Ianadmin

China is now the world’s largest importer of softwood lumber and logs

China is now the world’s largest importer of softwood lumber and logs despite a slowdown in imports during the 4Q/11, reports the Wood Resource Quarterly

Reduced activities in the housing construction sector in China decreased importation of softwood logs and lumber in late 2011, reports the Wood Resource Quarterly. Despite the decline in the 4Q, total imports during 2011 reached a record high, making China the largest importer of logs and lumber in the world.

Seattle, USA. Importation of softwood logs and lumber to China has increased continuously over the past 15 years, and in 2011 the country was the largest importer of softwood lumber and logs in the world, according to the Wood Resource Quarterly. Total import value equaled almost eight billion US dollars last year, which was an increase of 57 percent from 2010, and up from only 70 million dollars 15 years ago. Annual growth over the past five years has been almost 30 percent, and over the past 15 years, the CAGR has been as high as 36 percent.

Imports of softwood lumber have increased faster than imports of softwood logs over the past few years, but log imports still constitute a higher share of the total import value of softwood products. After having increased for seven consecutive quarters, the importation of softwood logs and lumber fell for the first time in the 4Q/11 because of reduced domestic demand and high inventories at many of the country’s ports. The decline was 14 percent from the 3Q/11, but the total import value was still higher than the fourth quarter in 2010.

By volume, importation of softwood log and softwood lumber to China fell 10 percent in the 4Q/11 as compared to the previous quarter. Importation of logs and lumber from

Russia decreased the most, while lumber from New Zealand and logs from Canada actually increased slightly during the fourth quarter.

Much of the increased import demand for softwood raw-material has been, and continues to be, driven by the fast expansion in the house construction sector combined with the fact the China lacks domestic forest resources to meet the growing demand for most forest products.

A tightening monetary policy with a restricted money supply resulted in reduced activities in the construction sector in the second half of 2011. It has also been reported that there were overstocked inventories of real estate (over 20 months of unsold inventory in Beijing and Shanghai), and that housing transaction volumes in many big cities fell by more than 50 percent in the fourth quarter. Societe Generale reported that housing starts were down 25 percent in December as compared to the same month in 2010.

It can be expected that the housing market will continue to face headwinds during the first half of 2012 unless the Chinese government steps in to ease the country’s monetary policy. As a consequence, the prospects for log and lumber imports will be faced with uncertainty short-term, but will likely continue to trend upward long-term.

Metso to supply fully automated crushing plant to Consórcio Construtor Belo Monte in Brazil

Metso has signed a contract with Consórcio Construtor Belo Monte (CCBM) to supply equipment to the construction of the Belo Monte hydroelectric power plant (UHE Belo Monte) in Brazil. The project is located at the Xingu River, Pará State, in the northern region of the country. In addition to the equipment, the contract also includes services and parts. The value of the order is some EUR 30 million.

According to the contract, Metso´s scope of delivery will comprise three automated large crushing plants, two portable plants and two mobile Lokotrack plants.

“This is the biggest contract Metso has signed in the Brazilian construction industry in the last few years. This supply with fully automated plants with the latest technology consolidates our presence in the construction of the largest hydroelectric power plants in the country. Furthermore, Belo Monte is a project that contributes to the development of the country by providing clean and renewable energy and economical growth,” notes Dionísio Covolo, Commercial Director for Construction Equipment, Metso.

The complete delivery is scheduled for the first quarter of 2013. The order has been included in Mining and Construction third and fourth quarter 2011 orders received.

Consórcio Construtor Belo Monte is a consortium of ten construction companies, hired by Norte Energia S.A. for the construction of the Belo Monte hydroelectric power plant. Norte Energia S.A. is the company responsible for the implementation, construction and operation of the project UHE Belo Monte.

UPM continues to invest in efficient energy generation

UPM continues to invest in efficient energy generation and builds a new combined heat and power plant at the UPM Schongau mill in Germany. The target is to significantly reduce energy costs as well as to secure the energy supply. The total investment is EUR 85 million.

The new power plant will generate process heat as well as electricity for the mill. It will also provide sustainable and energy efficient district heating for roughly 750 households and public institutions such as local school and hospital in Schongau. The renewed energy supply at the mill will be based on the highly efficient combined heat and power technology utilising gas as a fuel.

