activity through investment," emphasizes Prof. Dr. Maximilian Gege, chairman of B.A.U. M. "Some of our award winners are involved in responsible investment scientifically, journalistically or practically within their companies."

"As a long-standing B.A.U.M. member, we are pleased to present the environmental award in the science category to Prof. Dr. Bassen this year," says Dr. Bernd Gerecht from Mitsubishi HiTec Paper. "As an energy-intensive company, we attach particular importance to sustainable production, sustainable products and an appropriate company orientation. Sustainability and company success go hand in hand for us. "

Prof. Dr. Alexander Bassen conducts research on the fundamentals and concepts of Responsible Investment, i.e. sustainable investment. He examines the link between sustainability successes and the financial success of companies. The professor of business administration at the University of Hamburg has been particularly interested in the relevance of climate data for many years. He also explores experimentally the behaviour of investment professionals in investment decisions in sustainable financial products. A further focus of his work is sustainability reporting and its impact on the performance of companies, as well as the importance of sustainability information for the efficiency of capital markets.

Mitsubishi HiTec Paper Europe GmbH is a German subsidiary of Mitsubishi Paper Mills Ltd., Japan, one of the world's leading manufacturers of specialty paper. The roughly 700 employees at Mitsubishi HiTec Paper produce high-quality direct thermal, digital imaging, carbonless, label and barrier papers at two tradition-rich locations in Bielefeld and Flensburg.

Each factory stands out for own base paper production, state-of-the-art production machinery and innovative coating technologies. Through its dense global sales network, Mitsubishi HiTec Paper supplies a full range of specialty papers featuring a modular system for every application and printing technology – and is a highly capable partner whenever customized coated paper solutions are required. The industry’s first SIL 3 certified single controller for water and steam enables plants to protect valuable assets and improve worker safety

The industry’s first sil 3 certified single controller for water and steam enables plants to protect valuable assets and improve worker safety

Emerson’s Mobrey™ Hydratect™ 2462 provides proven, reliable detection of water or steam. It can now be used within an SIS loop to further reduce risk of dangerous failure.

Emerson’s water and steam detection system is the world’s first single controller solution to be certified to IEC 61508 for safety instrumented functions up to SIL 3. The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is used in a wide variety of applications where the detection of water or steam is vital for safe and efficient plant operation, such as boilers, steam drums and steam line drain pots. This helps to protect valuable plant assets, prevent downtime, save costs and improve worker safety.

The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is certified to IEC 61508 for safety instrumented functions up to SIL 3.

The Mobrey™ Hydratect™ 2462 Water and Steam Detection System is certified to IEC 61508 for safety instrumented functions up to SIL 3.

The functional safety assessment performed by Exida enhances Hydratect’s reputation for reliability and durability. Exida, world leaders in functional safety certification, have assessed Hydratect and determined that it meets the requirements of SIL 3. The Hydratect system is ideal for the most demanding applications within power generation, refineries, chemical, steel, pulp and paper plants. It can operate in process conditions of up to 300 bar and 560°C. Failure of equipment in such applications can have serious consequences – the Hydratect offers the benefit of SIL 3 approval guaranteeing its reliability.

Hydratect is a modern replacement for conventional float switches, and consists of a compact twin-channel electronic unit, connected to a pair of electrodes. Each channel gives independent indications of the presence of water or steam that are more reliable than those obtained with electro-mechanical devices, which have the possibility of failing in an unsafe condition. By installing the electrodes in vessels or steam lines and measuring the resistance, the presence of water can be detected, allowing appropriate safety measures to be taken.

By detecting low water level in steam drums, Hydratect helps to prevent boiler tubes overheating, which could lead to an explosion, while detecting high water level prevents the generation of wet steam which could cause costly turbine blade erosion. Using Hydratect to detect water in steam line drain pots, as part of a turbine water induction prevention system (TWIP), helps prevent damage to turbine blades, cylinders and the housing.

The electronics unit provides a local indication of steam, water and fault states, and features configurable fault and trip outputs. Component failure, cable faults, ground faults and electrode problems are continuously self-monitored. Additional reliability is provided by triple redundancy of critical components, which ensures that failures result in a safe condition. An individual power supply to each channel further enhances reliability.

About Emerson

Emerson (NYSE: EMR), headquartered in St. Louis, Missouri (USA), is a global technology and engineering company providing innovative solutions for customers in industrial, commercial, and residential markets. Our Emerson Automation Solutions business helps process, hybrid, and discrete manufacturers maximise production, protect personnel and the environment while optimising their energy and operating costs. Our Emerson Commercial and Residential Solutions business helps ensure human comfort and health, protect food quality and safety, advance energy efficiency, and create sustainable infrastructure. For more information visit www.Emerson.com.

