Ianadmin

Installation of the PM No. 2 in the paper mill Mayak-Vega in Russia

In June 2011 we signed a contract with a newly founded company Mayak-Vega, Russia, on reconstruction of the existing paper machine for production of testliners and flutings including delivery of new complete lines for stock preparation and approach systems for both layers. It is a two-wire paper machine with a longitudinal wire which should produce, after reconstruction, not only flutings and liners, but also plasterboards.

In June 2011 we signed a contract with a newly founded company Mayak-Vega, Russia, on reconstruction of the existing paper machine for production of testliners and flutings including delivery of new complete lines for stock preparation and approach systems for both layers. It is a two-wire paper machine with a longitudinal wire which should produce, after reconstruction, not only flutings and liners, but also plasterboards.

The PM capacity after its reconstruction shall reach 67 000 tpy with width on reel 2 600 mm at operating speed up to 700 m/min. It is another of more projects signed on provision of complete engineering services incl. commissioning and guarantee tests. Its financial volume exceeds 22 mio. EUR and it is in fact the greatest corporate project in the year 2011. The required reconstruction was aimed at the paper machine previously installed in Italy. This machine shall be completed with a new film press and a new top wire.

The company PAPCEL is a coordinator of all works related to deliveries of machinery, preparatory works to be done on projecting and initial documents for the on-site installations. Both the paper machine and the stock preparation line shall be installed in new factory buildings.

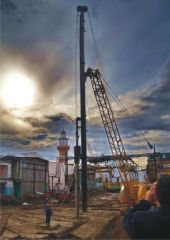

The capital project was opened on the premises in Penza in the presence of top management members and owners of the firm Mayak-Vega and also very important guests of culture and politics in the city Penza on 29. 9. 2011. The ceremonial act itself was opened with the first pile bore for the projected PM basement. Necessary building works commenced already in the third quarter 2011, the PM commissioning has been planned for the second quarter in 2013.

Ceremonial act for opening of building works – the first pile

New Toscotec Tissue Line Started up in China

Toscotec has started up on 16 January, according to the project time schedule, a new Ahead 1.5M tissue line for Chinese Ningxia Bauhinia Paper Co.Ltd, located in Yinchuan.Ningxia Bauhinia Paper Co. Ltd. was founded in 1989 and is part of Ningxia Zijinghua Group. The company started as a township enterprise and with this new successful investment, has increased its annual production capacity up to 100.000 tpy with 2000 employees and ranks the Top 10 tissue producers in China.

Toscotec has started up on 16 January, according to the project time schedule, a new Ahead 1.5M tissue line for Chinese Ningxia Bauhinia Paper Co.Ltd, located in Yinchuan.Ningxia Bauhinia Paper Co. Ltd. was founded in 1989 and is part of Ningxia Zijinghua Group. The company started as a township enterprise and with this new successful investment, has increased its annual production capacity up to 100.000 tpy with 2000 employees and ranks the Top 10 tissue producers in China.

Toscotec supply included Ahead 1.5M crescent former tissue machine with single-layer headbox and double press configuration, 15' Steel Yankee Dryer (TT SYD 15FT) a Milltech steam heated hood, machine auxiliaries, approach flow system, electrification and control system. Machine speed is up to 1500 mpm with a net trim width of 3450 mm.

Toscotec supply included Ahead 1.5M crescent former tissue machine with single-layer headbox and double press configuration, 15' Steel Yankee Dryer (TT SYD 15FT) a Milltech steam heated hood, machine auxiliaries, approach flow system, electrification and control system. Machine speed is up to 1500 mpm with a net trim width of 3450 mm.

The start up curve was very smooth and the machine already reached a stable speed of 1300 mpm few days after the start up with a 13 gsm product despite the outside very difficult weather condition with -20°C temperature.

The strong cooperation between customer and Toscotec teams made possible to start the production by mid of January before the Chinese new year and the Italian supplier is now performing the normal ‘baby-sitting' activities on-site through the personnel of its Toscotec Asia & Pacific team.