“The new gas power plant will improve the security and self-sufficiency of energy supply to our mill,” explains Winfried Schaur, General Manager, UPM Schongau. “The renewal of the energy generation ensures efficient production and will safeguard the competiveness of the mill. Furthermore, it guarantees a sustainable paper production loop based on innovative and low-emission technologies.”

The start-up is planned by the end of 2014. The gas power plant will replace the old plant facility which has operated more than 40 years.

UPM aims to achieve improved energy efficiency and energy savings in all its businesses. The company favours a wide range of low-emission energy sources. During the past decade UPM has invested over EUR 1 billion on carbon neutral power and heat generation at its mill sites.

(UPM-Kymmene)

Mondi Containerboard at Fruit Logistica 2012

Mondi Containerboard will exhibit at Fruit Logistica in Berlin during February 8 – 10th 2012. The focus of the exhibition will be the presentation of paper qualities for fruit and vegetable packaging.

Corrugated boxes for carrying and storing foods, such as fruit and vegetables, have to be able to protect their contents and provide excellent stability. Mondi Containerboard supplies solutions which totally meet these requirements. Its ProVantage product range embraces Kraftliner Aqua, Fluting Aqua and Fluting Frigo Forte for versatile applications in wet or cold conditions, offering excellent converting properties and cost savings.

Exhibition highlights:

-ProVantage Kraftliner Aqua is sufficiently water resistant to replace wax coated board. With regard to the converting process ProVantage Kraftliner Aqua has perfect gluing properties, shows excellent runnability, features good printability and allows higher speed at corrugators as no wax-dosing units are needed.

-ProVantage Fluting Aqua was developed after extensive research to perfect its resistance against water penetration and humidity and to replace wax coated flutings. This partly sized fluting is 100% recyclable and boasts excellent runnability and gluing properties.

-ProVantage Fluting Frigo Forte is the ideal choice for heavy-duty packaging applications, such as fruit and vegetable transportation, but also for packaging solutions in the cold chain. ProVantage Fluting Frigo Forte satisfies the FEFCO 9 test requirements and is used for containerboard that is stored in humid climates.

-ProVantage Baywhite, a premium quality uncoated white top kraftliner, is a 100% virgin grade containing no recycled fibre. The grammage range is 115, 125, 135, 160, 175, 200 and 250 gsm. Baywhite has a top sheet of bleached eucalyptus kraft pulp, and a base sheet containing unbleached softwood fibre.

-ProVantage Komiwhite is characterised by its excellent printability, flawless runnability, strength and versatility, making them the ideal choice for a wide range of packaging options where aesthetic impact counts. The good formation and a uniform, even and smooth paper profile result in outstanding printability even for high definition printing.

-ProVantage Fluting WB is the economical alternative for all types of boxes when strength and durability are required. Boasting excellent runnability on corrugators and optimum printability, this waste-based fluting of proven and consistent quality is 100% recycled paper.

(Mondi Packaging Corrugated)

Ahlstrom's Global Filtration Technical Center advances filtration testing

Ahlstrom Corporation, a global high-performance materials company, announced that it has completed significant upgrades to its Global Filtration Technical Center in Turin, Italy.

Ahlstrom has been investing in testing and processing equipment in its Global Filtration Technical Center in Turin during the last year. Now the state of the art technical center is equipped with various filtration testing and simulation equipment. Testing can be carried out as finished filters or flat sheet configuration, and the testing facility focuses on research and development for all transportation, air and liquid filtration applications.

In addition to the several filtration testing equipment, the center provides access to pleaters and processing equipment in order to build prototypes and simulate real life filtration conditions in order to achieve the specific performance needed for filtration norms and applications.

Investments made at the Technical Center offer support and expertise knowhow to all Ahlstrom global customers. "Our investment to the testing and development facility is yet another example of our commitment to the filtration market. We are now better equipped to collaborate with our customers and work together to develop the next generation filtration ideas," states Tommi Björnman, Executive Vice President, Filtration.

Ahlstrom is the world's largest filtration material producer. Ahlstrom Filtration has 5 other Technical Centers in North and South America and in Asia, which offer research and development support globally for testing and development of filter media.

Resolute Unveils Align™ Family of Environmentally Responsible Papers

Resolute Forest Products has unveiled its Align™ family of high brightness, environmentally responsible papers that can be used as alternatives to chemical pulp coated and uncoated freesheet in most commercial printing applications.