Metsä Board achieves EcoVadis Gold rating for its sustainability practices

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, has achieved the Gold level rating by EcoVadis for its approach to sustainability. Overall Metsä Board was ranked in the top 1% of suppliers assessed by EcoVadis across all categories.

“We are very proud to have achieved this level of ranking. The assessment further enforces Metsä Board’s continued commitment to sustainability. We recognise that sustainability must go beyond regulatory compliance to also focus on how companies manage their economic, social, and environmental impacts, as well as their relationships with stakeholders such as customers, employees, suppliers and government,” says Soili Hietanen, VP Sustainability and Energy at Metsä Board.

As part of the process, Metsä Board’s recent achievement of A-List recognitions in CDP’s Water and Climate programmes as well as Leadership status in CDP’s 2016 Forest and Supply Chain programmes were important considerations for the EcoVadis team.

EcoVadis operates a platform allowing companies to assess the environmental and social performance of its suppliers on a global basis. The criteria include four themes; the environment, labour practices, sustainable procurement and fair business practices. The methodology and criteria used are in line with international Corporate Social Responsibility (CSR) standards including the Global Reporting Initiative (GRI), UN Global Compact, and ISO 26000.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2016, the company’s sales totalled EUR 1.7 billion, and it has approximately 2,500 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and cooking papers.

Metsä Group’s sales totalled EUR 4.7 billion in 2016, and it employs approximately 9,300 people. The Group operates in some 30 countries. Metsäliitto Cooperative is the parent company of Metsä Group and owned by approximately 104,000 Finnish forest owners.

Iran unchained: new opportunities for forest products trade?

Over a year has gone by since the IAEA (International Atomic Energy Agency) verified Tehran’s compliance with the nuclear agreement, and many of the economic sanctions against Iran were removed. During that time, the country’s relative isolation from international markets, especially those in the West, has led the country to establish an independent economy. While Iran has been successful in becoming self-sufficient, its open doors to much of the world has now put a spotlight on areas for investment where growth has faltered since the sanctions.

One of these untapped markets is Iran’s forest products – an area showing significant growth potential. Considering Iran’s raw material balances and demand prospects for forest products, probably the most obvious business opportunities for international players can be found in the wood raw material supply.

Forest Resources

Iran is located in the mid-latitude belt of arid and semi-arid regions of the earth. Consequently, Iran is sparsely forested with only some 7 million hectares of forest covering less than 5% of the nation’s land area. Most of Iran’s forests are found in the North in a region called the Hyrcanian forests and is the primary wood production region in the country accounting for about 30% (2.1 million hectares) of the country’s forest area. About 15% of the Hyrcanian forests are protected from harvesting. The main species of the Hyrcanian forests are hardwoods, including beech, hornbeam, maple, oak, alder, elm, ash and ironwood and a few softwoods including cypress, juniper and yew.

Iran is located in the mid-latitude belt of arid and semi-arid regions of the earth. Consequently, Iran is sparsely forested with only some 7 million hectares of forest covering less than 5% of the nation’s land area. Most of Iran’s forests are found in the North in a region called the Hyrcanian forests and is the primary wood production region in the country accounting for about 30% (2.1 million hectares) of the country’s forest area. About 15% of the Hyrcanian forests are protected from harvesting. The main species of the Hyrcanian forests are hardwoods, including beech, hornbeam, maple, oak, alder, elm, ash and ironwood and a few softwoods including cypress, juniper and yew.

The second most important forest area is located to the west, accounting for about 40% of the Iranian forest area and comprising mainly oak. However, Zagros is not suitable for industrial production because much of the area has been converted to grazing but has been found suitable for forest plantations. The last major forest area is called Mangrove forests in the south and is protected from harvesting.

Growing Wood Products and Paper Market

At present, there are hardly any sawmills left due to the shortage of sawlog-sized wood and the shortage of adequate water resources is a major constraint to plantation development. The Iran Government is not placing any serious emphasis on securing domestic wood supply – instead, the industry’s sentiment is that the state encourages wood imports instead of domestic supply.

The development of wood-based panels industry has been quite divergent despite the fact that it shares upstream challenges similar to the sawmilling sector. The market size is not monumental, but the potential for growth is significant. The increasing demand for modern furniture, built-in-fitments and other home-furnishing products will keep the Iranian wood-based panels market in a growth track well into the future. Panel exporters will likely maintain their presence in the country, but in particular, suppliers of modern panel production lines will likely activate in the future, as Iranian companies will invest in new technologies in an attempt to become more competitive.