Thanks also to the recent acquisition of Milltech, Toscotec can now provide advanced energy saving solution adding a lot of value to the Chinese projects where lack of natural gas is a constant. Furthermore the fast growing Toscotec Asia & Pacific experienced team can provide qualified services to the demanding Chinese market.

These successful factors allowed Toscotec to get 15 new machine orders in the Mainland China in the last three years.

Russian Syassky Pulp & Paper Mill started up a new Toscotec line

Syassky Pulp and Paper Mill, based in Syasstroy St. Petersburg region - Russia, on January 27 has started up a new Toscotec Ahead 1.5M tissue line.

Syassky PPM, one of the oldest and important pulp and paper mill in the URSS period, was founded in 1928, with the unique aim to cover the needs of the domestic market. Actually, Syassky Pulp and Paper Mill is one of the most modern enterprises of the north west Russian region and the only integrated tissue producer in this area having in line pulp mill, tissue production (PM2, PM3 and PM5) and converting & packaging facilities.

Syassky PPM, one of the oldest and important pulp and paper mill in the URSS period, was founded in 1928, with the unique aim to cover the needs of the domestic market. Actually, Syassky Pulp and Paper Mill is one of the most modern enterprises of the north west Russian region and the only integrated tissue producer in this area having in line pulp mill, tissue production (PM2, PM3 and PM5) and converting & packaging facilities.

The Company has been reorganized as joint stock company with the result to be able to satisfy the growing demand for domestic but also for AFH export markets.In the last two years Syassky PPM put in progress a huge investment process that resulted in the start up of new converting lines, packaging lines and of a new Toscotec rewinder TT WIND-H.

The new Toscotec tissue line that has replaced the existing PM2 housed in the same original building, continues this strong investment process and will guarantee a leading position for the company in the growing Russian market.

The main tissue brand produced by Syassky is Myagky Znak that in 2011, according to AC Nielsen Market Research, has reached a 21% market share in Moscow and St.Petersburg regions.

The Ahead 1.5M crescent former machine features a single layer headbox, single press configuration TT SPR 1050, a 3660 mm diameter Steel Yankee Dryer TT SYD 12FT and a renewed reel TT REEL-P.

The Toscotec scope of supply included also upgrading of the existing stock preparation plant, a new approach flow system, gas heated hood, steam & condensate system as well as electrification & control system. A complete engineering, erection supervision, commissioning, training and start up assistance package was provided by Toscotec.

Machine speed is up to 1400 mpm with a trim width of 4200 mm, for a daily production of 125 tons.

Thanks to its Crescent Former configuration and to the high level of technology the machine is extremely flexible, compact and capable of producing high quality tissue from virgin pulp (dry & slush) with a reduced energy consumption.

The project has started with the dismantling of the old paper machine and with the civil works to get the necessary new foundations in the building. Thanks to the strong cooperation between Toscotec and Syassky team the challenging project has been successfully completed in less than one year from the contract signature.

This new successful installation strengths the Toscotec position as one of the leading tissue machinery supplier capable to provide full range of products and services worldwide. The Italian company is capable to manage projects from green field turnkey solutions to upgrading of the existing mills.

NewPage Seeks to Amend Its Amended and Restated Superpriority Debtor-In-Possession Credit and Guaranty Agreement

NewPage Corporation ("NewPage") has announced that it is seeking to amend its Amended and Restated Superpriority Debtor-In-Possession Credit and Guaranty Agreement dated as of September 23, 2011 (the "DIP Credit Agreement"; capitalized terms referenced below are defined in the DIP Credit Agreement). Among other things, NewPage is seeking to reduce the Minimum Consolidated Adjusted EBITDA covenant and in conjunction would increase the Notes Payment Reserve. In addition, NewPage intends to obtain the flexibility for cash collateralized letters of credit to mature beyond the term of the DIP Credit Facility.

Obtaining these amendments requires consent of a certain portion of the Lenders and some of the amendments may require the approval of the United States Bankruptcy Court for the District of Delaware. There are no assurances that NewPage will be successful in its negotiations with the Lenders or in obtaining court approval.