"Resolute Forest Products' Align Papers Logo (CNW Group/RESOLUTE FOREST PRODUCTS)"

Typical freesheet papers are designed for brightness and use more trees and chemicals than are needed for most print applications. Align papers are made with up to 50% less wood fiber and have a smaller environmental footprint than traditional offset papers, including some containing recycled content. By delivering higher opacity and bulk at a lower basis weight than traditional freesheet, Align also helps reduce paper, postage and transportation costs.

"For several years, Resolute has seen growing demand for high-quality, eco-conscious papers that can reduce print costs," said Richard Garneau, President and Chief Executive Officer. "With our Align papers, customers can reduce fiber consumption and save money without sacrificing quality in their printed products. Align makes sense for their budgets and the environment."

Align papers deliver three key advantages over freesheet paper:

Environmentally Responsible: Because Align grades use significantly less wood than freesheet, fewer trees are required for their production. Furthermore, when one compares the overall product life cycle, Align grades have less environmental impact than traditional offset papers. For instance, the comparative life cycle assessment commissioned by Resolute found that Align grades have a carbon footprint that is from 35% to 85% smaller than the average freesheet grade. For more details, visit resolutefp.com/LCA. Align helps customers make the right decision for the environment.

Budget Friendly: Thanks to its higher bulk and opacity at a lower basis weight, customers get all the printability they expect, but at a lower cost. Based on their needs, they can either pay less for paper, pay less for postage, or print and mail more at the same cost.

High Opacity and Bulk: Traditional offset papers are designed to deliver both brightness and longevity - but at a premium price. With Align, value-conscious customers can choose from a range of bright, opaque, high-bulk papers that are designed to meet their specific needs.

Align papers also help Resolute deliver on one of the commitments the Company made in joining the World Wildlife Fund (WWF) global Climate Savers program.

"When Resolute joined Climate Savers, it agreed to achieve a 65% reduction in greenhouse gas emissions from company operations by 2015, compared to 2000 levels," said Gerald Butts, President and Chief Executive Officer of WWF. "To support this effort, Resolute committed to market and sell products that would help its customers reduce their emissions."

To learn more about Resolute's Align papers or to order samples, please visit alignpaper.com.

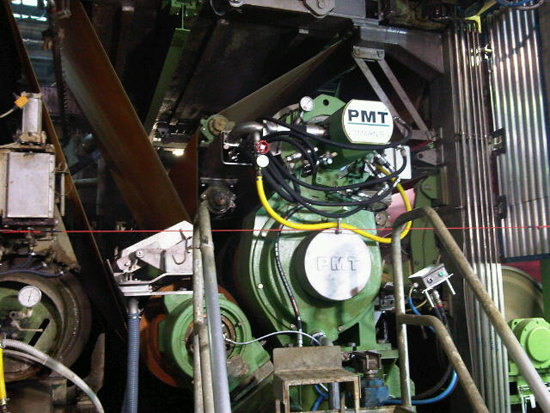

Italian Del Chiese Mill started up the SMARNIP® Shoe Press in Montichiari

PMT Italia S.p.A supplied, installed and started up a SMARNIP® Shoe Press at Cartiera del Chiese S.p.A. - Montichiari Mill.

The SMARNIP® Shoe Press was selected in order to optimise the production of smooth and semi-extensible sack kraft paper aiming production increase and quality improvement.

Also in this case the modularity and the compactness of the SMARNIP® Shoe Press resulted to be the key factor in applying the shoe press technology in a Press section rebuild, also improving the geometry of the first dryer group.

On January the 16th the SMARNIP® has been started up and the paper machine is now in its optimisation phase.

The SMARNIP® will achieve, thanks to its flexibility, the right balance among dry content after press, density, porosity and other typical sack kraft peculiarities.

This new project, developed by PMT, represents the confirmation of the market perception of PMT Italia as a reliable supplier amongst the leading paper machinery producers.

DS Smith’s acquire SCA´s packaging operations

Today, Friday February 3, 2012, the shareholders of UK-based packaging group DS Smith Plc approved the company´s proposal to acquire SCA’s packaging operations, excluding the two kraftliner mills in Sweden.

The transaction remains subject, amongst other things, to antitrust clearance from the European Commission. Closing is expected during the second quarter of 2012.