Reliable data on industry output and product demand for Iran’s pulp and paper market is lacking considerably. However, most Iranian paper industry players share the view of a growing domestic market. But they face many of the same challenges as the wood raw material industry; a costly and limited supply of wood or fiber; a need to modernize mill assets and the threat of strong international competition. Potential foreign investors should see the opportunity in those challenges; it opens doors for foreign capital and investment in a market with high demand and little production.

Several factors including the modernization of society and retail trade, along with the rise of the middle class will eventually lead to the rise of packaging industry in Iran. The packaging industry is seeking ways to modernize existing assets and invest in new production lines – including primary paperboard production and packaging converting through final products packaging. Historically, Chinese suppliers have been the main beneficiaries of the rise of the packaging machinery market in Iran. With the lift of the sanctions however, Iran is also looking for high quality machinery from regions outside China, eyeing markets that have been banned in recent years.

Another sector that has the potential for profitability for Western investors is the Iranian tissue and hygiene sector which up until now has been dominated by domestic suppliers, and one Turkish group, in the absence of strong international players. The industry has invested somewhat ahead of demand in the anticipation of rapidly growing market. In terms of per capita consumption, Iran is lagging far behind the large Middle East countries as well as its global peers of the same income level, but is quickly catching up with them in terms of demand level.

Dawn of a New Economic Era?

The oil embargo and other economic sanctions have been the key reasons behind Iran’s flimsy economy during the current decade. However, the sanctions may have helped the country cope with the commodities slump by forcing it to diversify its economy. Iran is the third largest economy in the MENA region after Turkey and Saudi Arabia. It has the second largest population of the region after Egypt with an estimated 82.8 million people in 2016. Compared to most MENA countries, Iran is in a relatively good position in terms of oil dependency, thanks to the Government’s efforts to reduce dependency on oil and gas by focusing on expanding other sources of revenue.

Because of the sanctions and its relative isolation from the rest of the industrial world, Iran has had to make itself independent from the rest of the world. As a result, Iran has fostered a strong workforce – the country’s vast population is young, urbanized and highly educated and the country has an established manufactured commodities market. The opportunity for strong growth in key markets along with a reliable domestic workforce makes Tehran and other thriving metropolises attractive destinations for foreign businesses and set the stage for future investment post sanctions.

While many sanctions banning trade and finance remain in place due to concerns over Iran’s human rights record and military programs, the overseas business community should not lose perspective on the growing opportunities in the country. Iran has taken crucial steps to mend business relations with the West. It privatized its industrial sector and gives investment incentives for foreign capital. Most national and EU-level restrictions were eliminated after January 2016 and several European companies have taken advantage of this situation. These include European Airbus, Italy’s state rail company, the French car maker Renault and the Danish pharmaceutical company Novo Nordisk to name a few. Further, a number of Asian firms are already making steady inroads to the Iranian markets.

China intends to fully exploit the potential for cooperation with Iran, predominately in infrastructural projects and manufacturing. China’s Silk Road Strategy provides the framework and encourages Chinese companies to increase their involvement in the opening Iranian market. This would be a reason good enough for the European businesses to take a closer look at hiding opportunities in one of the most stable Middle East markets at the moment.

Accessing the Market

Iran offers one of the few forest products markets that are showing significant growth potential which, owing to the country’s vast population base, can turn out considerable in terms of both volume and value. It is therefore recommended and meaningful for business developers and marketing managers to investigate the country’s existing and emerging opportunities.

Access to relevant market information is necessary for companies that want to discover trading and investment opportunities in Iran. The to-do list should include collection of market data and finding the right local partners in the country, as well as checking global compliance/sanctions lists to ensure that business is conducted by the book. All things considered, businesses need to understand the nature and extent of the current (remaining) restrictions and be prepared for possible challenges.

The Iranian wood processing, paper and packaging industry is currently modernizing its asset base. Investments that are enhancing cost competitiveness and product quality will be on the front burner, thus providing business opportunities for machinery and equipment vendors in Europe and Asia. New opportunities for packaging and converting firms will open up as FMCG companies have paved their way onto the market and started to form local and international partnerships in order to develop their offering in the country.

Standard HMIs used to reconfigure safety control functions

Using ABB’s safety PLC, standard HMIs such as control panels and mobile devices can be used to alter functional safety control functions in industrial applications.

ABB has developed a method of using standard human machine interface (HMI) products such as control panels, industrial PCs and mobile devices to reconfigure safety control functions.

Using ABB’s AC500-S safety programmable logic controller (PLC), operators of equipment such as harbor and factory cranes, hoists, elevators, airport passenger bridges, automatic guided vehicles (AGVs), robots, mining and pulp & paper machinery can select, modify and amend their safety control functions. This allows them to achieve high functional safety standard requirements while benefiting from the convenience and low costs of using standard HMIs.