SOURCE NewPage Corporation

ÅF wins contract with SKB for storage of nuclear fuel at Forsmark

ÅF has signed a contract, together with Tyréns AB, with the Swedish Nuclear Fuel and Waste Management Company, SKB, relating to the systems project management of the storage of spent nuclear fuel at Forsmark. At the end of 2011 ÅF and Tyréns announced their involvement in a preliminary study prior to systems project management (SEK 6 million). The new contract is estimated to be worth approximately SEK 75 million, at least half of which is expected to accrue to ÅF. The assignment will be carried out during 2012 and 2013.

Systems project management involves producing drawings, models, specifications and system solutions ahead of the planned starting date for the construction of the nuclear fuel storage facility in 2017.

Most of the work will be carried out by ÅF in Stockholm and will call upon resources and expertise from various ÅF divisions. Project management activities will be conducted in close liaison with SKB on site at Forsmark.

ÅF has won this order thanks both to a strong portfolio of references from major infrastructure and industrial projects and to the company's world-class expertise in the nuclear power industry.

Vacon Plc and European Batteries Oy to start technology cooperation

The global AC drives manufacturer Vacon Plc and European Batteries Oy, a Finland-based lithium-ion-iron-phosphate (LFP) battery systems manufacturer, have agreed on cooperation in the field of technology that combines the use of battery systems and AC drives in the same electrical system.

The two companies share the view that the field of energy production will be more and more fragmented in the future. In consequence, due to varied grid quality requirements, the use of battery systems will become an increasingly attractive option in energy production facilities. In addition, traditional power transmission systems will be supported, or even replaced, by fully electrical systems which allow energy to be stored e.g. in expandable battery systems.

The wide competence and experience of both companies, exchange of technical knowhow, common understanding of the challenges and boundaries of the technology create a solid foundation for a cooperation that aims at applying the two different technologies to conserving electrical energy and converting it into use in practical applications. This cooperation will bring immediate benefits to the mutual customers of Vacon and European Batteries.

Rayonier to Present at Credit Suisse 2012 Global Paper & Packaging Conference

Rayonier has announced that Hans Vanden Noort, senior vice president and CFO, will present at the Credit Suisse 2012 Global Paper & Packaging Conference in New York on Thursday, Feb. 23, 2012, at 12 p.m. EST.

A live audio webcast of the presentation will be accessible at Rayonier’s website by clicking on http://www.rayonier.com and following the directions. Listeners should go to the link at least 15 minutes prior to the start of the presentation to download and install any necessary audio software. A replay will be available on Rayonier’s website within 24 hours after the webcast.

Source: Rayonier

Xerium Technologies Reaches Milestone with Order of 200th SmartRoll™

Xerium Technologies, Inc., a leading global manufacturer of industrial textiles and rolls used primarily in the paper production process, passed a significant milestone by booking its 200th SmartRoll, the industry’s first continuous pressure-sensing paper machine press roll based on the SMART technology. Xerium’s SMART applications are all based on a proprietary embedded roll cover sensor system that provides constant realtime operating data to help optimize production, reduce energy consumption, and control costs.

“Since that first sale just over two years ago, we estimate that SmartRoll has saved our customers more than $40 million in reduced energy consumption and other cost reductions,” said Stephen R. Light, Chairman, CEO and President of Xerium Technologies. “Reaching this SmartRoll™ milestone in such a short time demonstrates that manufacturers are hungry for technology that produces real performance benefits at lower cost.”

Today’s announcement marks the 200th SmartRoll that has been booked since entering full commercial availability as a single application in mid-2009. Xerium now deploys 14 individual SMART technology applications throughout the paper machine, all of which are based on the Company’s advanced system for measuring nip pressures in realtime, to analyze and optimize the moisture removal in the press section. Since September 2011, Xerium has been marketing its latest SMART 4.0 Technology, which offers the most advanced functionality to help manufacturers reduce operational costs and maximize the output of existing equipment, while enhancing product customization capabilities.

Sonoco Announces Executive Officer Appointments

Sonoco, one of the largest diversified global packaging companies, today announced three executive officer appointments, according to Sonoco Chairman and Chief Executive OfficerHarris E. DeLoach, Jr., and M. Jack Sanders, president and chief operating officer.