Regarding the French part of the packaging operations, DS Smith has made a formal offer to acquire this business. This process is subject to an information and consultation procedure with the relevant works councils and will be treated separately.

The first press release on this deal was published on January 17, 2012. http://www.sca.com/en/Media/Press-releases/Press-releases/2012/2012-01-17-SCA-divests-its-packaging-operations/

PMT to supply board machine key components

PMT Italia has been selected by Jiangmen Xinghui Paper Mill Co., Ltd. as a key partner for its new “White Line Chip Board” machine project. The new board machine will be installed in the Jiangmen, Guangdong province, close to the town of Shuangshui in the People Republic of China. The Start-up is scheduled for the end of 2013.

PMT Italia has been selected by Jiangmen Xinghui Paper Mill Co., Ltd. as a key partner for its new “White Line Chip Board” machine project. The new board machine will be installed in the Jiangmen, Guangdong province, close to the town of Shuangshui in the People Republic of China. The Start-up is scheduled for the end of 2013.

PMT Italia has been commissioned to supply technological paper machine sections like the four M4 Headboxes of which one with dilution control, a Shoe Press and a Winder. The new PM1 board machine will be designed to produce White Line Chip Board in the range of 230 to 500 gsm at a speed of 650 mpm, the trim width at the reel being 4.360 mm, with a forecast output of 300.000 mt/year.

The scope of supply includes the control and automation systems of the related paper machine sections to be integrated into the main MCS together with erection supervision, commissioning and start-up services.

PMT is proud -of being awarded by Jiangmen Xinghui Paper Mill Co., Ltd this important project, focused on premium paper quality. It represents for PMT the acknowledgement of the highest level in board paper making technology reached through several successful projects. Moreover it is an opportunity to strengthen and consolidate once more its presence as well as to show its capabilities in the Chinese market.

Metso to supply Finland's largest pellet-fired heating plant

Metso will supply a pellet-fired heating plant to Tampereen Energiantuotanto Oy in the city of Tampere in Finland. The plant will be delivered by the Metso-Wärtsilä joint venture MW Power. The delivery will comprise a full-scope turn-key boiler plant solution, including all the necessary equipment and commissioning. The plant will be Finland's largest pellet-fired plant, based on a technological solution that is the first of its kind in Finland. The value of the order will not be disclosed.

The heating plant will be used as a peak load and backup plant and will replace some of the capacity of the existing oil- and gas-fuelled boiler plants. The plant will be fired with wood pellets and its heat input will be around 33 MW. Replacing the old boilers with a new modern pellet-fired boiler will significantly reduce the CO2 emissions resulting from the production of district heating.

"Our cooperation with MW Power has been smooth. When things started to fall in place concerning the plant's technology, it was clear that MW Power is the right partner for us for this challenging project. It was also important to us that the supplier would commit to the project with the necessary resources. This project will bring new expertise to Finland, and Tampereen Energiantuotanto Oy wishes to be at the forefront in sustainable energy generation. District heating has always been an efficient and environmentally friendly alternative and it will remain so in the future as well," says Development Manager Timo Heinonen from Tampereen Energiantuotanto Oy.

"It is inspiring to introduce new technology into the market for the first time, and commercial success is naturally our ultimate goal. Previously, peak load plants have been using fossil fuels because there was no other technology available. The technological solution supplied to Tampereen Energiantuotanto Oy will bring new opportunities to gear the structure of Finnish district heat production towards the goals of sustainable development," confirms Sales Manager Teemu Koskela from MW Power.

The production of heat at the new plant will start in late 2012. The order is included in Pulp, Paper and Power's first quarter 2012 orders received.

Technical information

Tampereen Energiantuotanto Oy's pellet heating plant utilizes a solution that combines pulverized combustion technology with MW Power's boiler expertise. The pellet fuel is pulverized in separate grinding mills and burned in a pulverized combustion boiler. The start-up and load control of the combustion process is remarkably rapid and the pulverized fuel allows for clean, energy efficient and flexible heat generation. Pulverized pellet combustion is new to Finland, but MW Power has been using it in Sweden on a smaller scale.

Tampereen Energiantuotanto Oy, a subsidiary of Tampere Power Utility, is responsible for the group's electricity and district heating production, maintenance and development. Increasing the proportion of renewable energy sources is part of the Tampere Power Utility's strategy.