Operators of these industrial applications need to reconfigure their safety control functions to adapt to changed application conditions and to optimize machine productivity. These reconfigurations, known as safety actions, are often performed using mechanical or electro-mechanical mode selector switches connected to the digital safety inputs of a safety PLC.

This method suffers from limited user-friendliness, inability to make modifications to switch layout and function, limited number of selection options and relatively high costs for the mode selector switches and digital safety input channels.

ABB solves these challenges by allowing standard HMIs, such as control panels, industrial PCs and mobile devices to interface with an ABB AC500-S safety PLC to carry out these safety actions.

Standard HMIs that support at least two different Ethernet based communication protocols can be used. ABB recommends Modbus©/TCP and ABB ETH. A mean time between failures (MTBF) greater than 22.5 years is required for standard HMIs to satisfy PL d (ISO 13849-1) requirements. HMIs with lower MTBFs may only satisfy PL c (ISO 13849-1) requirements.

Benefits of using standard HMIs include cost savings on safety I/O channels and mode selector switches. The ability to select from a wide range of HMI products offers the user independence from any one vendor, a larger range of input options and greater flexibility to adapt the connections and layout of the HMIs.

The method allows connecting to high and low level safety systems remotely. One example is in the selection of a crane, allowing it to be controlled remotely using the emergency stop located on the operator desk. A network links the AC500-S safety PLC in the control room with the safety PLCs at the cranes. The user in the control room can select, using standard HMI equipment, which of the cranes will stop if the emergency stop button is activated on the remote operator control station. Pressing the remote emergency stop button on the operator’s desk will therefore stop the selected crane only. Independent of the remote emergency stop function, all cranes still have their own local emergency stop controls.

ABB (ABBN: SIX Swiss Ex) is a pioneering technology leader in electrification products, robotics and motion, industrial automation and power grids, serving customers in utilities, industry and transport & infrastructure globally. Continuing more than a 125-year history of innovation, ABB today is writing the future of industrial digitalization and driving the Energy and Fourth Industrial Revolutions. ABB operates in more than 100 countries with about 132,000 employees. www.abb.com

James Cropper brings home a third award for sustainability initiative

British master papermaker James Cropper has added another trophy to its award cabinet following its win of the prestigious Green Award at Luxe Pack New York.

The company won the award at the exhibition for its support of the Burneside Community Energy (BCE) project, a social initiative that saw the installation of a 250KW Solar PV Array on the roof of James Cropper’s mill in the village of Burneside in the Lake District.

The multi-award winning project, which launched in December 2015, generates clean, green electricity, and enables residents of the village – many of whom are also employees – to benefit from investment in renewable energy.

James Cropper recently won in the same category for this project at Luxe Pack’s Shanghai edition. This time, James Cropper was selected as a winner by an esteemed panel of judges comprising senior packaging consultants from brands including Elizabeth Arden, Bacardi and Estee Lauder, as well as the editor-in-chief of Beauty Packaging.

Susan Wilson, group packaging director at James Cropper, said: “We’re absolutely thrilled to have picked up the Green Award again for a project so close to our hearts. The installation generates 200,000 kWh of renewable electricity per year, which is enough to offset the energy requirements of our specialist laminating and technical coating facility, or the equivalent of powering 50 UK homes. It’s also been calculated that the initiative will reduce our carbon dioxide emissions by 1.91 million kilograms over the next two decades.”

As well as the positive impact on the environment, the BCE scheme delivers a five per cent annual dividend to investors, and an additional £50,000 for a community fund to deliver projects of social and environmental benefit to Burneside over a 20-year period. The scheme has been widely praised as a sustainable, eco-friendly solution that benefits the local parish and demonstrates James Cropper’s long-term commitment to supporting sustainable initiatives in the community.

Luxe Pack is the premier exhibition for creative and innovative packaging and this year marked its 15th show in New York, which took place on 10 and 11 May at Pier 92 in the city. The event played host to over 250 leading global packaging manufacturers and suppliers within the beauty, fragrance, wine and spirit, and gourmet food markets.

Susan added: “We’ve been loyal exhibitors at Luxe Pack for many years now and have witnessed more and more brands and suppliers plough investment into sustainability initiatives as green credentials become increasingly important to consumers. At James Cropper, we’ve always strived to innovate in this arena, and to be recognised within the packaging industry for this commitment means a great deal indeed.”

James Cropper was also recently highly commended at Insider Media’s 2017 Made in the North West Awards in the Green / Sustainable Manufacturer category.

For more information about James Cropper, visit www.jamescropper.com.

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

For further information visit: www.jamescropper.com , www.jc3dp.com and www.tfpglobal.com.