John M. Colyer, Jr. has been promoted to vice president, Global Paper and Industrial Converted Products. In this new role, Colyer has responsibility for Sonoco’s largest business segment, including global tubes and cores, paper, recycling, wire and cable reels, and internal supply businesses, including adhesives and forest products. In total, this segment has 198 global plant locations in North America, Europe, South America, Australia/New Zealand and Asia. Colyer is a member of the Company’s executive committee, reporting to Sanders.

Prior to this new assignment, Colyer, 51, served as vice president, Global Industrial Converting, and was responsible for leading the effort to complete the recent acquisition of Tegrant Corporation, a leading North American supplier of protective, temperature-assured and retail security packaging. Colyer has more than 28 years of experience with Sonoco and has held numerous leadership and manufacturing management positions in businesses serving industrial and consumer markets. He is a graduate of Southern Oregon State University with a Bachelor of Science degree in business administration.

Ronald G. Leach has been named vice president of Sonoco’s recently expanded Global Protective Packaging segment, elected an officer of the Company and appointed to the executive committee, reporting to Sanders.

Leach, 54, was president and chief executive officer of Tegrant Corporation, prior to the acquisition in November 2011. He also has served as president of SCA Packaging N.A. and president and chief executive officer of Alloyd Company, Inc. Before becoming Alloyd’s president and chief executive officer, he was the company’s vice president of Operations. Leach holds a Bachelor of Science degree in packaging engineering from Michigan State University.

R. Howard Coker, 49, has been named to the Company’s executive committee and remains vice president, Global Rigid Paper and Closures, reporting to Sanders. In this position, Coker has global responsibility for the Company’s composite can, and metal and peelable membrane ends and closures businesses.

Prior to this appointment, Coker was vice president, Rigid Paper and Closures – North America. He has held several leadership positions within the Company, including division vice president and general manager, Sonoco Phoenix; director of sales and marketing, Rigid Paper and Plastics – North America; and general manager, Rigid Paper and Plastics – Asia/Pacific. Coker is a graduate of Wofford College in Spartanburg, S.C., with a Bachelor of Arts in business administration. He also received a Master of Arts in business administration from Wake Forest University.

Resolute Applies to Cease Trade Mercer's Offer to Acquire Fibrek

AbitibiBowater Inc., doing business as Resolute Forest Products, has announced that it applied to the Bureau de décision et de révision (Québec), the administrative tribunal with statutory jurisdiction in securities law and regulatory matters in Quebec, for an order to cease trade the proposed offer by Mercer International Inc. to acquire all of the issued and outstanding common shares of Fibrek Inc. Fibrek and Mercer announced the offer on February 10.

In its application, Resolute requested that the Bureau exercise its public interest jurisdiction to cease trade the offer on the basis, among other things, that it includes an improperly discounted and dilutive private placement of warrants and an unreasonable break fee. Resolute requested that the Bureau hear its application on an expedited basis, and will argue that these measures are unlawful and inappropriate defensive measures to Resolute's offer. On February 9, the Bureau rendered an order to cease trade Fibrek's tactical poison pill effective as of 3:00 p.m. today.

The offer to acquire all of the issued and outstanding shares of Fibrek made by Resolute, together with RFP Acquisition Inc., a wholly-owned subsidiary, is more fully described in the offer circular and other ancillary documentation that Resolute filed on December 15, 2011, on the Canadian Securities Administrators' website ("SEDAR"), as varied and extended. The offer will expire at 5:00 p.m. (Eastern Standard Time) on February 23, 2012, unless it is extended or withdrawn by Resolute. Resolute continues to work diligently with a view to obtaining all required approvals from the Canadian regulatory authorities.

Questions and requests for assistance or further information on how to tender Fibrek common shares to the offer should be directed to, and copies of the above referenced documents may be obtained by contacting, Georgeson at 1-866-598-0048 or by email at This email address is being protected from spambots. You need JavaScript enabled to view it.">This email address is being protected from spambots. You need JavaScript enabled to view it..